Flexible water-based sodium-ion batteries and preparation method thereof

A sodium-ion battery and water-based technology, applied to secondary batteries, circuits, electrical components, etc., to achieve low cost, good rate performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

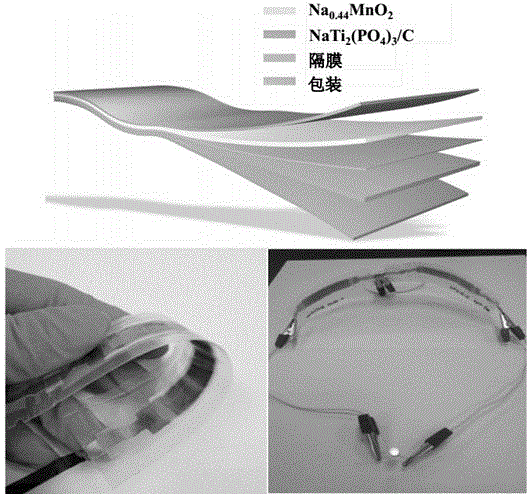

[0028] Embodiment 1: based on Na 0.44 MnO 2 Cathode and NaTi 2 (PO 4 ) 3 Ribbon-shaped flexible aqueous sodium-ion battery with / C negative electrode.

[0029] Take Na 0.44 MnO 2 as the positive active material. The preparation of the positive electrode film is as follows: first prepare the positive electrode material Na 0.44 MnO 2 . The specific steps are: the precursor Na 2 CO 3 and Mn 3 o 4 Mix at a ratio of 0.726:1, grind and mix evenly by hand; then roast the mixture in a muffle furnace at 500 degrees for 5 hours; then perform ball milling at a speed of 300 rpm for 10 hours, and then place it in a muffle furnace for roasting at 900 degrees 10 hours to get Na 0.44 MnO 2 . According to the active substance (Na 0.44 MnO 2 ): Acetylene black: PTFE (20%) = 80:10:10 Ratio roll out the film, dry the active material film and cut it into strips with a size of 1×5 cm, Na 0.44 MnO 2 Loaded at 10 mg cm -2 . NaTi 2 (PO 4 ) 3 / C is the negative electrode acti...

Embodiment 2

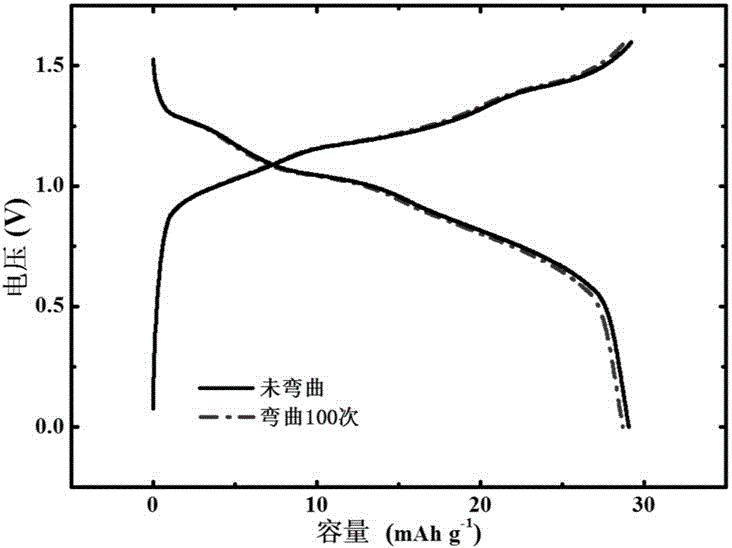

[0030] Embodiment 2: based on Na 0.44 MnO 2 Cathode and NaTi 2 (PO 4 ) 3 Comparison of charge-discharge curves of ribbon-shaped flexible aqueous sodium-ion batteries with / C anode under different bending angles.

[0031] The ribbon-shaped aqueous sodium-ion battery prepared in Example 1 was separated at 0.2 A g -1 Under the current density, bend 100 times in six bending states of 0°, 45°, 90°, 135°, 180°, and bend into a ring, and then conduct charge and discharge tests. After comparison, it is found that after bending at different angles, the battery capacity It is basically not affected by bending, and still has good cycle performance. The average charge and discharge platform is around 1.1V at each bending angle, and there is basically no capacity fading (Table 1), which fully demonstrates its good bending performance. performance.

Embodiment 3

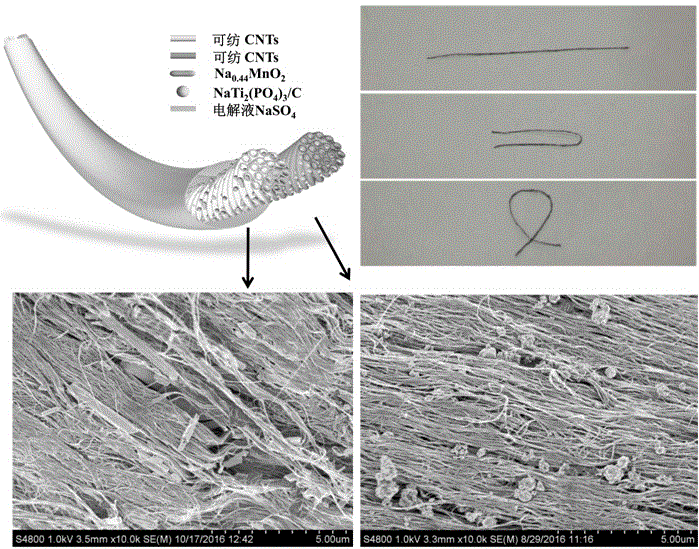

[0032] Embodiment 3: Based on Na 0.44 MnO 2 Cathode and NaTi 2 (PO 4 ) 3 Wire-shaped flexible aqueous sodium-ion battery with / C negative electrode.

[0033] In CNT / / Na 0.44 MnO 2 The composite fiber is a positive electrode active material. Spinnable CNT arrays were first prepared according to the chemical vapor deposition method. The specific method is: successively deposit aluminum oxide (Al 2 o 3 ) and iron (Fe), where Al 2 o 3 For the buffer layer, Fe is the catalyst. Silicon wafer thickness is 400 μm, Al 2 o 3 The layer thickness is 3 nm and the Fe layer thickness is 1.2 nm. First, put the silicon wafer coated with the catalyst into the center of the tube furnace, and adjust the flow rate of the ventilation pipe as follows: Argon: 400 sccm; Hydrogen: 30 sccm; Ethylene: 90 sccm. First pass argon only for 10 minutes, remove the air in the pipeline, then pass hydrogen and ethylene, control the tube furnace to rise from room temperature to 740°C in 15 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com