Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "Sodium manganate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium manganate is the inorganic compound with the formula Na₂MnO₄. This deep green solid is a rarely encountered analogue of the related salt K₂MnO₄. Sodium manganate is rare because it cannot be readily prepared from the oxidation of manganese dioxide and sodium hydroxide. Instead this oxidation stops at the level of Na₃MnO₄, and this Mn(V) salt is unstable in solution. Sodium manganate can be produced by reduction of sodium permanganate under basic conditions...

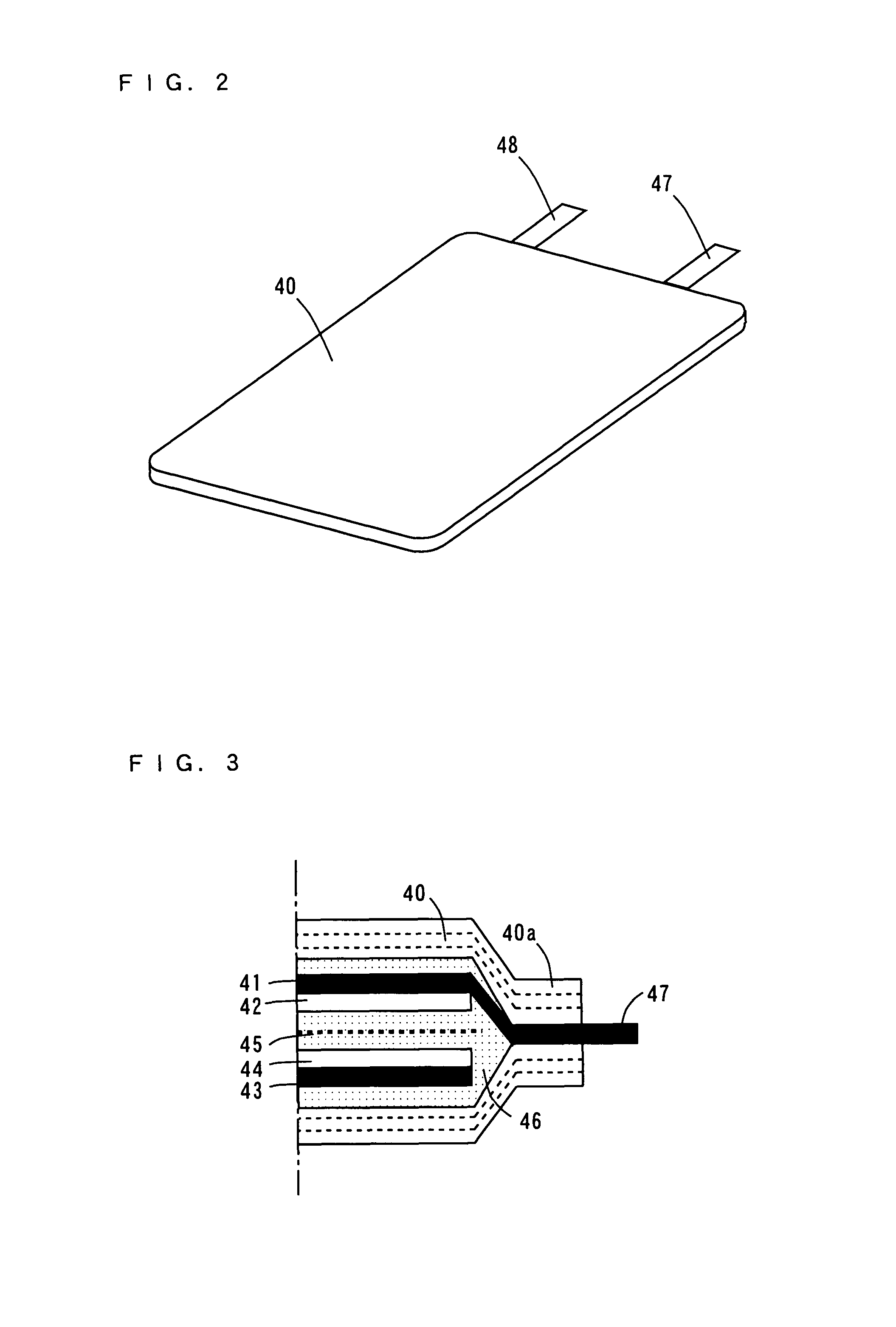

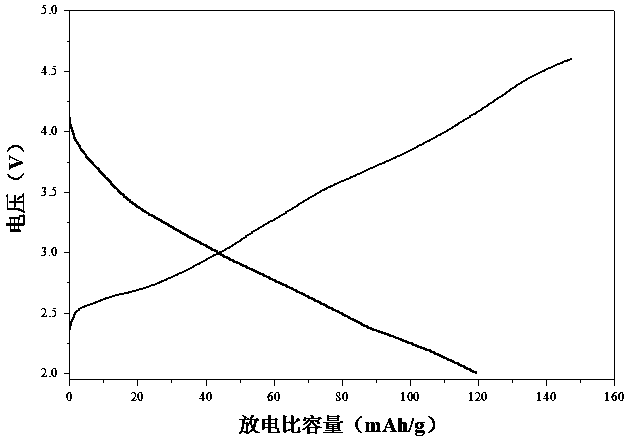

Positive Electrode and Non-Aqueous Electrolyte Secondary Battery

ActiveUS20090053613A1Low costAlkaline accumulatorsNon-aqueous electrolyte accumulatorsElectrical batterySodium phosphates

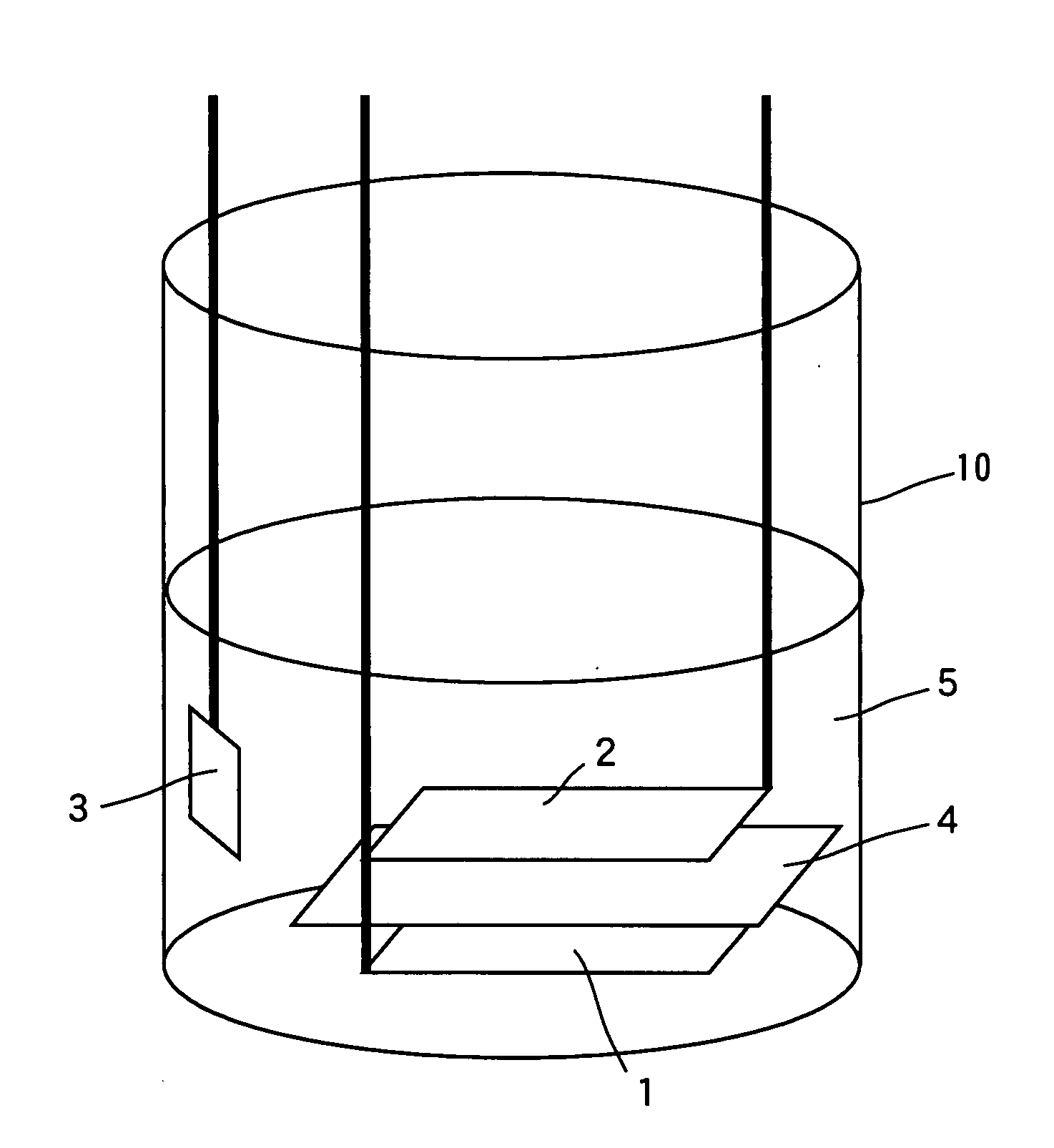

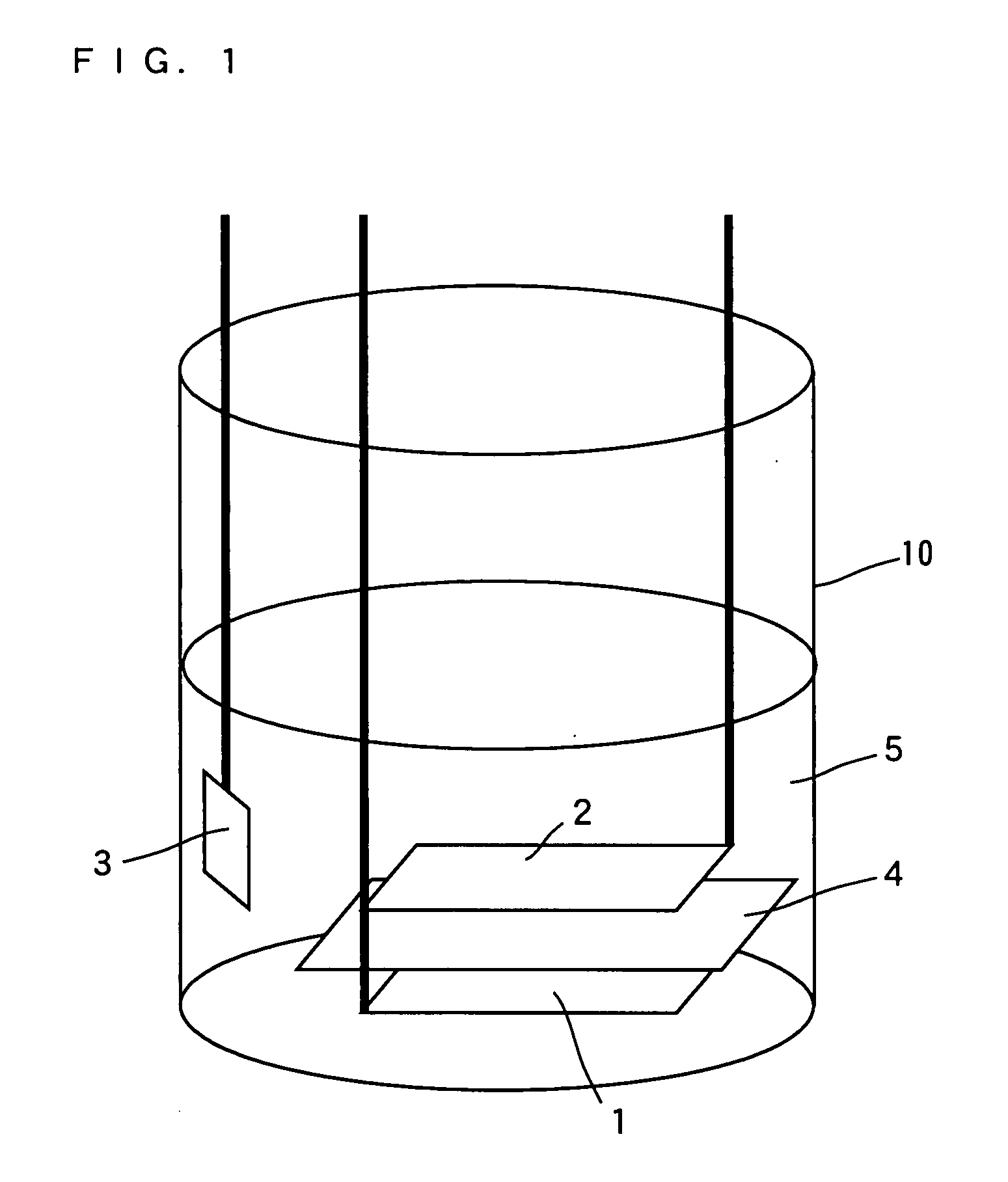

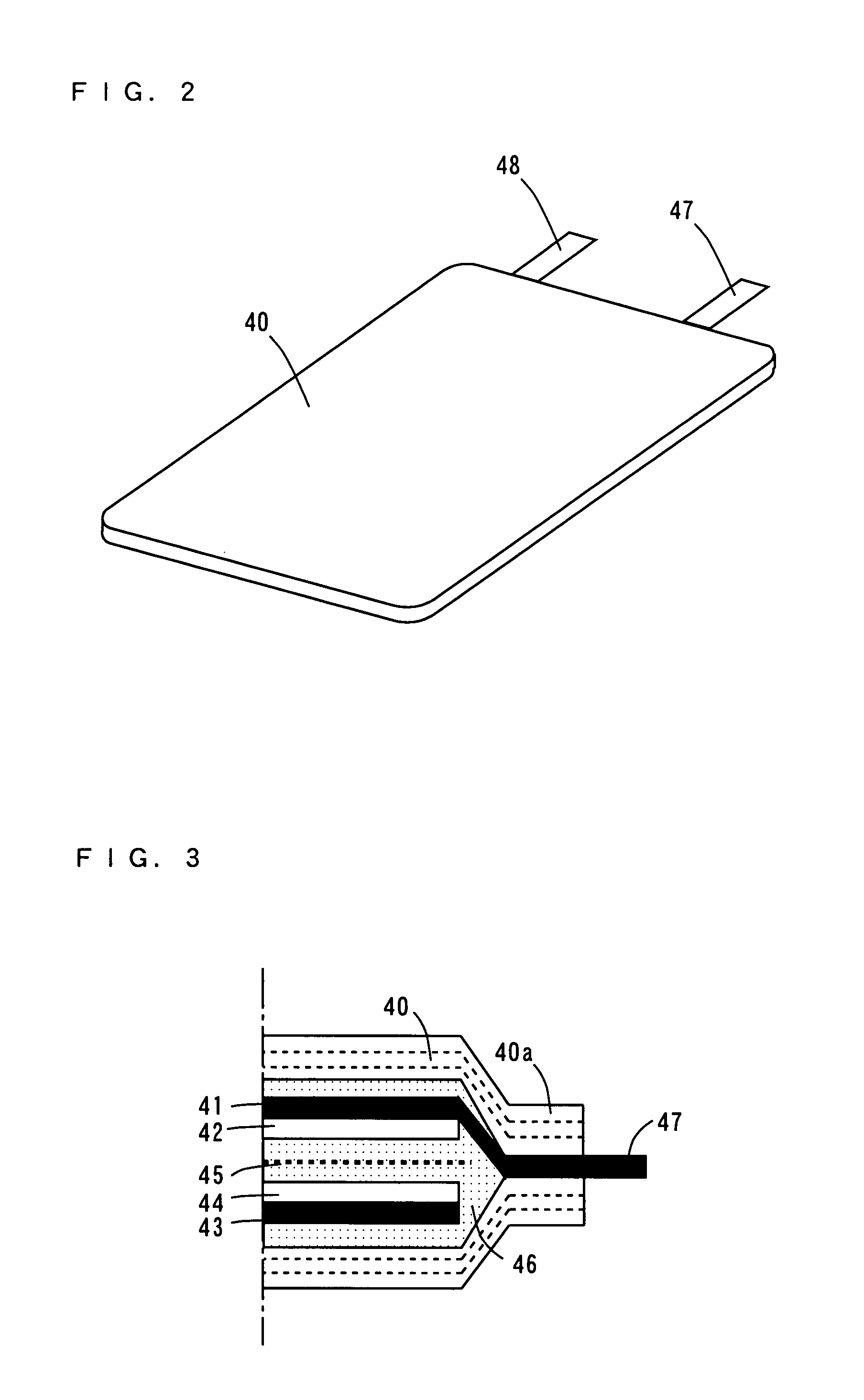

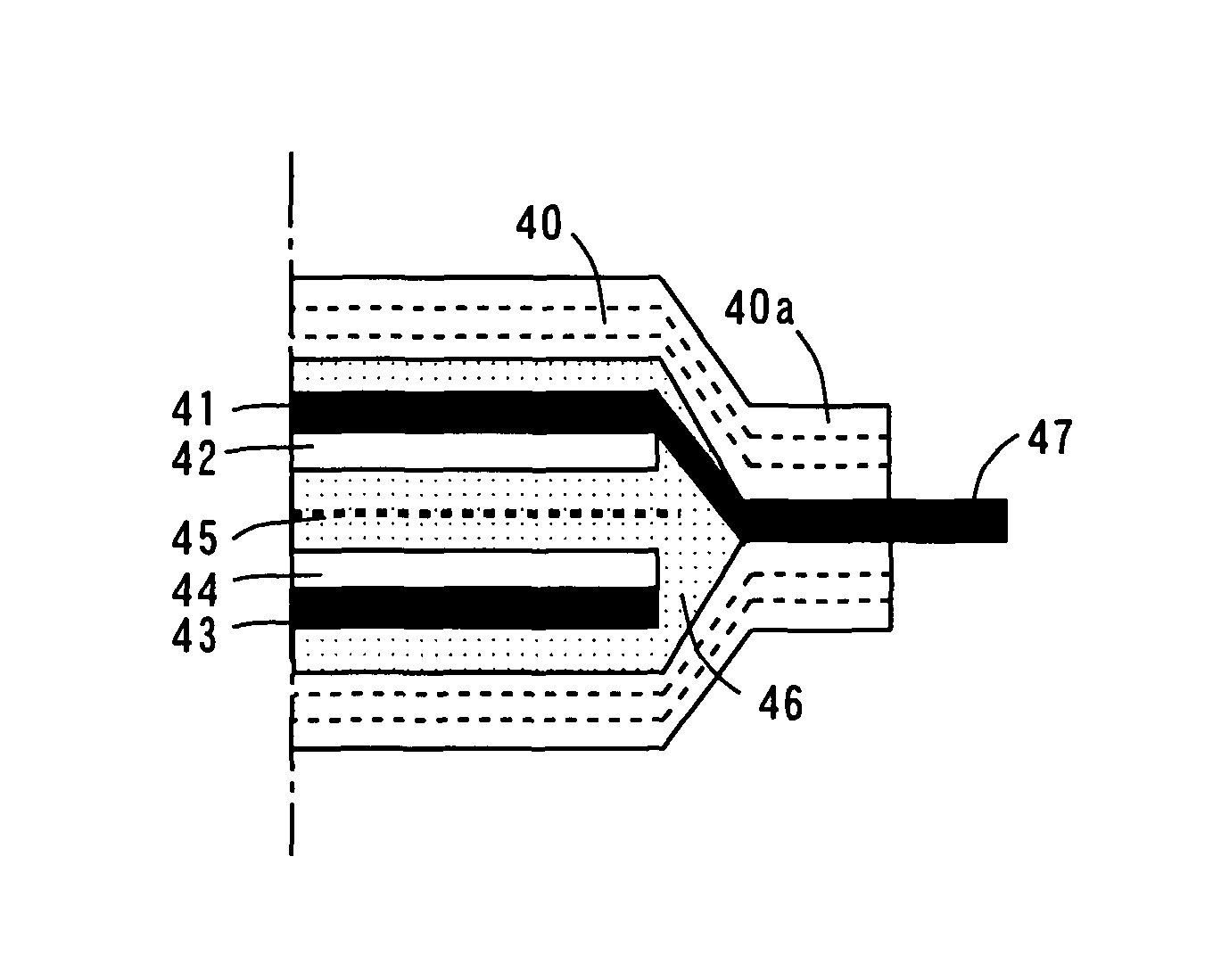

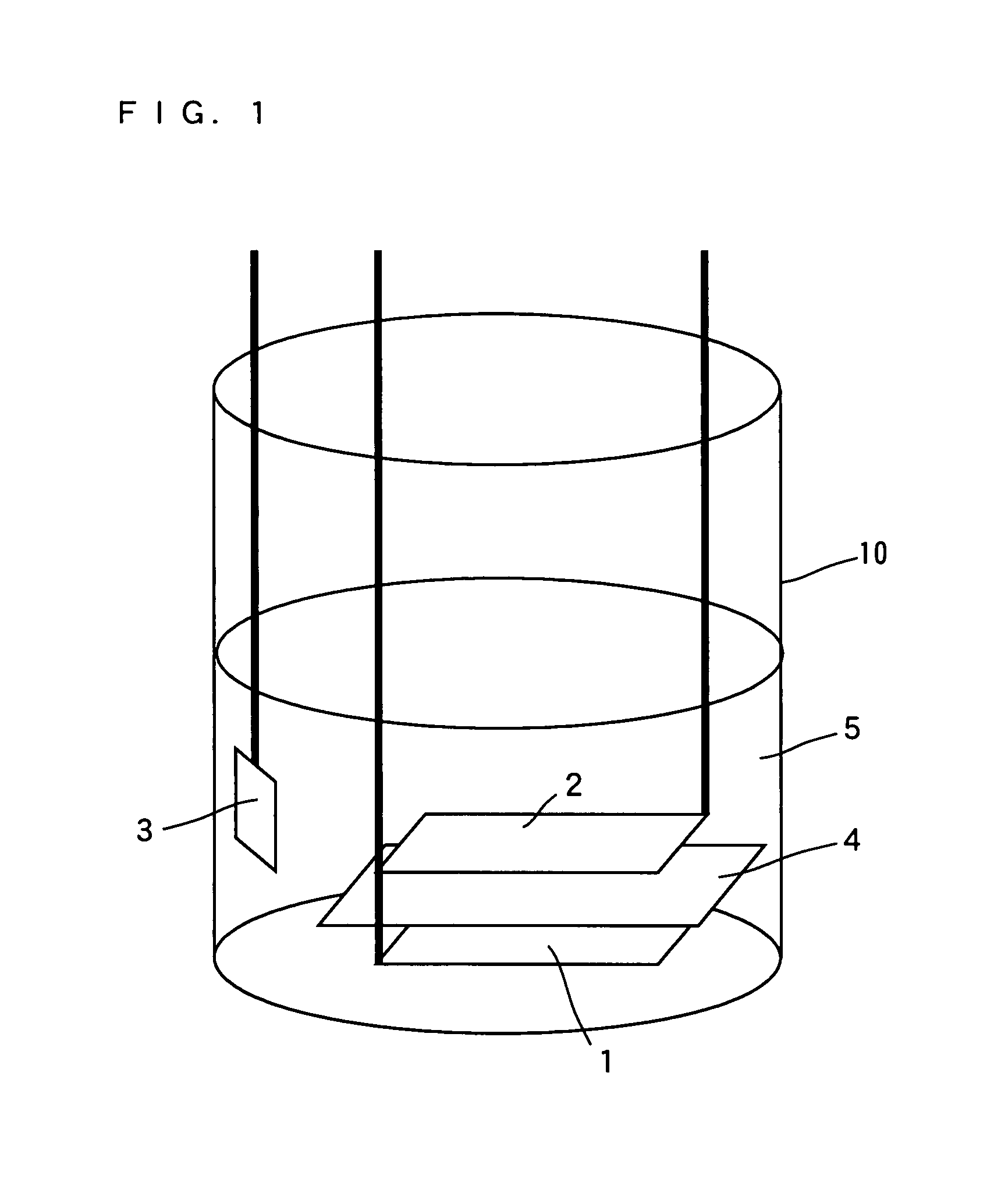

A material (hereinafter referred to as “positive electrode material”) including sodium manganate powder as a positive electrode active material, carbon black powder as a conductive agent, and polytetrafluoroethylene as a binder is prepared. The positive electrode material is mixed in an N-methylpyrrolidone solution to produce slurry as a positive electrode mixture. A working electrode is produced by applying the slurry on a positive electrode collector. A negative electrode containing tin or germanium is produced. The non-aqueous electrolyte is produced by adding sodium hexafluorophosphate as an electrolyte salt in a non-aqueous solvent produced by mixing ethylenecarbonate and diethyl carbonate.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Sodium ion battery positive electrode material, and preparation method and application method thereof

