Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1531 results about "Plastics extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

Flexible 3D Freeform Techniques

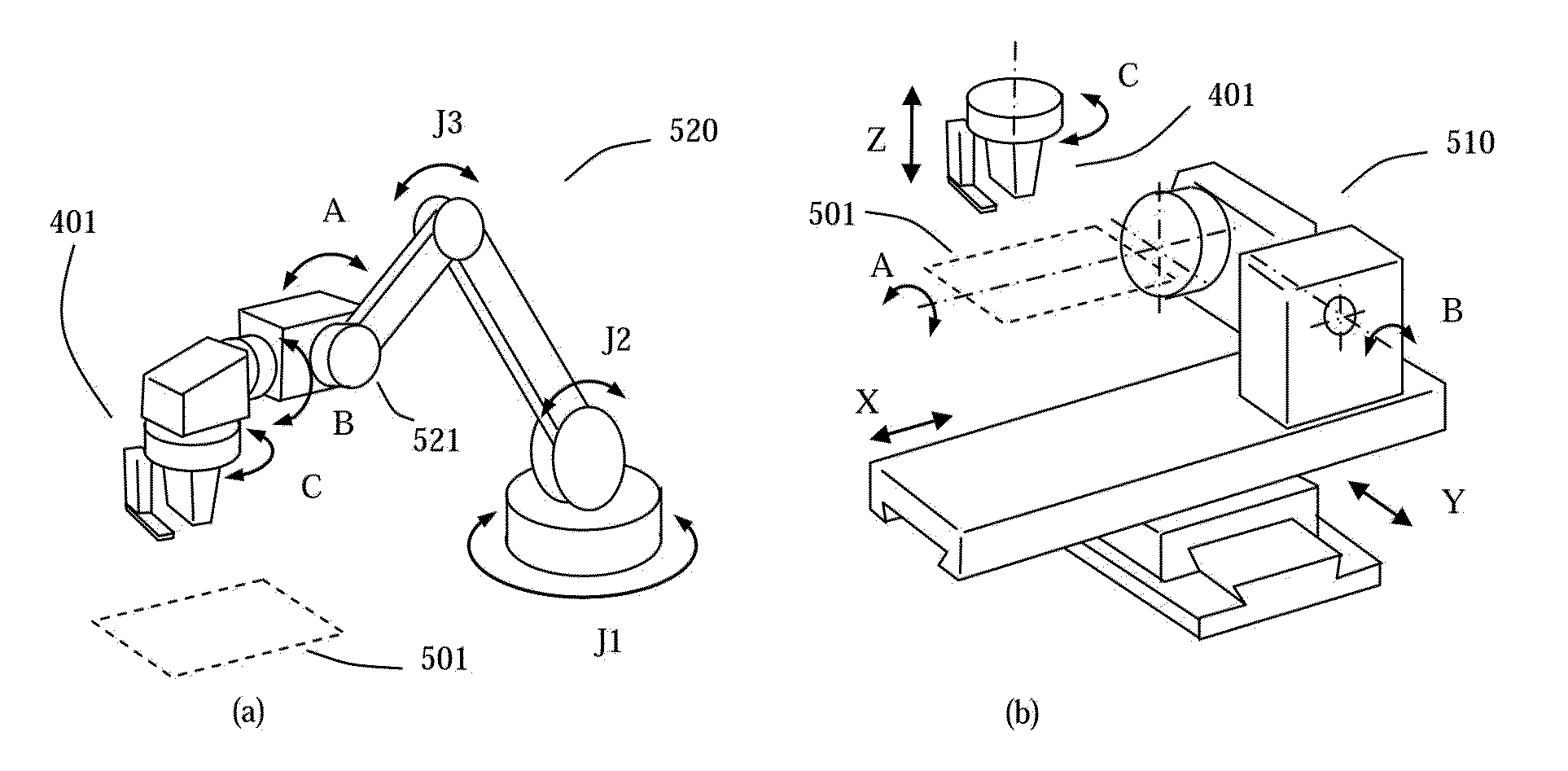

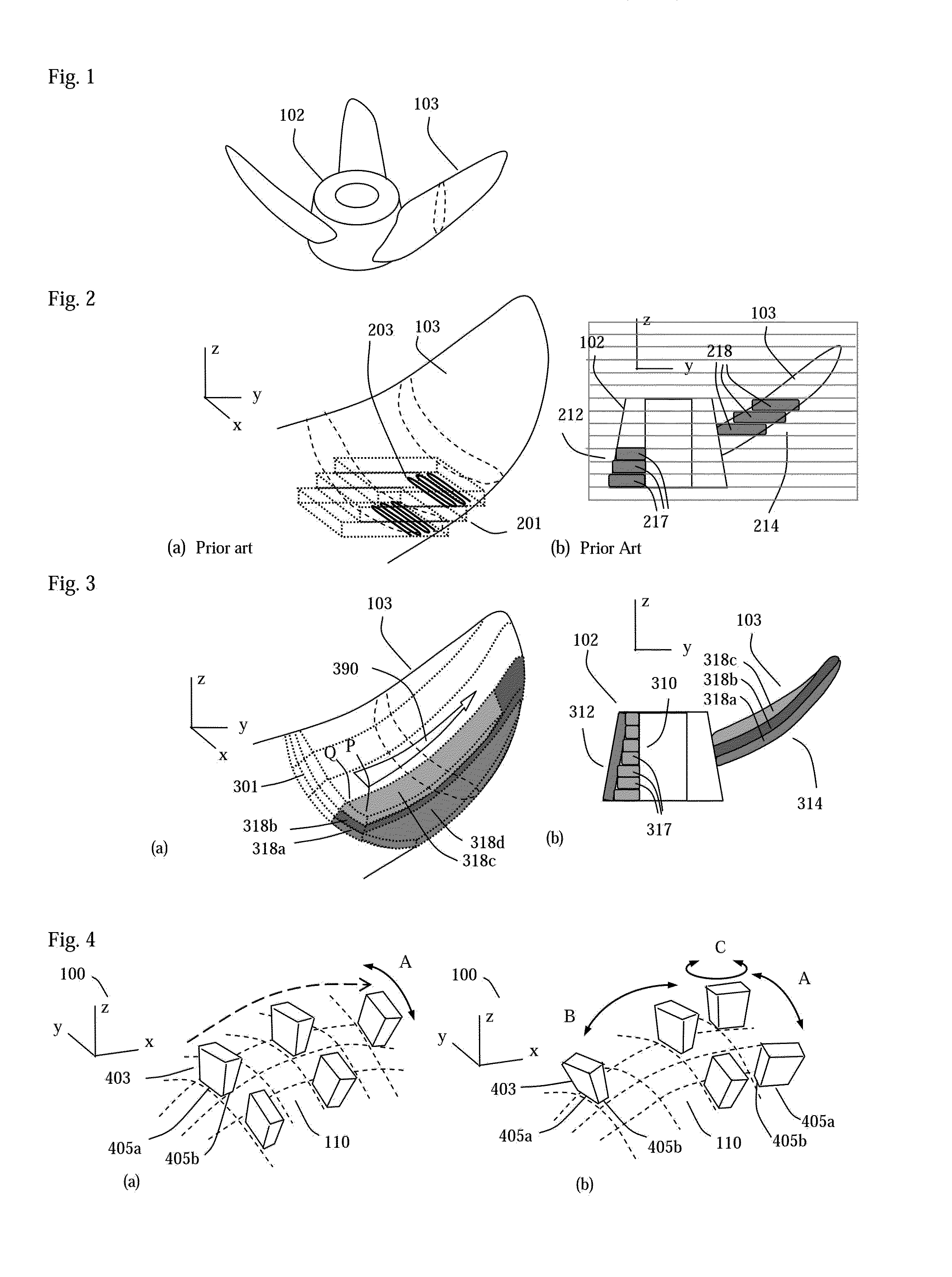

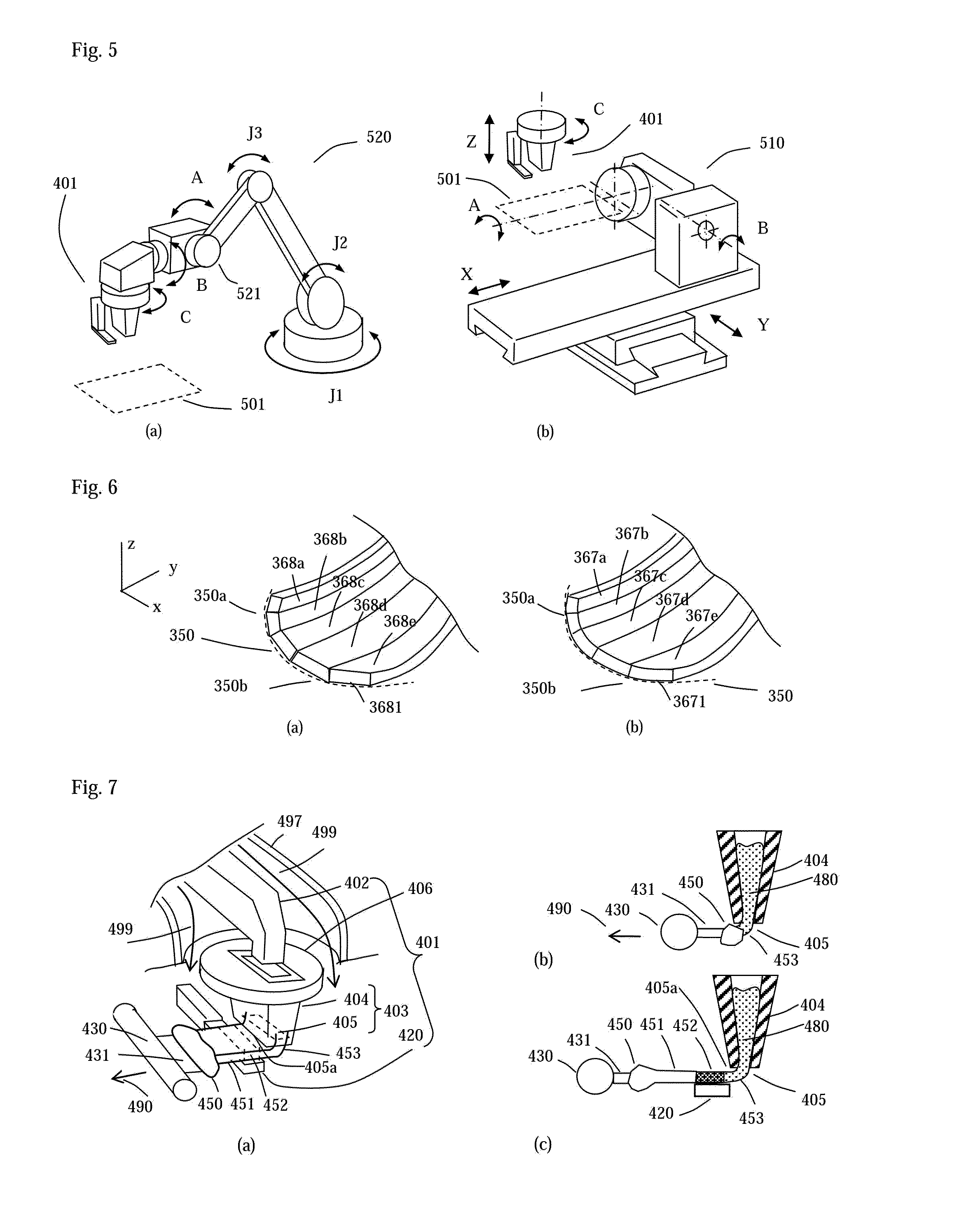

ActiveUS20160151833A1Improve manufacturing speedBuild fine and complexConfectioneryGlass forming apparatusEngineeringInjection molding machine

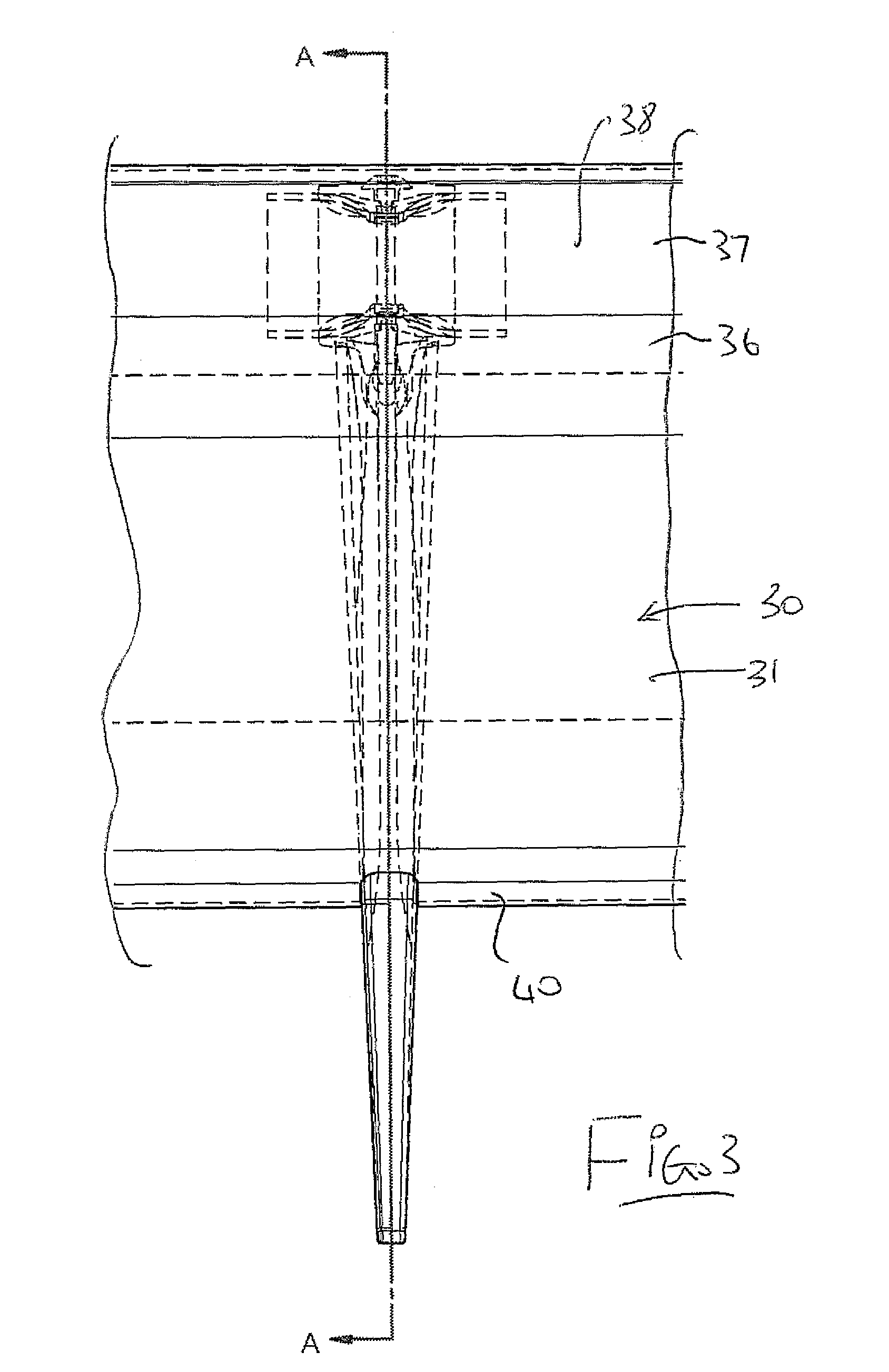

This invention relates to processes and systems of rapid prototyping and production. Its features includes flexible material deposition along tangential directions of surfaces of a part to be made, thereby eliminating stair-shape surface due to uniform horizontal layer deposition, increasing width of material deposition to increase build up rate, applying the principles of traditional forming / joining processes, such as casting, fusion welding, plastic extrusion and injection molding in the fabrication process so that various industrial materials can be processed, applying comparatively low cost heating sources, such as induction heating and arc-heating. Additional features include varying width and size of material deposition in accordance with geometry to be formed and applying a differential molding means for improved shape formation and surface finishing.

