Method for producing potassium manganite or sodium manganate

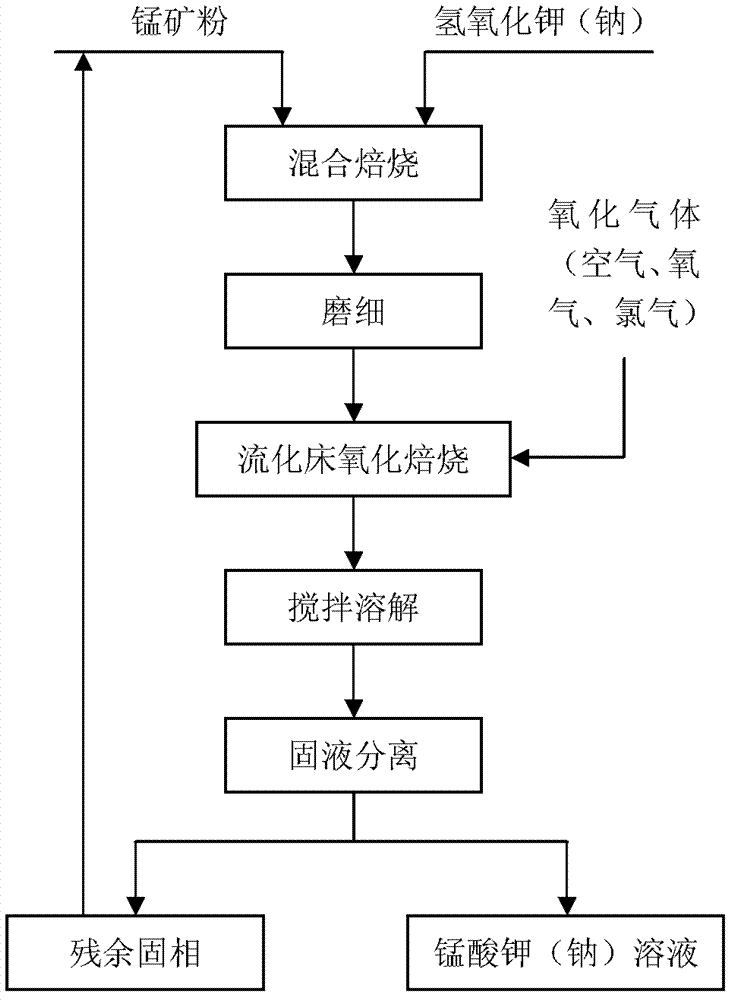

A technology for the production of potassium manganate and sodium manganate, applied in the direction of manganate/permanganate, etc., can solve the problems of high requirements on equipment structure and compressive performance, unsuitable manganese carbonate ore resources, etc., to shorten the production cycle , good adaptability, the effect of improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Crush 500g of pyrolusite with a manganese content of 35% to -200 mesh and account for 70% of the content, weigh 392g of potassium hydroxide, add 350ml of water, stir to dissolve the potassium hydroxide, in which the alkali concentration is 53%, add manganese ore Powder and stir to form a paste, put it into a roasting furnace, and sinter at 400°C for 1h, and the manganese-alkali molar ratio of the pyrolusite to potassium hydroxide is 1:2.2;

[0024] (2) Pulverizing the sintered ore obtained in step (1), so that the -200 mesh content accounts for 70%;

[0025] (3) Put the fine-grained powder ore in the step (2) into a fluidized bed reactor, feed air to keep the material in a suspended state, and keep the water content in the air at 50g / m 3 , Oxidative roasting at 220 ° C for 2h.

[0026] (4) Dissolving the roasted product in the step (3), the amount of water added is twice the mass of the roasted product, the stirring speed is 10r / min, the stirring time is 10min, and...

Embodiment 2

[0028] (1) Grind 500g of pyrolusite with a manganese content of 50% until the -200 mesh content accounts for 72%, weigh 473g of sodium hydroxide, stir and mix the two materials, put them in a roaster, and sinter at 350°C for 1h , the manganese alkali mol ratio of described pyrolusite and sodium hydroxide is 1:2.6;

[0029] (2) Pulverizing the sintered ore obtained in step (1), so that the -200 mesh content accounts for 70%;

[0030] (3) Put the fine-grained powder ore in the step (2) into a fluidized bed reactor, feed oxygen to keep the material in a suspended state, and keep the water content in the oxygen at 100g / m 3 , Oxidative roasting at 240 ° C for 1 h.

[0031] (4) Dissolving the roasted product in the step (3), the amount of water added is 2.5 times the quality of the roasted product, the stirring speed is 10r / min, the stirring time is 10min, and the solid-liquid separation is carried out. The obtained solid phase is mainly un The manganese dioxide of reaction, the g...

Embodiment 3

[0033] (1) Crush 650g of manganese carbonate with a manganese content of 30% to -200 mesh and account for 75%, weigh 556g of potassium hydroxide, add 550ml of water, and stir to dissolve the potassium hydroxide. The alkali concentration is 50%, and add manganese ore Powder and stir to form a paste, put it into a roasting furnace, and sinter at 800°C for 1.5h, and the manganese-alkali molar ratio of the manganese carbonate to potassium hydroxide is 1:2.8;

[0034] (2) Pulverizing the sintered ore obtained in step (1), so that the -200 mesh content accounts for 75%;

[0035] (3) Put the fine-grained powder ore in the step (2) into a fluidized bed reactor, feed in heated chlorine gas to keep the material in a suspended state, and keep the volume fraction of nitrogen in the chlorine gas at 70%, at 250°C Oxidation roasting 1h.

[0036] (4) Dissolve the roasted product in the step (3), add water 3 times the mass of the roasted product, stir at a speed of 10r / min, stir for 15min, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com