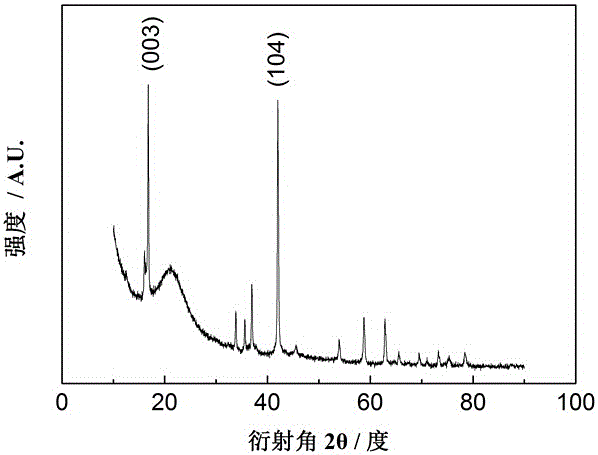

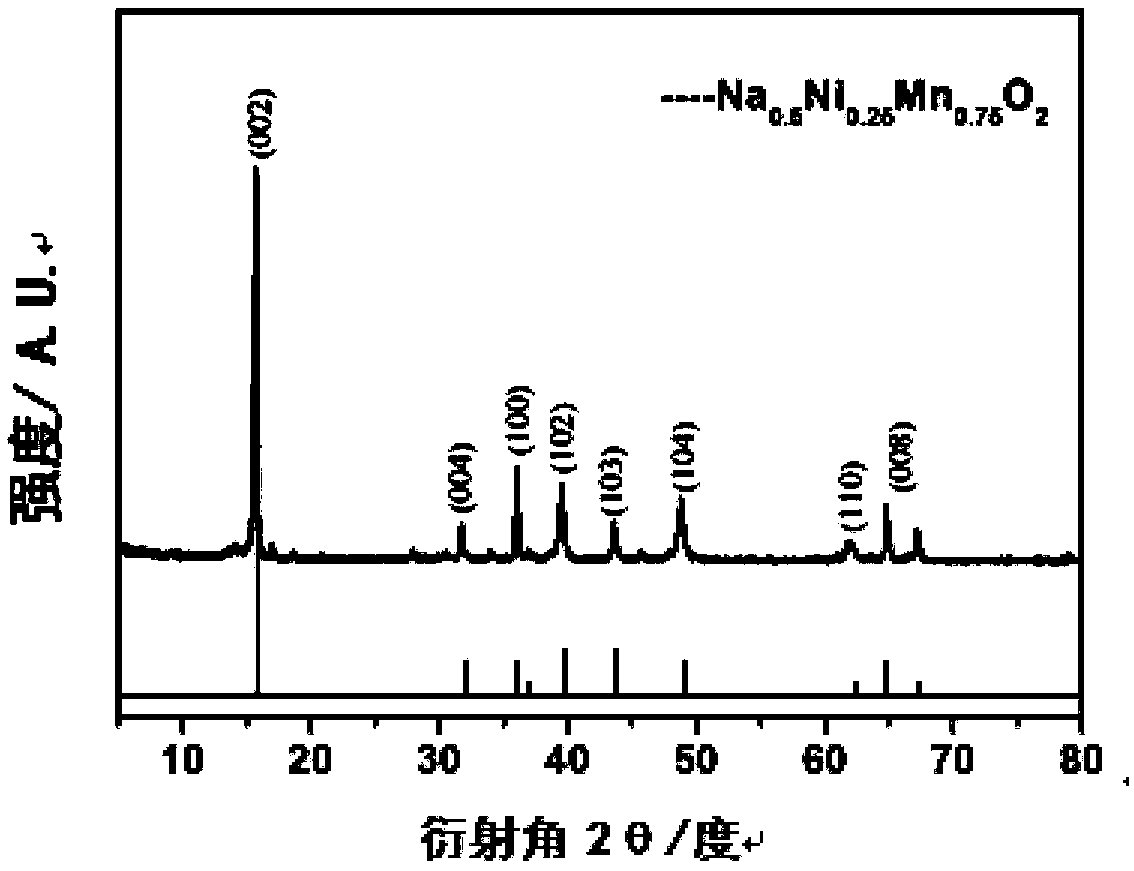

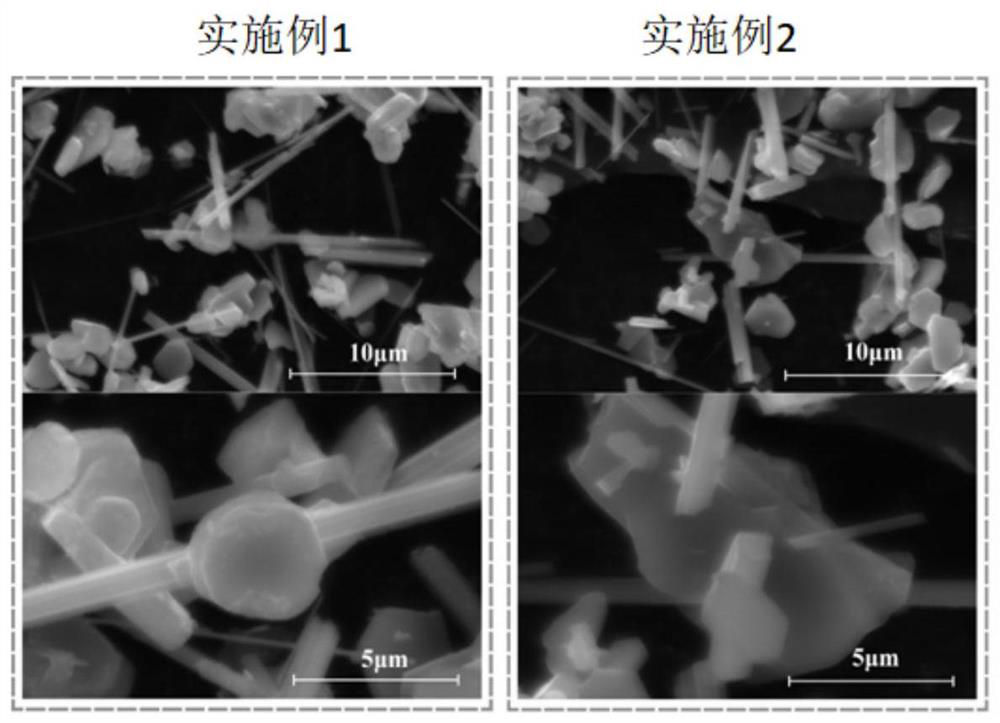

ActiveCN105692721AUniform structureStoichiometric ratio is accurateCell electrodesSecondary cellsOxalate precipitationNickel compounds

The invention discloses a sodium ion battery positive electrode material, and a preparation method and application method thereof, belonging to the field of electrochemistry. The component of the material is laminar sodium manganate nickelate of which the chemical general formula is NaxNi[0.5+y]Mn[0.5-y]O2, wherein x is 0.9-1.1, and y is 0-0.2. The preparation method comprises the following steps: precipitating a soluble manganese compound-nickel compound mixed solution through oxalates, carrying out hydrothermal reaction in a water-ethanol mixed solution, and finally, carrying out heat treatment to obtain the laminar sodium manganate nickelate product. The invention solves the problems of poor precursor composition control reproducibility, controllable product structure and shape and the like in the prior art. Since the precursor structure is uniform and the stoichiometric proportion is accurate, the structure is further optimized after the ethanol / hydrothermal treatment, thereby finally obtaining the material prepared by the obviously better traditional method.

Owner:浙江瓦司特钠科技有限公司

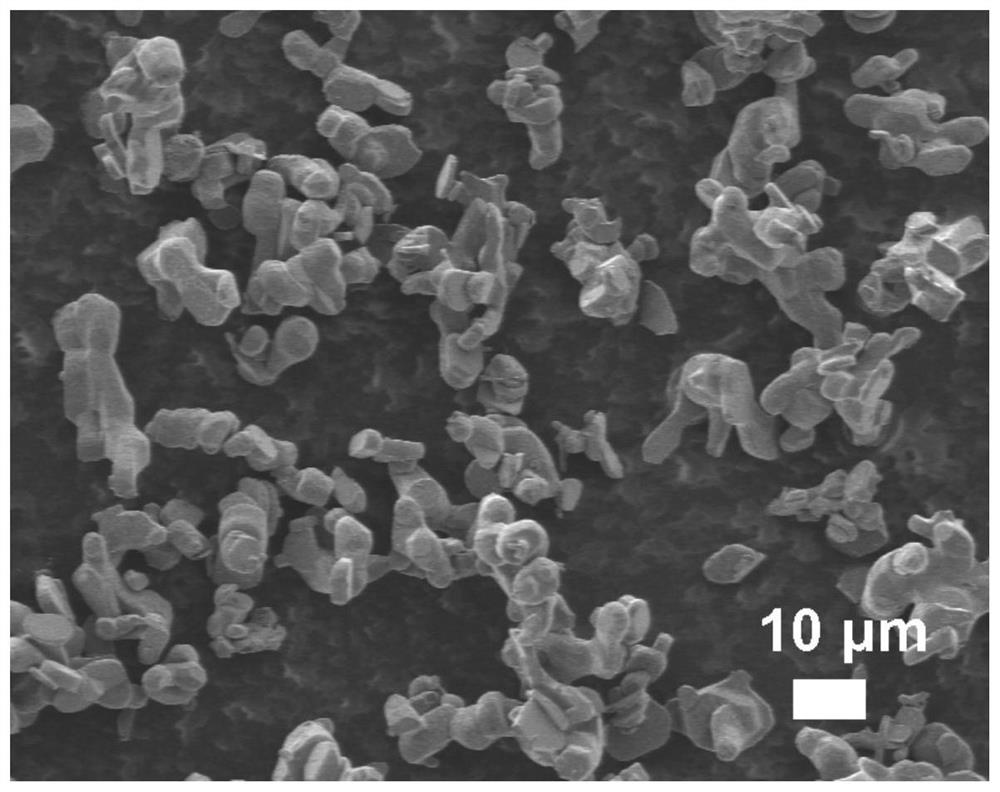

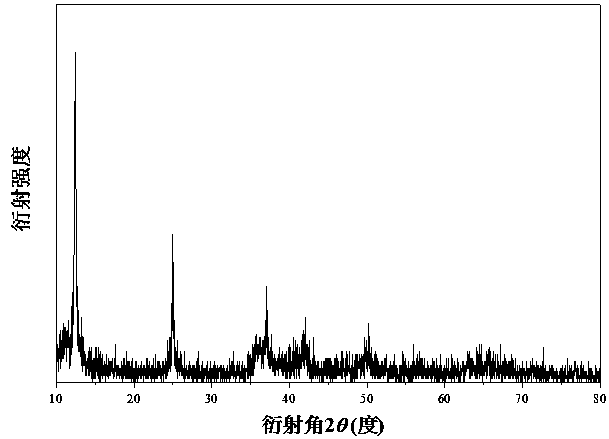

Preparation method of layered chemical manganese dioxide

ActiveCN103172119AMild reaction conditionsRaw materials are easy to getManganese oxides/hydroxidesChemical reactionPtru catalyst

The invention discloses a preparation method of layered chemical manganese dioxide. The method comprises the steps of evenly mixing powder manganese dioxide with solid sodium hydroxide; roasting at a high temperature in an air atmosphere, so as to generate sodium manganate at high temperature from the manganese dioxide and sodium hydroxide; leaching and dissolving the roasted product sodium manganate by water to obtain sodium manganate solution; then adding dissoluble manganese salt solution into the sodium manganate solution to carry out oxidation reduction reaction; and filtering, washing, baking and crushing the reacted materials to obtain the layered chemical manganese dioxide product. The manganese dioxide content of the product is 74-80%; the sodium content is 5.0-6.5%; the mean grain size is 1-5 microns; and the specific surface is 20-25m<2> / g. The preparation method of the layered chemical manganese dioxide disclosed by the invention has the characteristics of being mild in reaction condition, easy to obtain materials, low in production cost and the like; the obtained layered chemical manganese dioxide can be used as an oxidant, a catalyst, a heavy metal ion adsorbent, a vulcanization curing agent and the like for organic chemical reaction.

Owner:湖南海利锂电科技有限公司

Sodium permanganate ethylene absorption agent

InactiveUS20060070523A1Fruit and vegetables preservationIsotope separationAqueous solutionSodium permanganate

A process for absorbing ethylene comprising preparing a support material impregnated with an aqueous sodium permanganate solution, wherein the ethylene absorption agent is prepared by a process of selecting a support material, preparing a sodium permanganate solution, and impregnating the carrier material with the sodium permanganate solution.

Owner:SUD CHEM INC +1

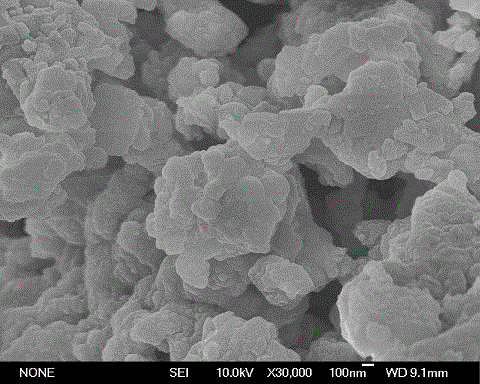

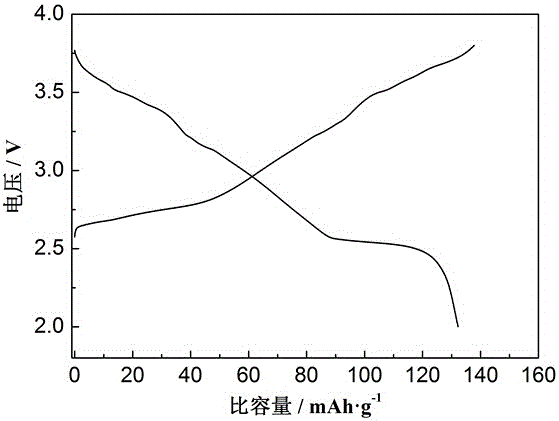

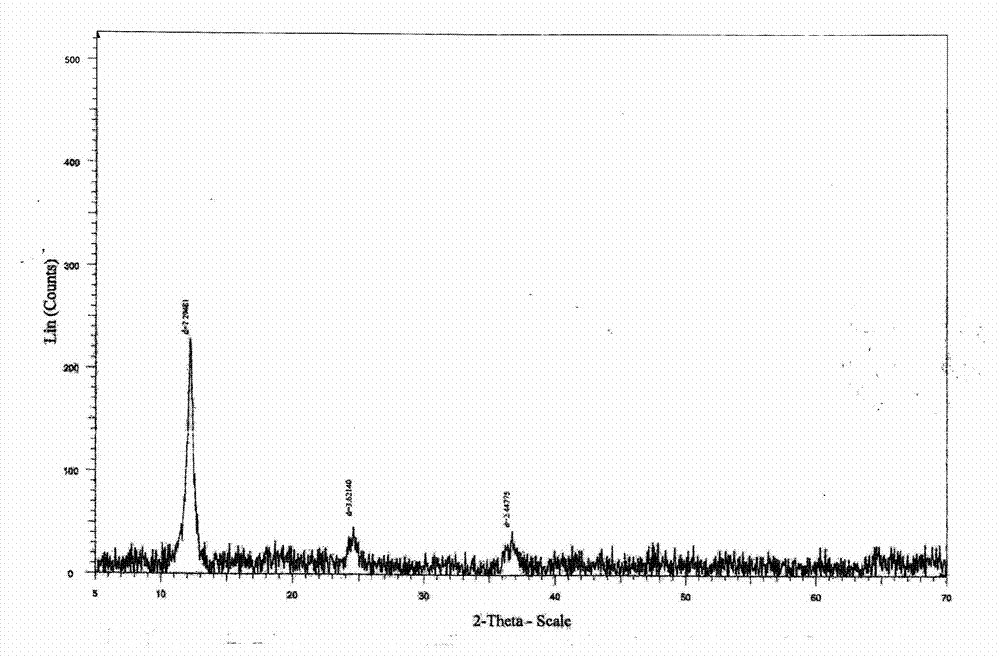

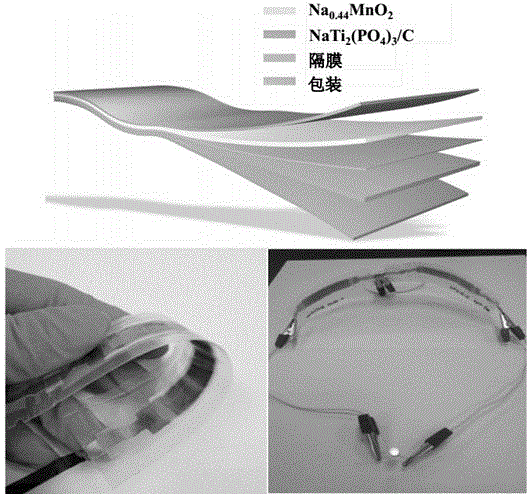

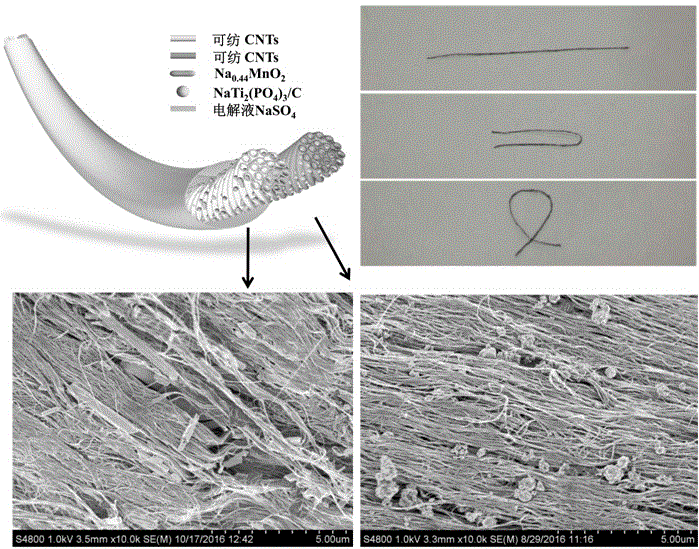

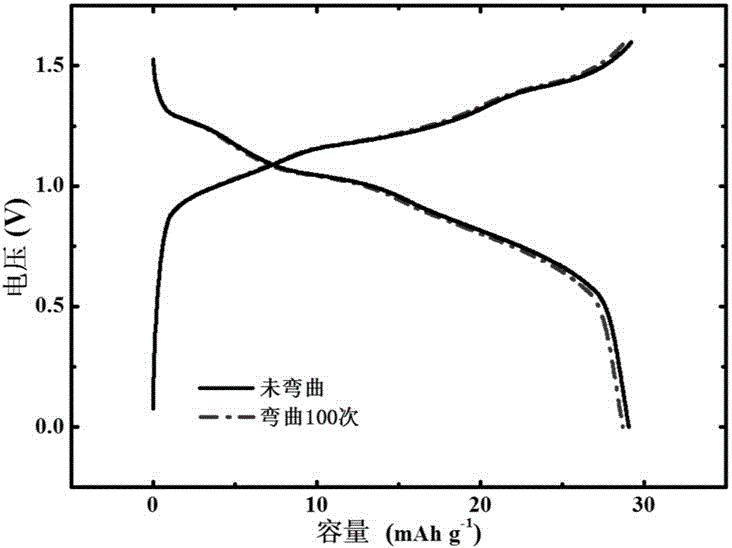

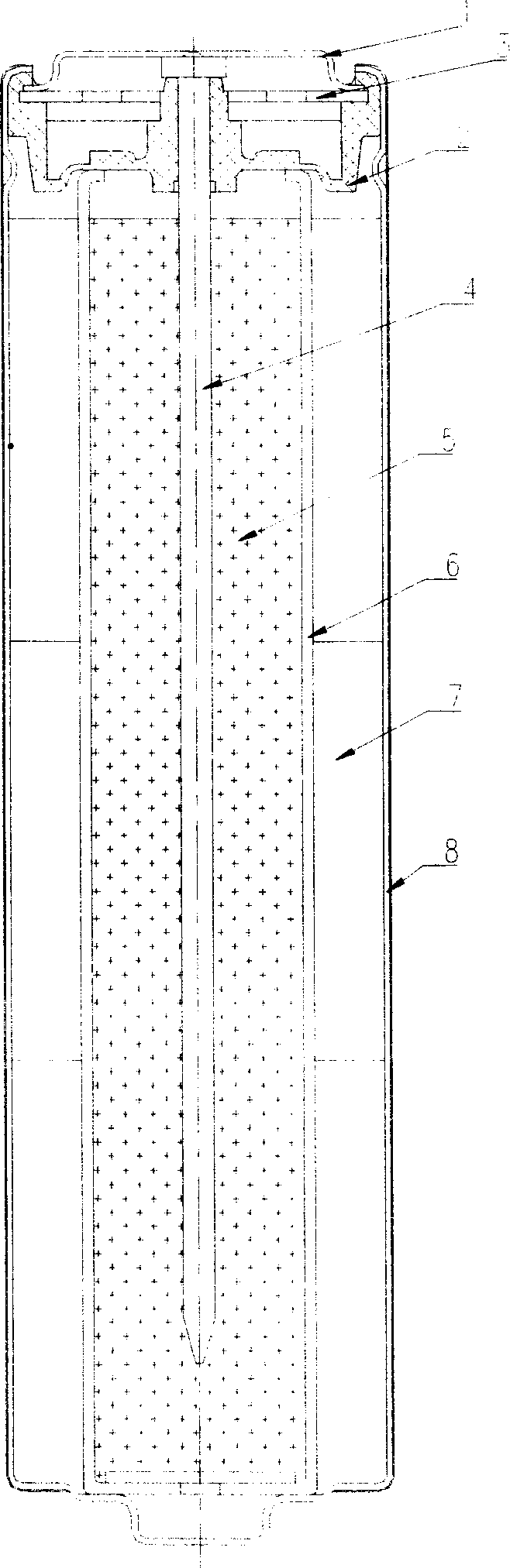

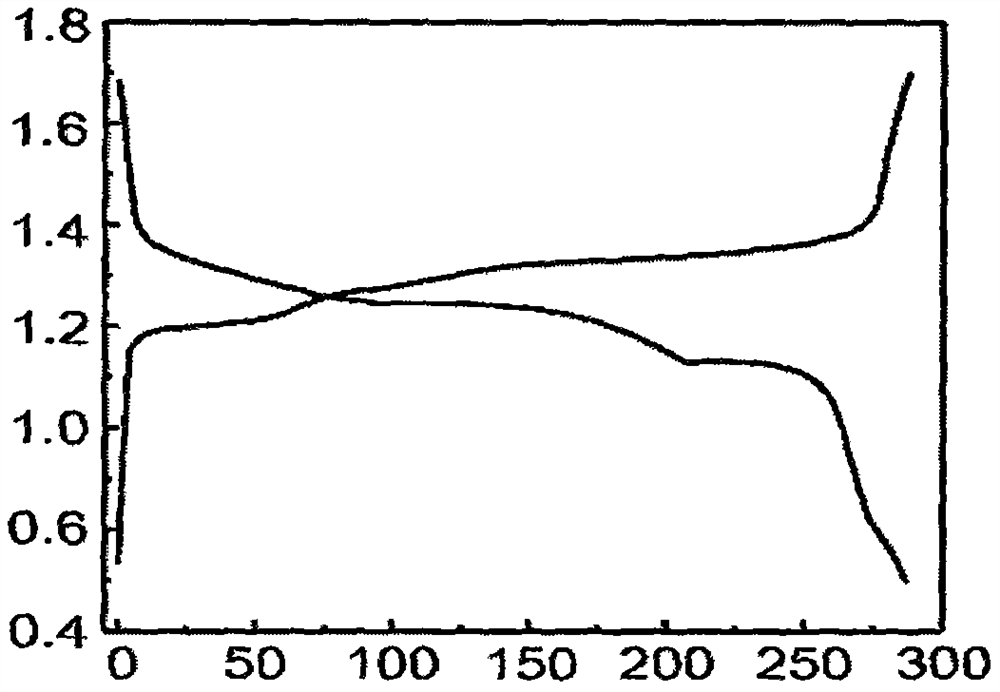

Flexible water-based sodium-ion batteries and preparation method thereof

InactiveCN106374147AImproved magnification performanceImprove cycle stabilityFinal product manufactureSecondary cellsWater basedFiber