Owner:NATIONAL TSING HUA UNIVERSITY

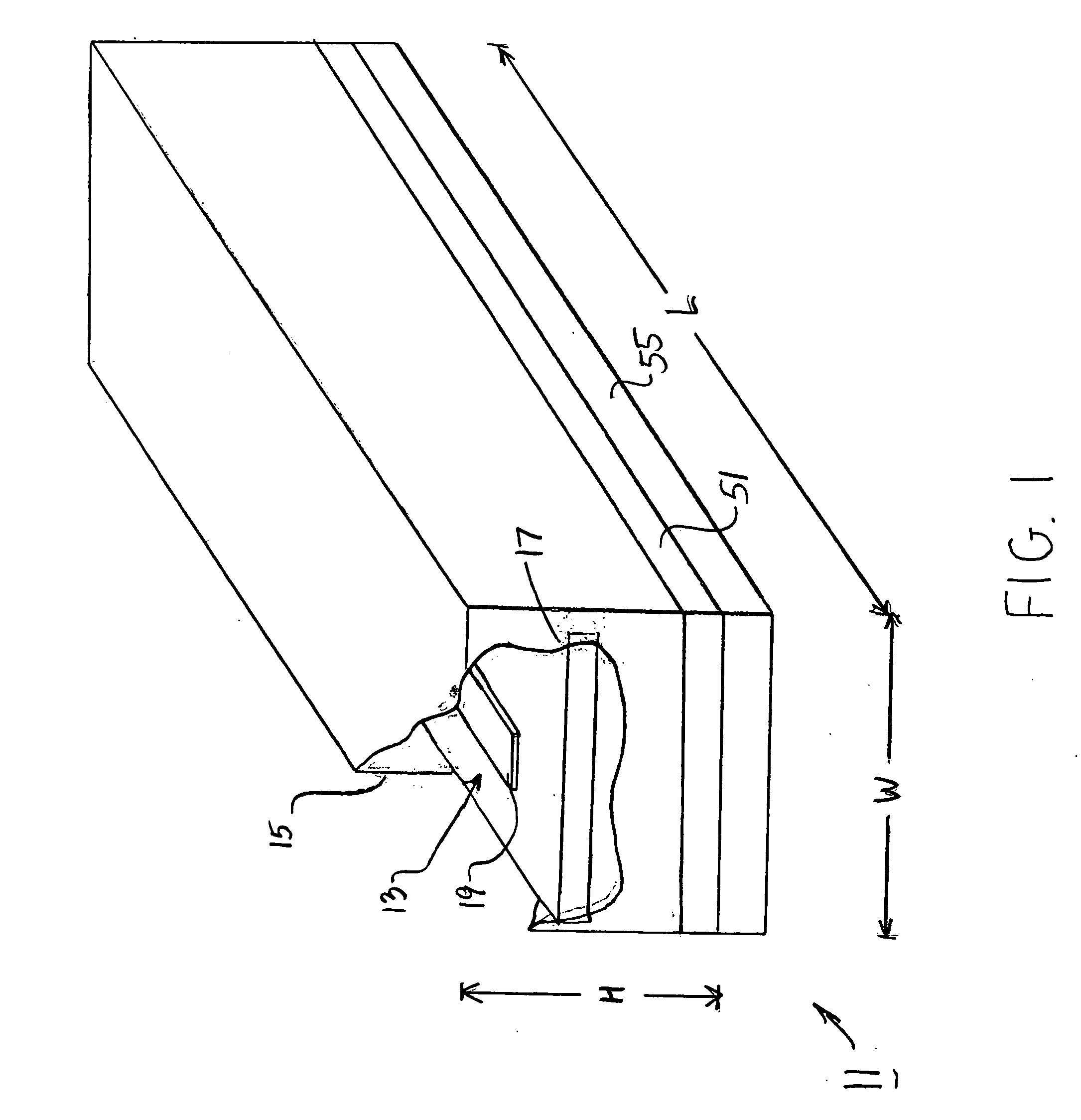

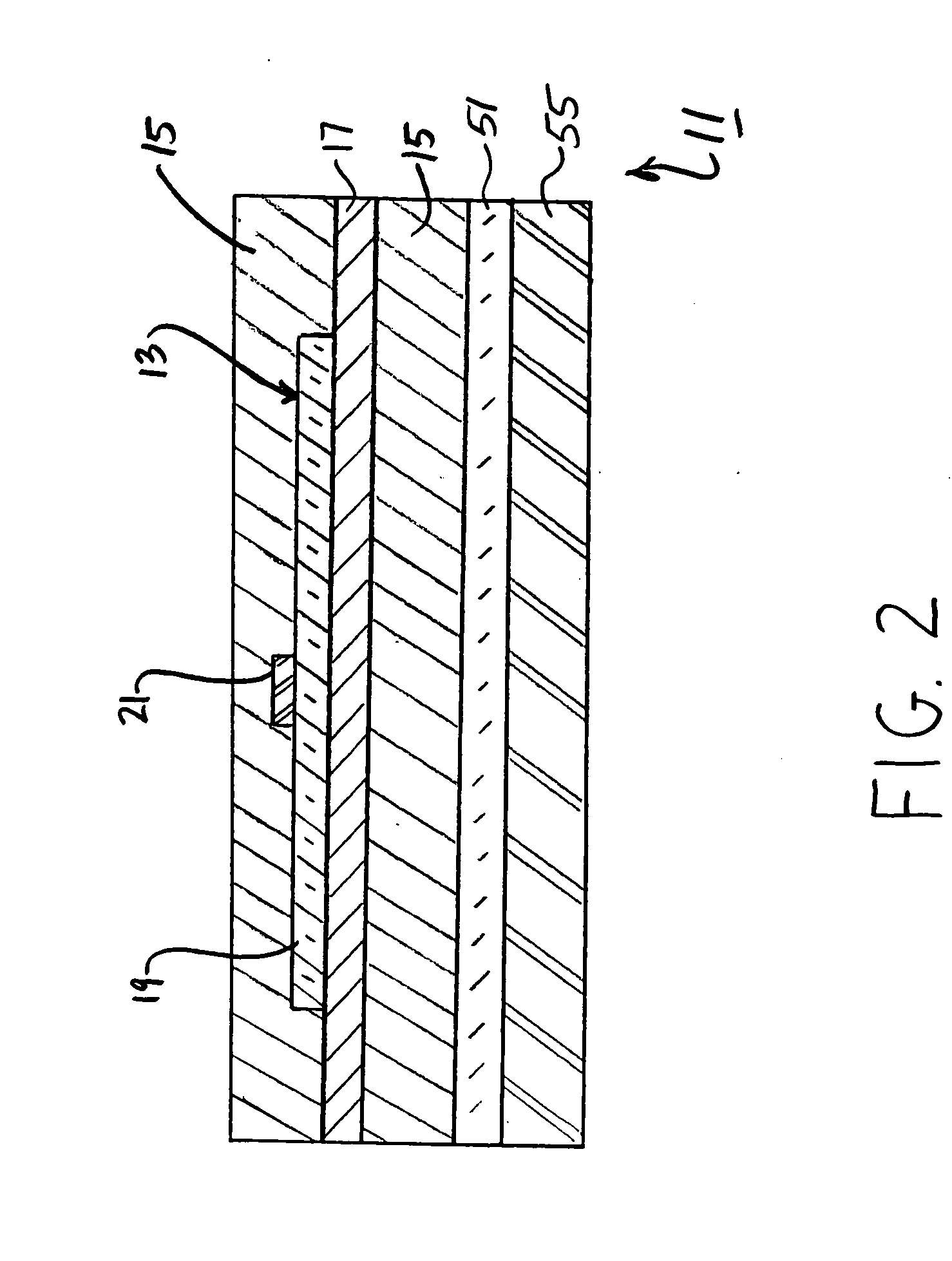

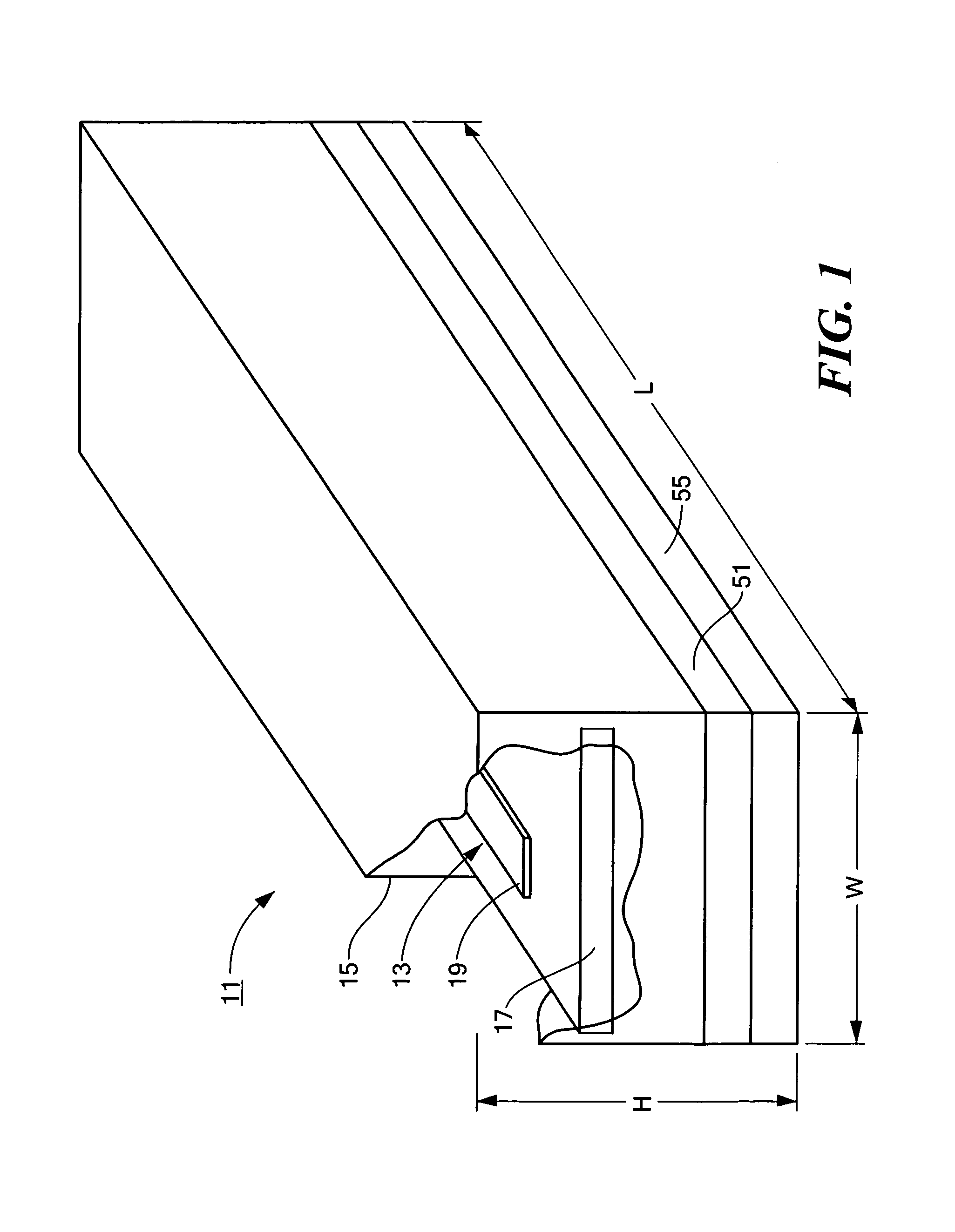

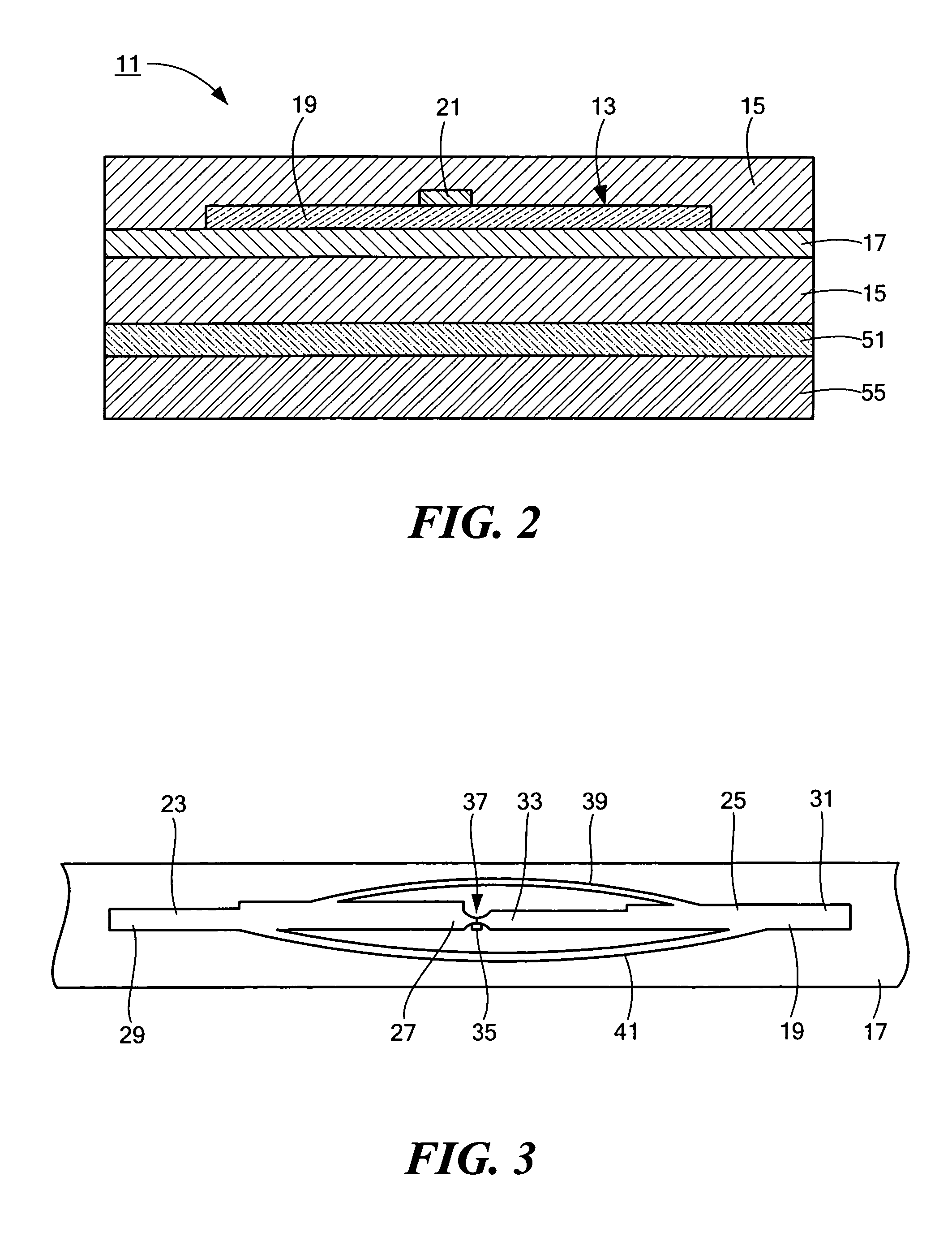

Deck plank extrusion and retaining clip

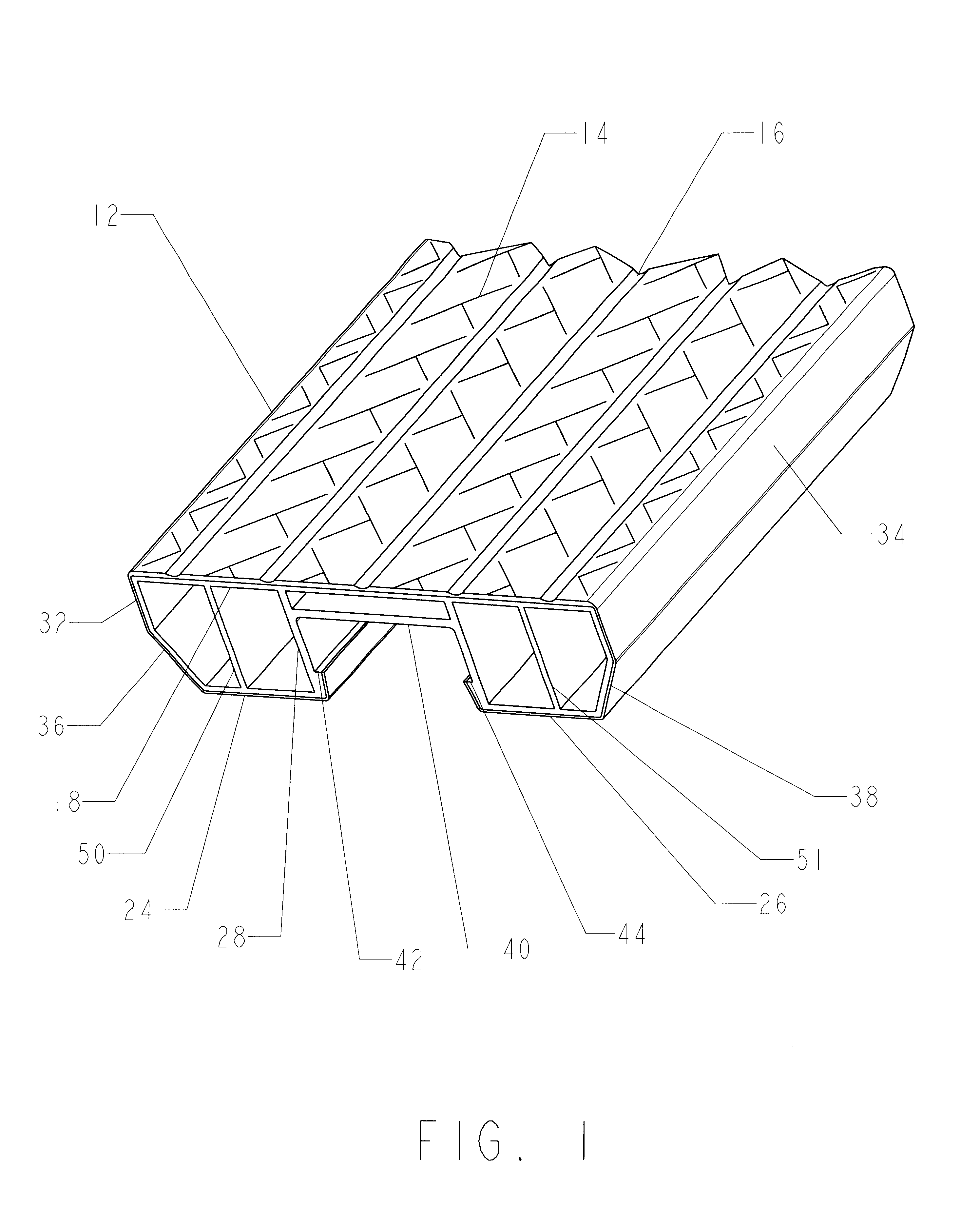

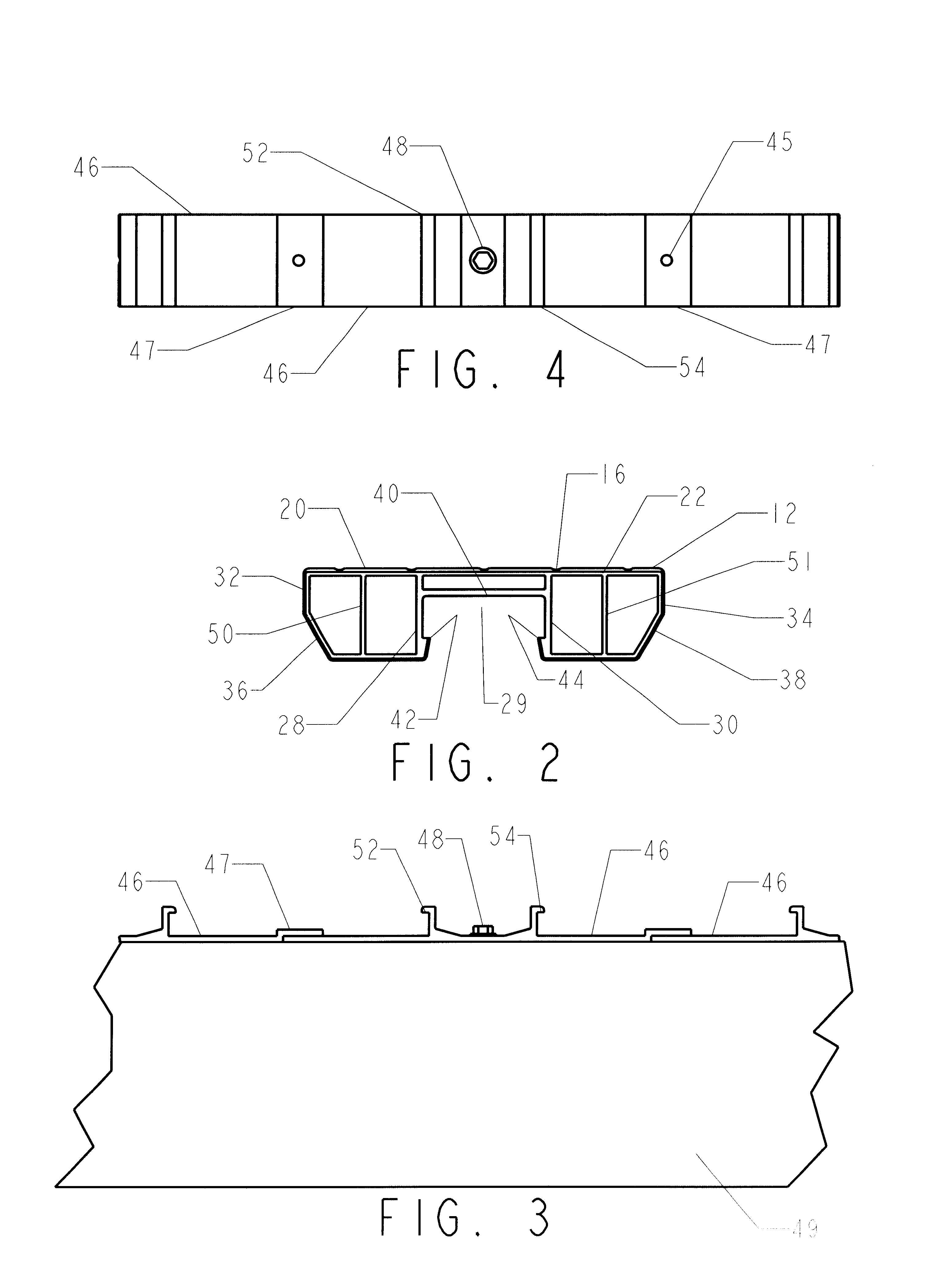

A deck plank (12) readily attaches to an engagement clip (46) when force is applied over the plank. When a plurality of clips are attached to underlying joists in parallel with the joists, and a plurality of deck planks are oriented to the clip perpendicular to the joist and pushed down over clips, a secure deck structure is provided. Each clip has a pair of horizontal flanges (52 and 54), which snap over a plurality of ledges (42 and 44) in a channel under each plank. The deck planks (12) are embossed (14) so as to form a slip resistant surface to be walked upon. The plastic extruded deck plank (12) resists rot, deterioration and insect infection found in current wood products. The deck plank assembly is simple enough so that a homeowner or do-it-yourselfer can install or alter it with minimal effort and direction.

