Magnesium-rare earth alloy melt purification and refinement composite treatment flux and application thereof

A magnesium rare earth alloy and composite treatment technology, applied in the field of magnesium alloys, can solve the problems of Zr oxidation burning and other problems of melt purification and refinement treatment effect, and achieve the effects of improving the wetting and capturing speed, increasing the density, and reducing the oxidation tendency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

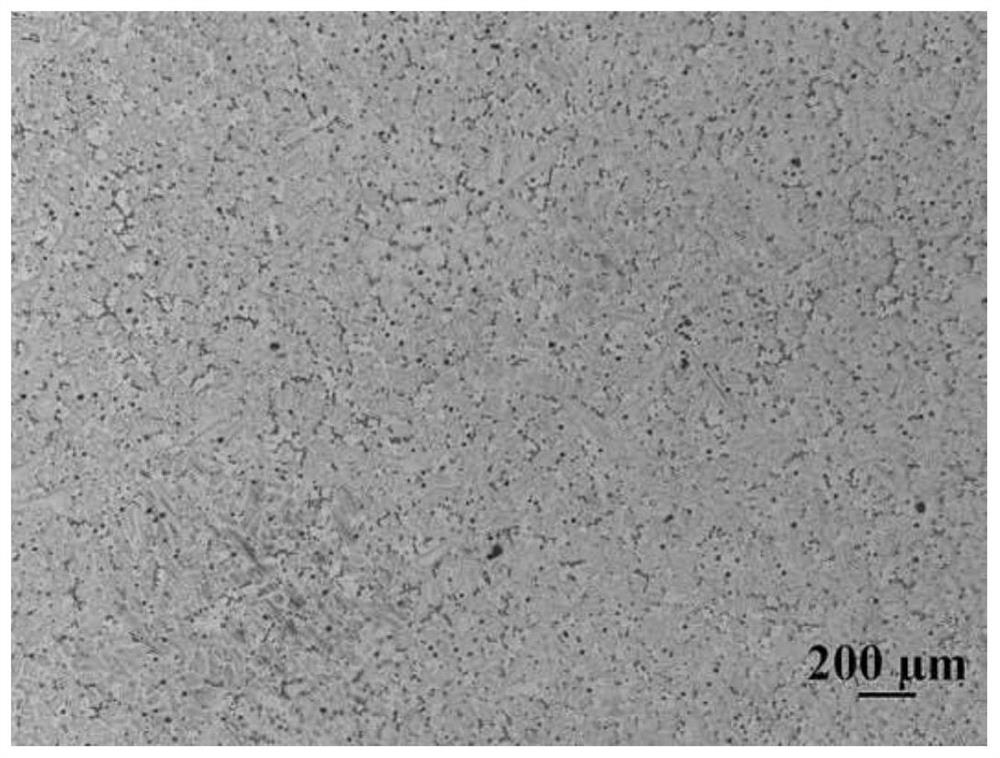

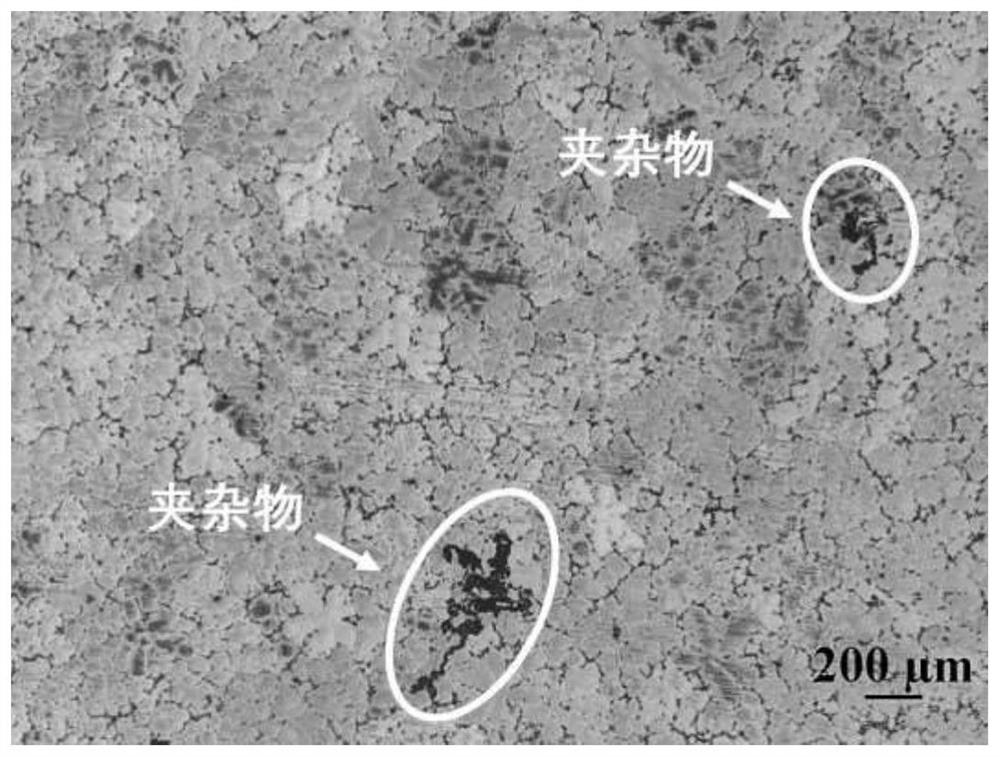

[0031] Taking Mg-8Gd-3Y-0.5Zr (wt%) magnesium rare earth alloy as an example, the composite flux of the present invention is used for melt treatment.

[0032] Purification refinement composite treatment flux composition (mass percentage): 30% magnesium chloride, 8% potassium chloride, 8% sodium chloride, 16% barium chloride, 8% barium sulfate, 15% zirconium diboride, 15% zirconium sulfate .

[0033] First add magnesium chloride to the crucible and heat it to 720°C to make it reach a molten state, then add potassium chloride, sodium chloride, barium chloride, and barium sulfate in batches in sequence, stir fully after all the salts are melted, and cast to obtain Refining agent compound salt block, then crush the refining agent compound salt block and pass through a 200-mesh sieve, then put the sieved refining agent compound salt powder, zirconium diboride, and zirconium sulfate into a ball mill, and take it out after ball milling for 5 hours. Go through a 50-mesh sieve again t...

Embodiment 2

[0037] Taking Mg-8Gd-3Y-0.5Zr (wt%) magnesium rare earth alloy as an example, the composite flux of the present invention is used for melt treatment.

