Magnetic porous iron-zirconium bimetal composite coagulant aid as well as preparation method and application thereof

A porous iron, bimetallic technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of poor fluoride ion adsorption capacity, low adsorption rate, secondary pollution, etc. , to achieve the effect of simple and easy operation of the synthesis method and process, increase of surface active groups, and overcoming difficulty in regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

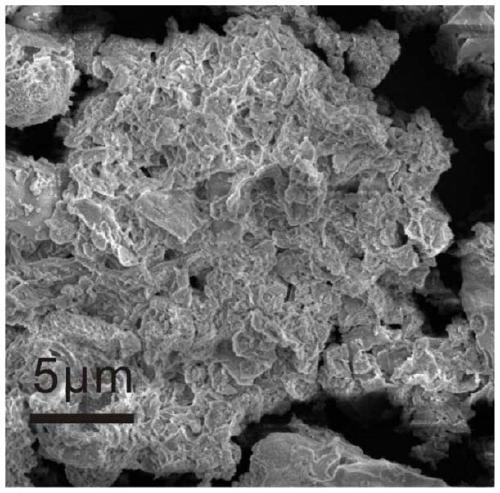

Image

Examples

Embodiment 1

[0029] A preparation method of a magnetic porous iron-zirconium bimetallic composite coagulant, comprising the following steps:

[0030] Step 1. Disperse zirconium sulfate and iron sulfate in 3:1 molar ratio (zirconium sulfate 28.34g, iron sulfate 13.33g) in 300mL pure water, stir and mix evenly to obtain a mixed solution;

[0031] Step 2, adding sodium hydroxide solution to the mixed solution to adjust the pH to 8.0 to obtain an iron / zirconium hydroxide mixed solution;

[0032] Step 3, stirring the iron / zirconium hydroxide mixed solution under hydrothermal conditions, adding 40 g of glacial acetic acid, and reacting in an oil bath at 80° C. for 2 hours to obtain an iron / zirconium oxide colloidal solution;

[0033] Step 4, putting the iron / zirconium oxide colloidal solution into a high-pressure reactor and heating at 180°C for 1 day, and cooling naturally after the reaction;

[0034] Step 5. The cooled reaction product is separated and extracted by centrifugation, dried at 60...

Embodiment 2

[0037] A preparation method of a magnetic porous iron-zirconium bimetallic composite coagulant, comprising the following steps:

[0038] Step 1. Disperse zirconium sulfate and iron sulfate in 250mL pure water at a molar ratio of 2:1 (zirconium sulfate 18.89g, iron sulfate 13.33g), stir and mix evenly to obtain a mixed solution;

[0039] Step 2, adding sodium hydroxide solution to the mixed solution to adjust the pH to 9.0 to obtain a mixed solution of iron / zirconium hydroxide;

[0040] Step 3. Stir the iron / zirconium hydroxide mixed solution under hydrothermal conditions, add 30 g of glacial acetic acid, and mature for 3 hours in an oil bath at 80° C. to obtain an iron / zirconium oxide colloidal solution;

[0041] Step 4, putting the iron / zirconium oxide colloidal solution into a high-pressure reactor and heating at 160°C for 1 day, and cooling naturally after the reaction;

[0042] Step 5. The cooled reaction product is separated and extracted by centrifugation, dried at 70° ...

Embodiment 3

[0045] A preparation method of a magnetic porous iron-zirconium bimetallic composite coagulant, comprising the following steps:

[0046] Step 1. Disperse zirconium sulfate and iron sulfate in 1:1 molar ratio (zirconium sulfate 9.45g, iron sulfate 13.33g) in 200mL pure water, stir and mix evenly to obtain a mixed solution;

[0047] Step 2, adding sodium hydroxide solution to the mixed solution to adjust the pH to 8.5 to obtain a mixed solution of iron / zirconium hydroxide;

[0048] Step 3. Stir the iron / zirconium hydroxide mixed solution under hydrothermal conditions, add 30 g of glacial acetic acid, and mature for 2 hours in an oil bath at 80° C. to obtain an iron / zirconium oxide colloidal solution;

[0049] Step 4, putting the iron / zirconium oxide colloidal solution into a high-pressure reactor and heating at 140°C for 2 days, and cooling naturally after the reaction;

[0050] Step 5. The cooled reaction product is separated and extracted by centrifugation, dried at 60° C., a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com