Recycling method of liquid zirconium sulfate hydrolysate for coating rutile titanium dioxide

A rutile type titanium dioxide and hydrolyzate technology, which is applied in zirconium sulfate, chemical instruments and methods, energy and wastewater treatment, etc., can solve the problems of large water consumption for washing and sodium removal, long treatment process, and high recycling cost, and achieves reduction of Emissions, shortening of process flow, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

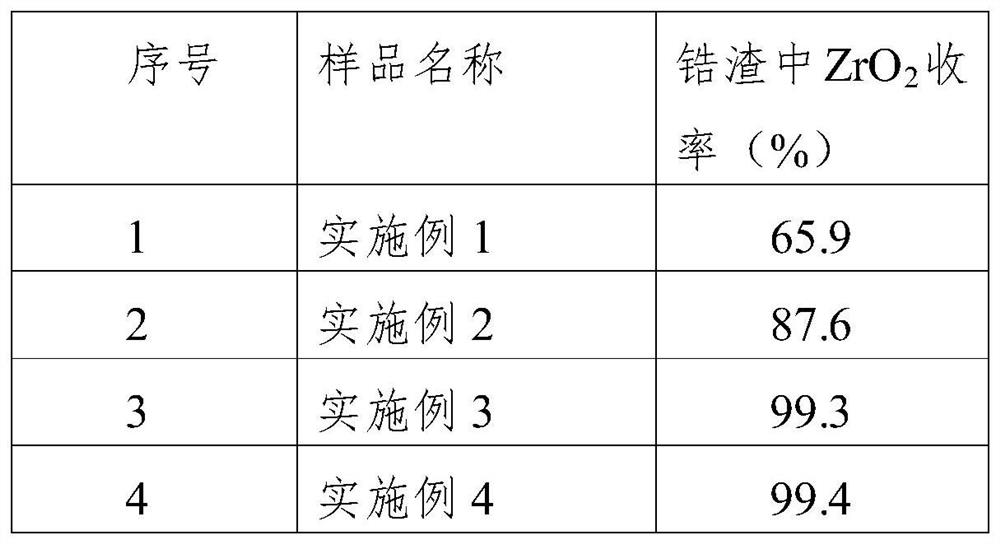

Examples

Embodiment 1

[0022] Take 100g of sulfuric acid mother liquor and pour it into a 500ml burner, stir and pour into 100g of zirconium slag hydrolyzed with rutile titanium dioxide coated with zirconium sulfate (broken into powdery particles with a particle size of 80 meshes), and mix at a stirring condition of 200 rpm. For 30min, slowly pour 80g 98% concentrated sulfuric acid into the burner, continue to stir, the temperature rises, control the temperature of the system to continue the reaction at 105±3℃ for 65min, the zirconium sulfate crystals are continuously precipitated in the middle, and start when there are zirconium sulfate crystals. Gradually lower the temperature to 40°C, pour it into a Φ100mm Buchner funnel for suction filtration, and use the filtrate to wash the burnt and prepare it for later use. Then add 300 g of tap water to the burner, add the filter cake just filtered under stirring at 63 rpm, and add 30 g of sulfuric acid mother liquor or filtrate, and continue stirring for 10...

Embodiment 2

[0024] Take 100g of sulfuric acid mother liquor and pour it into a 500ml burner, stir and pour in 100g of zirconium slag hydrolyzed with zirconium sulfate coated with rutile titanium dioxide (crushed into powdery particles with a particle size of 80 meshes) and 0.05g of conversion accelerator A, at 200 rpm Mixing for 30min under stirring conditions per minute, then slowly pour 80g 98% concentrated sulfuric acid into the burner, continue stirring, the temperature rises, control the temperature of the system to continue the reaction at 105±3°C for 65min, and zirconium sulfate crystals are continuously precipitated in the middle. When zirconium sulfate crystals are precipitated, the temperature is gradually lowered to 40°C, and all are poured into a Φ100mm Buchner funnel for suction filtration. Then add 300 g of tap water to the burner, add the filter cake just filtered under stirring at 63 rpm, and add 30 g of sulfuric acid mother liquor or filtrate, and continue stirring for 10 ...

Embodiment 3

[0026] Take 100g of sulfuric acid mother liquor and pour it into a 500ml burner, stir and pour 100g of zirconium slag hydrolyzed with rutile titanium dioxide coated with zirconium sulfate (crushed into powdery particles with a particle size of 80 meshes) and 0.05g of conversion accelerator B, at 200 rpm Mixing for 30min under stirring conditions per minute, then slowly pour 80g 98% concentrated sulfuric acid into the burner, continue stirring, the temperature rises, and the temperature of the control system is kept at 105±3°C for 65min, and zirconium sulfate crystals are continuously precipitated in the middle. When zirconium sulfate crystals are precipitated, the temperature is gradually lowered to 40°C, and all are poured into a Φ100mm Buchner funnel for suction filtration. Then add 300 g of tap water to the burner, add the filter cake just filtered under stirring at 63 rpm, and add 30 g of sulfuric acid mother liquor or filtrate, and continue stirring for 10 min to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com