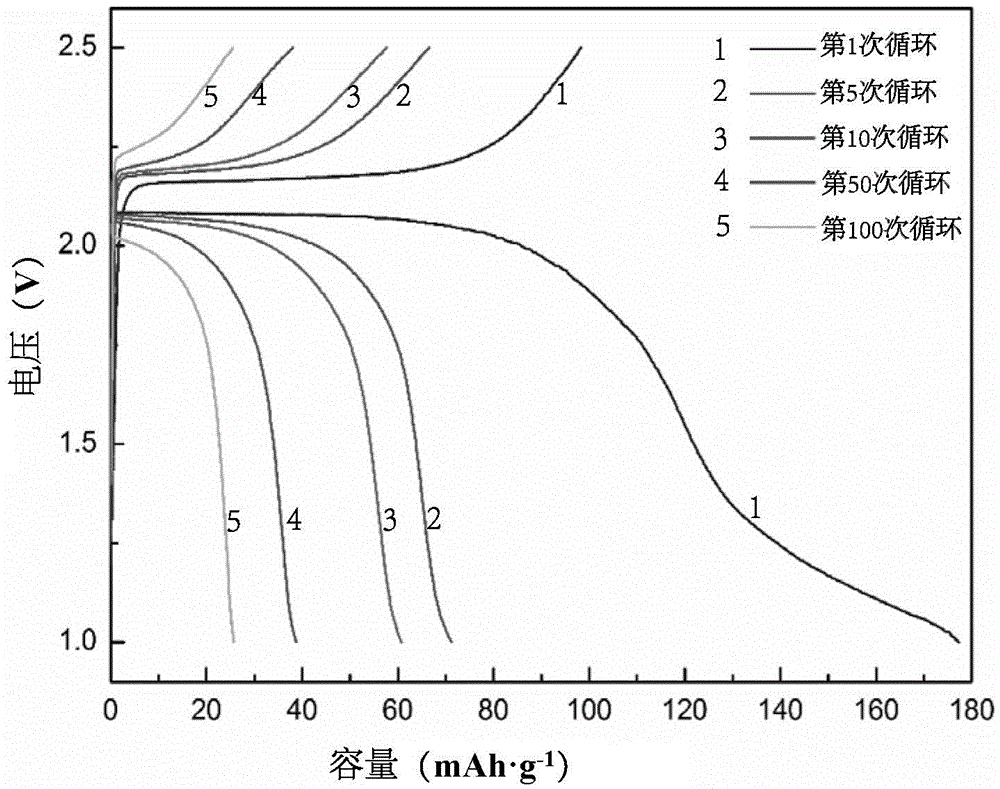

The invention belongs to the technical field of energy storage devices, and in particular relates to flexible water-based sodium-ion batteries and a preparation method thereof. The flexible water-based sodium-ion batteries take sodium manganate as a positive active material and carbon-coated sodium-titanium phosphate as a negative active material; the flexible water-based sodium-ion batteries with excellent electrochemical performance are prepared from the sodium manganate and the carbon-coated sodium-titanium phosphate according to an appropriate mass ratio; the two types of flexible water-based sodium-ion batteries are a two-dimension band-shaped flexible water-based sodium-ion battery and a one-dimensional thread-shaped flexible water-based sodium-ion battery. The band-shaped flexible water-based sodium-ion battery takes soft stainless steel as a current collector; the thread-shaped water-based sodium-ion battery enables the active materials to be rolled into an orientation carbon nano tube (CNT) to prepare composite fibers, and the CNT is used as a current collector and a conductive additive at the same time, so that the mass and volume of the battery are reduced, the flexibility of the battery is improved, and the thread-shaped water-based sodium-ion battery is easy to weave and integrate. The two-dimension band-shaped flexible water-based sodium-ion battery and the one-dimensional thread-shaped flexible water-based sodium-ion battery have excellent electrochemical performance, and have the advantages of being light in mass, low in cost, high in flexibility and safety, environmental-friendly, and the like, thus providing possibility for the application in the field of wearable electronic devices. The thread-shaped flexible water-based sodium-ion battery can even be implanted in a human body for assisting health monitoring and treatment of diseases.

Owner:FUDAN UNIV

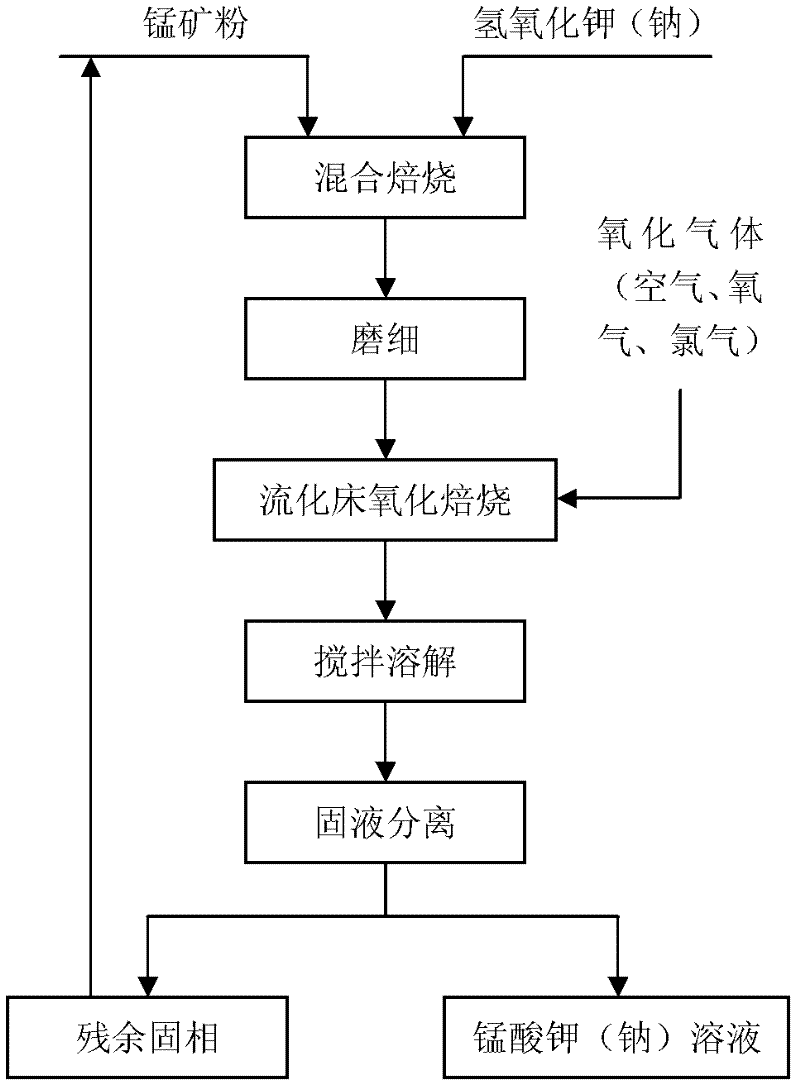

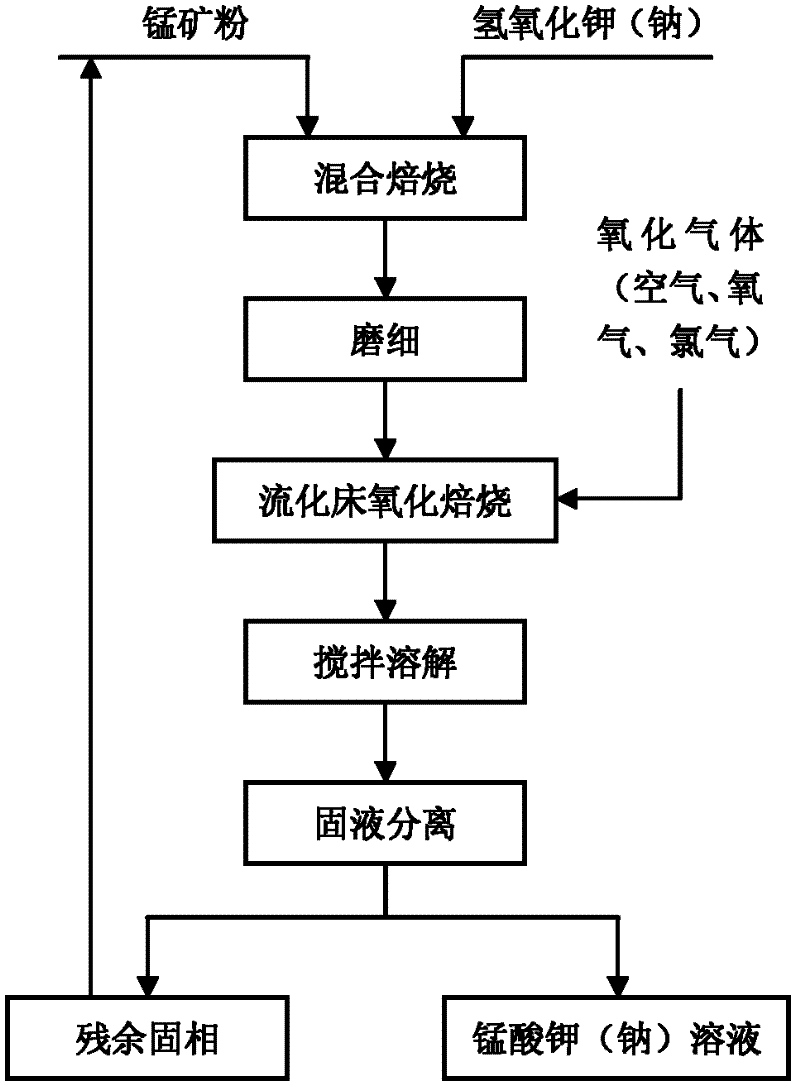

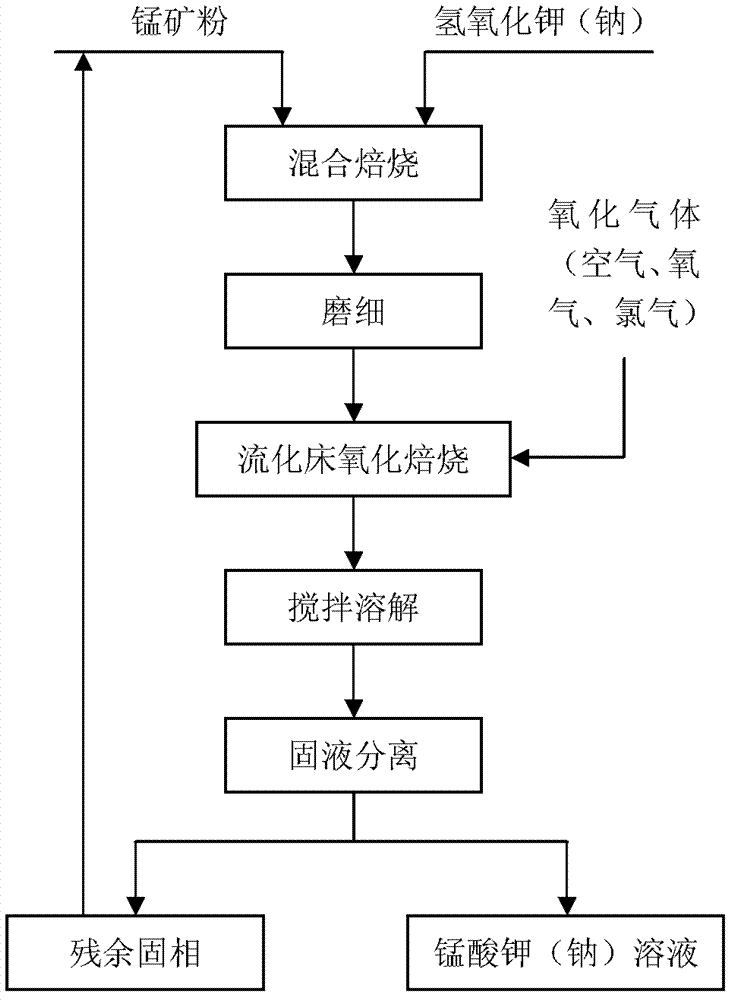

Method for producing potassium manganite or sodium manganate

InactiveCN102249342AWide variety of sourcesFully contactedManganates/permanganatesFluidized bedPotassium

The invention belongs to the field of production of potassium (sodium) manganite. In the method, a mixed calcining material of manganese mineral powder and potassium (sodium) hydrate is oxidized by using an oxidizing gas, and the potassium (sodium) manganite is produced intermittently by adopting a gas-solid fluidized bed reactor. The method comprises the following steps of: (1) adding potassium (sodium) hydrate into manganese mineral powder serving as a raw material, stirring and calcining to obtain sintering charge; (2) milling the obtained sintering charge; (3) adding the obtained powder into the gas-solid fluidized reactor, introducing the oxidizing gas, regulating the ventilation amount to keep the powder to be in a fluidized state, keeping the temperature in the reactor to be between 220 DEG C and 300 DEG C, and reacting for 0.5-3 hours to obtain a potassium (sodium) manganite product; and (4) dissolving, stirring and standing the sintering product, performing solid-liquid separation to obtain a liquid phase which is a potassium (sodium) manganite solution and a solid phase which is unreacted manganese ore, and returning to the step (1). The method has the advantages of short process flow, simple equipment, high oxidation speed, short production period and capability of remarkably increasing the transformation rate of potassium (sodium) manganite.

Owner:UNIV OF SCI & TECH BEIJING

Positive pole material of alkaline dry cell and high power alkaline dry cell, and preparation method

InactiveCN1697213AReduce deterioration rateImprove performancePrimary cell electrodesDry cellsManganateNickel zinc

The material of positive pole includes compound of containing 0.l%- 20% of barium or calcium according to weight ration. Barium manganate or calcium manganate is optimal. The invention also discloses method for preparing alkaline cell in high power. Admixture from barium manganate or calcium manganate and hydroxy nickel oxide or admixture from hydroxy nickel oxide and manganese dioxide is as active material of positive pole so as to obtain new type alkaline dry battery with long service time and good storage quality. Comparing with nickel zinc cell in current market, the disclosed cell raises current capability more than 30%, and storage quality more than 50%.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Lithium sodium manganate cathode material and preparation method thereof

ActiveCN103078100AReduce pollutionStable structureCell electrodesManganates/permanganatesDispersed mediaManganate

The invention discloses a lithium sodium manganate cathode material. The lithium sodium manganate cathode material consists of lithium sodium manganate with a layered structure, or sodium manganate with a layered structure, or lithium sodium manganate with a layered structure and a lithium manganate with a spinel structure. A preparation method comprises the following steps: mixing a manganese surface and a sodium surface, or a lithium surface, the manganese surface and the sodium surface and dispersing a mixture in a liquid disperse medium; mixing for 2-8 h through ball milling to obtain a ball-milled material; and putting the ball-milled material in an atmosphere of reducing gas, inert gas or air, roasting the ball-milled material for 6-50 h at 500-1,200DEG C, and cooling the ball-milled material to room temperature to obtain the lithium sodium manganate cathode material. The lithium sodium manganate cathode material is stable in structure, large in specific capacity, stable in cycle capacity, low in cost and environment-friendly; and the preparation method is simple in process, easy to control conditions, low in production cost and low in environment pollution and conducive to large-scale production.

Owner:CENT SOUTH UNIV

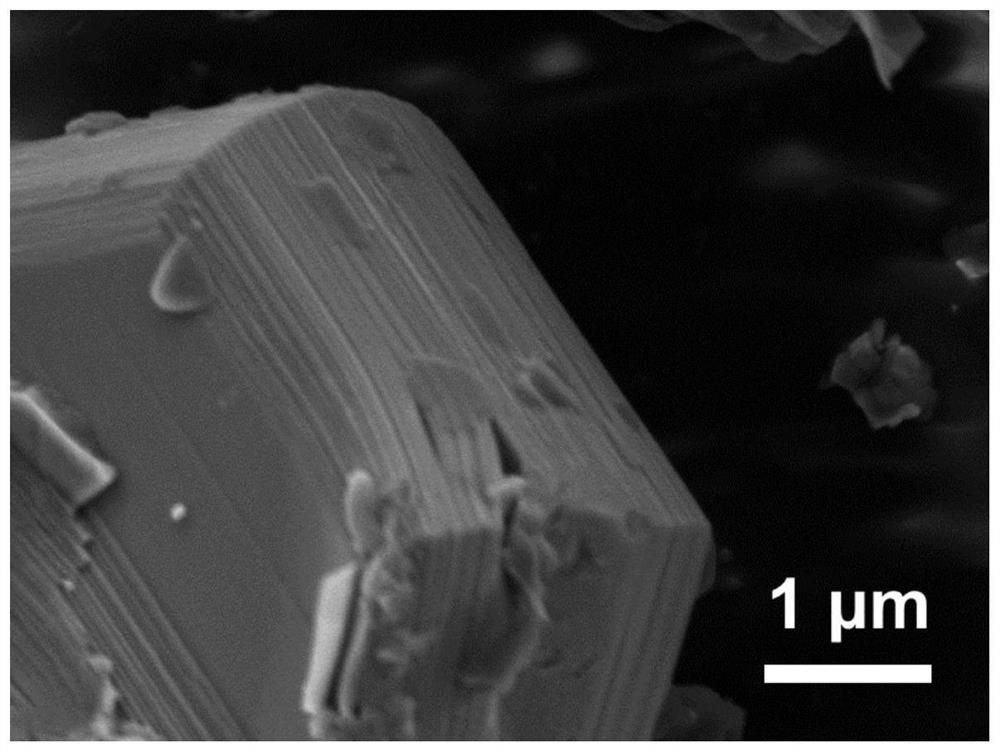

Hollow spherical sodium nickel manganate and preparation method thereof, sodium ion battery positive electrode, and sodium ion battery

InactiveCN109599553AEasy to handleSimple and fast operationCell electrodesSecondary cellsManganateSodium-ion battery

The present invention provides a hollow spherical sodium nickel manganate and a preparation method thereof, a sodium ion battery positive electrode, and a sodium ion battery, which belongs to the technical field of sodium ion batteries. The present invention provides a hollow spherical sodium nickel manganate having a particle diameter of 2.5-3.5 micrometer, a wall thickness of 0.5-1.0 micrometer,and a smooth outer surface. A chemical composition of the hollow spherical sodium nickel manganite is NaxNiyMnzO2, where x:y:z=2:1:3. The sodium nickel manganate provided by the present invention hasa hollow spherical structure with regular morphology and high crystallinity, which is beneficial for sodium ions to rapidly enter a solid phase medium from the surface, a diffusion path between solidphase particles is shortened. The sodium ion battery assembled from the sodium ion battery positive electrode obtained by using the hollow spherical sodium nickel manganate as a raw material has excellent cycle stability and rate performance.

