Hollow spherical sodium nickel manganate and preparation method thereof, sodium ion battery positive electrode, and sodium ion battery

A technology of sodium nickel manganese oxide and spherical shape, which is applied in the field of hollow spherical sodium nickel manganese oxide and its preparation, and the positive electrode sheet of sodium ion battery, which can solve the problems of limited cycle performance, complicated preparation process, capacity decay, etc., and save the stirring process , waste liquid treatment is simple, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method for preparing the hollow spherical sodium nickel manganate described in the above scheme, which includes the following steps:

[0032] (1) Provide a nickel-manganese mixed solution including nickel salt, manganese salt, water and alcohol solvent;

[0033] (2) Mixing the nickel-manganese mixed solution with the carbonate aqueous solution and standing still to obtain a nickel-manganese carbonate composite salt;

[0034] (3) Pre-burning the nickel-manganese carbonate composite salt to obtain a nickel-manganese composite oxide;

[0035] (4) Mix and grind the nickel-manganese composite oxide and sodium salt, and obtain a hollow spherical sodium nickel manganate after calcination.

[0036] The present invention provides a nickel-manganese mixed solution including nickel salt, manganese salt, water and alcohol solvent. In the present invention, the nickel salt preferably includes nickel chloride, nickel nitrate or nickel sulfate, and the manganes...

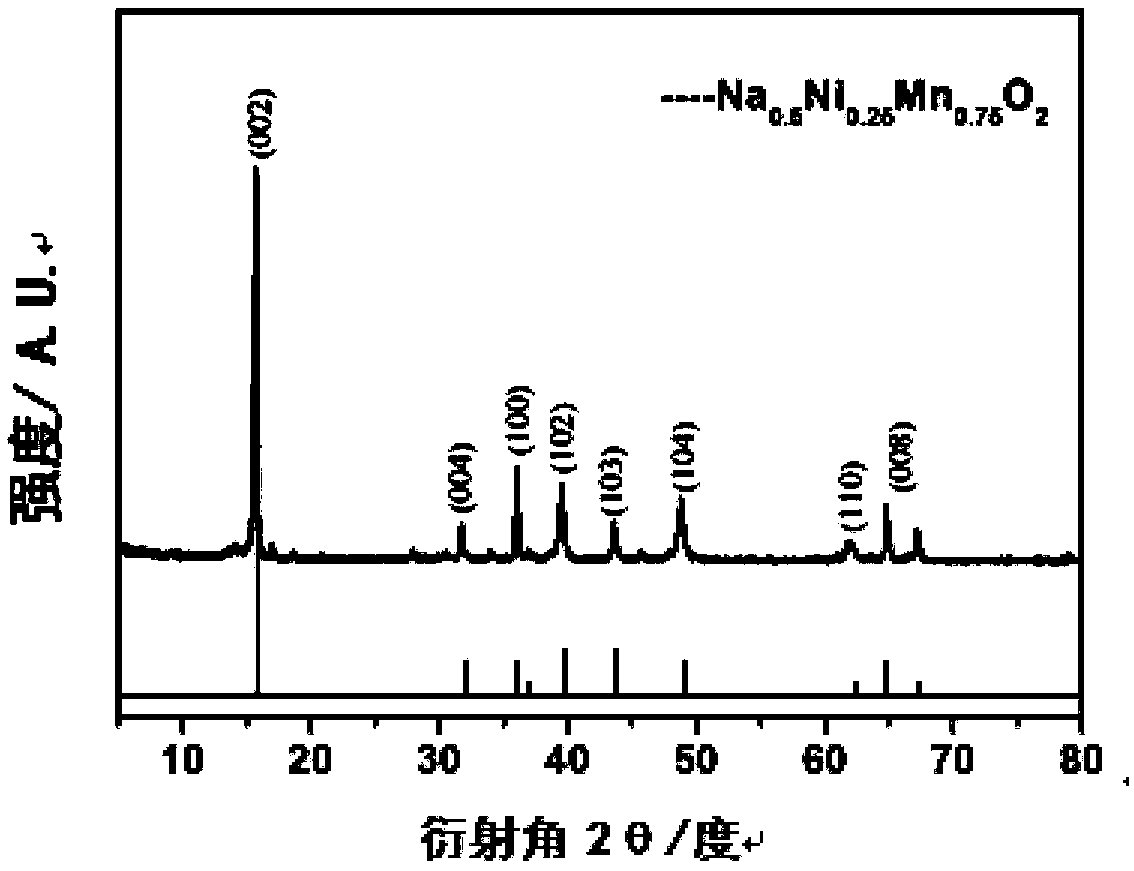

Embodiment 1

[0050] Dissolve 0.22g nickel nitrate hexahydrate and 0.56g manganese nitrate tetrahydrate in 200mL deionized water, add 15mL glycerol, and stir for 20min to obtain a nickel-manganese mixed solution;

[0051] Heat the nickel-manganese mixed solution at 40°C; at 40°C, dissolve 2.37 g of ammonium bicarbonate in 200 mL of deionized water and stir for 20 minutes to obtain an aqueous carbonate solution; pour the nickel-manganese mixed solution Put it into the carbonate aqueous solution, keep it at 40°C for 4 hours, use a vacuum suction pump for suction filtration, wash with distilled water 3 to 5 times, and vacuum dry at 80°C for 12 hours to obtain a nickel-manganese carbonate composite salt;

[0052] The nickel-manganese carbonate composite salt is placed in a muffle furnace for pre-sintering to obtain a nickel-manganese composite oxide, wherein the pre-sintering parameters are: a temperature of 400°C, a heating rate of 1°C / min, and a pre-sintering time: 5h;

[0053] The nickel-manganese...

Embodiment 2

[0058] Dissolve 0.2 g nickel sulfate and 0.56 g manganese nitrate tetrahydrate in 200 mL deionized water, add 15 mL isopropanol, and stir for 30 min to obtain a nickel-manganese mixed solution;

[0059] Heat the nickel-manganese mixed solution at 60°C; at 60°C, dissolve 1.8g sodium bicarbonate in 200mL deionized water and stir for 30min to obtain a carbonate aqueous solution; pour the nickel-manganese mixed solution into the carbon In the acidic acid solution, keep it at 60℃ for 5h, use a vacuum suction filter to filter, and rinse with deionized water and 99.7% ethanol solution for 2 to 3 times, and vacuum dry at 80℃ 12h, obtain nickel manganese carbonate composite salt;

[0060] The hollow spherical nickel-manganese carbonate composite salt is placed in a muffle furnace for pre-sintering to obtain a nickel-manganese composite oxide, wherein the pre-sintering parameters are: a temperature of 500°C, a heating rate of 1°C / min, and a pre-sintering Time is 5h;

[0061] The nickel-manga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com