Aqueous sodium-based mixed ion secondary battery

A hybrid ion and secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of small reversible capacity of positive and negative electrode materials, small choice of positive and negative electrode materials, and low energy density of batteries, etc., to achieve Good cycle performance, high energy density, high specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

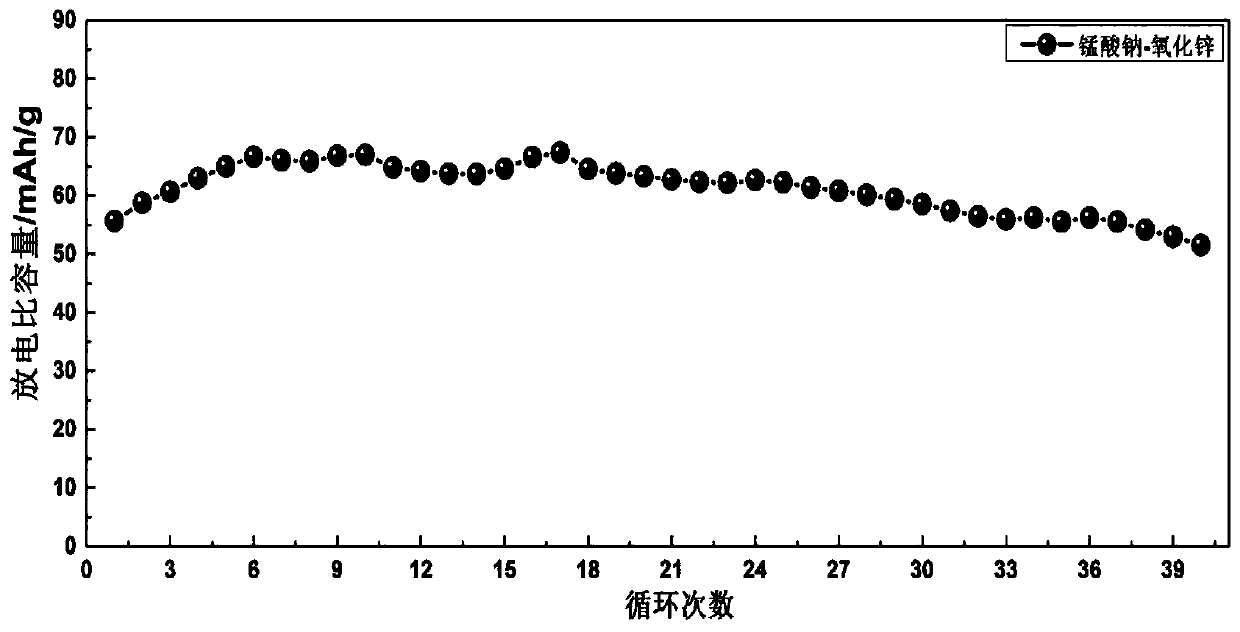

[0029] The positive electrode formula is 50wt.% sodium manganate Na x MnO 2(X=0.2~1.0) powder, 30wt.% AC and 10wt.% SP mixed conductive carbon material and 10wt.% PTFE as binder; negative electrode formula is 80wt.% zinc oxide powder, 12% SP conductive Carbon materials and 8% PTFE are used as binders; according to the positive and negative electrode formulas, the positive electrode electrode sheet and the negative electrode electrode sheet are prepared respectively by kneading and smelting thick film forming process, and the electrolyte is dissolved with saturated zinc oxide with a solubility of 6mol / L sodium hydroxide solution, the diaphragm is selected as 0.2mm thick non-woven fabric + hydrophilic PP composite diaphragm, and assembled into a water-based sodium-based mixed-ion secondary battery A according to this, and the battery A is tested for 40 cycles at a rate of 1C. The capacity retention rate after the cycle, the results are as follows figure 1 shown.