Owner:XIANGTAN UNIV

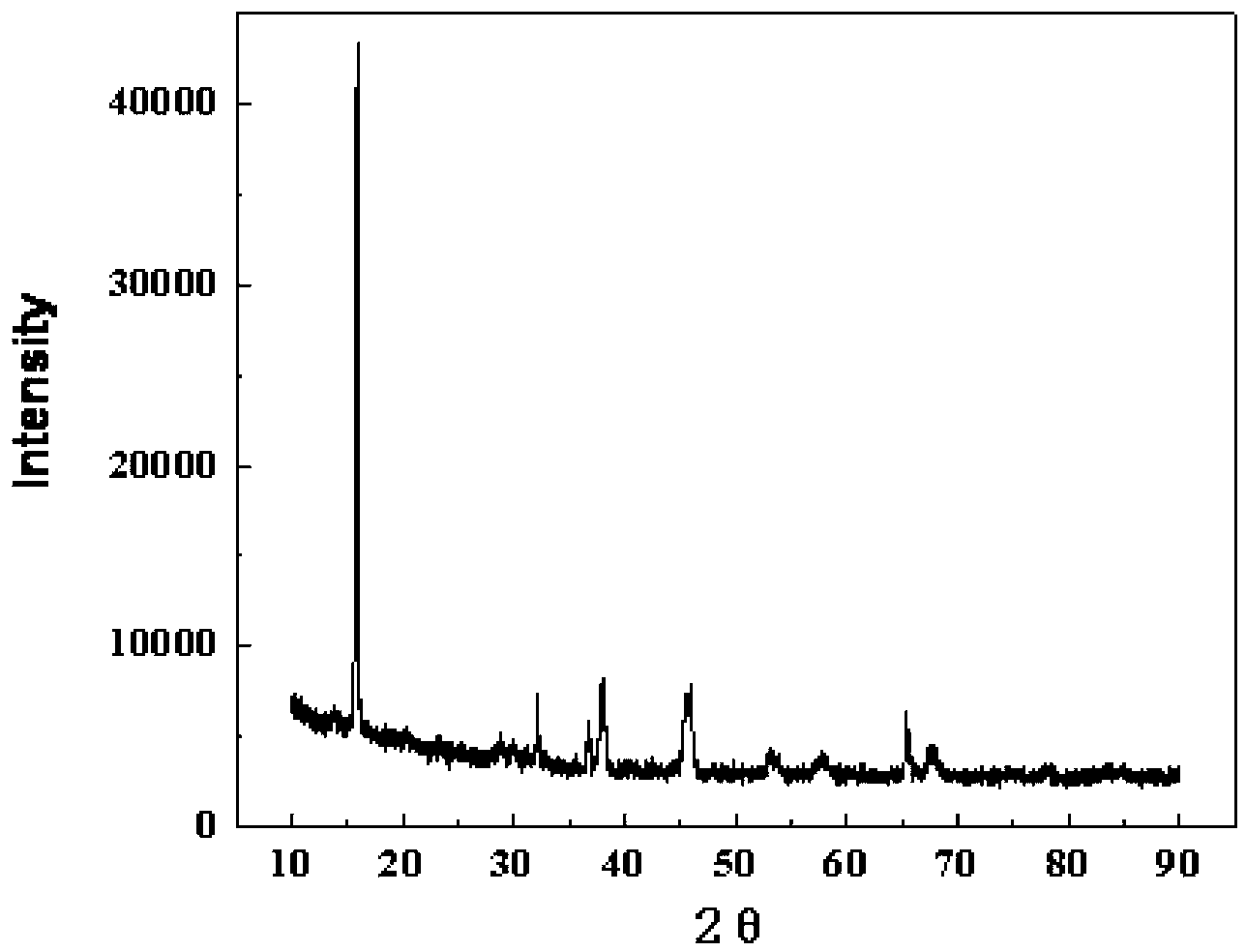

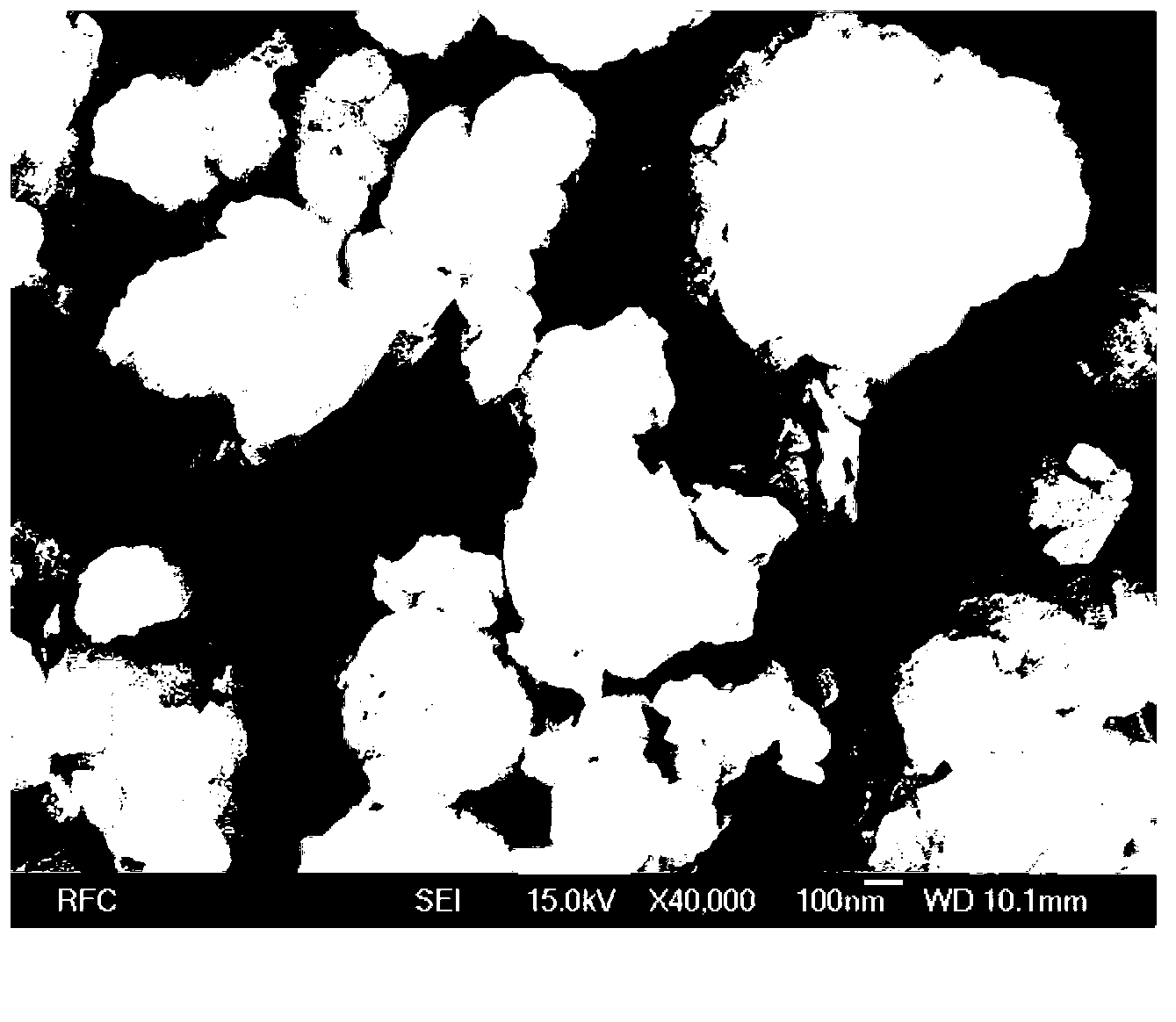

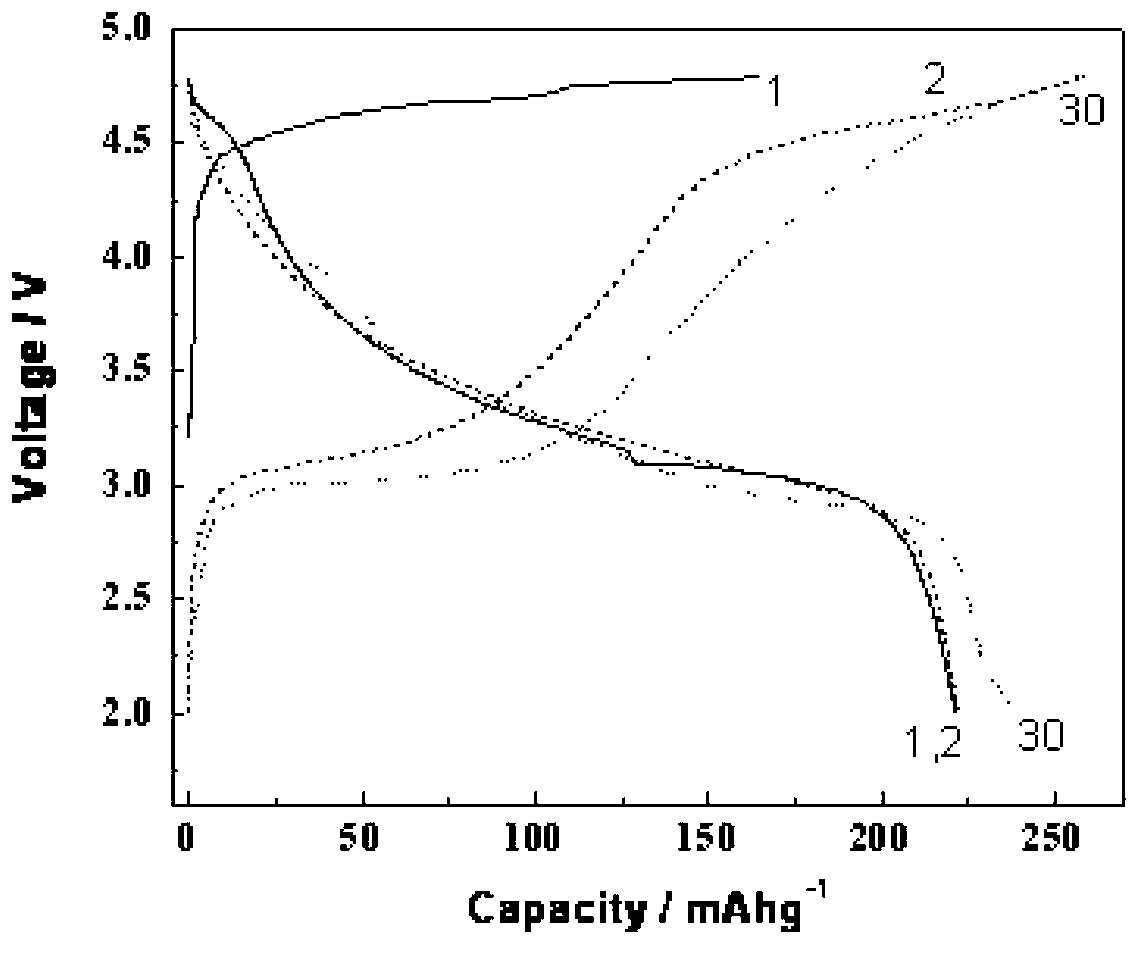

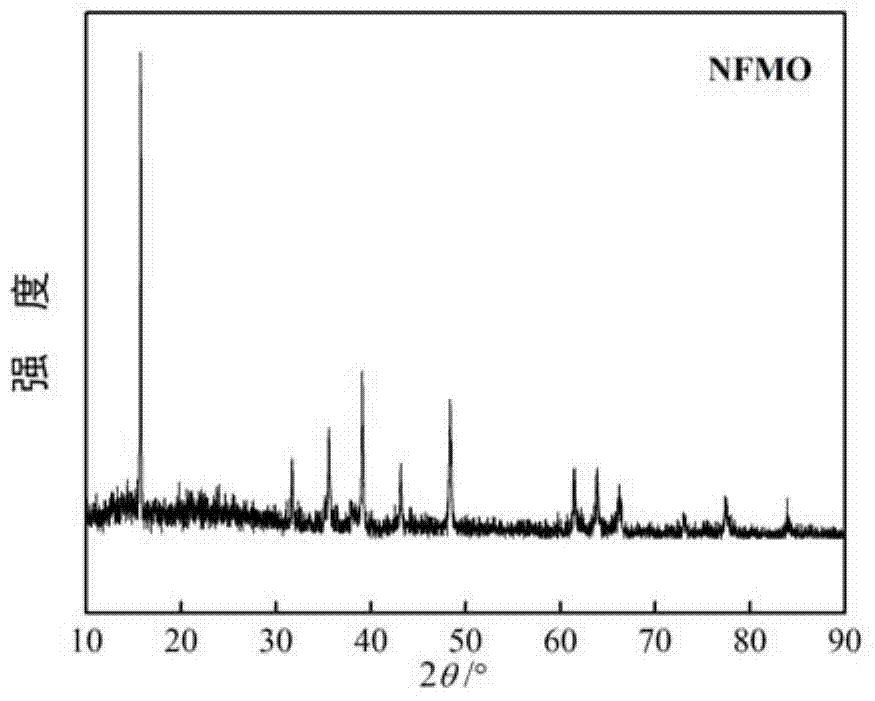

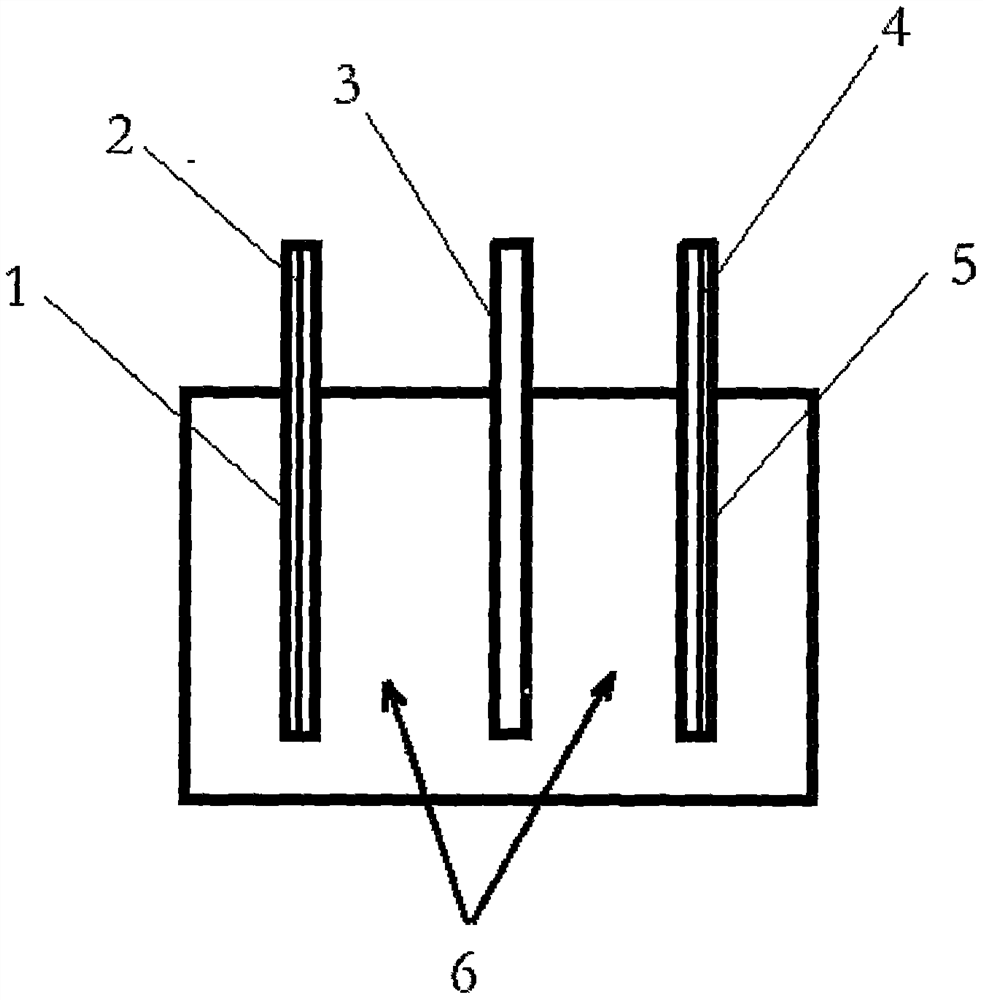

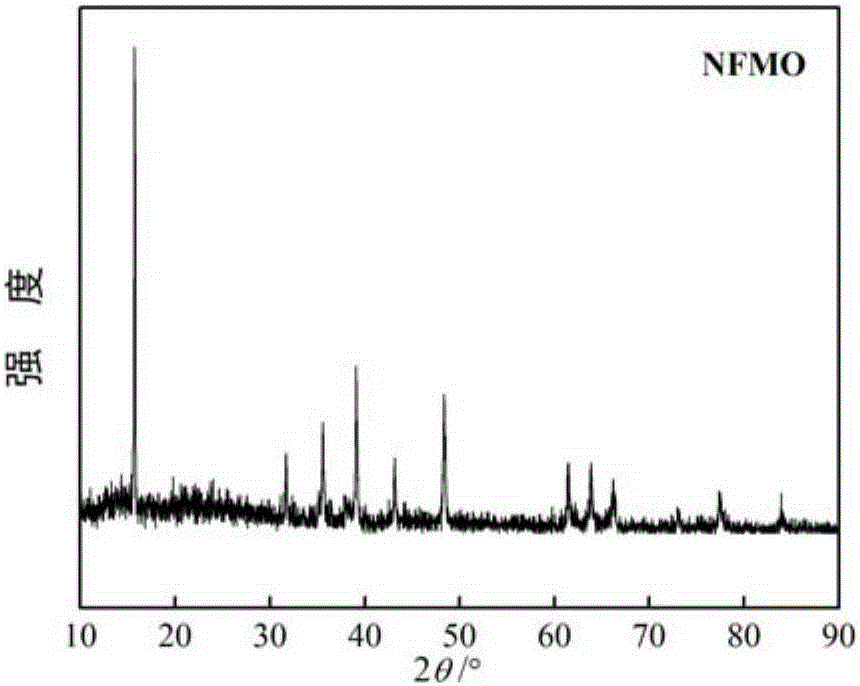

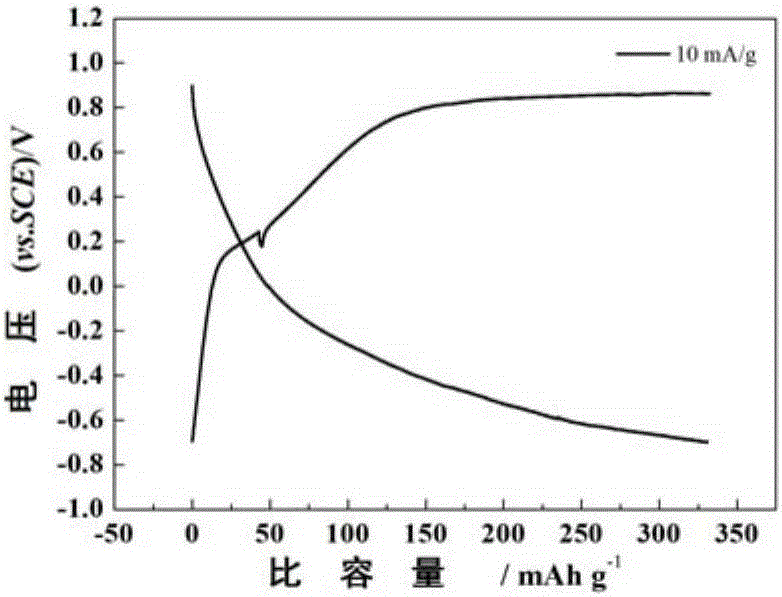

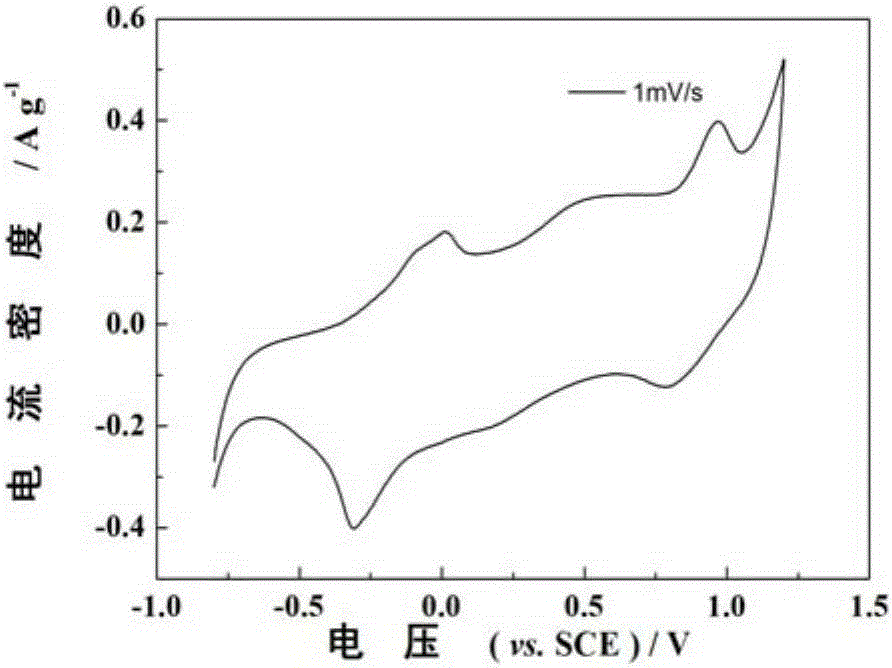

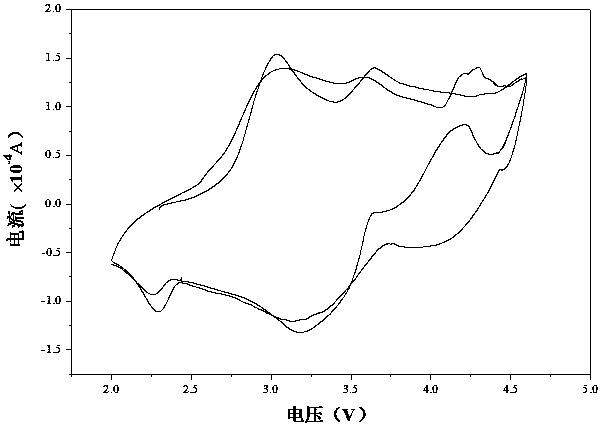

Hydro-thermal synthesizing method for iron sodium manganate of electrode material of aqueous cationic battery and preparation method of aqueous battery

ActiveCN104118913ALarge specific heat capacityZero pollutionCell electrodesIron compoundsFiltrationAqueous electrolyte

