Polypyrrole-coated porous sodium manganate composite material, preparation method and application thereof

A technology of porous sodium manganate and composite materials, which can be used in electrical components, electrochemical generators, battery electrodes, etc., and can solve the problems of poor electrochemical cycle performance and rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

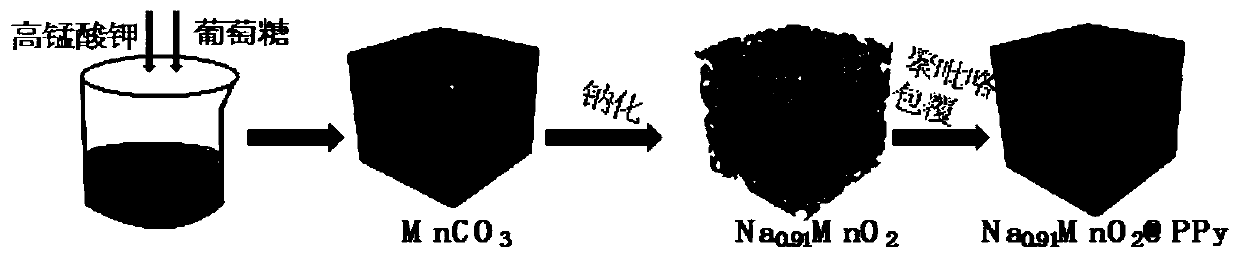

[0034] The present invention also provides a preparation method of the polypyrrole-coated porous sodium manganate composite material described in the above technical scheme, comprising the following steps:

[0035] Potassium permanganate, glucose and water are mixed, carry out hydrothermal reaction, obtain manganese carbonate solid cube;

[0036] After the manganese carbonate solid cube and sodium hydroxide are mixed and ground, calcined to obtain a porous sodium manganate cube;

[0037] Mixing pyrrole monomer, water and sodium perchlorate to obtain a mixed solution;

[0038] The porous sodium manganate cube is immersed in the mixed solution to obtain a polypyrrole-coated porous sodium manganate composite material (the specific preparation process is as follows: figure 1 shown).

[0039] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0040] In the invention, pota...

Embodiment 1

[0057] Mix 0.005mol potassium permanganate and 100mL water to obtain potassium permanganate solution; mix with 0.004mol glucose, perform hydrothermal reaction (140°C, 14h), filter to obtain 0.005mol manganese carbonate solid cube;