Embodiment 2

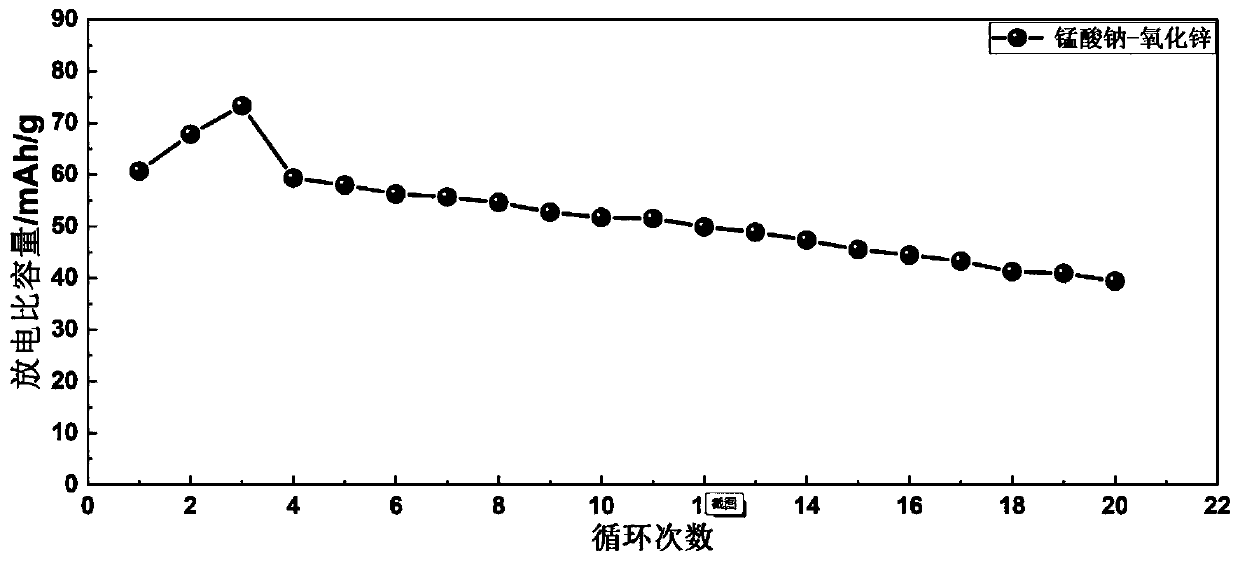

[0031] The positive electrode formula is 85wt.% sodium manganate Na x MnO 2 (X=0.2~1.0) powder, 8wt.% of AC and 2wt.% of SP mixed conductive carbon material and 5wt.% of PVA as binder; the negative electrode formulation is 92wt.% of zinc oxide powder, 3wt.% of SP and 2wt.% AC mixed conductive carbon material and 3wt.% CMC as a binder; according to the positive and negative electrode formulas, the positive electrode and the negative electrode are prepared by the coating process, and the electrolyte is dissolved with saturated oxidation 8mol / L sodium hydroxide solution of zinc; the diaphragm is selected as 0.2mm thick non-woven fabric + hydrophilic PP composite diaphragm, and assembled into a water-based sodium-based mixed-ion secondary battery B according to this, and its 1C rate is measured for battery B The capacity retention rate after 40 cycles of the next cycle, the results are as follows figure 2 shown.

Embodiment 3

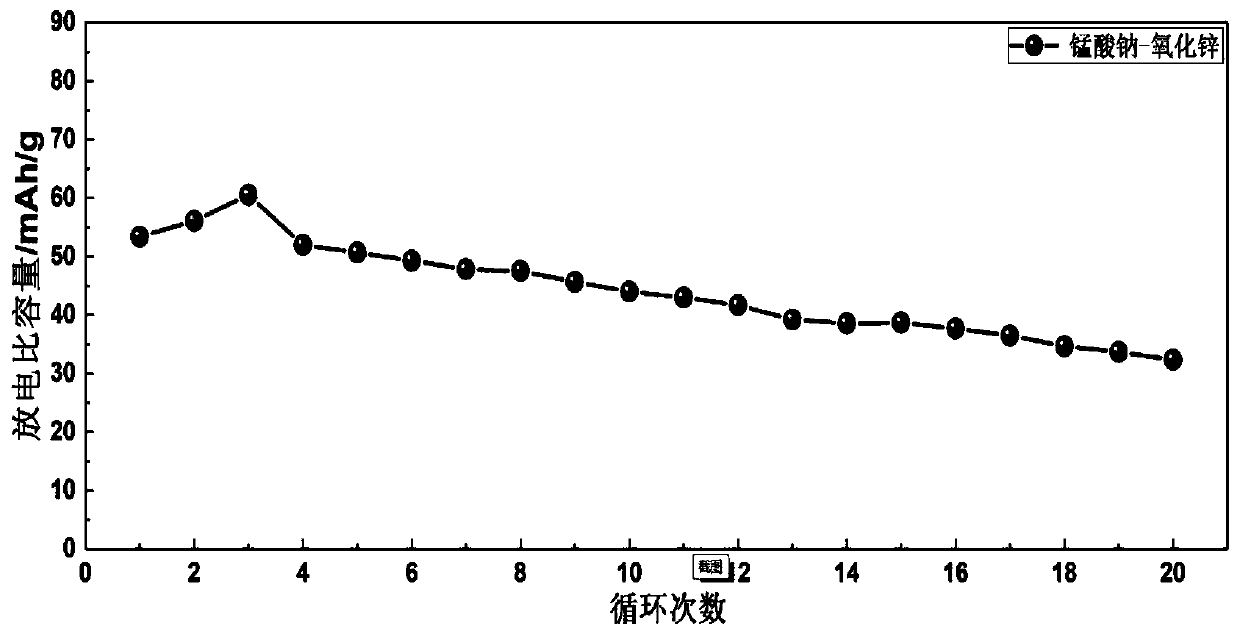

[0033] The positive electrode formula is 70wt.% sodium manganate Na x MnO 2 (X=0.2~1.0) powder, 10wt.% of AC and 10wt.% of SP mixed conductive carbon material and 10wt.% of PTFE as binder; the negative electrode formulation is 73wt.% of zinc oxide powder, 10wt.% of SP and 5wt.% AC mixed conductive carbon material and 12wt.% PTFE were used as binders; according to the positive and negative electrode formulas, the positive electrode pole piece and the negative pole pole piece were prepared by kneading and kneading thick film forming process, and the electrolyte was 4mol / L sodium hydroxide solution with saturated zinc oxide dissolved, the diaphragm is selected as 0.2mm thick non-woven fabric + hydrophilic PP composite diaphragm, and assembled into a water-based sodium-based mixed-ion secondary battery C according to this, and the battery C is measured Its capacity retention rate after 40 cycles at 1C rate, the results are as follows image 3 shown.

[0034] Table 1 Example 1 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com