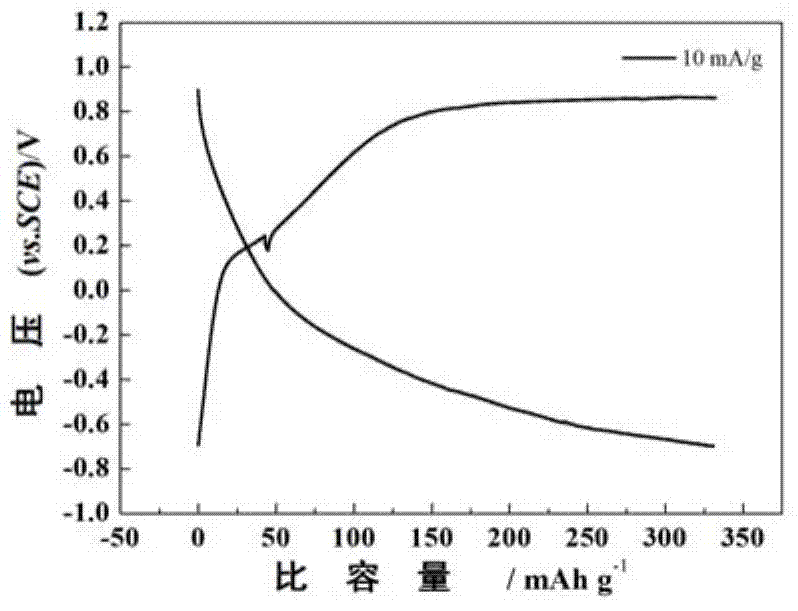

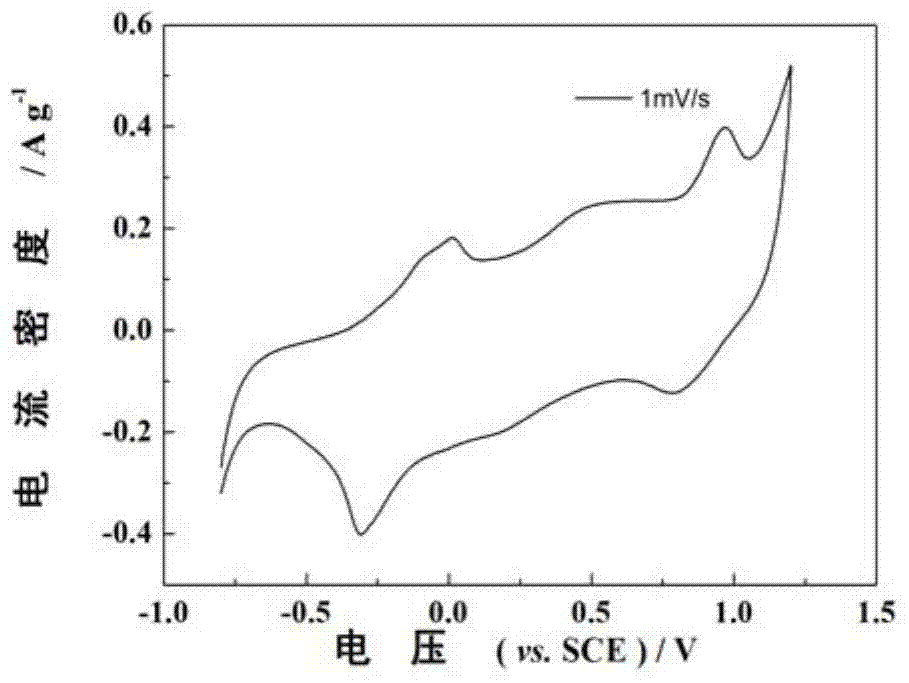

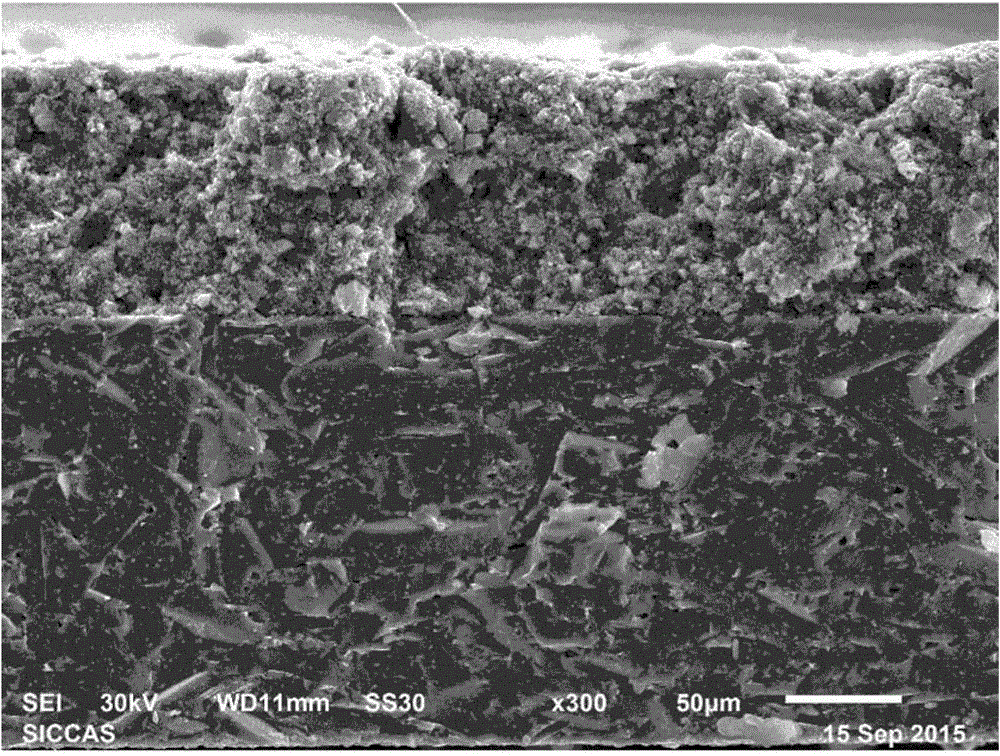

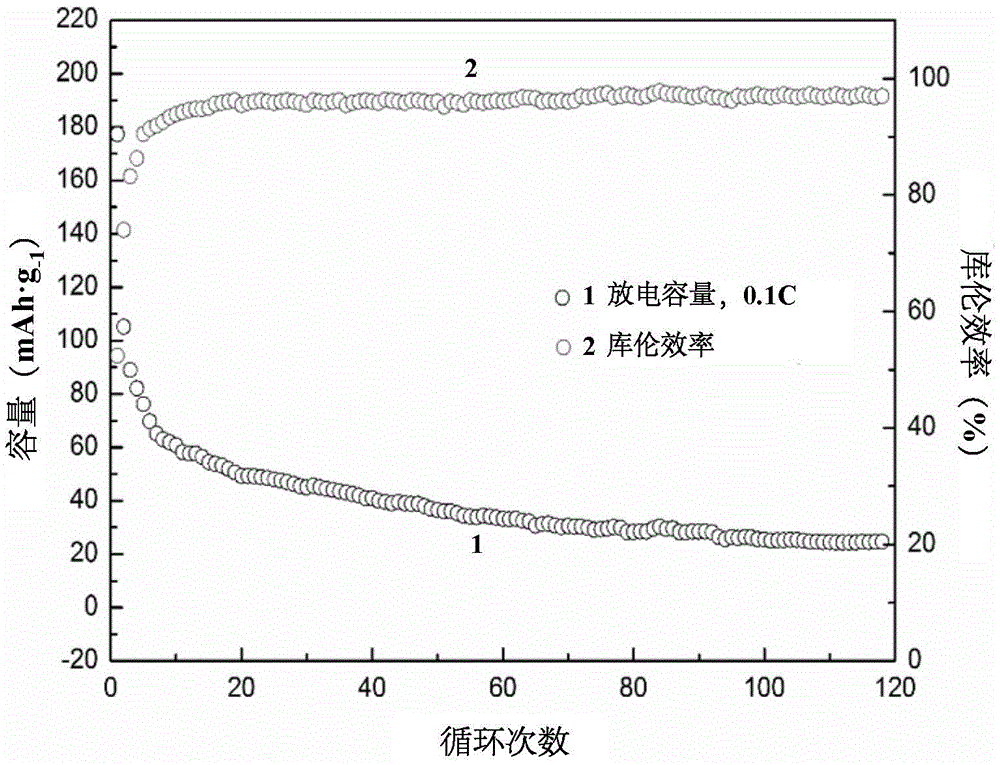

The invention provides a hydro-thermal synthesizing method for iron sodium manganate of an electrode material of an aqueous cationic battery and a preparation method of the aqueous battery. The method provided by the invention comprises the following steps of: (1) preparing an iron-sourced compound and a manganese-sourced compound into 0.5 mol / L of solution, mutually mixing, simultaneously, adding ammonium bicarbonate and ethanol as dispersing agents, and strongly stirring for 1 h; (2) transferring the mixed solution obtained in the step (1) into a reaction kettle to carry out hydro-thermal reaction, and carrying out suction filtration, cleaning and drying on the obtained precipitate; (3) ball-milling and mixing the dried product and a sodium-sourced compound in the stoichiometric ratio for 3-10 h; and (4) putting the ball-milled mixture into a muffle to be pre-processed and roasted at high temperature to obtain a final product Na0.3Fe0.5Mn0.5O2, NFMO for short. Electrochemical tests prove that the electrode material provided by the invention is maximally up to 340 mAh / g in 1 mol / L of Na2SO4 electrolyte and is maximally up to 250 mAh / g in 1 mol / L of MgC12 electrolyte under 10 mA / g of current density; the electrode material is wide in raw material and easy to prepare; and the aqueous electrolyte is low in cost, environment-friendly and non-toxic.

Owner:HARBIN ENG UNIV

Composite sodium-storage positive electrode for solid-state secondary sodium battery and preparation method for composite sodium-storage positive electrode

ActiveCN105489880AIncrease energy densityImprove securityCell electrodesSecondary cellsElectrical conductorElectrical battery

The invention relates to a composite sodium-storage positive electrode for a solid-state secondary sodium battery and a preparation method for the composite sodium-storage positive electrode. The composite sodium-storage positive electrode comprises an electrode active substance selected from any one kind of sodium manganate and sodium-titanium phosphate, and a sodium ion conductor selected from any one kind of sodium perchlorate and sodium hexafiuorophosphate. The preparation method is simple in preparation process and low in cost; and the prepared solid-state secondary sodium battery operating at the room temperature is high in energy density and high in safety.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

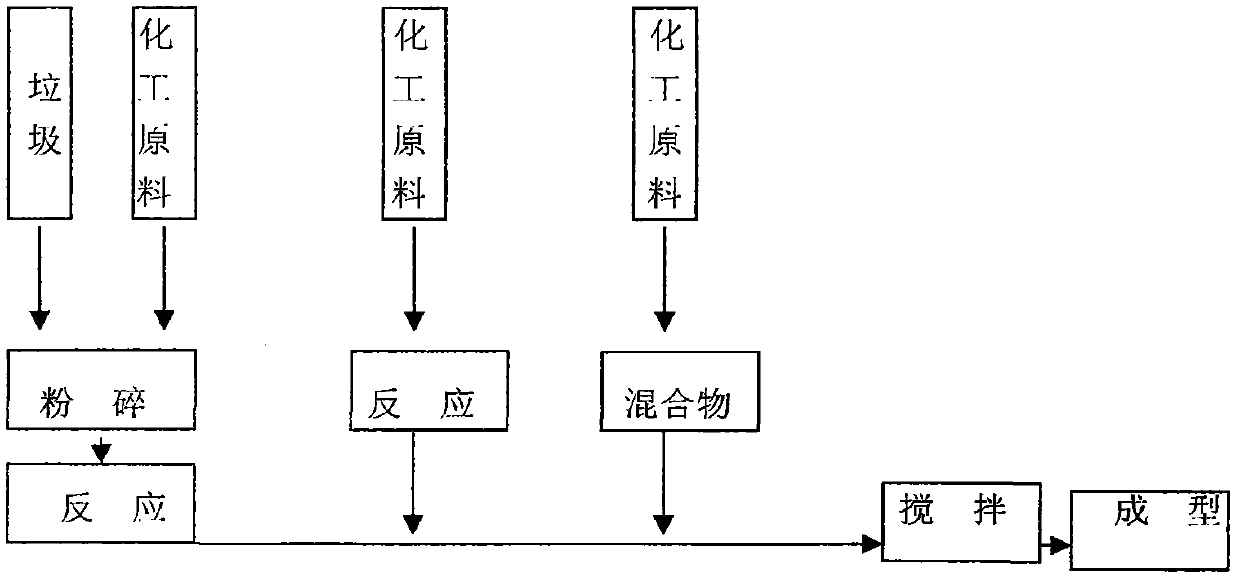

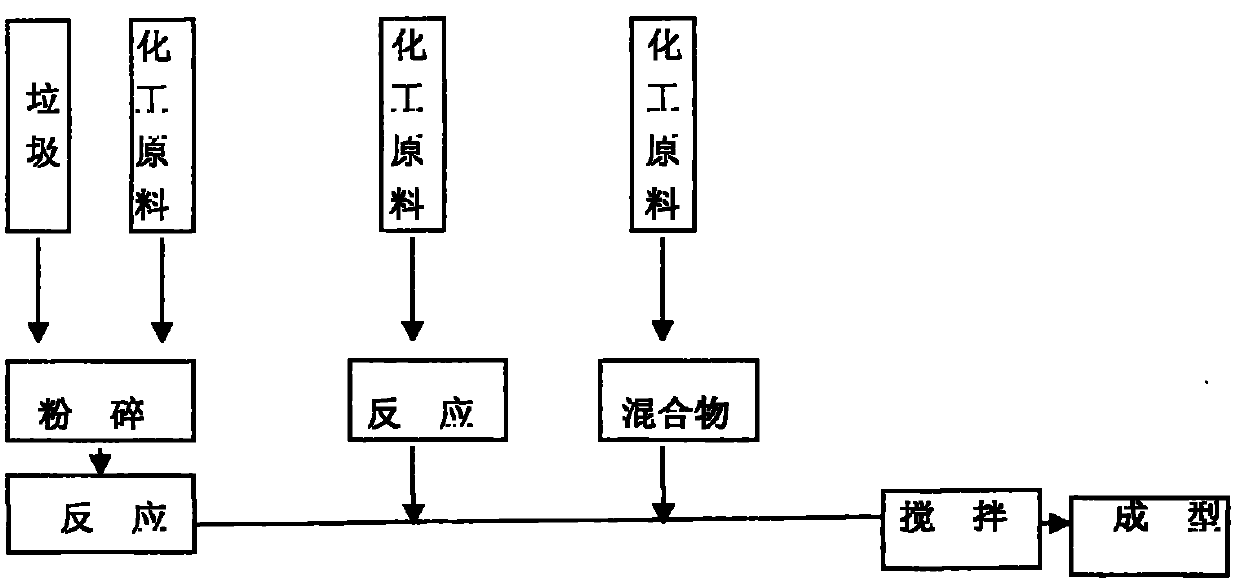

Novel environment-friendly domestic garbage recycled coal production method and product thereof

The invention relates to the technical field of domestic garbage recycling, in particular to a novel environment-friendly domestic garbage recycled coal production method. The method can fully treat domestic garbage, so that environment pollution caused by the domestic garbage can be reduced, moreover, production is simple, and the cost is low. The method includes the following steps that: according to proportion, the domestic garbage, bleaching powder, sodium hydroxide, sodium permanganate, calcium carbonate and urea are fed into a grinder and ground, and the ground mixed particle-like garbage is kept still for reaction under normal temperature; under normal temperature, anhydrous sodium sulphate is dissolved in clean water to the saturation state, and sodium chloride, graphite powder, ammonium nitrite, zinc oxide and sodium permanganate are added to carry out normal-temperature reaction; a moderate amount of clean water is added in the sodium permanganate, used oil, olefin, carbon powder and sodium chloride in an iron kettle, the mixture is heated to 75 DEG C and dissolved, and various products are mixed and shaped, so that a novel domestic garbage recycled coal product is produced.

Owner:徐日生

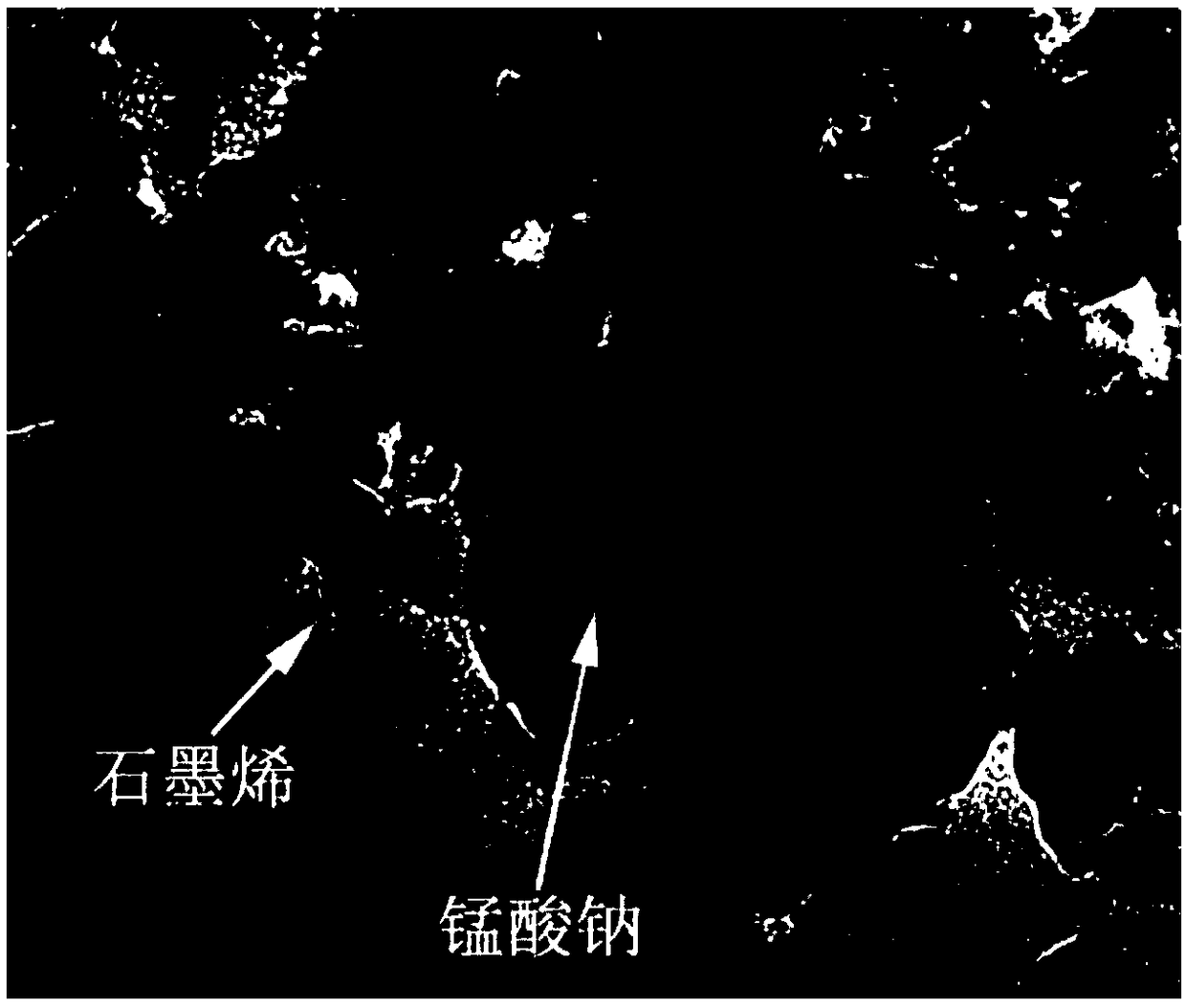

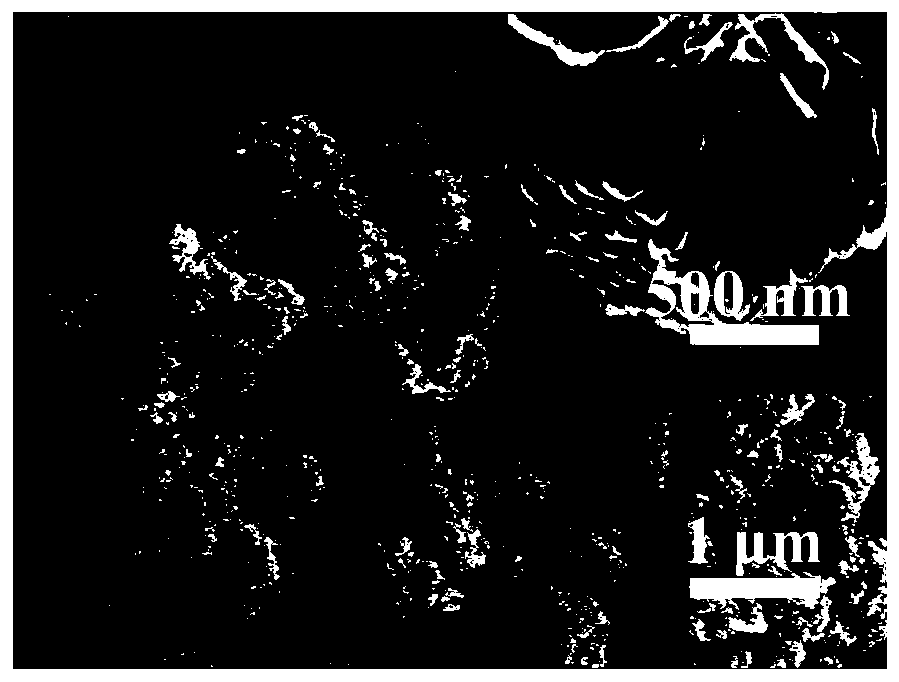

Sodium manganate/graphene composite electrode material, preparation method therefor and application

ActiveCN108878826AThe process is simple and easy to controlLow costCell electrodesSecondary cellsAir atmosphereMicro nano

Owner:SHANGHAI HANHANG TECH CO LTD

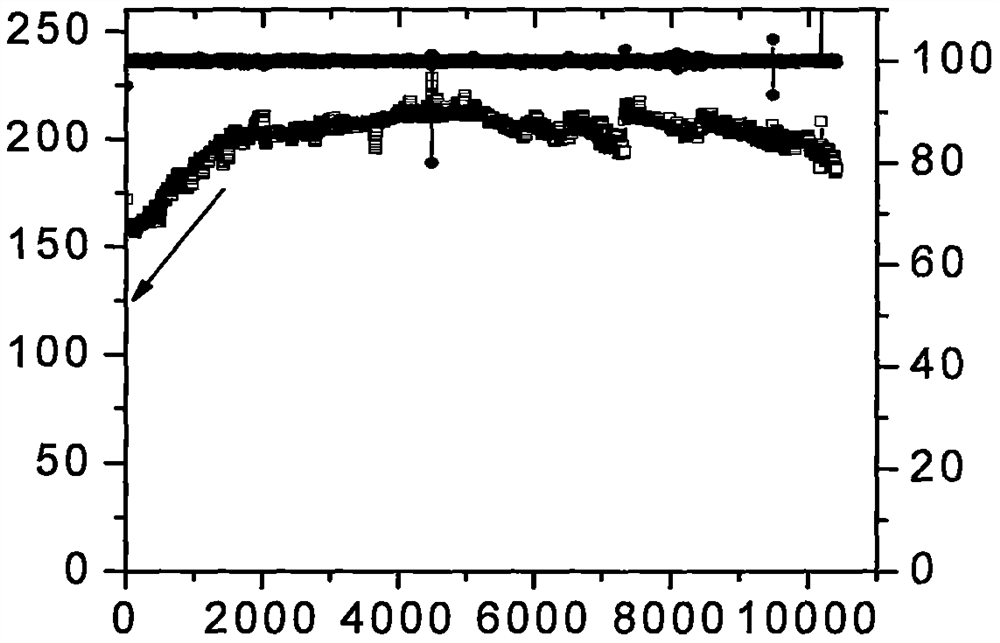

Carbon-azine composite water-based negative electrode material and application thereof

PendingCN112038632AImprove conductivityEvenly dispersedSecondary cellsNegative electrodesElectrolytic agentPolycyclic aromatic hydrocarbon

The invention relates to a carbon-azine composite water-based negative electrode material and application thereof. The carbon-azine composite water-based negative electrode material utilizes the conductivity, porosity and adsorbability of a nano carbon material and the reaction capability of polycyclic aromatic hydrocarbon-like compounds of the carbon material to carry out functionalized graftingto form a cross-linked network structure, so as to improve the liquid absorbency and ionic conductivity of the carbon material, and compound the heterocyclic azine compound onto carbon granules to form a carbon-azine composite material. The carbon-azine composite material is used as a water-based negative electrode, a sodium manganate or nickel hydroxide electrode is used as a positive electrode,and an electrolyte is a liquid or gel-state material taking sodium salt or sodium hydroxide as a solute and water as a solvent; and the positive electrode and the negative electrode are separated by adiaphragm to form a battery. The negative electrode material has high utilization rate and capacity, is applied to an aqueous rechargeable battery, and has high specific discharge capacity and good cycle performance; and a water-based rechargeable battery composed of the carbon-azine composite water-based negative electrode material and the sodium manganate or nickel hydroxide positive electrodehas the advantages of relatively high specific energy, safety, low cost, environmental protection and long cycle life.

