Preparation method and application of sodium manganate

A technology of sodium manganate and sodium manganate, applied in the direction of manganate/permanganate, structural parts, electrical components, etc., can solve the problems of fast capacity fading, poor speed capability, etc., and achieve low cost and good economy Benefits, beneficial to the effect of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 0.01 mol of manganese acetate into 40 mL of deionized water, heat and stir at 80°C for 1 h. Then add 0.01 mol of sodium citrate dihydrate, stir at 80° C. for 2 h, and stir at a speed of 300 rpm. Afterwards, the temperature was raised to 100° C., the stirring speed was 500 rpm, and the solution was stirred until the solution became a gel. Then move into the oven and dry at 120°C. Grind the dried precursor evenly. Then use a muffle furnace for heat treatment, and use a segmented heating method to process the sample. First heat to 350°C and keep warm for 4 hours, then heat to 950°C and keep warm for 24h. Sodium manganate product is obtained.

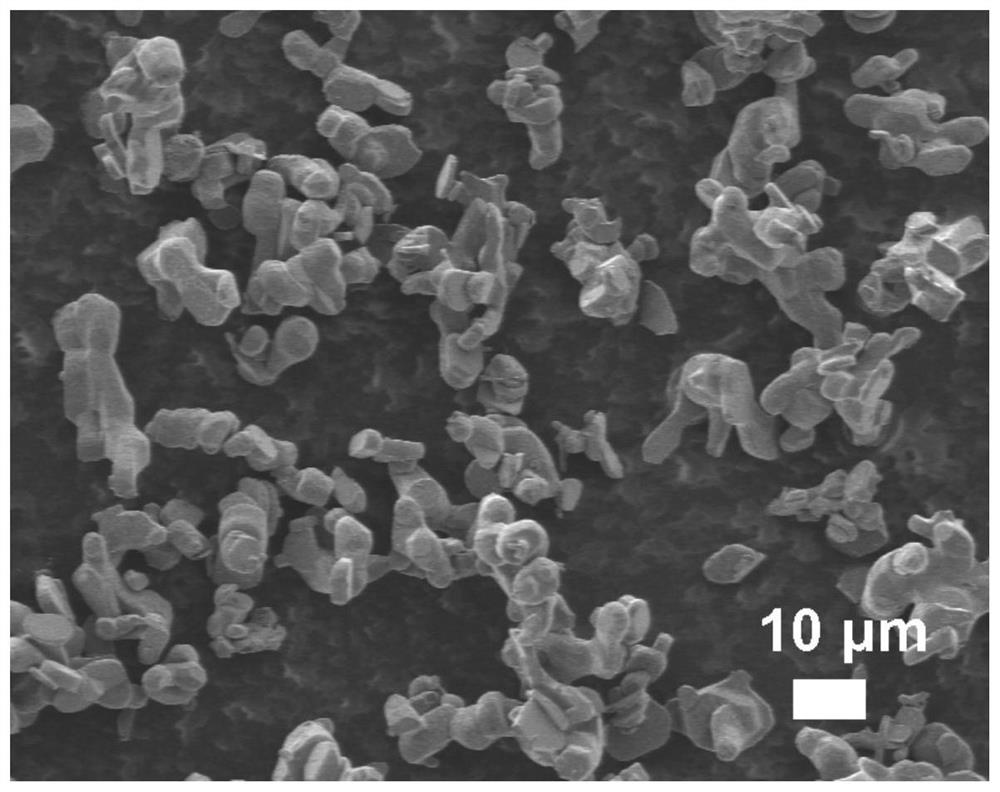

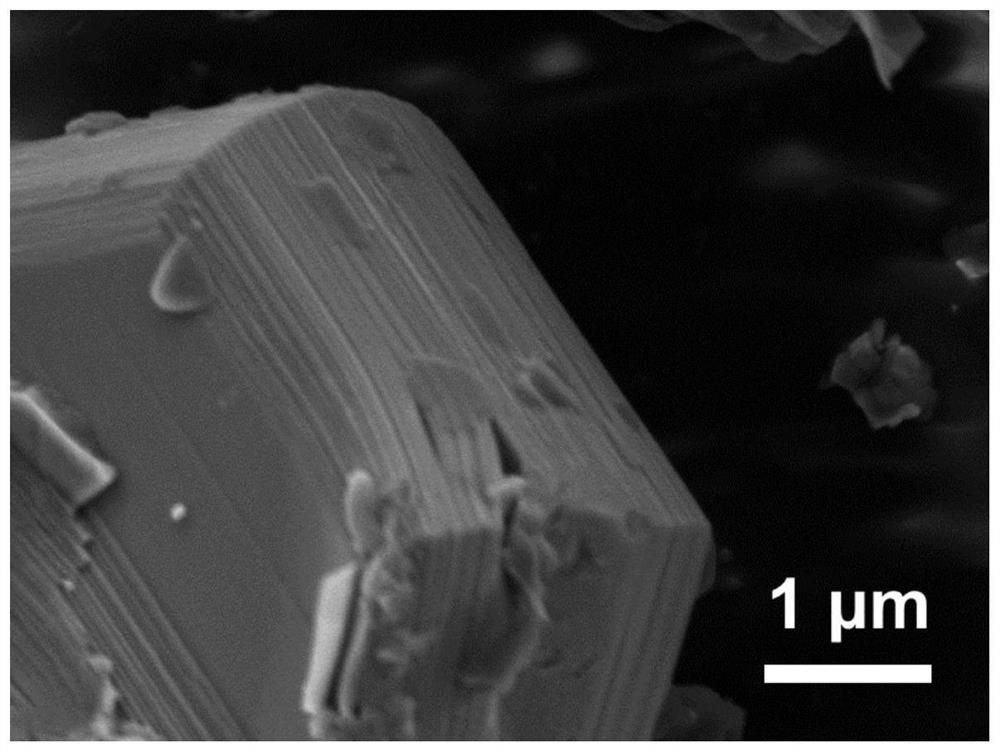

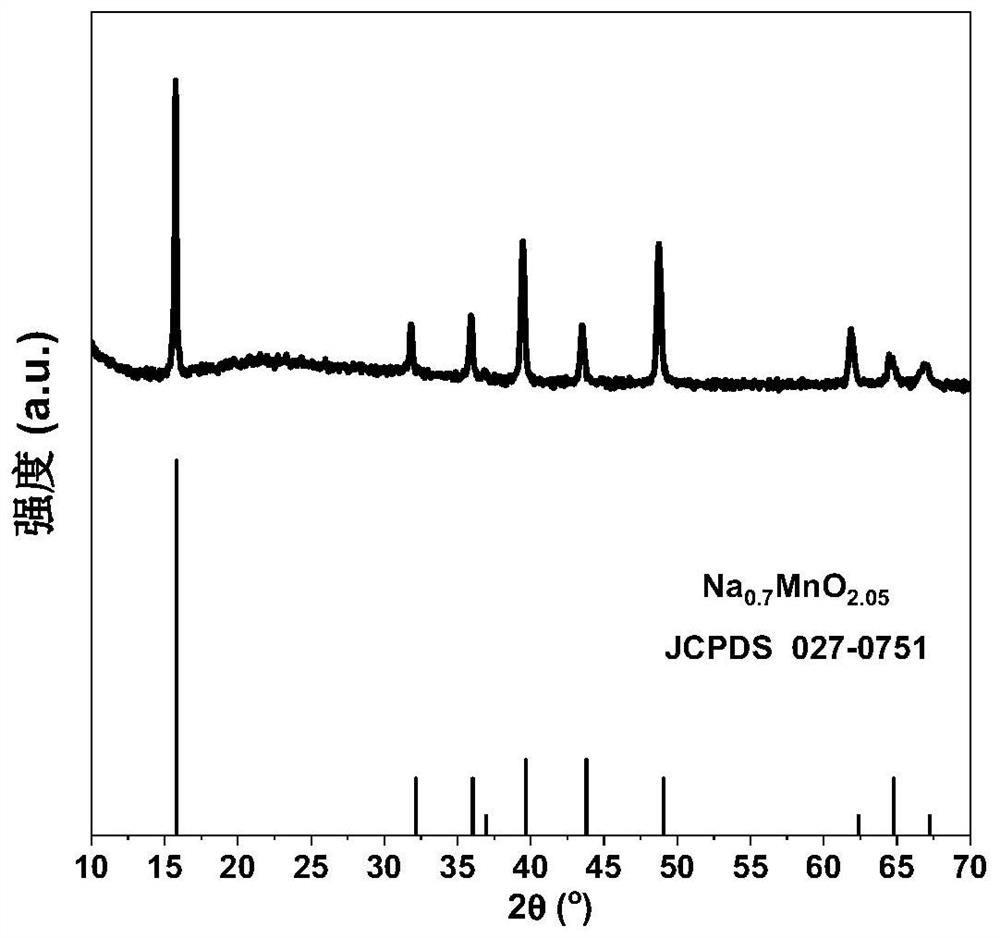

[0046] by attaching figure 1 It can be seen from the scanning electron microscope (SEM, 10 μm) that the prepared sodium manganate is a single crystal crystal, and the grain size is 5-30 μm; figure 2 It can be seen from the scanning electron microscope image (SEM, 1 μm) that the prepared sodium manganate has a layered struc...

Embodiment 2