Owner:LEINES RICHARD ALAN

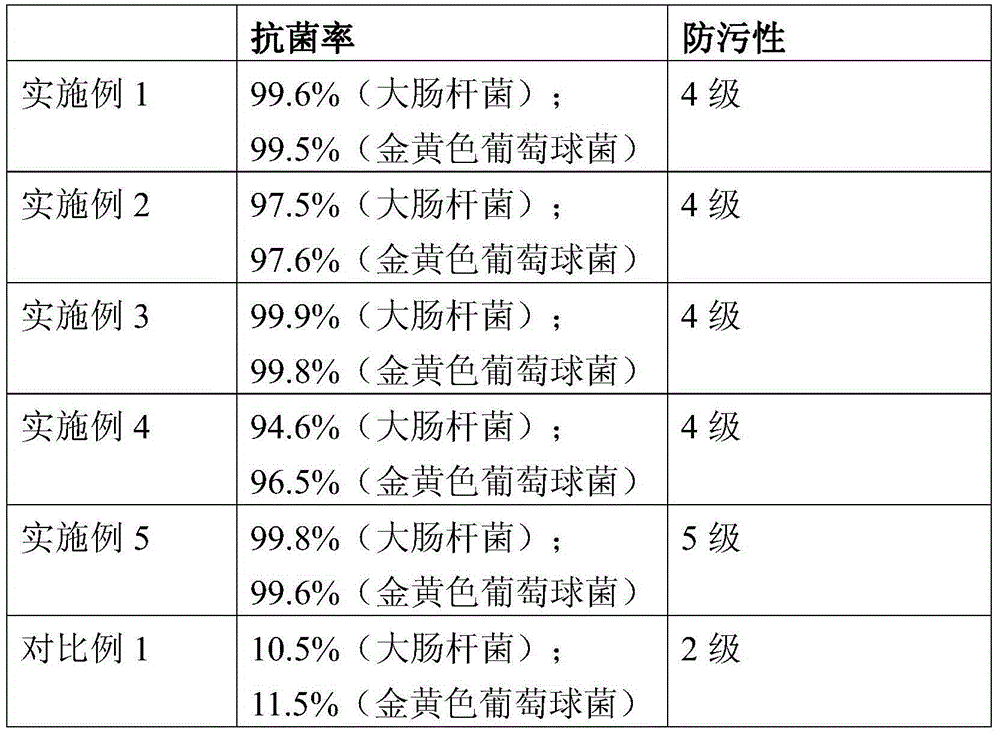

3D printing material having self-cleaning antibacterial function as well as preparation method and application of 3D printing material

The invention discloses a 3D printing material having a self-cleaning antibacterial function as well as a preparation method and an application of the 3D printing material. The 3D printing material consists of the following components: 70-85 parts of a high-molecular polymer, 1-5 parts of pigment powder, 1-5 parts of inorganic filler, 0.5-1.5 parts of a nanometer antibacterial agent and 10-20 parts of a binding material. The 3D printing material having the self-cleaning antibacterial function is prepared by the following steps: uniformly mixing the components; adding the uniformly mixed materials to a single-screw plastic extruder, extruding, cooling and shaping, drying, drawing and winding. The 3D printing material disclosed by the invention is excellent in toughness and mechanical property, and furthermore the 3D printing material is good in self-cleaning and antifouling properties; and the 3D printing material has high application potential.