Owner:中国人民解放军军事科学院防化研究院 +2

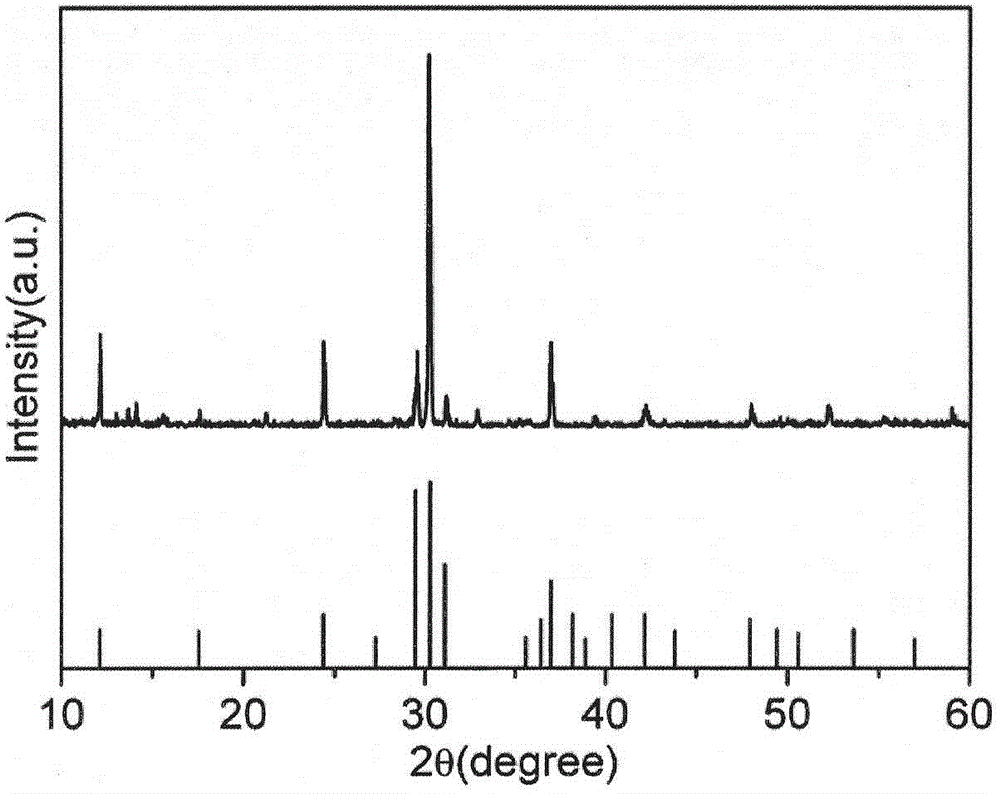

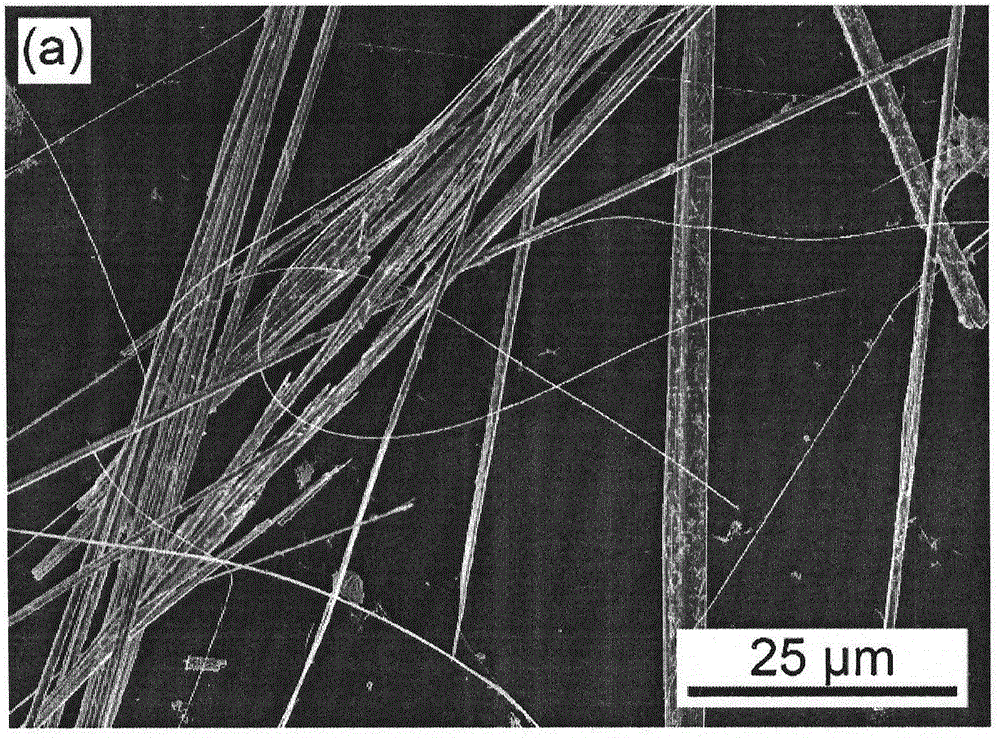

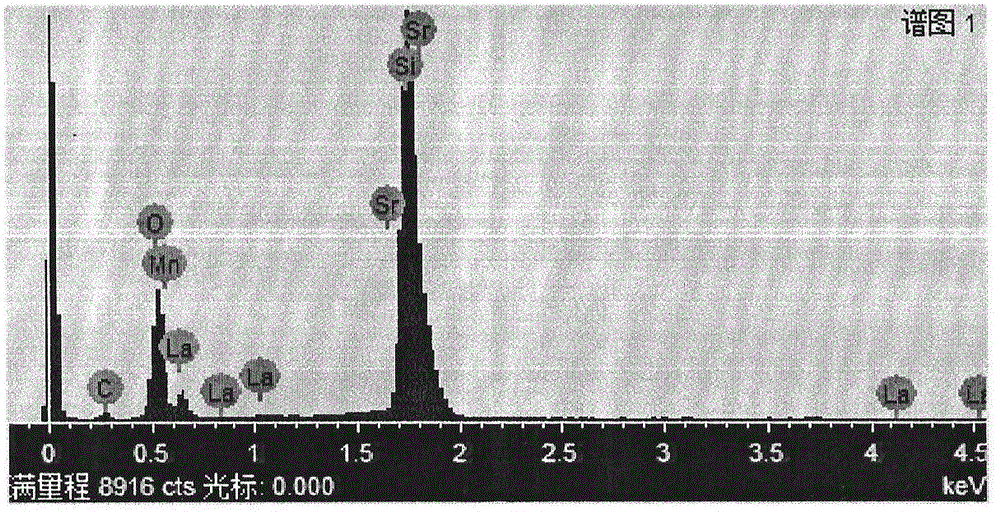

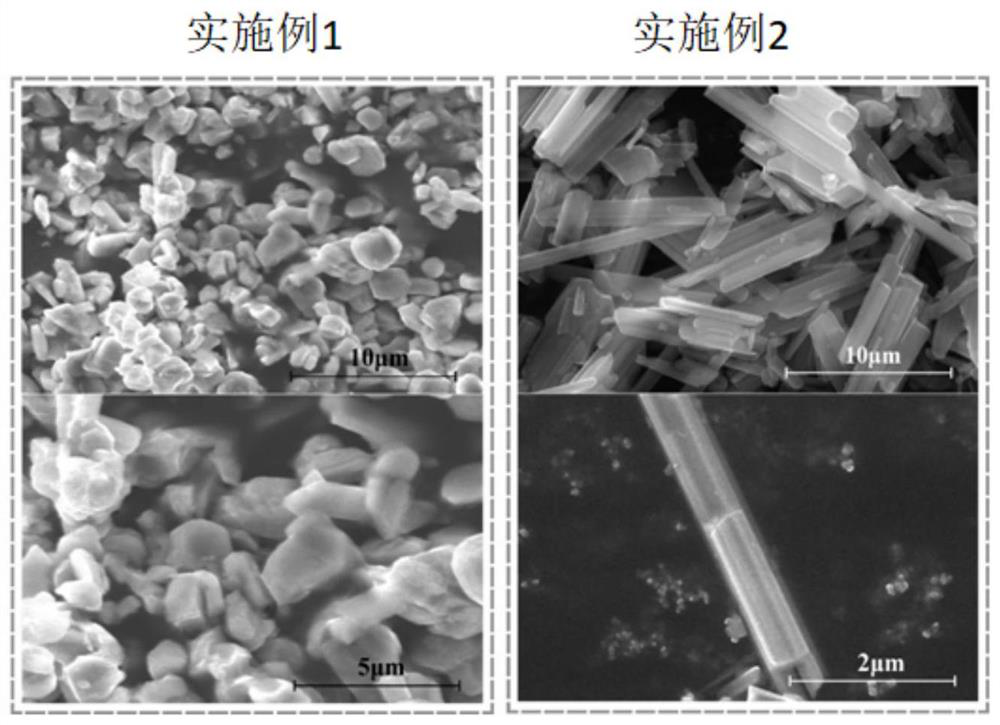

Strontium manganate nanowires and microwires and preparation method thereof

ActiveCN105540673AOvercoming Difficult Doping ProblemsSimple processNanotechnologyManganates/permanganatesNanowireSorbent

The invention discloses strontium manganate nanowires and microwires and a controllable hydrothermal preparation method thereof. The chemical formula of strontium manganate is SrMn3O(6-x), and lanthanum doping can be performed within certain range; and the regulation of wire size and doping amount can be realized by changing the conditions such as reaction temperature, time and raw material proportioning, wherein the wire diameter is 50nm-5mum, the length is 40-300mum, and the doping amount is 0-0.25% by weight. The system has excellent specific surface area, ion exchangeability and stability as well as unique molecule-grade tunnel space and has an important application value in the fields such as catalysts, secondary battery electrode materials, adsorbents, molecular sieves and sensors. Meanwhile, the unique magnetic and electrical properties are of important application value in terms of magnetic recording and magnetic sensors. The method has the advantages of easiness, low equipment requirements and low energy consumption and can be applied to the strontium manganate preparation as well as one-dimensional system synthesis of other similar multielement materials, for example, nanowires and microwires of barium manganate, calcium manganate and sodium manganate.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

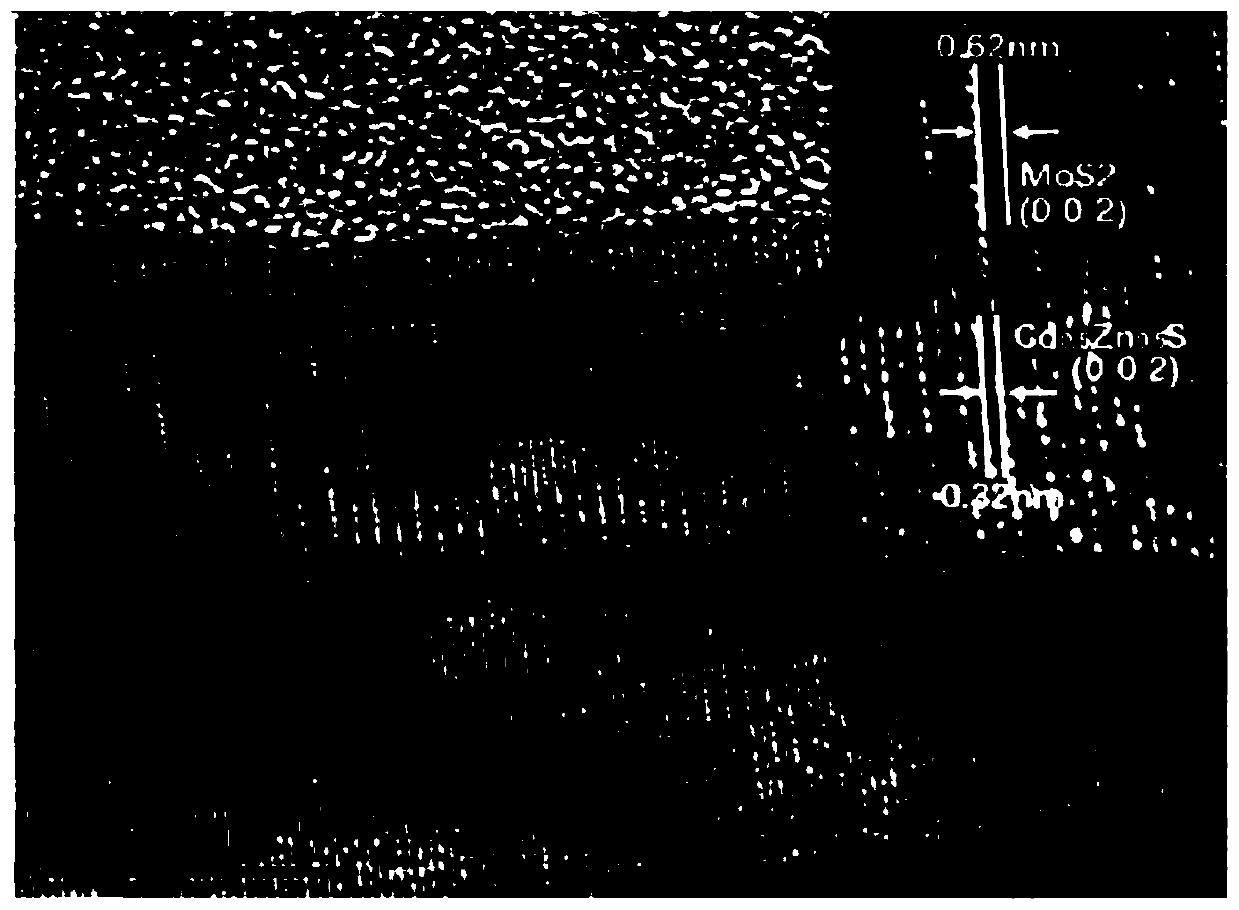

Method for preparation of deuterium gas by photocatalysis of deuterium oxide

The invention discloses a method for preparation of deuterium gas by photocatalysis of deuterium oxide. The method is low in cost, safe, environment-friendly and high in preparation efficiency. The method comprises the steps of: 1) mixing cadmium acetate tetrahydrate, zinc acetate dihydrate, thiourea and sodium manganate dihydrate, then dissolving the mixture in ethylenediamine, and performing stirring to obtain a reaction mixed solution; and 2) putting the mixed solution obtained in step 1) into a polytetrafluoroethylene-lined stainless steel autoclave, adding sodium manganate dehydrate, carrying out programmed heating to 150-200DEG C, conducting heat preservation for 8-24h, performing cooling to room temperature and performing separation, conducting washing with water and ethanol repeatedly, and staying the product overnight in a vacuum drying oven to obtain a MoS2-Cd0.5Zn0.5S photocatalyst containing MoS2; and 3) suspending the MoS2-Cd0.5Zn0.5S photocatalyst in D2O, adding Na2SO3 and Na2S as the sacrificial agent, and performing irradiation with Xe lamp-300W to obtain deuterium gas.

Owner:曾功昶

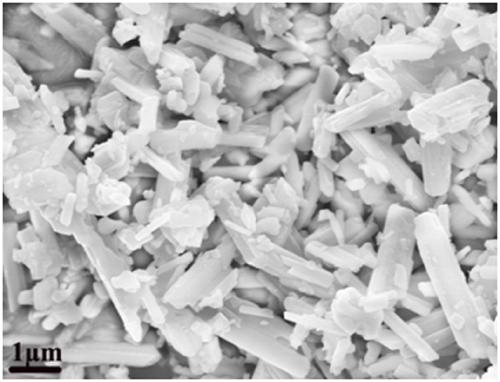

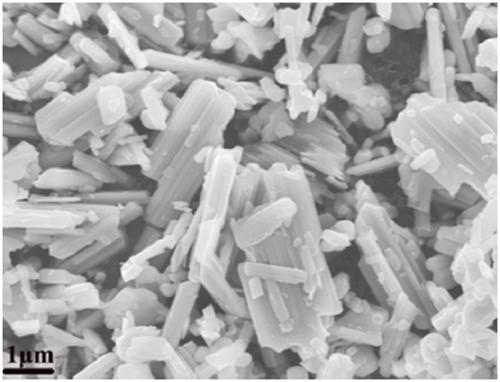

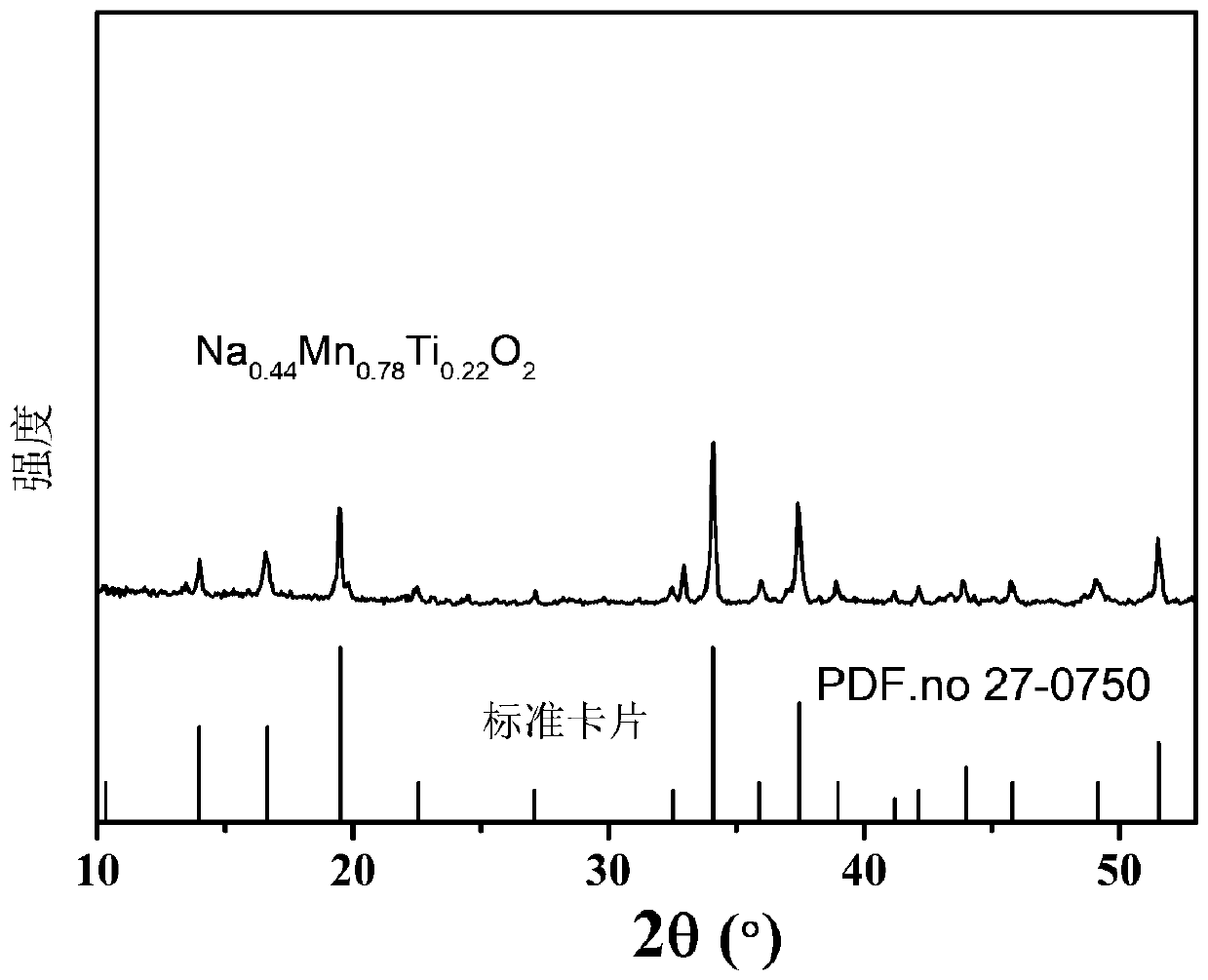

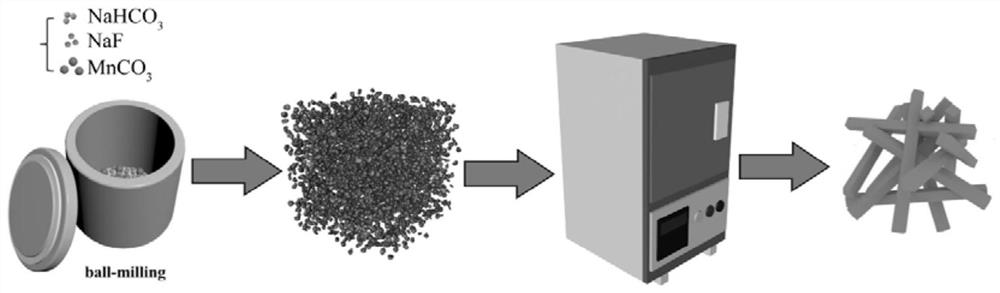

Preparation method of sodium ion battery positive electrode material titanium sodium manganate

PendingCN111180706AStable structurePromote circulationSecondary cellsPositive electrodesOXALIC ACID DIHYDRATEElectrical battery

The invention discloses a preparation method of sodium ion battery positive electrode material titanium sodium manganate. The technical process is as follows: respectively adding a specific sodium source into an oxalic acid solution; uniformly mixing manganese source and titanium source compounds; carrying out stirring for 1 hour at 60 DEG C; then, putting the mixture into an air drying oven and evaporating for 12h at 70-90 DEG C to evaporate the mixture to dryness; and grinding the mixture in a mortar for 20-30 minutes, carrying out sintering in a muffle furnace at 800-1000 DEG C for 2-12 hours under a certain atmosphere condition, and cooling to room temperature to obtain a Na0.44TixMn1-x O2 positive electrode material with a stable structure and good cycle performance.

Owner:TAIYUAN UNIV OF TECH

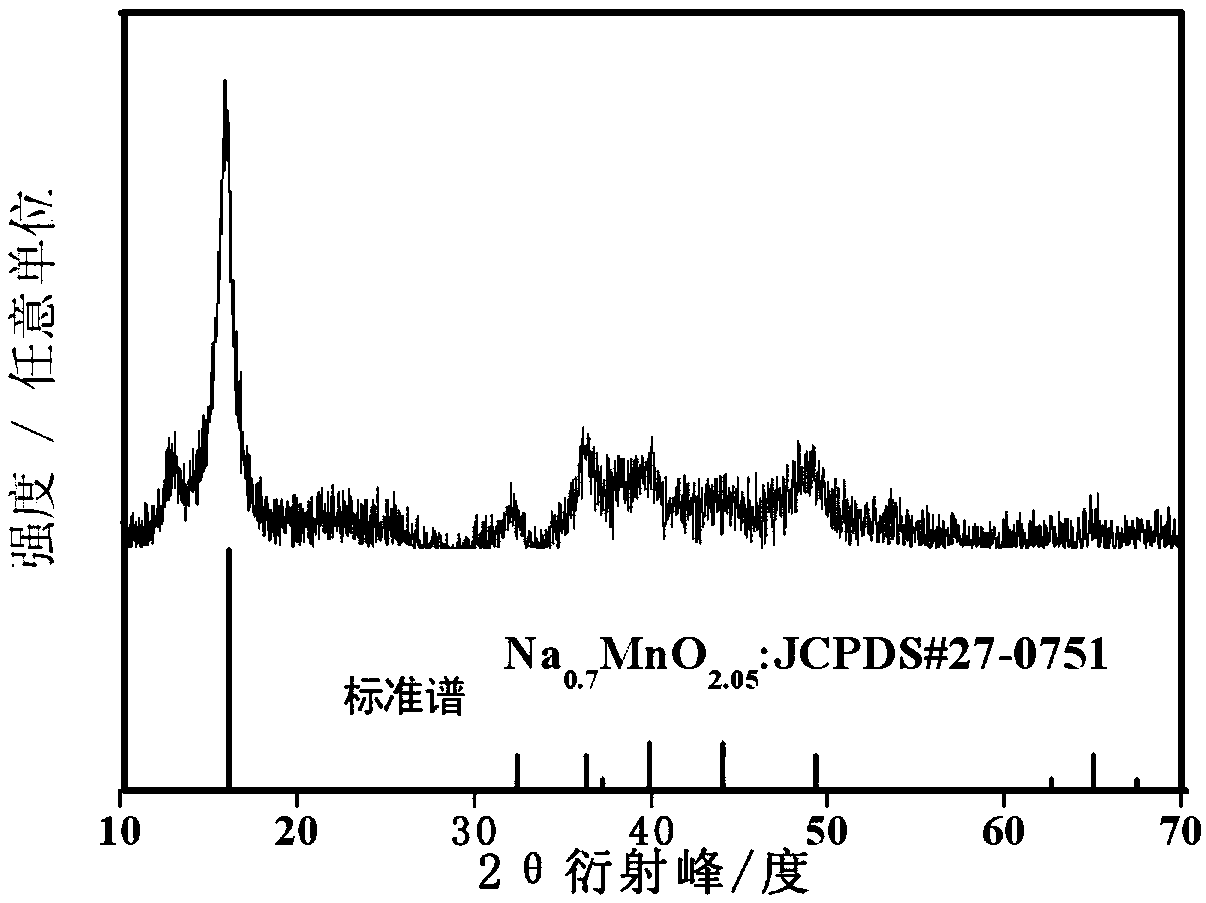

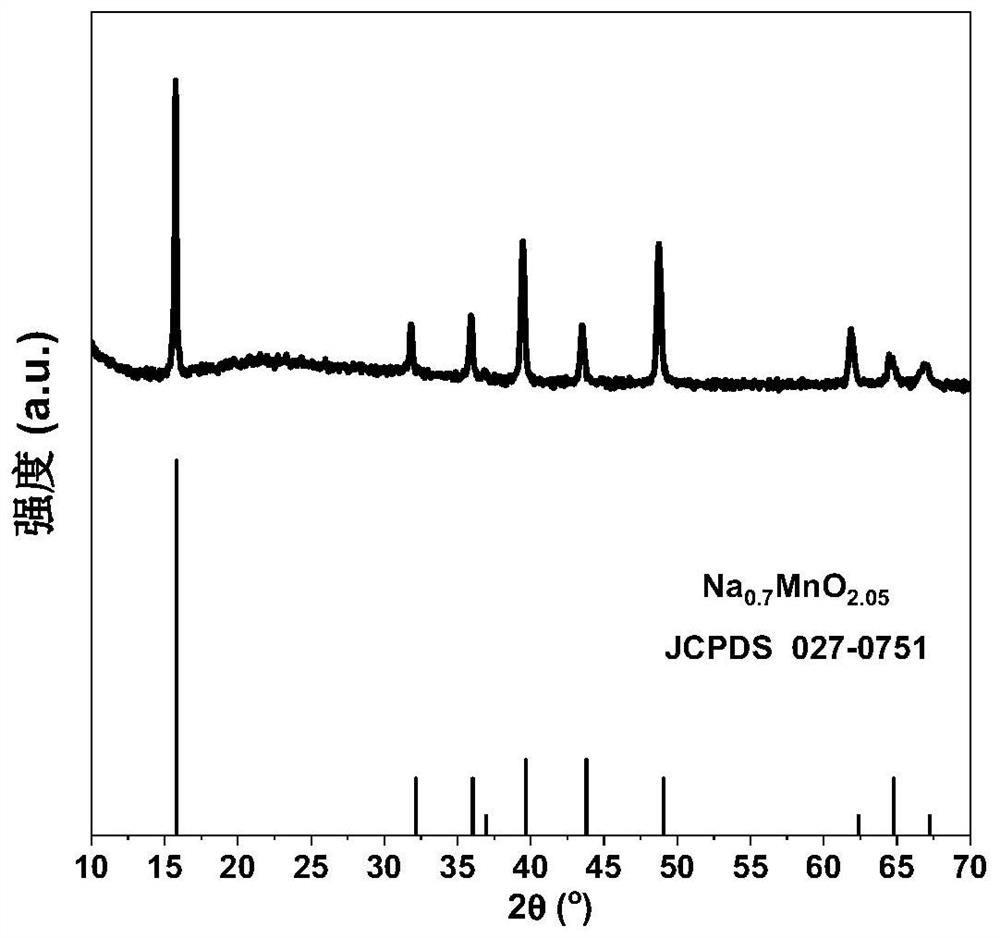

Synthesis method of tunnel layered intergrowth phase sodium manganate serving as positive electrode material of sodium-ion battery

PendingCN113140724AInhibition of volume changeHigh charge and discharge capacityCell electrodesSecondary cellsSodium-ion batteryBattery cell

The invention discloses a synthesis method of tunnel layered intergrowth phase sodium manganate serving as a positive electrode material of a sodium-ion battery. According to the method, the sodium ion positive electrode material Na0.5MnO<2-x>Fx with a tunnel phase and layered phase intergrowth structure is synthesized in one step by adopting a solid-phase sintering method. The layered phase structure in the intergrowth phase plays a role in improving the charge-discharge specific capacity, and the tunnel structure in the intergrowth phase inhibits the volume change of the material in the charge-discharge process and plays a role in improving the cycle stability. The synthesis method is simple, the raw materials are low in price, and the synthesized tunnel layered intergrowth phase Na0. 5MnO<2-x>Fx serving as a sodium-ion battery positive electrode material has high charge-discharge specific capacity, cycle performance and rate capability and has wide application prospects in the aspect of large-scale energy storage.