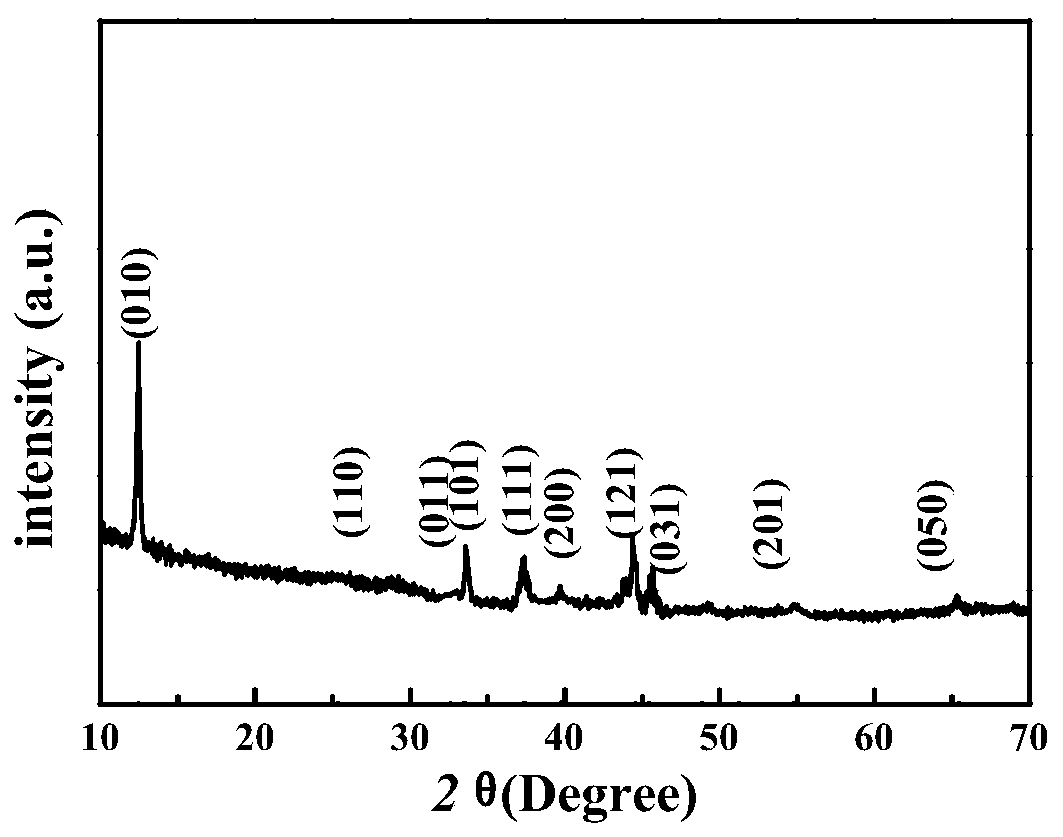

[0058] After mixing and grinding 0.005mol manganese carbonate solid cube and 0.005mol sodium hydroxide, it was calcined (650°C, 4h) to obtain 0.005mol porous sodium manganate cube (Na 0.91 MnO 2 );

[0059] Mix 5mL of pyrrole, 100mL of water and 0.0006mol of sodium perchlorate to obtain a mixed solution;

[0060] Immerse 0.0025mol porous sodium manganate cube in 100mL mixed solution, and continuously feed N 2 , impregnated (25°C, 6h) to obtain a polypyrrole-coated porous sodium manganate composite material (the mass ratio of polypyrrole to porous sodium manganate is 1:19);

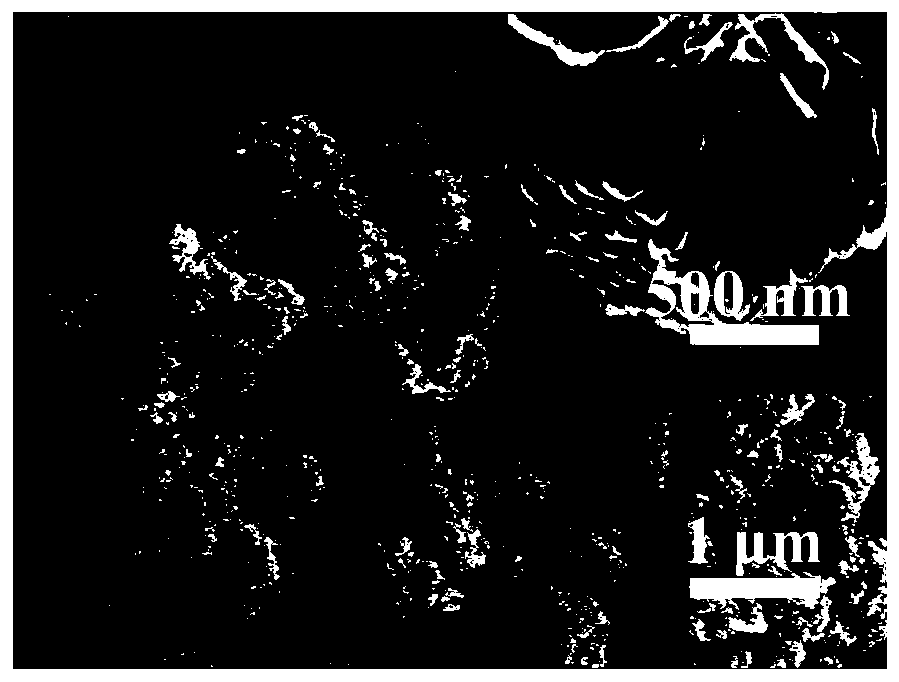

[0061] The porous sodium manganate cube is carried out SEM test, test result is as follows image 3 shown by image 3 It can be seen that the particle diameter of the poro...

Embodiment 2

[0064] Mix 0.004mol potassium permanganate and 100mL water to obtain potassium permanganate solution; mix with 0.003mol glucose, perform hydrothermal reaction (135°C, 13h), filter to obtain 0.004mol manganese carbonate solid cube;

[0065] After mixing and grinding 0.004mol manganese carbonate solid cubes and 0.004mol sodium hydroxide, they were calcined (700°C, 3h) to obtain 0.004mol porous sodium manganate cubes (Na 0.91 MnO 2 );

[0066] Mix 4mL of pyrrole, 100mL of water and 0.0005mol of sodium perchlorate to obtain a mixed solution;

[0067] Immerse 0.002mol porous sodium manganate cube in 100mL mixed solution, and continuously feed N 2 , impregnated (25°C, 6h) to obtain a polypyrrole-coated porous sodium manganate composite material (the mass ratio of polypyrrole to porous sodium manganate is 7:93);

[0068] According to the test shown in Example 1, the product of this example was tested by SEM and TEM, and the test results were similar to Example 1. The particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com