Owner:GUANGZHOU FEISHENG HIGH POLYMER MATERIAL CO LTD +1

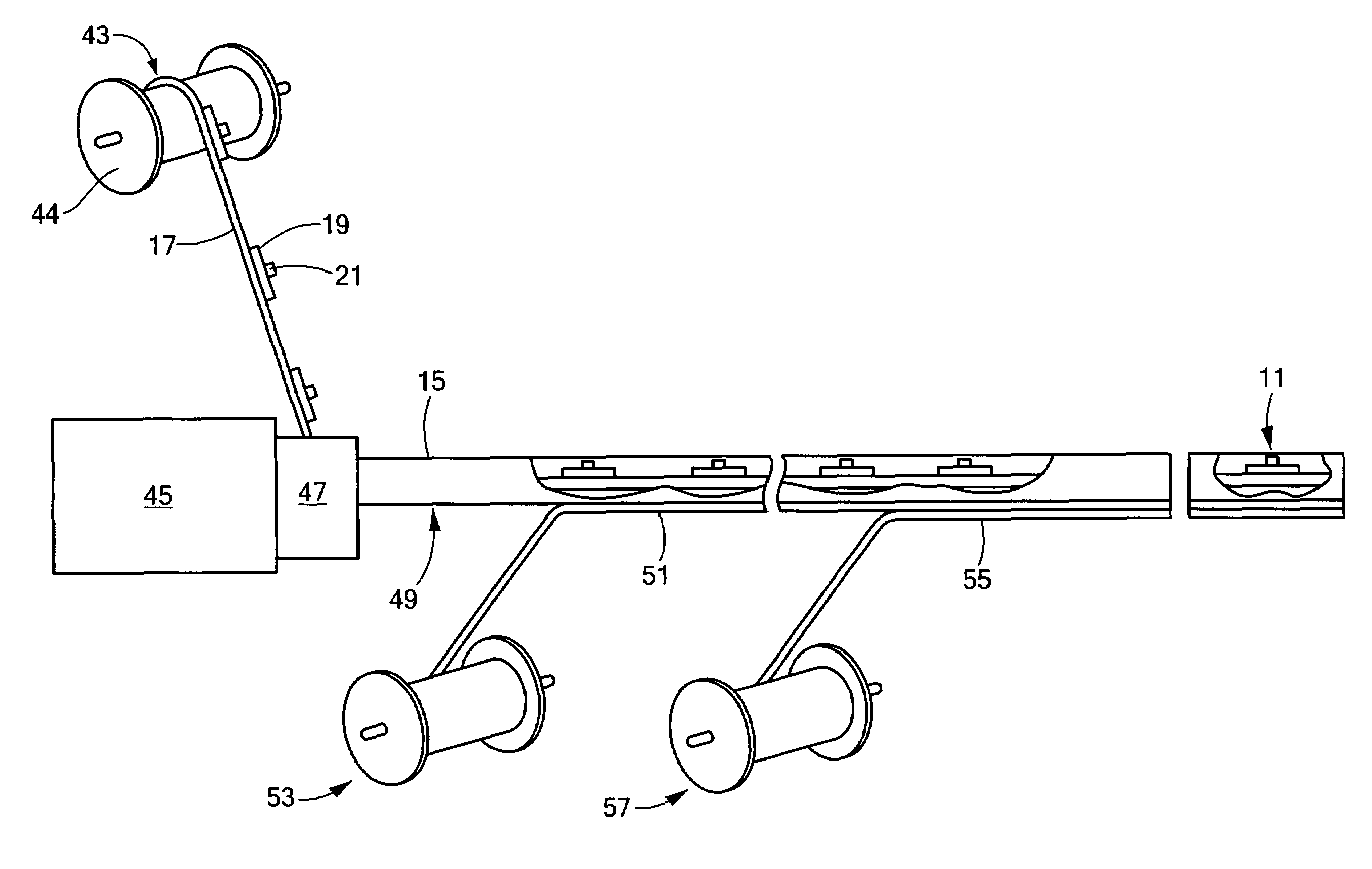

RFID tag and method of manufacturing the same

ActiveUS20050197074A1Improve throughputSolid-state devicesTransmissionRadio frequencyCommunication device

A radio frequency identification (RFID) tag and method of manufacturing the same. In a preferred embodiment, the RFID tag includes a radio frequency (RF) inlay, the RF inlay including a carrier sheet, an antenna printed on the carrier sheet and a wireless communication device bonded to the antenna. The RFID tag also includes a plastic extrudate, the RF inlay being disposed within the extrudate so that the antenna and the wireless communication device are encapsulated on all sides within the extrudate. Optional metallic reflector and mounting adhesive layers may be laminated onto the underside of the extrudate. The present invention is also directed to an automated method for manufacturing the above RFID tag, such a method involving, in one embodiment, feeding a continuous supply of RF inlays into a cross-head extruder to yield a continuously extruded block and then cutting the block between successive antennae to yield a plurality of individual RFID tags.

Owner:CASCADE ENG

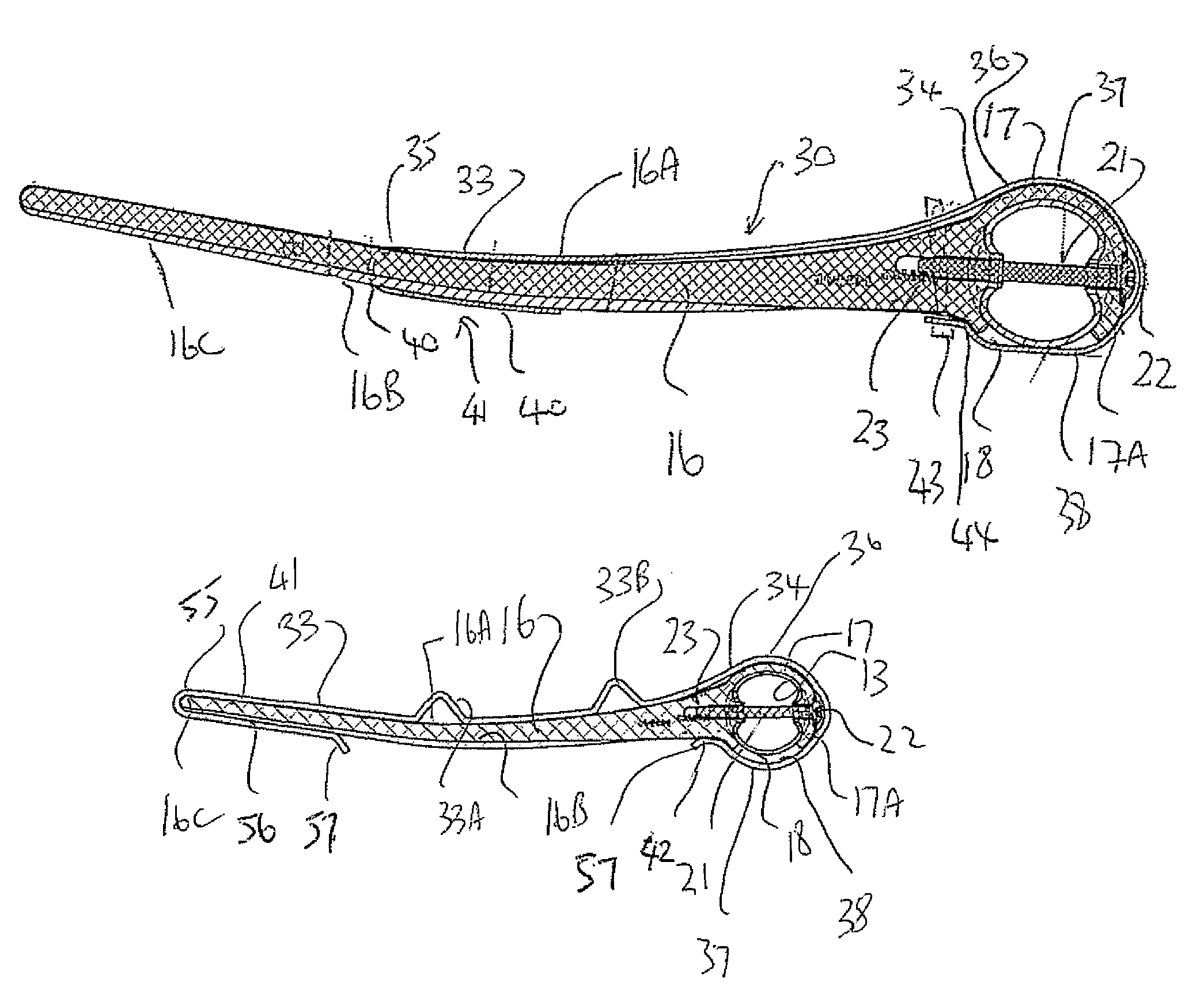

Pouch for collecting human waste

ActiveUS20040049837A1Simple manufacturing processFacilitate great freedom of designBagsBathroom accessoriesHuman wastePlastics extrusion

A drainable ostomy pouch has an outlet. Reinforcing members at the outlet are deformable by application of manual pressure at their ends to distend the outlet. The lateral edges of the reinforcing members may be offset, which encourages the reinforcing members to consistently bend away from each other. A peelable distributed mechanical engagement fastener secures the outlet in a folded condition. The fastener parts are hook-hook type plastic extrusions, and provide a snap-engagement. A security flap is foldable under the outlet when in its folded condition. The outlet is released in two stages.