Owner:NANJING UNIV OF SCI & TECH

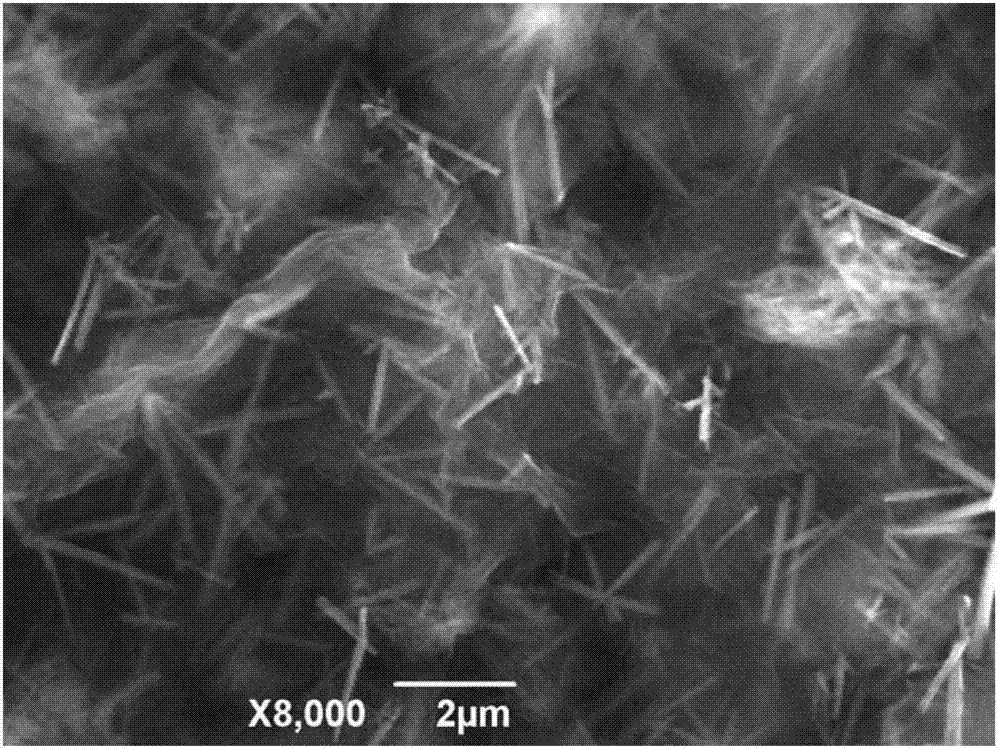

Method for preparing graphene/sodium manganate flexible thin film and method using graphene/sodium manganate flexible thin film to prepare aqueous sodium-zinc compound battery

ActiveCN107154496AImprove conductivityImprove electrochemical performanceCell electrodesGrapheneZinc compoundsCvd graphene

The invention discloses a method for preparing a graphene / sodium manganate flexible thin film and a method using the graphene / sodium manganate flexible thin film to prepare an aqueous sodium-zinc compound battery, relates to methods for preparing graphene thin films and methods using the graphene thin films to prepare compound batteries, and aims to solve the problem that an existing battery anode material is complex in preparation process, low in conductivity and unstable in electrochemical performance. The method for preparing the graphene / sodium manganate flexible thin film includes the steps of firstly, preparing Na4Mn9O18 powder; secondly, adding graphene oxide into deionized water, and performing ultrasonic treatment to obtain a solution A; thirdly, preparing a graphene oxide / sodium manganate flexible thin film; fourthly, drying the graphene oxide / sodium manganate flexible thin film to obtain the graphene / sodium manganate flexible thin film. The prepared graphene / sodium manganate flexible thin film is simple in process, has sufficient toughness, can be curled at will and can be directly cut to serve as a flexible electrode. By the methods, the graphene / sodium manganate flexible thin film and the aqueous sodium-zinc compound battery can be prepared.

Owner:ANKANG UNIV

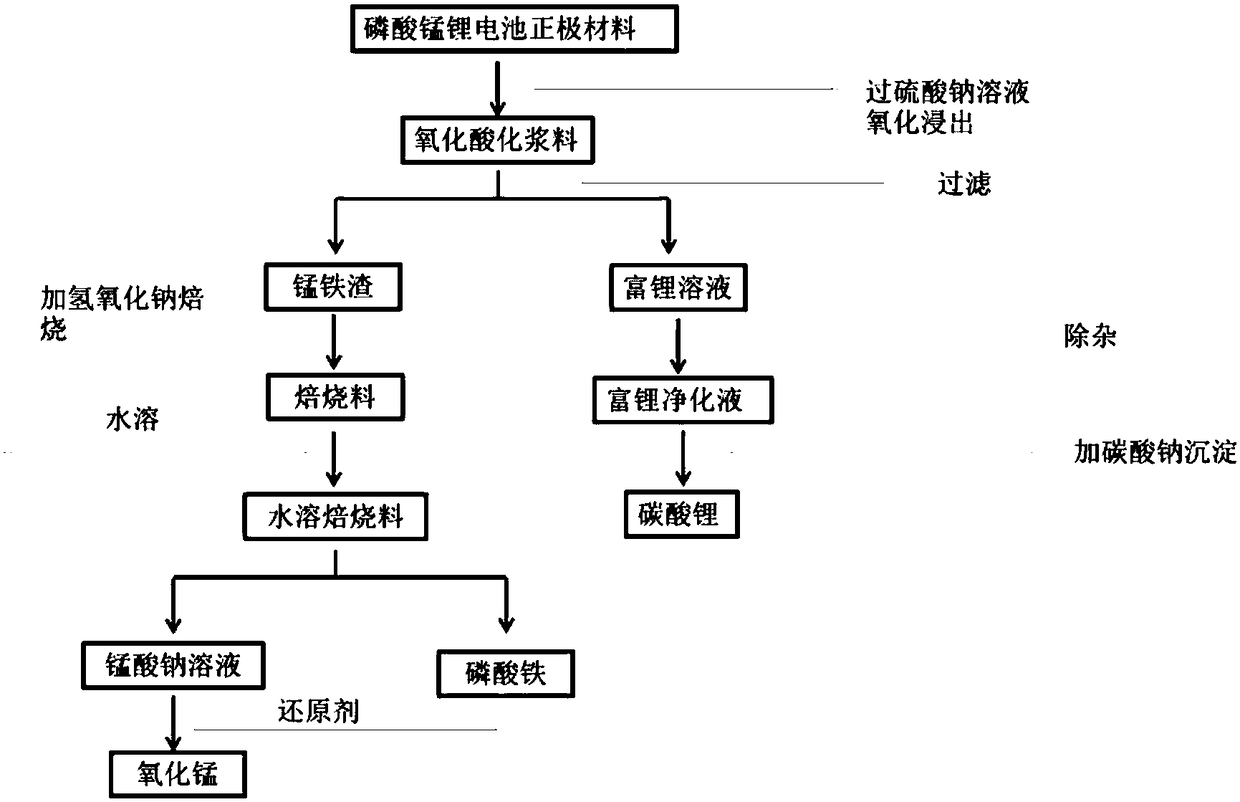

Recycling method for lithium iron manganese phosphate positive electrode material for battery

ActiveCN108736090AEfficient removalReduced service lifeWaste accumulators reclaimingBattery recyclingSlagPhosphoric acid

The invention discloses a recycling method for a lithium iron manganese phosphate positive electrode material for a battery and relates to the technical field of recycling of waste power batteries. The method comprises the steps of firstly dissolving a lithium iron manganese phosphate positive electrode material for a battery into an oxidizing acid solution, carrying out oxidizing reaction to obtain oxidized and acidified slurry and then filtering to obtain a lithium-rich solution and ferromanganese slag, wherein the ferromanganese slag is a mixture of manganese oxide and iron phosphate; carrying out purification on the lithium-rich solution to obtain a lithium-rich purified liquid and carrying out sodium carbonate precipitation on the lithium-rich purified liquid to obtain lithium carbonate; adding sodium hydroxide to the ferromanganese slag for calcination, adding water to the obtained calcined material for dissolving to obtain a water-soluble calcined material, filtering the water-soluble calcined material to obtain a sodium manganate solution and the iron phosphate; and adding a reducing agent to the sodium manganate solution and carrying out redox reaction to obtain manganesedioxide. According to the recycling method, recovery of all components of lithium iron manganese phosphate is achieved, and lithium carbonate, iron phosphate and manganese oxide products are finally obtained.

Owner:安徽南都华铂新材料科技有限公司

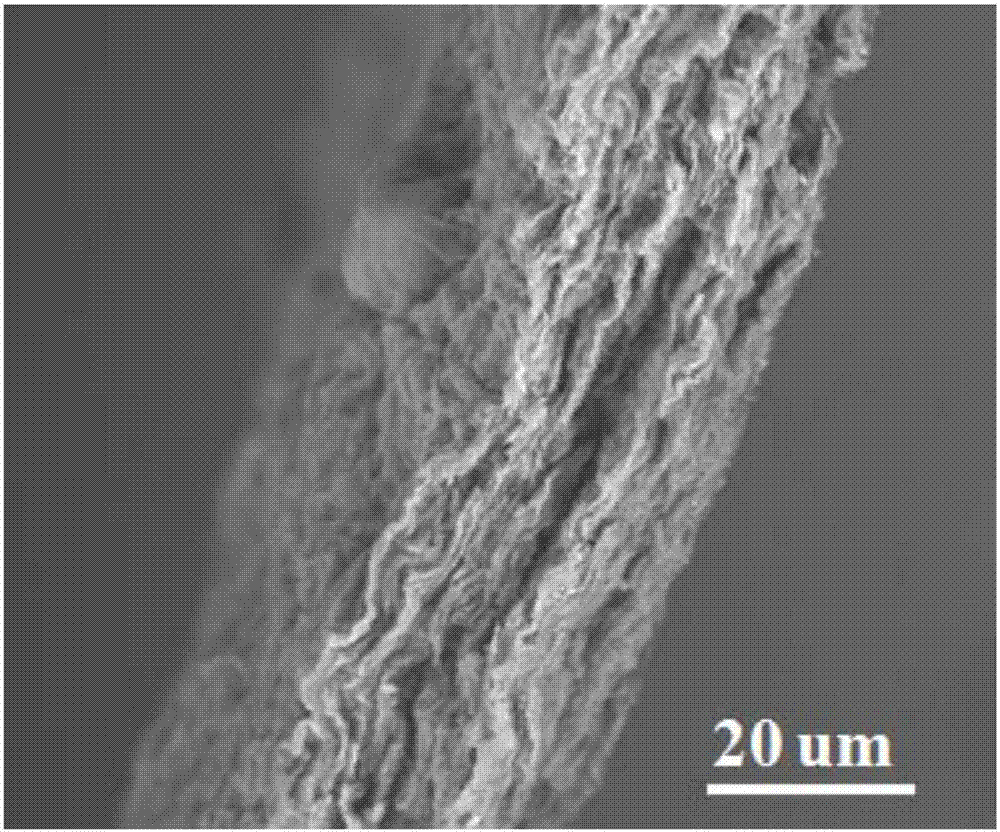

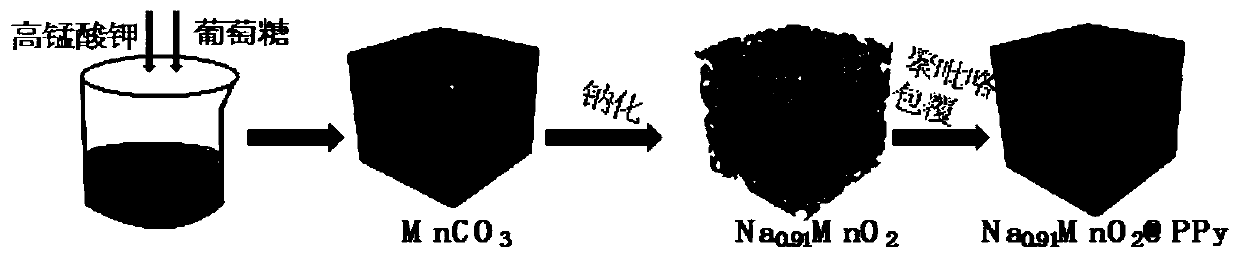

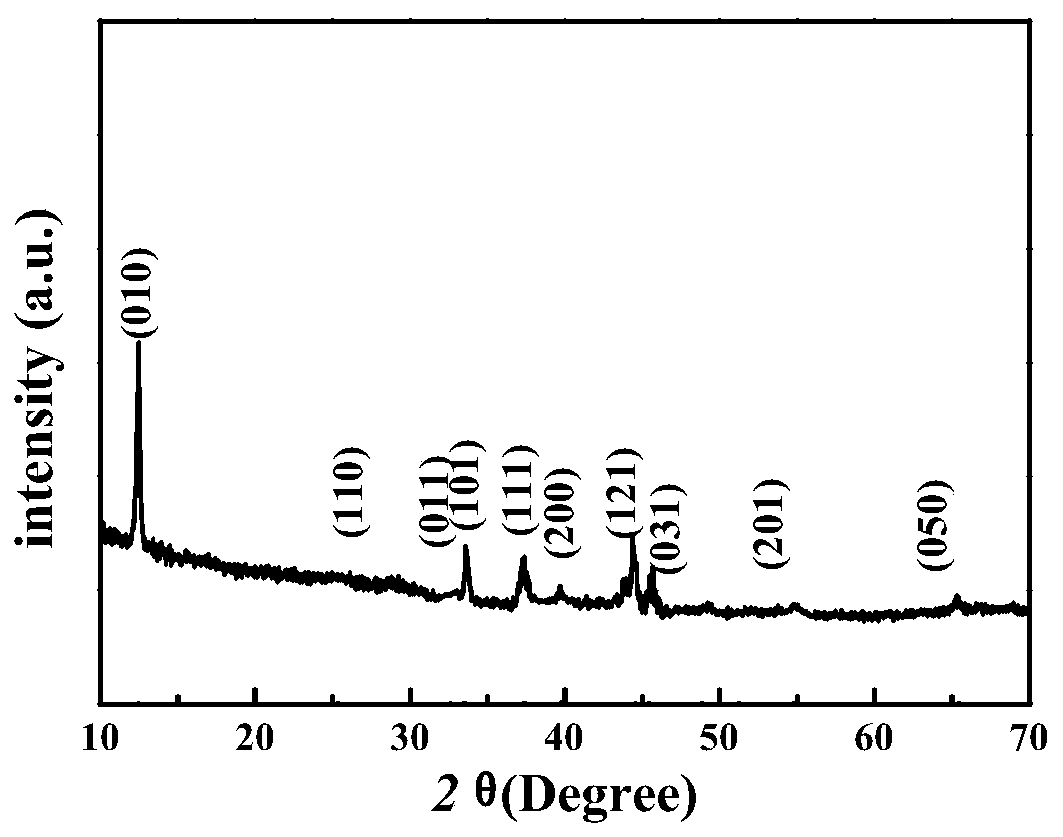

Polypyrrole-coated porous sodium manganate composite material, preparation method and application thereof

ActiveCN110504437AImprove conductivityTissue lysisCell electrodesSecondary cellsPolypyrroleElectrical battery

The invention relates to the technical field of electrode materials, in particular to a polypyrrole-coated porous sodium manganate composite material, a preparation method and application thereof. Thepolypyrrole-coated porous sodium manganate composite material comprises porous sodium manganate and polypyrrole coated on the surface of the porous sodium manganate; and the porous sodium manganate is cubic, and the chemical formula thereof is Na<x>MnO2, wherein x is equal to 0.91. The polypyrrole-coated porous sodium manganate composite material disclosed by the invention has good electrochemical cycling stability and rate performance as a positive electrode material of a sodium ion battery. The invention further provides a preparation method of the polypyrrole-coated porous sodium manganatecomposite material. The preparation method can be carried out at a low temperature, and energy can be effectively saved.

Owner:SHANDONG IND TECH RES INST OF ZHEJIANG UNIV

Method for preparing ultrafine manganese dioxide from potassium permanganate and potassium manganate

The invention relates to a method for preparing ultrafine manganese dioxide from potassium permanganate and potassium manganate. The method comprises the following steps: primary hydro-thermal reaction, secondary hydro-thermal reaction, filtering and separating, roasting, etc. The method is short in process flow and mild in conditions and does not need complex equipment; and a manganese dioxide product has high purity, and the maximal granularity of the manganese dioxide product can reach a micron grade.

Owner:山东华太新能源电池有限公司

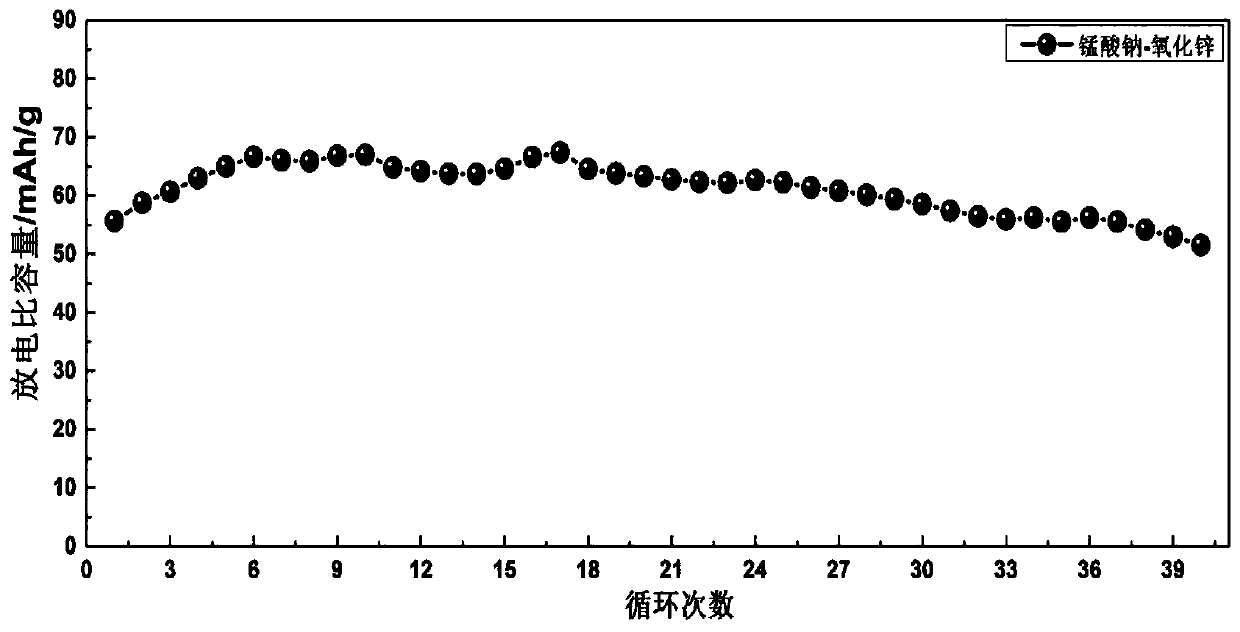

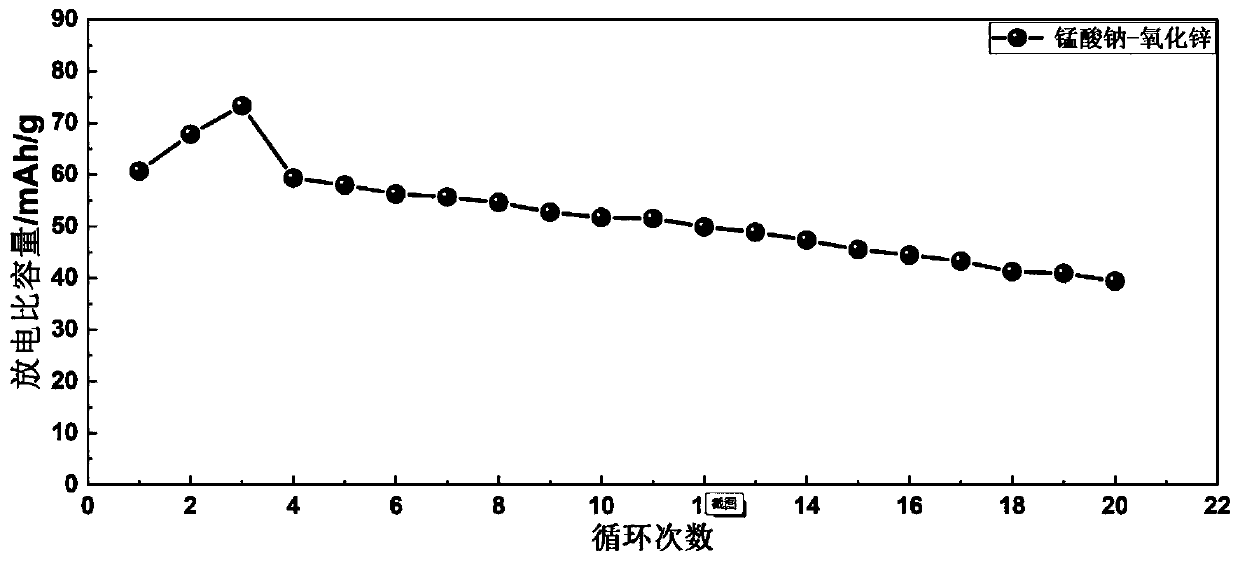

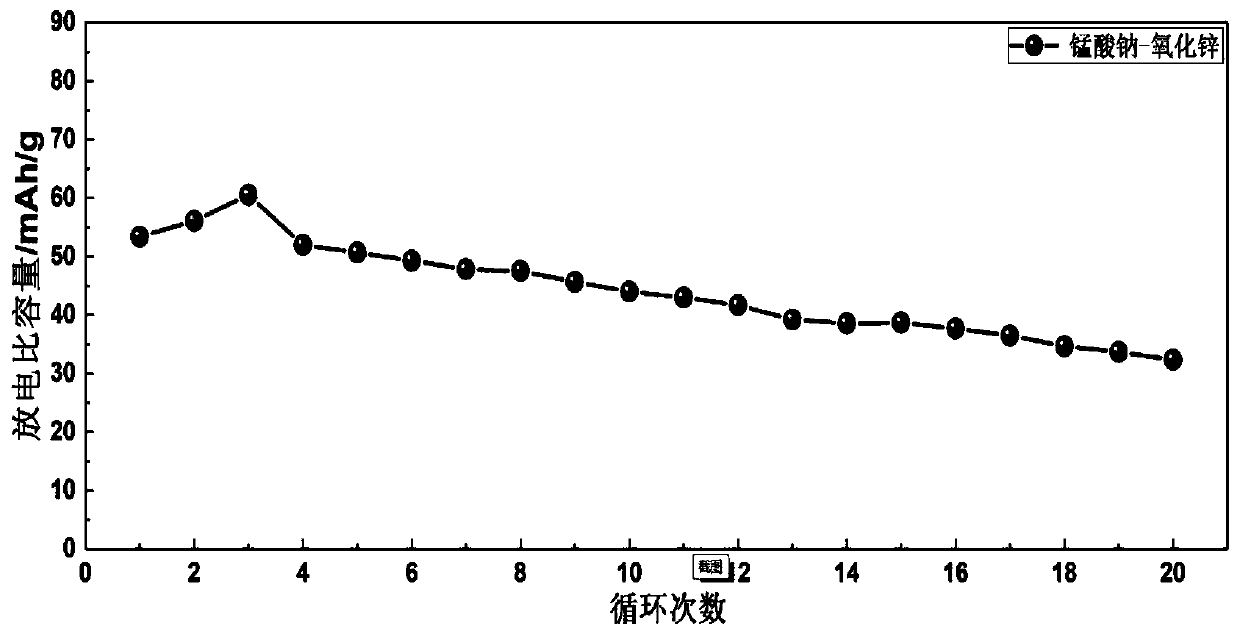

Aqueous sodium-based mixed ion secondary battery

ActiveCN111477853AAvoid disadvantagesWide range of optionsCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention provides an aqueous sodium-based mixed ion secondary battery. A positive electrode active material of the battery is sodium manganate NaxMnO2 (X is equal to 0.2 to 1.0); a negative electrode active material of the battery is a metal oxide; an electrolyte is a sodium hydroxide solution dissolved with the saturated metal oxide; and a diaphragm is a composite diaphragm of non-woven fabric and hydrophilic PP; the positive electrode comprises a positive electrode active material (45 to 85 wt.%), a first conductive carbon material (10 to 45 wt.%) and a first binder material (5 to 10 wt.%); and the negative electrode comprises a negative electrode active material (73 to 92 wt.%), a second conductive carbon material (5 to 15 wt.%) and a second binder material (3 to 12 wt.%). The capacity retention ratio of the aqueous sodium-based mixed ion secondary battery is 92.6% after the aqueous sodium-based mixed ion secondary battery is cycled for 40 circles at the rate of 1C, and the aqueous sodium-based mixed ion secondary battery has good charge-discharge cycling stability.