[0038] Purification refinement composite treatment flux composition (mass percentage): 40% magnesium chloride, 10% potassium chloride, 10% sodium chloride, 15% barium chloride, 5% barium sulfate, 10% zirconium diboride, 10% zirconium sulfate .

[0039] First add magnesium chloride to the crucible and heat it to 730°C to make it reach a molten state, then add potassium chloride, sodium chloride, barium chloride, and barium sulfate in batches in sequence, stir fully after all the salts are melted, and cast to obtain Refining agent compound salt block, then crush the refining agent compound salt block and pass through a 200-mesh sieve, then put the sieved refining agent compound salt powder, zirconium diboride and zirconium sulfate into a ball mill, and take it out after ball milling for 6 hours. Go through a 100-mesh sieve again...

Embodiment 3

[0043] Taking Mg-8Gd-3Y-0.5Zr (wt%) magnesium rare earth alloy as an example, the composite flux of the present invention is used for melt treatment.

[0044] Purification refinement composite treatment flux composition (mass percentage): 34% magnesium chloride, 10% potassium chloride, 10% sodium chloride, 16% barium chloride, 6% barium sulfate, 12% zirconium diboride, 12% zirconium sulfate .

[0045] First add magnesium chloride to the crucible and heat it to 740°C to make it reach a molten state, then add potassium chloride, sodium chloride, barium chloride, and barium sulfate in batches in sequence, stir fully after all the salts are melted, and cast to obtain Refining agent compound salt block, then crush the refining agent compound salt block and pass through a 200-mesh sieve, then put the sieved refining agent compound salt powder, zirconium diboride, and zirconium sulfate into a ball mill, and take it out after ball milling for 8 hours. Go through a 150-mesh sieve agai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com