Owner:CONVATEC TECH INC

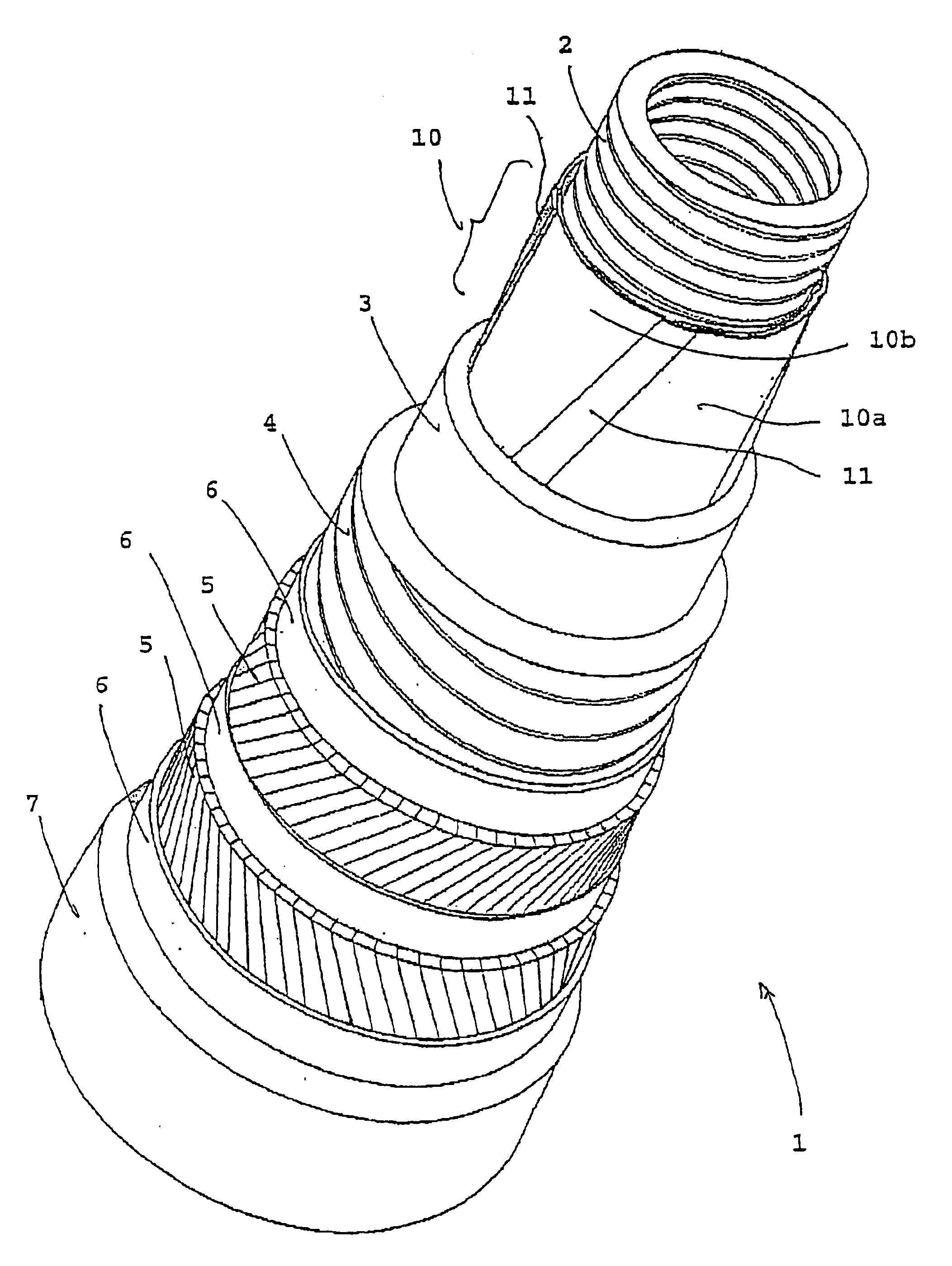

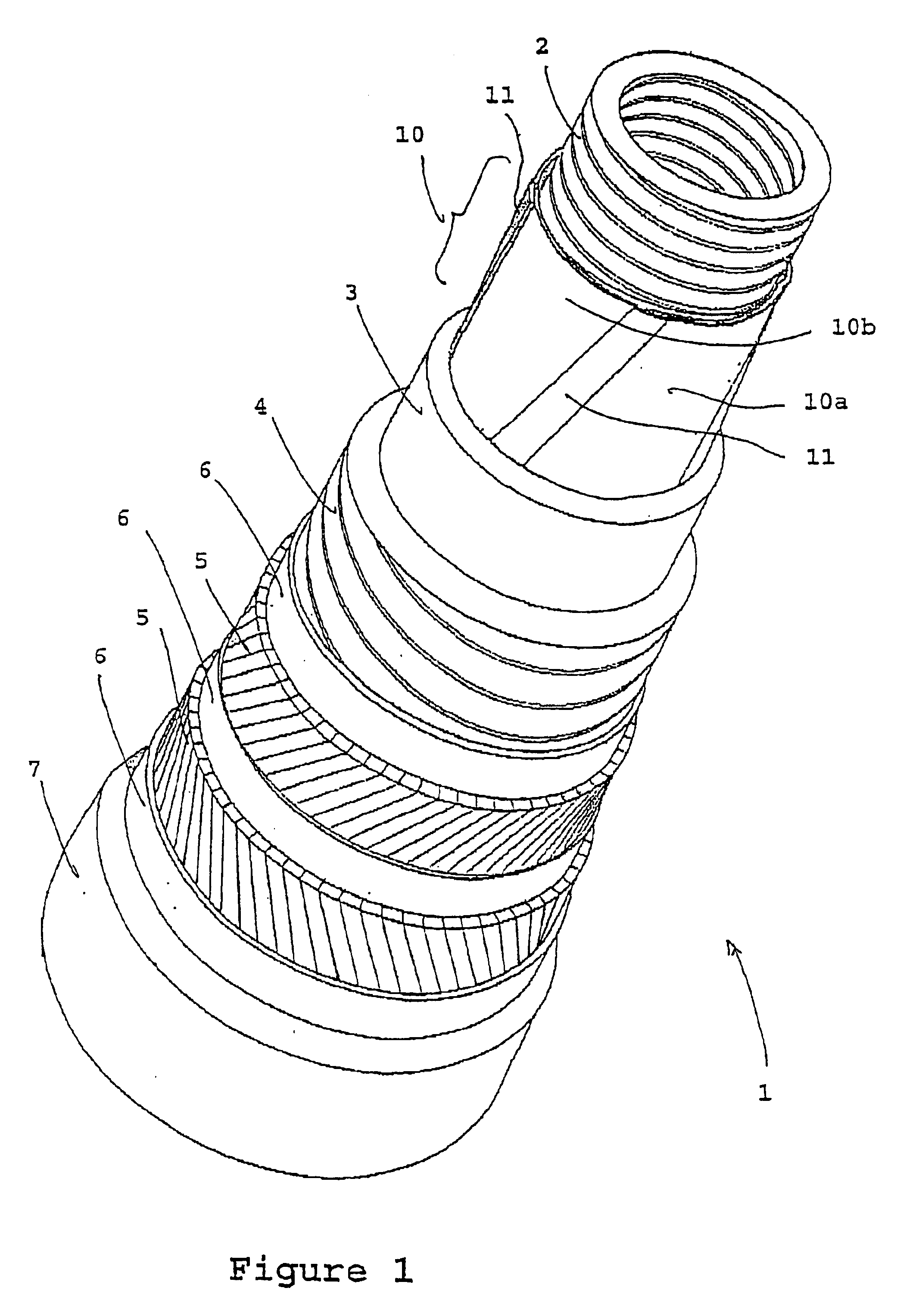

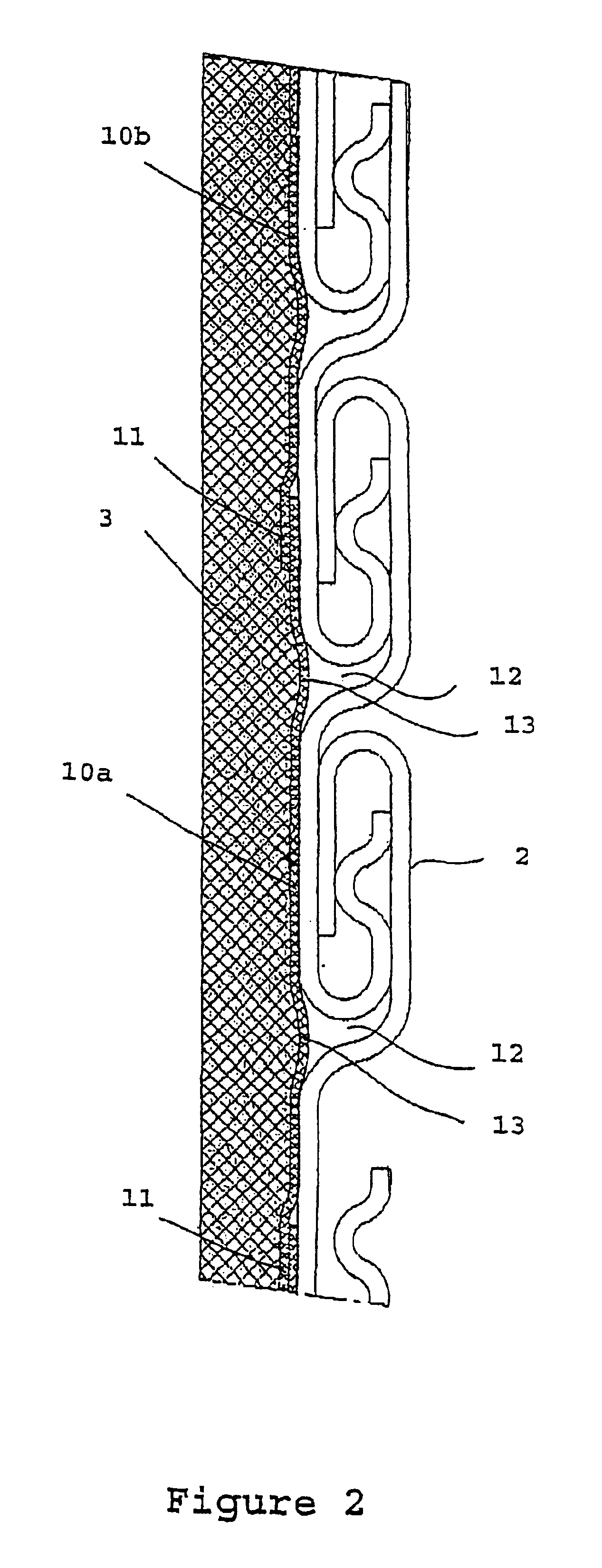

Flexible duct with shrinkage-proof film

The invention concerns a flexible duct (1) comprising from inside outwards a carcass (2) produced by a short-pitched metallic helical winding forming butt gaps (12), an overlapping layer (10) acting as a heat shield consisting of helically wound plastic strips (10a, 10b), a sealed inner pressure sheath (3), extruded in plastic on said overlapping layer (10), at least an armouring web (5) and at least an outer sealing sheath (7). The invention is characterised in that the overlapping strips (10a, 10b) are wound at a winding angle less than 35°.

Owner:TECH FRANCE SA

Special material for polychloroethylene insulating electrical casing pipe

The invention discloses a special material of polyvinyl chloride for electric isolated sleeve, comprising polyvinyl chloride, stabilizing agent, modifying agent for processing, shock resistance modifying agent, plasticizer, stearic acid, calcium stearate, polyethylene (PE) wax, pigment and 6000 mesh inorganic materials powder. The preparation method is as below: combine the measured 6000 mesh inorganic materials powder and the stearic acid first and then add shock resistance modifying agent to modify the inorganic materials powder. The combined material is granulated by an extruder for reservation. Then mix the measured material evenly by the high mixing machine to form the special powder material for polyvinyl chloride insulated sleeve or granulate the special powder material for polyvinyl chloride insulated sleeve by the extruder to form the special granule for polyvinyl chloride insulated sleeve which is later molded by the plastic extruding machine to form insulated electric sleeve with various specifications. The invention has the advantages of sound dispersion and compatibility, better product quality and lower cost.

Owner:TIANJIN DEHAO NEW MATERIALS

ABS//PET alloy and method for producing the same

The invention discloses an ABS / PET alloy and a preparation method thereof. The ABS / PET alloy comprises the components with the weight percentage as follows: 21-72 percent of ABS, 14-60 percent of PET, 3-10 percent of compatilizer, 0.4-0.6 percent of antioxidant, 5-15 percent of toughener and 0.3-1 percent of lubricant. In the invention, proper compatilizer and intensifier are selected to melt an ABS system and a PET system together very well and the material which has stable size, high strength, high modulus and high fluidity is produced. The ABS / PET alloy integrates the advantages of ABS and PET and improves the heat resistance, impact resistance, processability and the like of the PET. The method for manufacturing the ABS / PET alloy comprises the technical steps as follows: firstly, the raw materials are mixed in proportion as above and then are put into a plastic extruder to be granulated at the temperature controlled within 230 DEG C to 260 DEG C; and the ABS / PET alloy is obtained.

Owner:SHENZHEN KEJU NEW MATERIAL

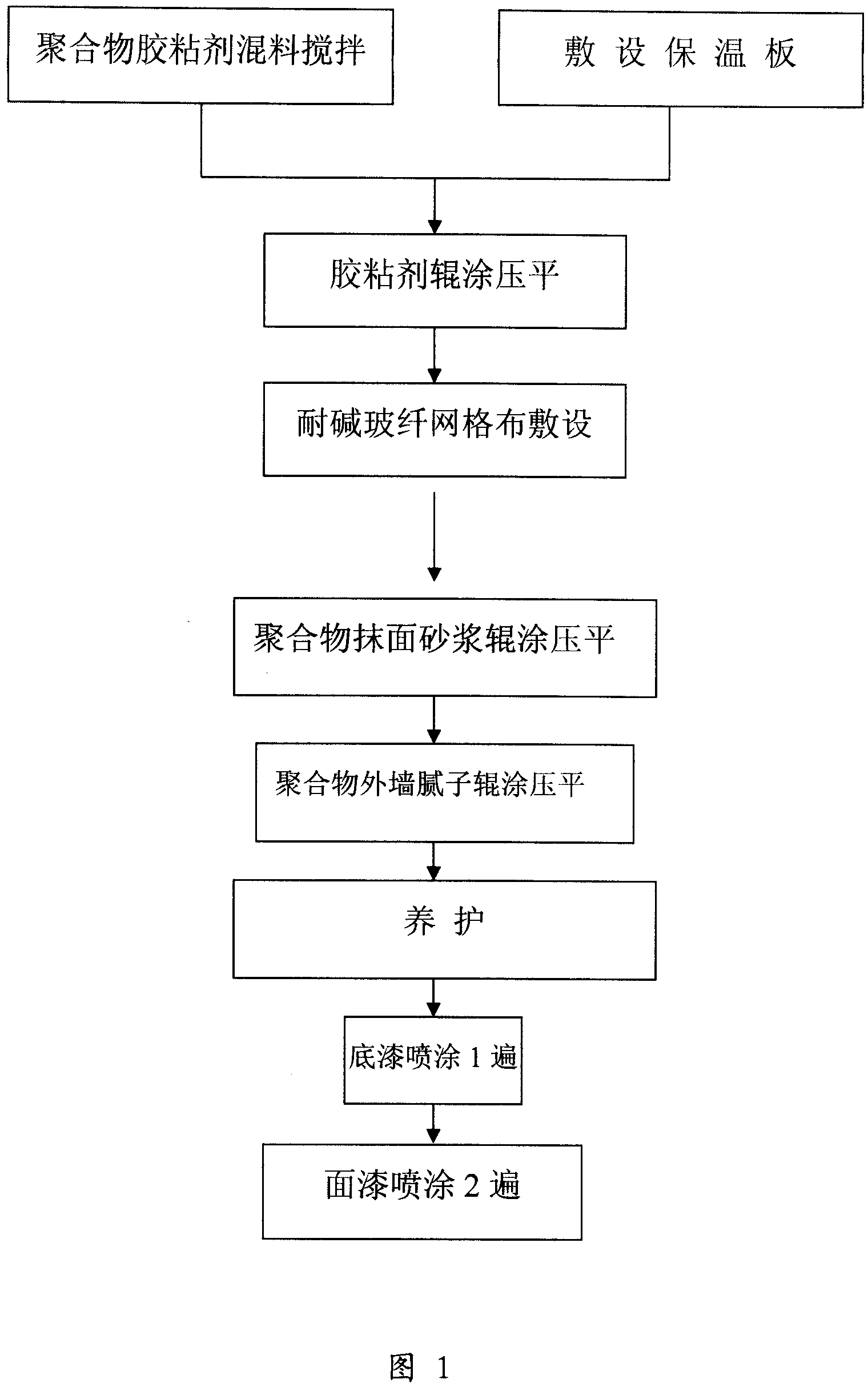

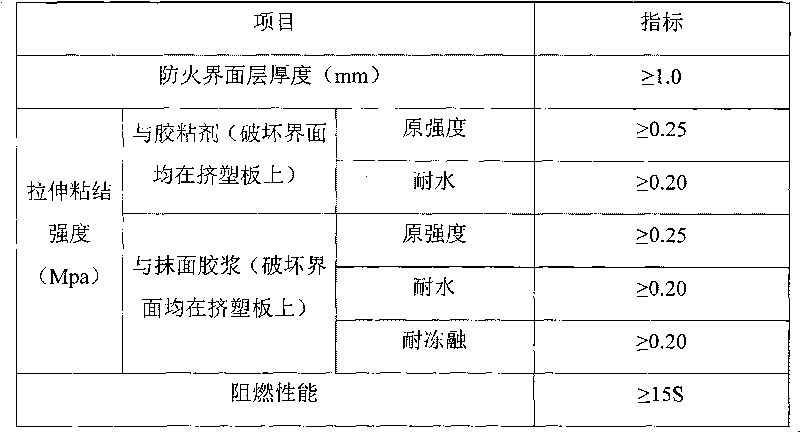

Insulating decoration integral board for building exterior wall

InactiveCN101205753AAdequate bond strengthImprove crack resistanceCovering/liningsSolid waste managementEngineeringEnergy consumption

The invention relates to a constructional material, in particular to a heat preservation and decoration board for a building exterior wall. The invention has a structure that the board mainly comprises three layers; an inner layer serves as an insulating course, an outer layer serves as a decorative layer and a middle layer serves as a binding course; wherein, the insulating course has a polyphenyl board or a plastic extrusion plate or a polyurethane board; the decorative board has various exterior wall facing dopes or a decorative plate; the binding course is the polymer caking agent layer, the insulating course and the decorative layer are stuck into a whole by the cementing action of the polymer caking agent. The invention has convenient construction, easy manipulation, low cost, good heat prevention effect and strong suitability, thereby contributing to the quick popularization of energy consumption of a building.