Owner:北京恩力动力科技有限公司 +3

Hydrothermal synthesis method of sodium ferromanganate used as electrode material of aqueous cation battery and preparation method of aqueous battery

ActiveCN104118913BGood for large area contactQuick exchangeCell electrodesIron compoundsFiltrationAqueous electrolyte

The invention provides a hydro-thermal synthesizing method for iron sodium manganate of an electrode material of an aqueous cationic battery and a preparation method of the aqueous battery. The method provided by the invention comprises the following steps of: (1) preparing an iron-sourced compound and a manganese-sourced compound into 0.5 mol / L of solution, mutually mixing, simultaneously, adding ammonium bicarbonate and ethanol as dispersing agents, and strongly stirring for 1 h; (2) transferring the mixed solution obtained in the step (1) into a reaction kettle to carry out hydro-thermal reaction, and carrying out suction filtration, cleaning and drying on the obtained precipitate; (3) ball-milling and mixing the dried product and a sodium-sourced compound in the stoichiometric ratio for 3-10 h; and (4) putting the ball-milled mixture into a muffle to be pre-processed and roasted at high temperature to obtain a final product Na0.3Fe0.5Mn0.5O2, NFMO for short. Electrochemical tests prove that the electrode material provided by the invention is maximally up to 340 mAh / g in 1 mol / L of Na2SO4 electrolyte and is maximally up to 250 mAh / g in 1 mol / L of MgC12 electrolyte under 10 mA / g of current density; the electrode material is wide in raw material and easy to prepare; and the aqueous electrolyte is low in cost, environment-friendly and non-toxic.

Owner:HARBIN ENG UNIV

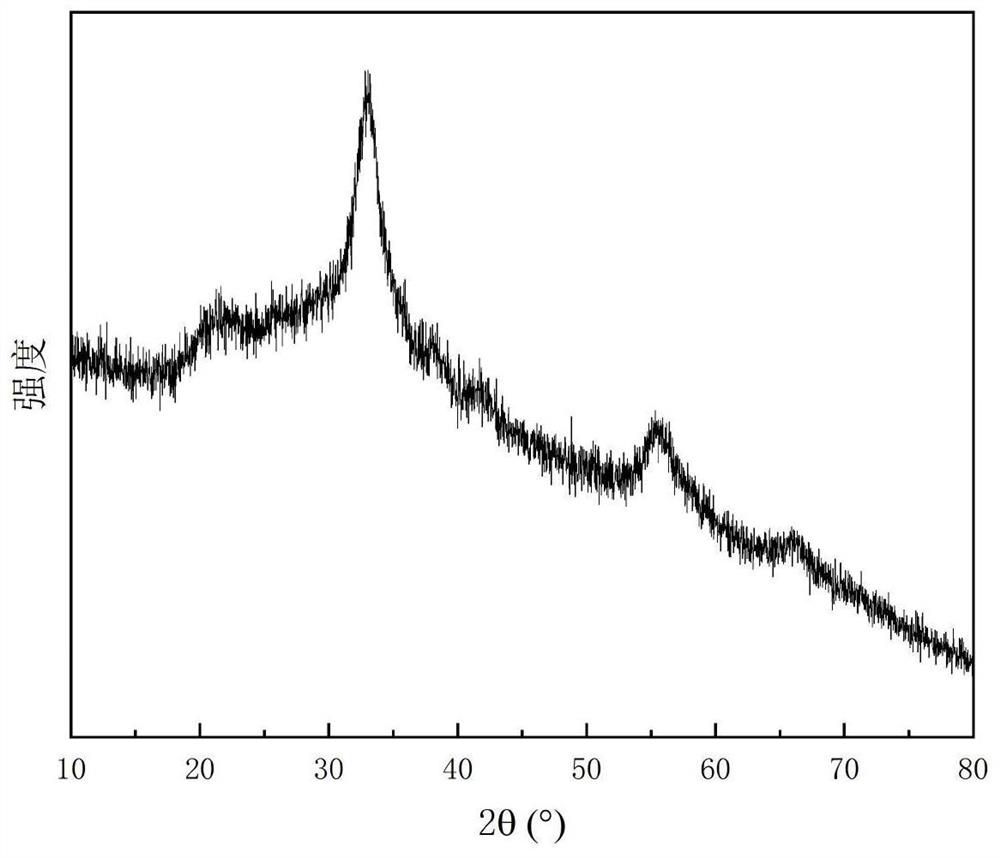

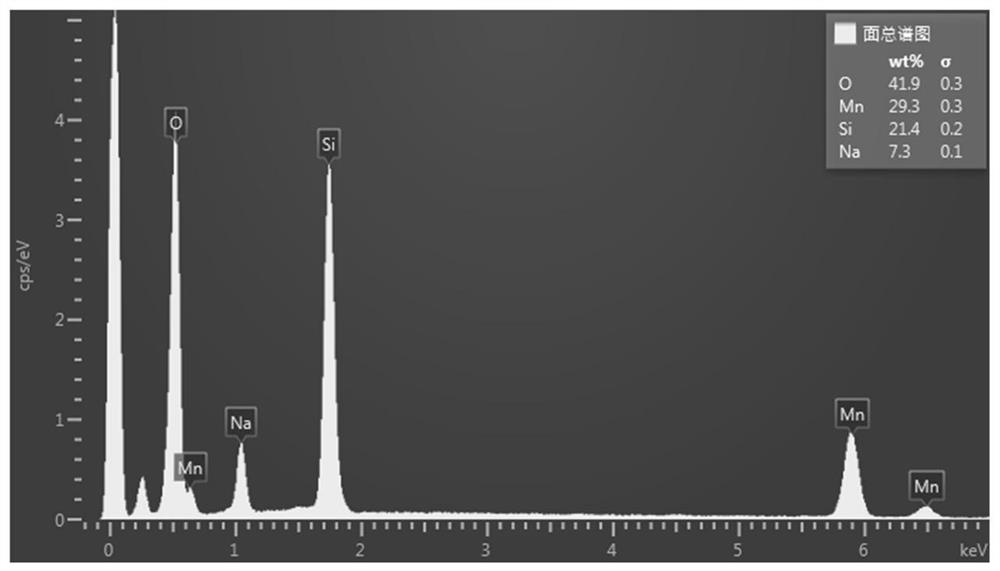

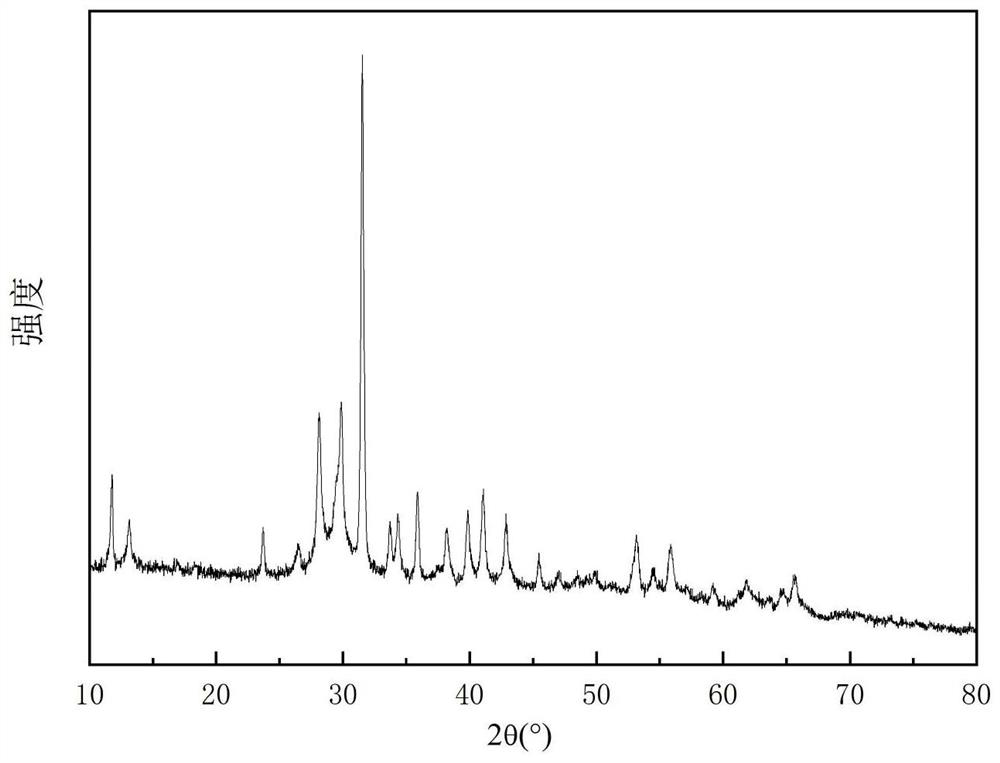

Method for treating radioactive strontium by using sodium manganate adsorbent

ActiveCN113000013AEasy to prepareMild conditionsOther chemical processesRadioactive contaminantsSorbentInorganic ions

The invention discloses a preparation method and an application method of sodium manganate. The method comprises the following steps: adding sodium hydroxide, sodium chloride and sodium silicate into water, and dispersing manganese salt into the water; stirring, transferring into a hydrothermal kettle, carrying out hydrothermal reaction, washing with water, filtering, and drying to obtain the target product sodium manganate, wherein the molar ratio of manganese to silicon is 0.25-1. The prepared sodium manganate can be used as an inorganic ion adsorbent, and has relatively strong adsorption capacity on strontium in radioactive wastewater. The sodium manganate prepared by the method has high selectivity, adsorption capacity, mechanical property and irradiation resistance on strontium ions in radioactive wastewater, so that the strontium ions in the radioactive wastewater can be effectively removed.

Owner:XIAMEN UNIV

Positive electrode and non-aqueous electrolyte secondary battery

ActiveUS8815449B2Low costAlkaline accumulatorsNon-aqueous electrolyte accumulatorsSlurryMaterials science

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method for producing potassium manganite or sodium manganate

InactiveCN102249342BWide variety of sourcesFully contactedManganates/permanganatesFluidized bedPotassium

The invention belongs to the field of production of potassium (sodium) manganite. In the method, a mixed calcining material of manganese mineral powder and potassium (sodium) hydrate is oxidized by using an oxidizing gas, and the potassium (sodium) manganite is produced intermittently by adopting a gas-solid fluidized bed reactor. The method comprises the following steps of: (1) adding potassium (sodium) hydrate into manganese mineral powder serving as a raw material, stirring and calcining to obtain sintering charge; (2) milling the obtained sintering charge; (3) adding the obtained powder into the gas-solid fluidized reactor, introducing the oxidizing gas, regulating the ventilation amount to keep the powder to be in a fluidized state, keeping the temperature in the reactor to be between 220 DEG C and 300 DEG C, and reacting for 0.5-3 hours to obtain a potassium (sodium) manganite product; and (4) dissolving, stirring and standing the sintering product, performing solid-liquid separation to obtain a liquid phase which is a potassium (sodium) manganite solution and a solid phase which is unreacted manganese ore, and returning to the step (1). The method has the advantages of short process flow, simple equipment, high oxidation speed, short production period and capability of remarkably increasing the transformation rate of potassium (sodium) manganite.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method and application of sodium manganate

ActiveCN114180633ASimple compositionHigh crystallinityCell electrodesSecondary cellsHigh volume manufacturingElectrical battery

The invention discloses a preparation method of sodium manganate, which at least comprises the following steps: a) heating and complexing an aqueous solution containing a manganese source and sodium citrate to obtain gel; b) drying the gel to obtain a precursor; and c) grinding the precursor, and calcining to obtain the sodium manganate. The sodium manganate is simple in preparation process, simple in raw material composition and suitable for mass production. Meanwhile, when the sodium manganate material is applied to the positive electrode of the sodium ion battery, excellent long cycle performance and rate capability can be shown.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of preparation method for sodium-ion battery cathode material sodium manganite

ActiveCN106800312BImprove electrochemical performanceEasy to operateCell electrodesSecondary cellsElectrical batteryHigh energy

Owner:UNIV OF JINAN

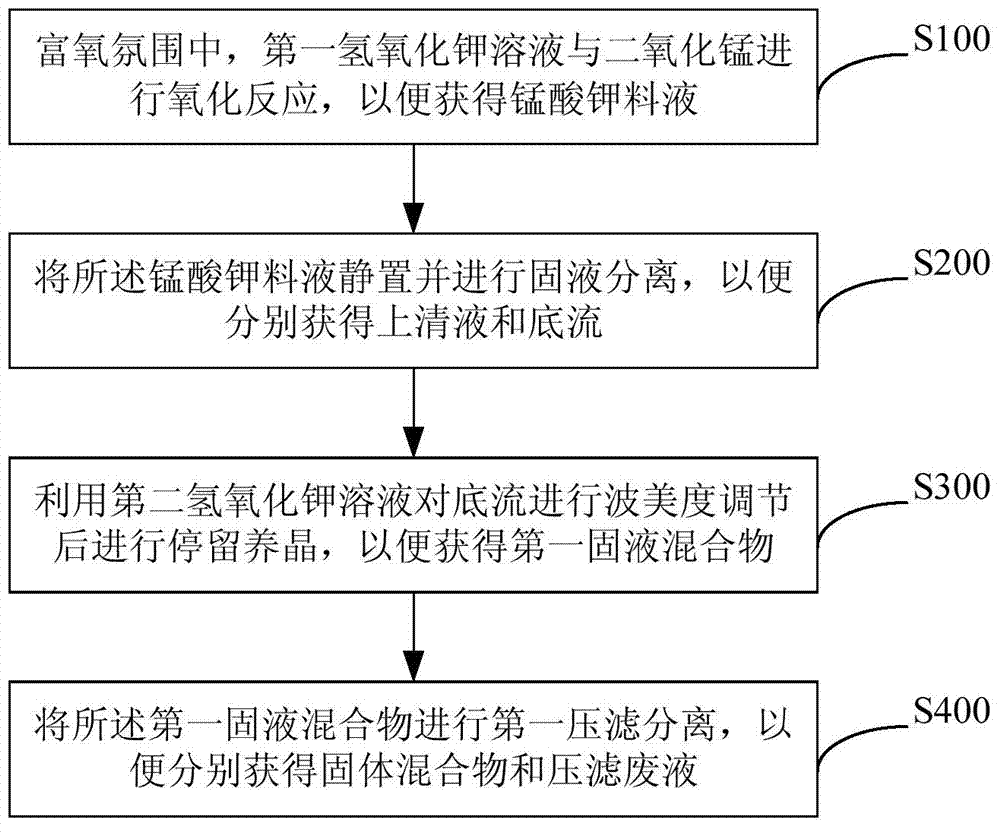

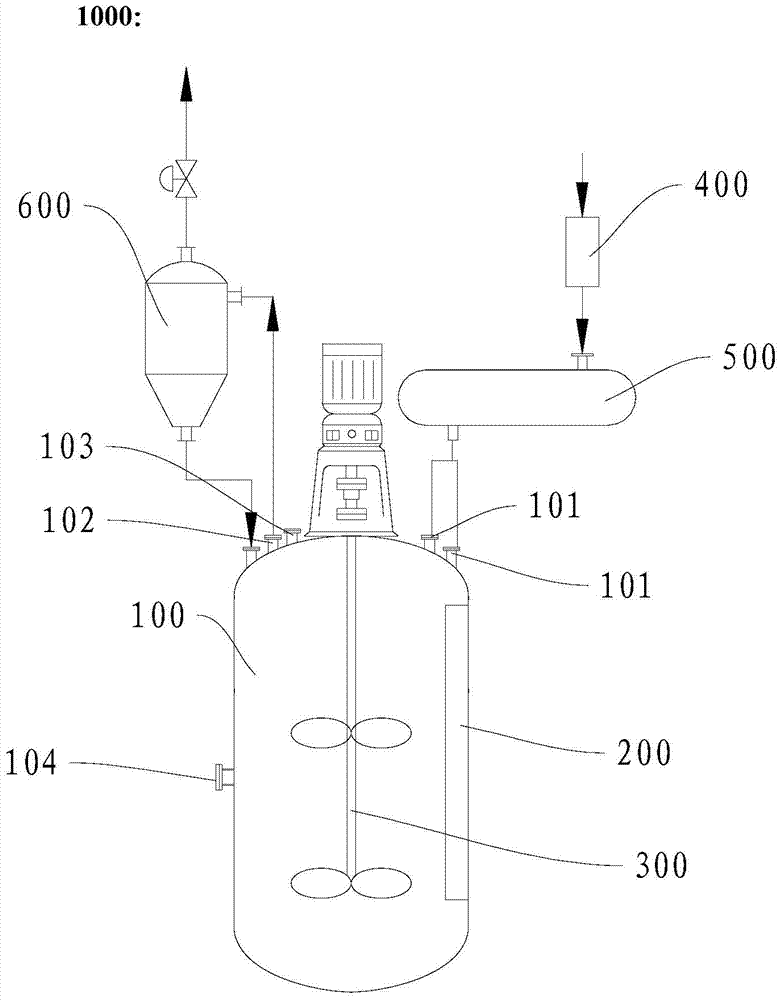

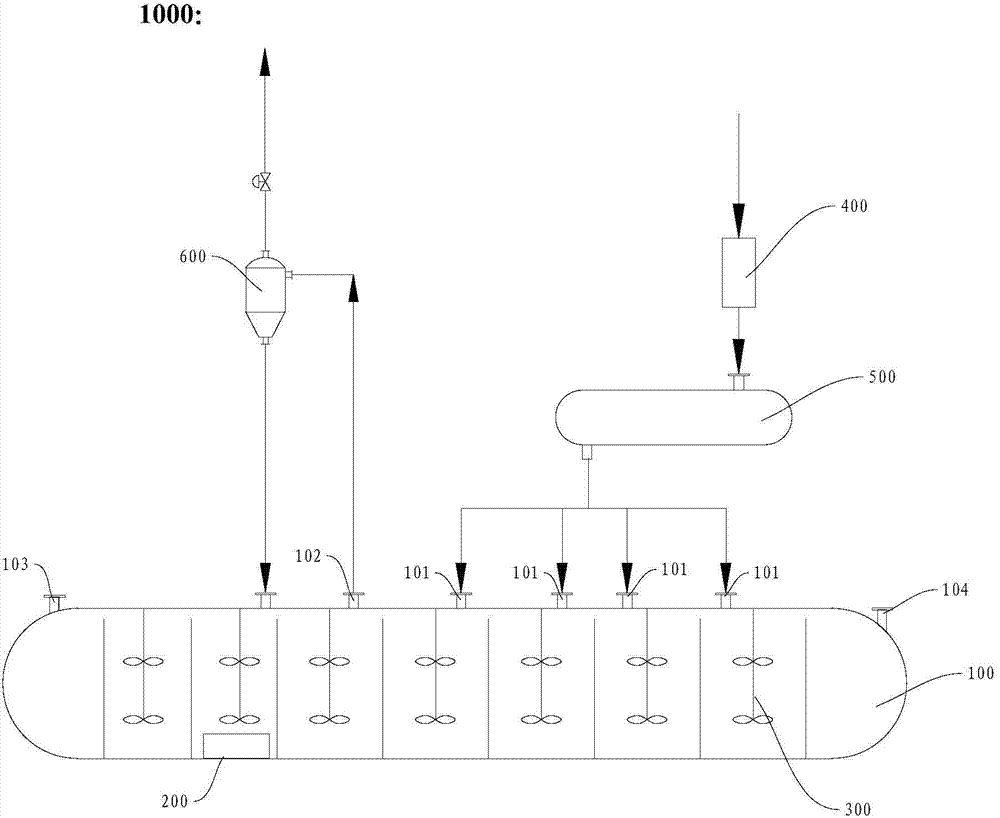

Method for preparing potassium manganate

ActiveCN103570076AEfficient manufacturingHigh recovery rateManganates/permanganatesPhysical chemistryPotassium hydroxide

The invention discloses a method for preparing potassium manganate. The method comprises the following steps: in an oxygen-enriched atmosphere, at 250-260 DEG C and 0.2-1.2 MPa, causing a first potassium hydroxide solution with concentration being 45-70 weight percent and manganese dioxide to conduct oxidation reaction to obtain potassium manganate material liquid; standing the potassium manganate material liquid and carrying out solid-liquid separation to respectively obtain supernatant and bottom flow; utilizing a second potassium hydroxide solution to adjust the baume degree of the bottom flow to 50 and then staying for crystal growing to obtain a first solid-liquid mixture; carrying out first filter-pressing separation for the first solid-liquid mixture to respectively a solid mixture and filter-pressing waste liquid, wherein the solid mixture is potassium manganate. The method utilized for producing potassium manganate has the advantages of simple production processes, high manganese dioxide conversion rate, high recovery rate of manganese and potassium hydroxide, low energy consumption, cleanness and environmental friendliness.

Owner:YUNNAN JIANSHUI MANGANESE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com