A micro-nanoporous polymeric aluminum coagulation aid and its preparation method and application

A technology of porous polymerization and coagulant aid, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of poor fluoride ion adsorption capacity, separation, and low adsorption rate. to overcome the low adsorption capacity, the increase of surface active groups, and the difficulty of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a micro-nanoporous polymeric aluminum coagulant, comprising the following steps:

[0033] Step 1. Disperse aluminum isopropoxide and calcium sulfate in 3:1 molar ratio (20.42 g of aluminum isopropoxide and 5.73 g of calcium sulfate) in 200 mL of pure water, stir and mix evenly to obtain a mixed solution;

[0034] Step 2, adding sodium hydroxide solution to the mixed solution to adjust the pH to 8.0;

[0035] Step 3, aging the obtained alkaline solution in an oil bath at 80°C for 2 hours to obtain a precursor;

[0036] Step 4. Put the cured precursor into the autoclave and heat it at 180ºC for 1 day;

[0037] Step 5. The cooled reaction product is separated and extracted by centrifugation, dried at 60°C, and then ground into powder to 200 mesh to obtain the micro-nanoporous polymeric aluminum coagulation aid.

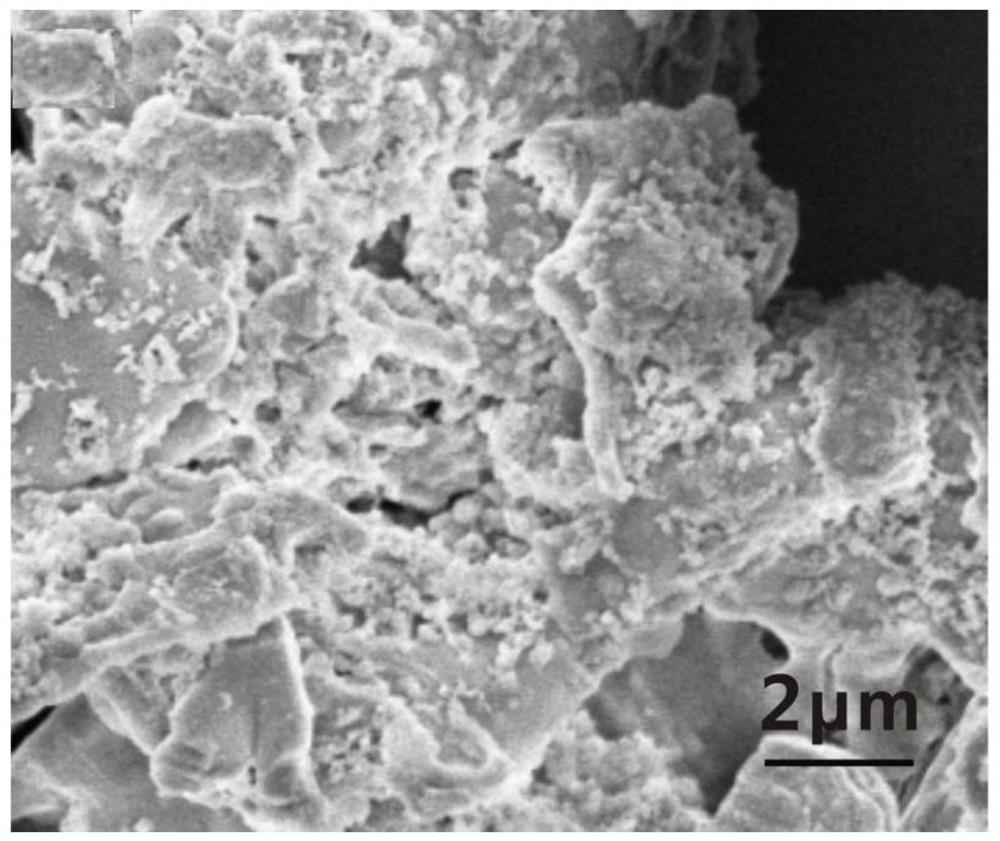

[0038] The morphology of the micro-nanoporous polyaluminum-calcium coagulant synthesized in Example 1 was characterized by a scanning el...

Embodiment 2

[0040] A preparation method of a micro-nanoporous polymeric aluminum coagulant, comprising the following steps:

[0041] Step 1. Disperse aluminum isopropoxide and iron sulfate in 3:1 molar ratio (20.42 g of aluminum isopropoxide and 13.33 g of iron sulfate) in 200 mL of pure water, stir and mix evenly to obtain a mixed solution;

[0042] Step 2, adding sodium hydroxide solution to the mixed solution to adjust the pH to 8.0;

[0043] Step 3, aging the obtained alkaline solution in an oil bath at 80°C for 2 hours to obtain a precursor;

[0044]Step 4. Put the cured precursor into the autoclave and heat it at 180ºC for 1 day;

[0045] Step 5. The cooled reaction product is separated and extracted by centrifugation, dried at 60°C and ground into powder to 200 meshes to obtain the desired micro-nanoporous polymeric aluminum coagulation aid.

[0046] For the micro-nanoporous polymeric aluminum-iron coagulant synthesized in Example 2, the test results for actual fluorine-containin...

Embodiment 3

[0048] A preparation method of a micro-nanoporous polymeric aluminum coagulant, comprising the following steps:

[0049] Step 1. Disperse aluminum isopropoxide and magnesium sulfate in 3:1 molar ratio (20.42 g of aluminum isopropoxide and 4.00 g of magnesium sulfate) in 200 mL of pure water, stir and mix evenly to obtain a mixed solution;

[0050] Step 2, adding sodium hydroxide solution to the mixed solution to adjust the pH to 8.0;

[0051] Step 3, aging the obtained alkaline solution in an oil bath at 80°C for 2 hours to obtain a precursor;

[0052] Step 4. Put the cured precursor into the autoclave and heat it at 180ºC for 1 day;

[0053] Step 5. The cooled reaction product is separated and extracted by centrifugation, dried at 60°C and ground into powder to 200 meshes to obtain the desired micro-nanoporous polymeric aluminum coagulation aid.

[0054] For the micro-nanoporous polymeric aluminum-magnesium coagulant synthesized in Example 3, the test results for actual flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com