Owner:李旭东

PC/PET alloy and manufacture method thereof

The invention discloses a PC / PET alloy and its producing method with a composite weight ratio (%): PC 65-87%; PET5-20%; elasticizer 6-10%; compatilizer 1-3%; antioxidant 0.2-0.6%; other assistant agents 0.1-2%. The inventive material has a high impacting strength, a high module, a high rigidity, a high surface gloss and a low density, which improves the PC resistance to solvent, abrasion resistance, resistance to stress cracking and processing fluidity. The plastic producing method contains following steps: firstly mixing the material according to above proportion, then entering into the plastic extruder at 245-280 DEG C, prilling, getting PC / PET alloy.

Owner:SHENZHEN KEJU NEW MATERIAL

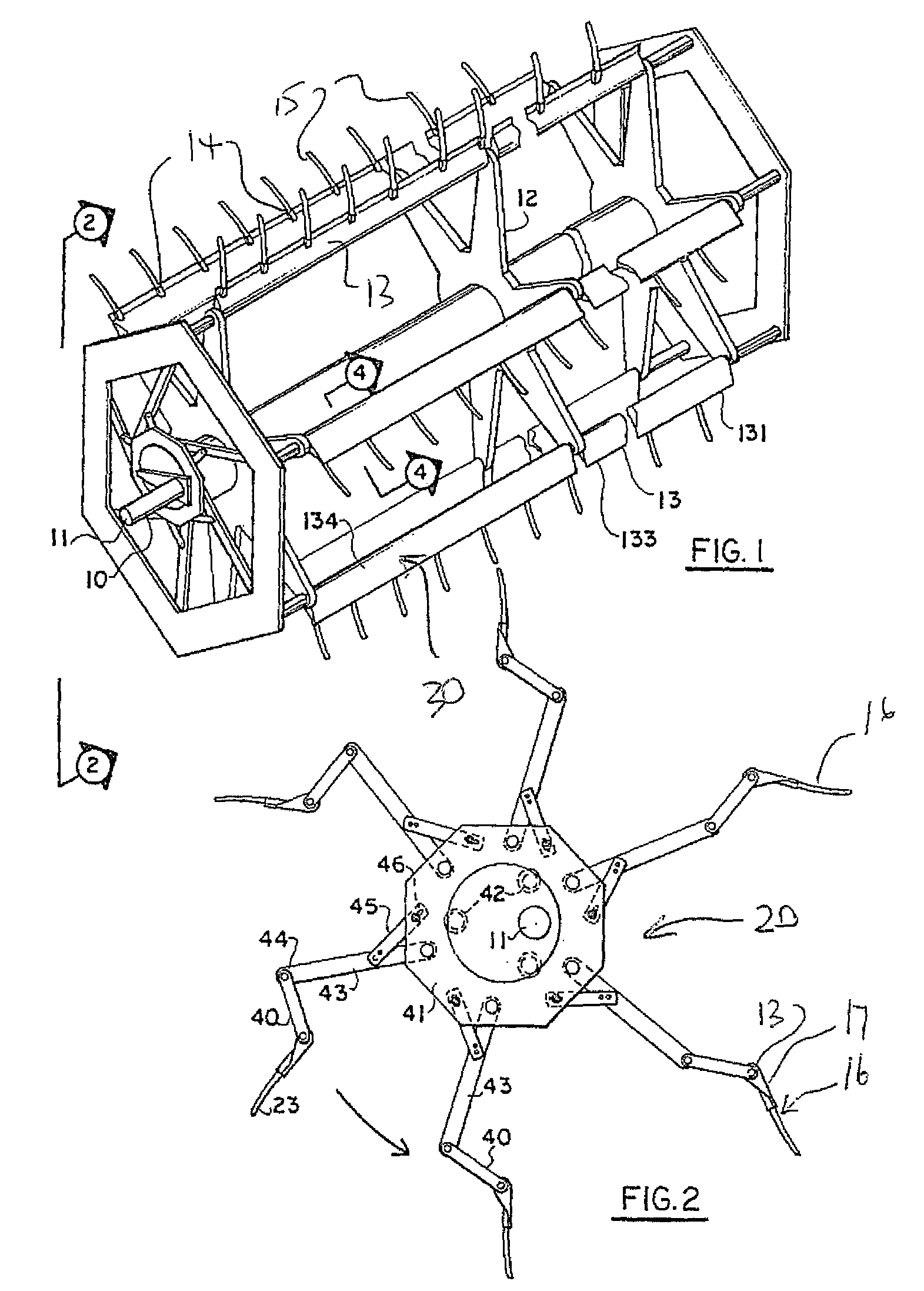

Extruded bat for the reel of a crop harvesting header

A removable bat attachment to be applied when required over the tine tubes and fingers of reel of a harvesting machine is formed by an elongate flexible plastic extruded member having a first wall lying against the leading face of the plurality of fingers, a second wall at the inner edge of the first wall wrapping around the tine tube to define a generally cylindrical channel shaped receptacle to receive the tine tube therein and a third wall at the outer edge. In one arrangement the outer edge wraps around an outer end of the fingers and is snap fit onto the outer ends of the fingers and on to the tine tube so as to be held in place thereon by the snap fit. In another arrangement the outer edge has an end wall with a series of holes one for each finger so that the fingers project outwardly from the outer edge.

Owner:MACDON INDS

Thermoplastic elastomer material, preparation thereof and method for manufacturing medicinal bottle stopper by using the same

InactiveCN101376730ACreate pollutionWon't releasePharmaceutical containersMedical packagingRubber materialAntistatic agent

The invention provides thermoplastic elastomer materials used for a bottle cork for manufacturing medicines, a preparation method thereof and a method for applying the bottle cork for manufacturing medicines thereof. The materials are prepared by the following components: styrene copolymer or rubber materials as well as polyolefine matters. The styrene copolymer is PP or PE; besides, the materials also contain a plasticizer and a loading agent, contain or do not contain a compatibilizer, contain or do not contain an antioxidant, contain or do not contain an antistatic agent, contain or do not contain adhesion preventives. The preparation method thereof includes the steps of drying the materials, fusing a reaction kettle, using a plastic extruding machine to extrude the materials, using a cooling water slot to cool and shape the materials, using a hauling machine to haul and cut off the materials, and the like. The thermoplastic elastomer materials provided by the invention have the advantages of stable chemical property, no poison, low polarity and good rebound resilience.

Owner:谷其昌

Special fireproof mortar of plastic extrusion plate

The invention relates to special fireproof mortar of a plastic extrusion plate. A fireproof protection layer is formed at the surface of the plastic extrusion plate, can act as the function of isolating oxygen and enables the oxygen not to directly contact with the extrusion molding plate, thereby avoiding the generation of a combustion reaction. The mortar comprises the following components: 20-50% of cement, 20-60% of sand, 2-10% of dispersible emulsion powder, 0-40% of inorganic composite material and 0.5-10% of organic composite material.

Owner:北京艺高世纪科技股份有限公司

Pouch for collecting human waste

ActiveUS7306581B2Easy to bendPromote bending in opposite directionsNon-surgical orthopedic devicesColostomyHuman wasteEngineering

A drainable ostomy pouch has an outlet. Reinforcing members at the outlet are deformable by application of manual pressure at their ends to distend the outlet. The lateral edges of the reinforcing members may be offset, which encourages the reinforcing members to consistently bend away from each other. A peelable distributed mechanical engagement fastener secures the outlet in a folded condition. The fastener parts are hook-hook type plastic extrusions, and provide a snap-engagement. A security flap is foldable under the outlet when in its folded condition. The outlet is released in two stages.

Owner:CONVATEC TECH INC

Novel 6063 aluminum alloy material and its production technology

The invention discloses a novel 6063 aluminum alloy material. Rare earth elements are added into the original 6063 aluminum alloy. The novel 6063 aluminum alloy material comprises, based on the weight percentage,0.36%- 0.4% of Si, 0.48% - 0.52% of Mg, 0 -0.35% of Fe, 0 -0.1% of Cu, 0 - 0.05% of Mn, 0 - 0.05% of Cr, 0 - 0.05% of Zn, 0 - 0.05% of Ti, 0.18%-0.22% rare earth elements, 0-0.1% of the remaining impurities and the balance of Al. According to the invention, the content of Mg and Si is controlled within a narrow range. At the same time, cerium-based mixed rare earth elements and alloying element boron are added, which keeps alloy material high strength and high electrical and thermal conductivity; improves machining property and plastic extrusion; and improves production efficiency.

