A kind of methane halogen oxidation catalyst and its preparation method and application

A technology of methane halogen oxidation and catalyst, which is applied in the field of methane halogen oxidation catalyst and its preparation, and can solve the problems of low yield of methyl halide, reduction of selectivity of methyl halide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

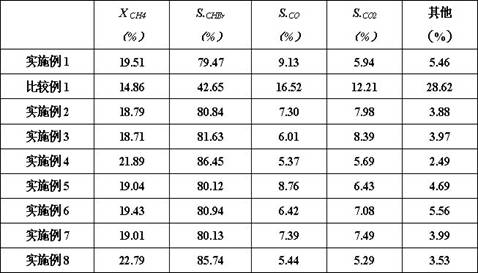

Examples

Embodiment 1

[0024] Prepare aluminum hydroxide slurry by hydrolysis of aluminum isopropoxide: mix water and aluminum isopropoxide at a molar ratio of 120:1, control the hydrolysis temperature at 80°C-85°C, hydrolyze aluminum isopropoxide for 1.5h, and then carry out aging , the aging temperature was controlled at 90°C-95°C, the aging time was 18h, and an aluminum hydroxide slurry with a solid content of 21.3wt% was obtained.

[0025] Preparation of zinc-loaded alumina: use equal volume impregnation method on alumina (commercially available, the properties are as follows: L acid content is 0.2mmol g -1 ; BET specific surface is 200; pore volume is 0.3ml / g) impregnated with zinc nitrate solution, dried and roasted after impregnation, the drying time is 2h, and the drying temperature is 130°C; the roasting time is 4h, and the temperature is 400°C , the zinc-loaded alumina is spherical, and the equivalent diameter of the zinc-loaded alumina is 2mm;

[0026] Spray immersion process: mix approp...

Embodiment 2

[0030] Prepare aluminum hydroxide slurry by hydrolysis of aluminum isopropoxide: mix water and aluminum isopropoxide at a molar ratio of 120:1, control the hydrolysis temperature at 80°C-85°C, hydrolyze aluminum isopropoxide for 1.5h, and then carry out aging , the aging temperature was controlled at 90°C-95°C, the aging time was 18h, and an aluminum hydroxide slurry with a solid content of 21.3wt% was obtained.

[0031] Preparation of zinc-loaded alumina: use equal volume impregnation method on alumina (commercially available, L acid content is 0.1mmol g -1 ;BET specific surface is 300m 2 / g; the pore volume is 0.5ml / g) impregnated with zinc sulfate solution, dried and roasted after immersion, the drying time is 3h, and the drying temperature is 120°C; the roasting time is 5h, the temperature is 450°C, the load Zinc alumina is spherical, and the equivalent diameter of zinc-loaded alumina is 2mm;

[0032] Spray immersion process: mix appropriate amount of zirconium sulfate s...

Embodiment 3

[0036] Prepare aluminum hydroxide slurry by hydrolysis of aluminum isopropoxide: mix water and aluminum isopropoxide at a molar ratio of 120:1, control the hydrolysis temperature at 80°C-85°C, hydrolyze aluminum isopropoxide for 1.5h, and then carry out aging , the aging temperature was controlled at 90°C-95°C, the aging time was 18h, and an aluminum hydroxide slurry with a solid content of 21.3wt% was obtained.

[0037] Preparation of zinc-loaded alumina: using an equal volume impregnation method on alumina (commercially available, the properties are as follows: the content of L acid is 0.05 mmol g -1 ;BET specific surface is 250m 2 / g; pore volume is 0.3 ~ 0.6ml / g, preferably 0.4ml / g,) impregnated with zinc bromide solution, dried and roasted after impregnated, the drying time is 4h, and the drying temperature is 100°C; The calcination time is 4 hours, the temperature is 500°C, the zinc-loaded alumina is spherical, and the equivalent diameter of the zinc-loaded alumina is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com