[0049] Add 0.1 mol of manganese acetate into 100 mL of deionized water, heat and stir at 80°C for 1 h. Then 0.12 mol of sodium citrate dihydrate was added, stirred at 80° C. for 2 h, and the stirring speed was 500 rpm. Afterwards, the temperature was raised to 100° C., the stirring speed was 500 rpm, and the solution was stirred until the solution became a gel. Then move into the oven and dry at 150°C. Grind the dried precursor evenly. Then use a muffle furnace for heat treatment, and use a segmented heating method to process the sample. First heat to 350°C and keep warm for 4 hours, then heat to 800°C and keep warm for 24h. Sodium manganate product is obtained. The SEM, XRD and electrical performance tests of the product prepared in Example 2 are all similar to the sample prepared in Example 1.

Embodiment 3

[0051] Add 0.1 mol of manganese sulfate to 100 mL of deionized water, heat and stir at 90°C for 1 h. Then add 0.12 mol of sodium citrate dihydrate, stir at 90° C. for 2 h, and stir at a speed of 500 rpm. Afterwards, the temperature was raised to 100° C., the stirring speed was 500 rpm, and the solution was stirred until the solution became a gel. Then move into the oven and dry at 120°C. Grind the dried precursor evenly. Then use an argon atmosphere for heat treatment, and use a segmented heating method to process the sample. First heat to 400°C and keep warm for 4 hours, then heat to 850°C and keep warm for 12h. Sodium manganate product is obtained.

[0052] The SEM, XRD and electrical performance tests of the product prepared in Example 3 are all similar to the sample prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com