Owner:CHENGDU SUNSHINE ALUMINUM

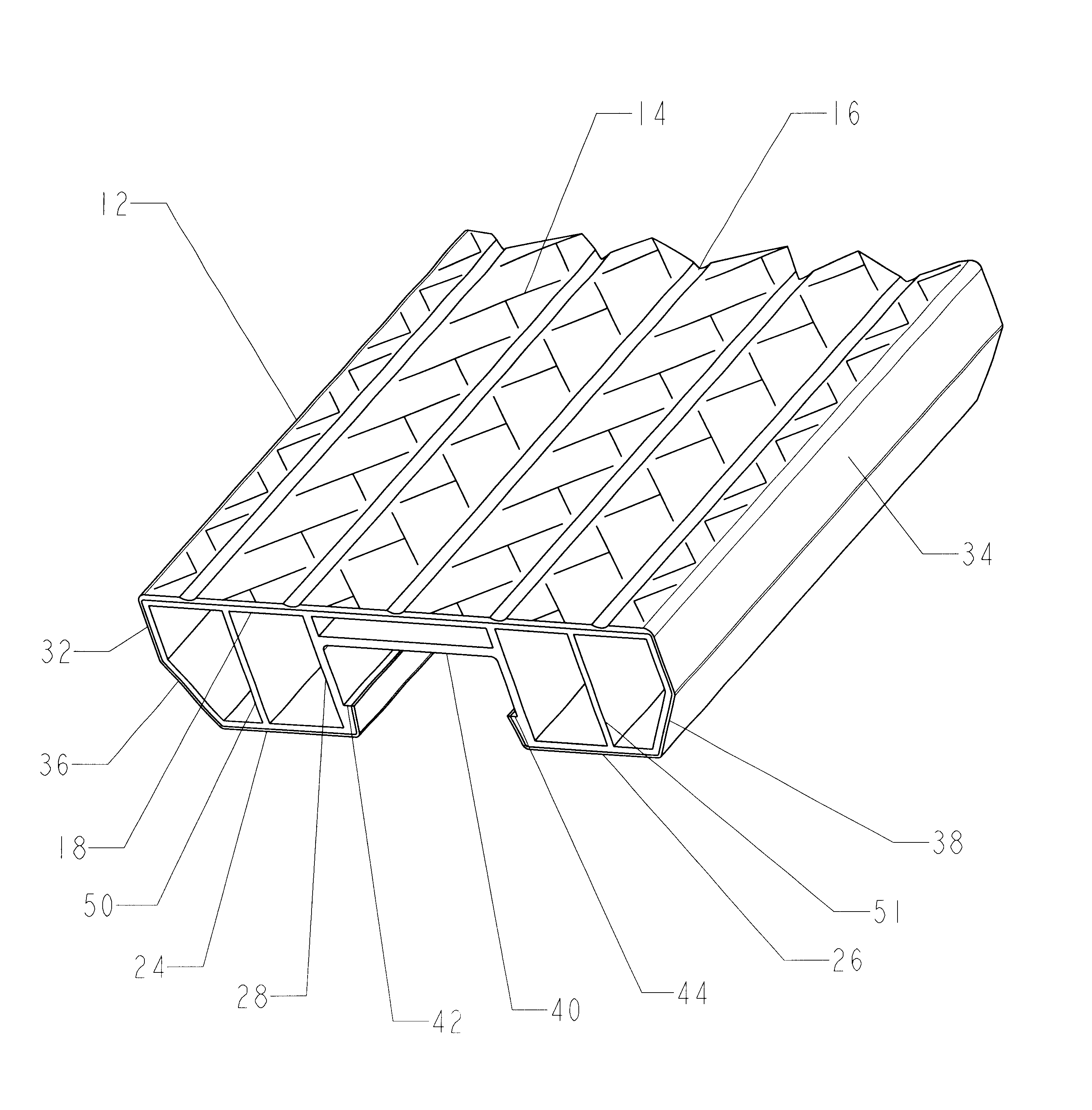

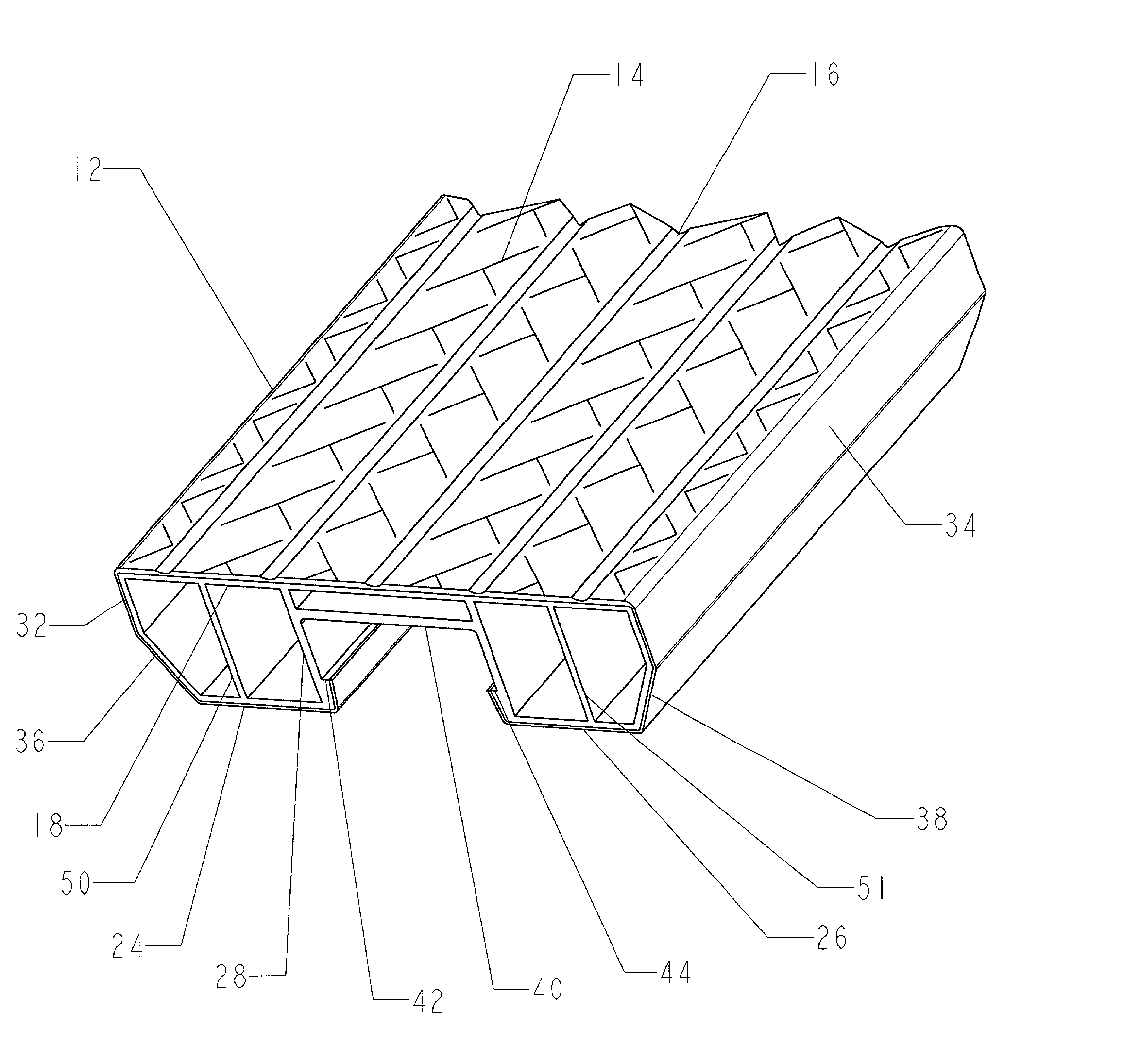

Deck plank extrusion and retaining clip

A deck plank (12) readily attaches to an engagement clip (46) when force is applied over the plank. When a plurality of clips are attached to underlying joists in parallel with the joists, and a plurality of deck planks are oriented to the clip perpendicular to the joist and pushed down over clips, a secure deck structure is provided. Each clip has a pair of horizontal flanges (52 and 54), which snap over a plurality of ledges (42 and 44) in a channel under each plank. The deck planks (12) are embossed (14) so as to form a slip resistant surface to be walked upon. The plastic extruded deck plank (12) resists rot, deterioration and insect infection found in current wood products. The deck plank assembly is simple enough so that a homeowner or do-it-yourselfer can install or alter it with minimal effort and direction.

Owner:LEINES RICHARD ALAN

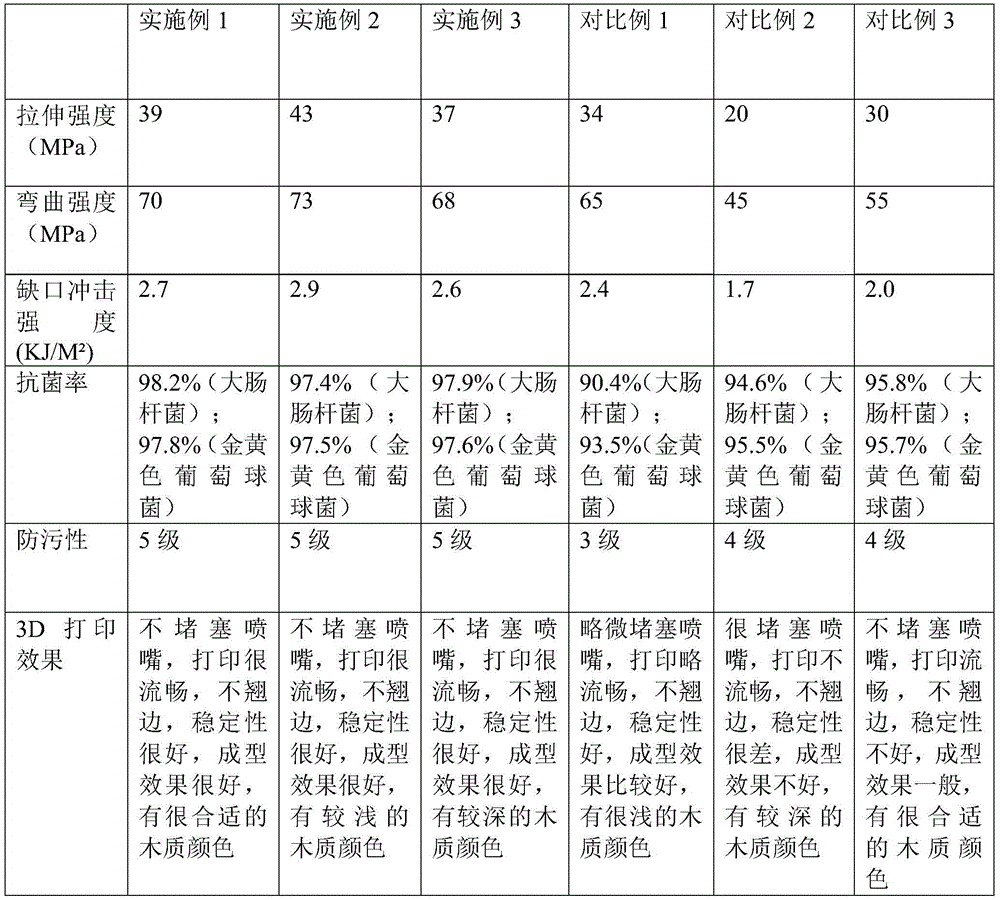

Modified polylactic acid compound 3D printing material with wood property, as well as preparation method and application thereof

The invention discloses a modified polylactic acid compound 3D printing material with wood property, as well as a preparation method and application thereof. The printing material is prepared from the following components in parts by mass: 70-90 parts of a polylactic acid raw material, 7.5-20.5 parts of alkali-treated wood powdered particles, 1-3 parts of a silane coupling agent, 1-5 parts of a thermoplastic elastomer and 0.5-1.5 parts of a nano-antibacterial agent. The preparation method comprises the following steps: mixing the raw materials; cooling and molding the melt extruded by a single-screw plastic extruder; and drying, drawing and winding to obtain the printing material. The printing material has excellent toughness and mechanical performance, has texture, color and smell of woods, and can be used for improving the phenomenon that the end cap is easily blocked by wood powder and expanding the optional varieties of wood powder, so that the printing material can be used for printing wood-like furniture products; and the self-cleaning antibacterial capability of wood-plastic materials is increased, and the environmental-friendliness performance of furniture products printed by the materials can be greatly improved.

Owner:GUANGZHOU FEISHENG HIGH POLYMER MATERIAL CO LTD +1

High-light ABS alloy and method for producing the same

The invention discloses a high light ABS alloy and a preparation method thereof. The high light ABS alloy comprises the components with the weight percentage as follows: 30-60 percent of ABS, 20-30 percent of PMMA, 10-25 percent of AS, 1-15 percent of toughener, 1-3 percent of black master and 0.3-0.6 percent of lubricant. The material has high impact strength, high modulus, high rigidity, high surface glossiness and good surface scratch-resistance, preserves the good processability and toughness of ABS and also has the advantages of the excellent weatherability, surface rigidity, and glossiness and the like of PMMA and AS, so the ABS alloy has the weatherability, the surface scratch-resistance and the glossiness far better than the ordinary ABS material. The high light ABS alloy has the low content of the PMMA and can reduce the production cost. The preparation method comprises the technical steps as follows: firstly, the raw materials are mixed in proportion as above and then are put into a plastic extruder to be granulated at the temperature controlled within 185 DEG C to 220 DEG C; and the high light ABS alloy is obtained.

Owner:徐东

Wood-plastic material and producing method thereof

The present invention relates to one kind of wood-plastic material and its production process. The wood-plastic material consists of plastic 29-70 wt%, wood fiber 28-69 wt%, cross-linking agent 1-2 wt%, and coupling agent 1-2 wt%. The plastic may be high pressure polyethylene, low pressure polyethylene, non-toxic polyvinyl chloride and polypropylene; and the wood fiber may be plant root, branch, leaf, bark, peanut shell, wheat straw and sawdust. Its production process includes the following steps: 1. washing waste plastic and wood fiber, stoving and crushing; and 2. heating to 160-200 deg.c in an extruder and extruding to form plate and other shaped material. The wood-plastic material has the advantages of non-solubility, high ageing resistance, good machinability, etc and may be used to replace wood, steel and non-ferrous metal. The production process has waste utilized.

Owner:李大正

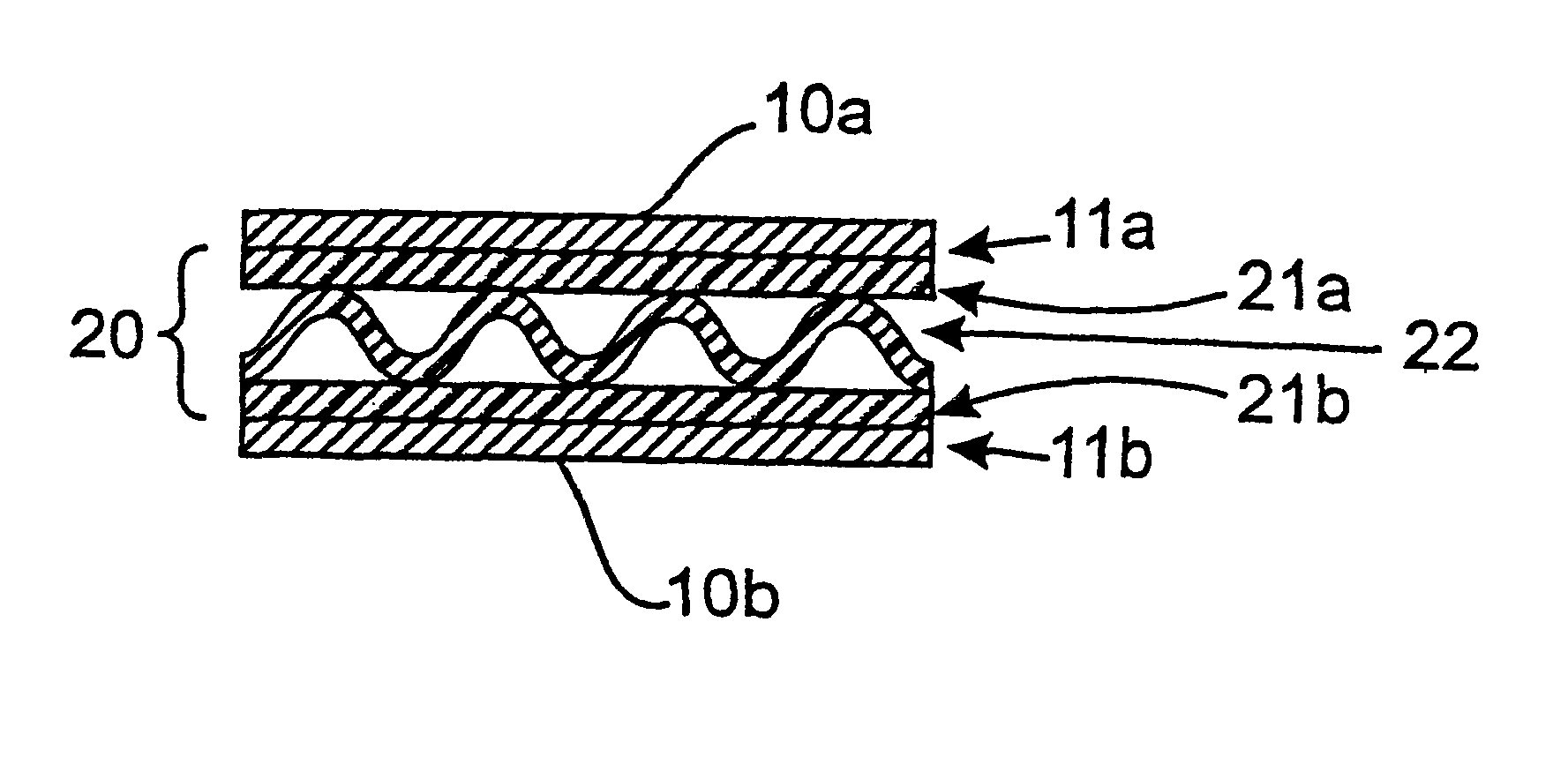

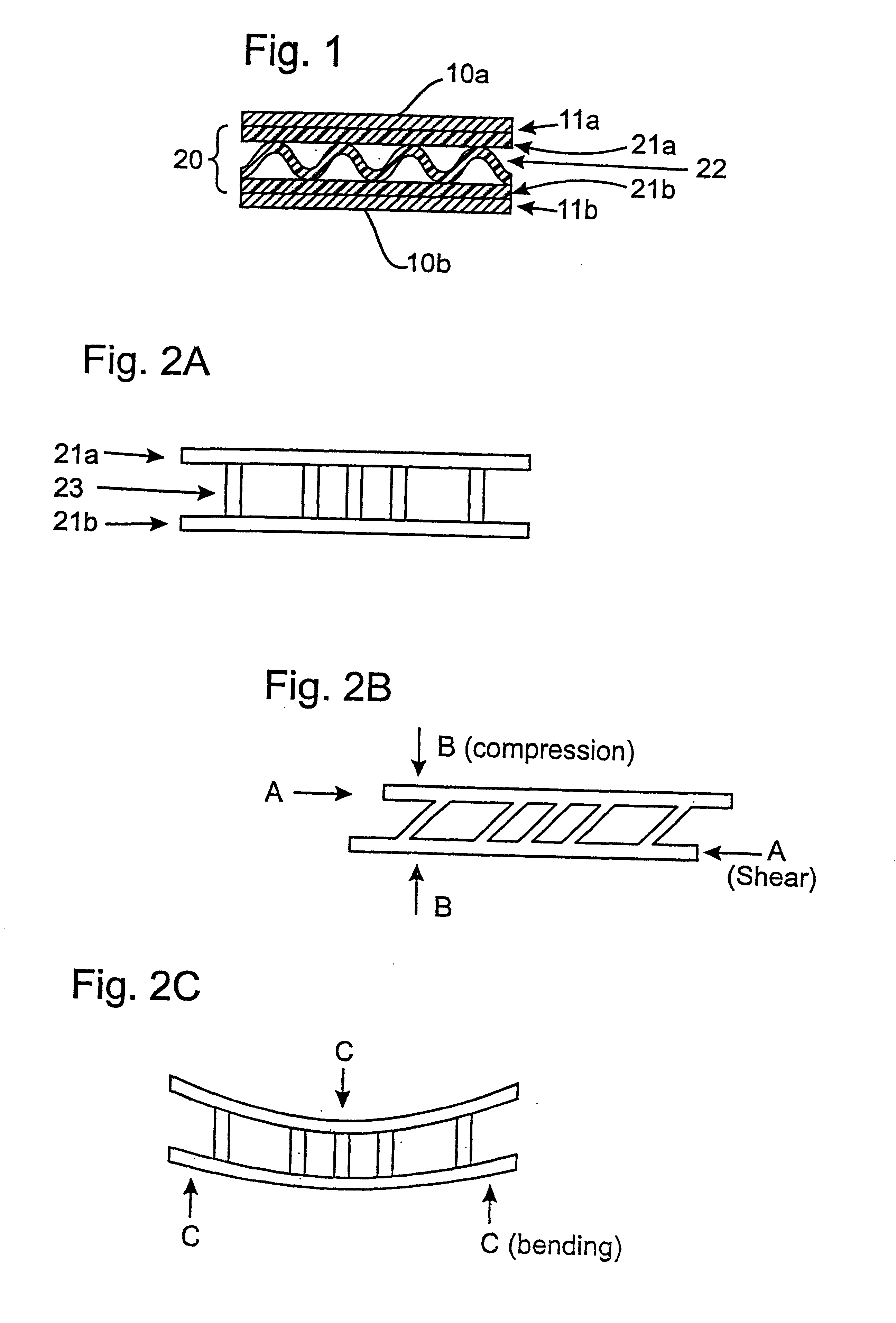

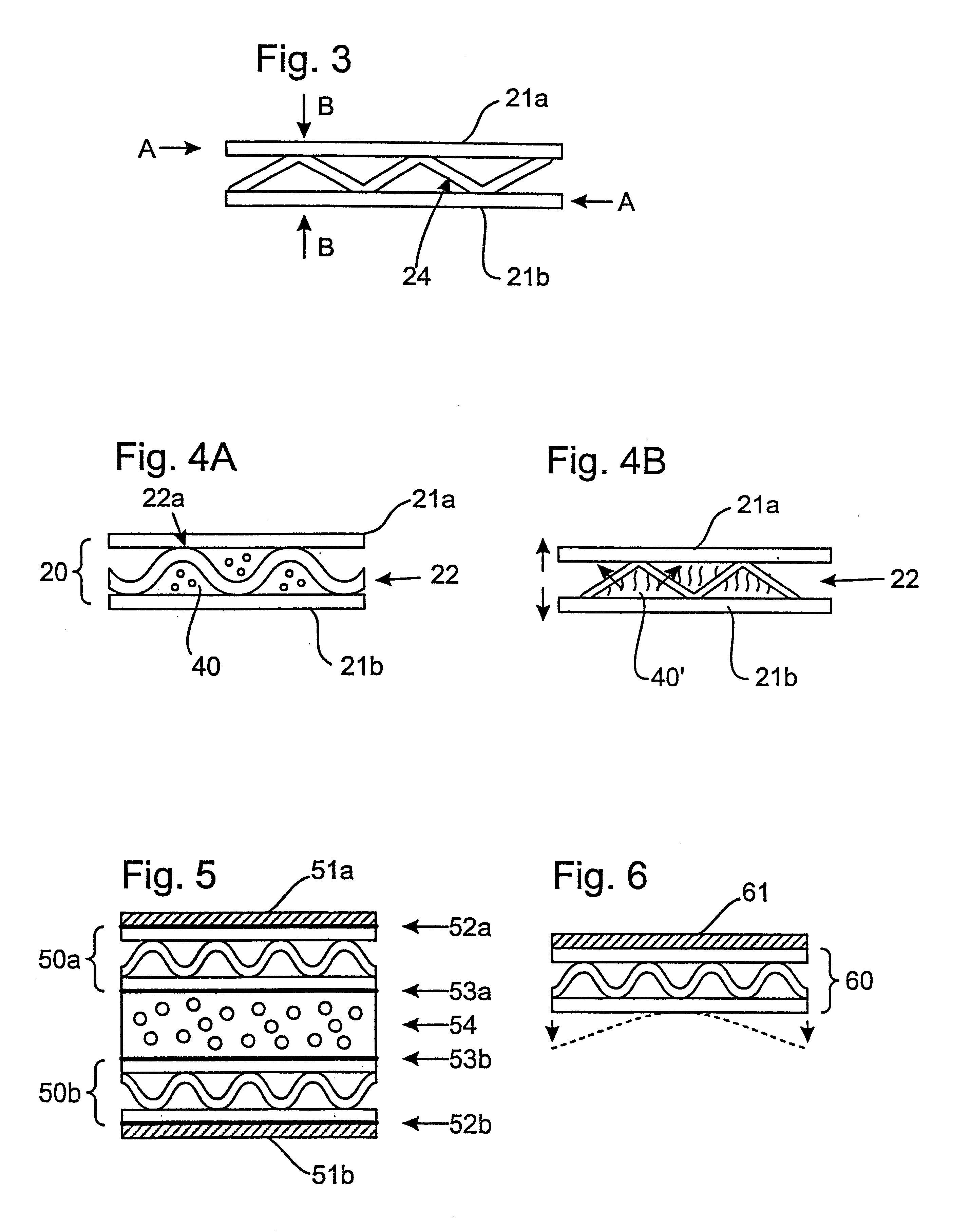

Structural panels with metal faces and corrugated plastic core

InactiveUSRE38508E1Easy to makeImprove overall utilizationMechanical working/deformationCovering/liningsThermal expansionFace sheet

A structural panel has one or more face sheets bonded by adhesive layers to a core body having two outer plastic liner sheets fusion-bonded to linear ends of inner plastic truss elements spaced apart with open spaces therebetween extending in a plane direction of the plastic liner sheets. The sheet-to-sheet adhesive bonding provides a high-strength laminate bonding that is very resistant to delamination, simple and inexpensive, and can be carried out by a preferred continuous sheet bonding technique. The all-plastic core body is highly resistant to moisture attack, and the open spaces between truss elements provide flexibility to accommodate thermal expansion and contraction. The truss construction of the core body provides high compressive and shear strength, while minimizing the amount of material required to be used. In one preferred embodiment, two metal face sheets are used, and the core body has plastic liner sheets fusion-bonded to a corrugated plastic core sheet. The corrugated plastic core sheet can be formed by a continuous plastic extrusion technique. Diagonal plastic webs or perpendicular plastic I-beams may also be used for the truss elements. Another preferred embodiment has two metal face sheets bonded to two plastic core bodies which in turn are bonded to a center foam core layer. A further embodiment has only one metal face sheet bonded to one side of the plastic core body, allowing it to be used as veneer or curved around rounded structures.

Owner:LAMINATORS

A long-term, high-efficiency termite bait and its manufacturing method

InactiveCN102258061ALong-term preventionLong-term booby trapBiocidePest attractantsDecoyPreservative

The termite bait and its manufacturing method of the present invention include adhesive ingredients, waterproof ingredients, attracting ingredients, oily termiticides, termite pheromones and preservatives in the formula, and the manufacturing method is to dry, pulverize and mix the raw materials in the formula A plastic extruder integrating heating, hot-melt mixing and pressurization is selected. After heating, hot-melt mixing, pressurized extrusion, cooling and shearing. The termite bait product of the present invention has the advantages of termites like to eat, good combination, suitable density, waterproof, anti-corrosion and good loss resistance. It can achieve long-term and long-term prevention and trapping of termites for several years.

Owner:刘川

Method for producing polystyrene extruded sheet with compressive strength larger than 700 kPa

InactiveCN101890782AReasonable productivityReasonable design processFlat articlesPolymer scienceFire retardant

The invention relates to a method for producing a polystyrene extruded sheet with compressive strength larger than 700 kPa, in particular to a production formula and a process method for high-strength polystyrene extruded sheet (XPS) with compressive strength larger than 700 kPa. The method for producing the polystyrene extruded sheet with the compressive strength larger than 700 kPa of the invention is characterized by comprising the following steps: taking general purpose polystyrene (GPPS), high impact polystyrene (HIPS), a foaming agent, a nucleating agent, color master batches and a fire retardant in certain weight proportion as raw materials; utilizing a plastic extruding machine 1 to heat the raw materials so as to melt and mix polystyrene materials to form polymer melt; utilizing a plastic extruding machine 2 and a static mixer or a heat exchanger to carrying out mixing and cooling; enabling cooled gel to enter into a pressure lowered or decreased area through a die to form a foaming structure; leveling and typing by utilizing a bump-cutter machine; cooling by utilizing a cooling fan; and removing edges and carrying out fix-length cutting to prepare the high-strength polystyrene extruded sheet (XPS) with the compressive strength larger than 700 kPa.

Owner:南京法宁格节能科技股份有限公司

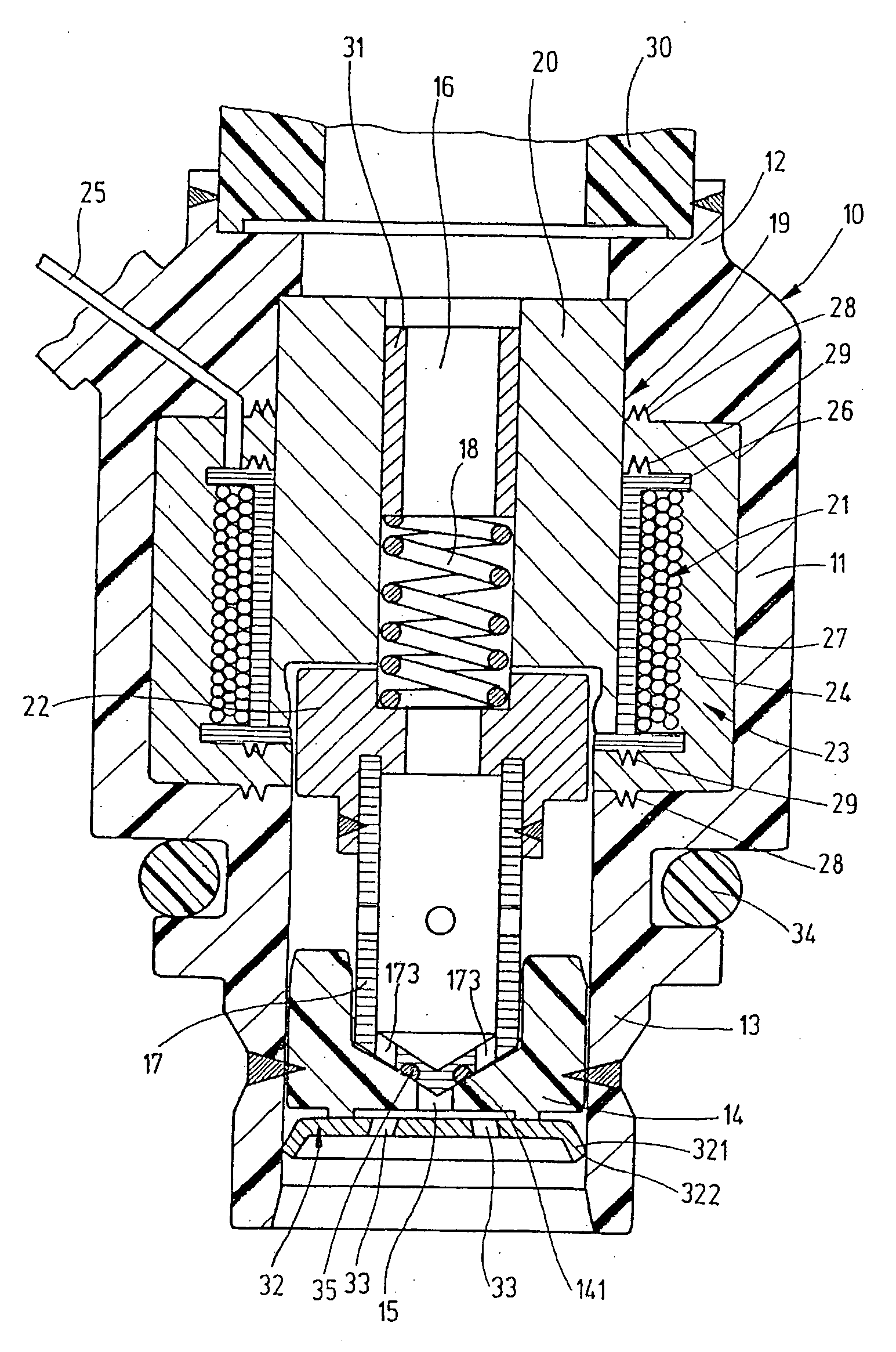

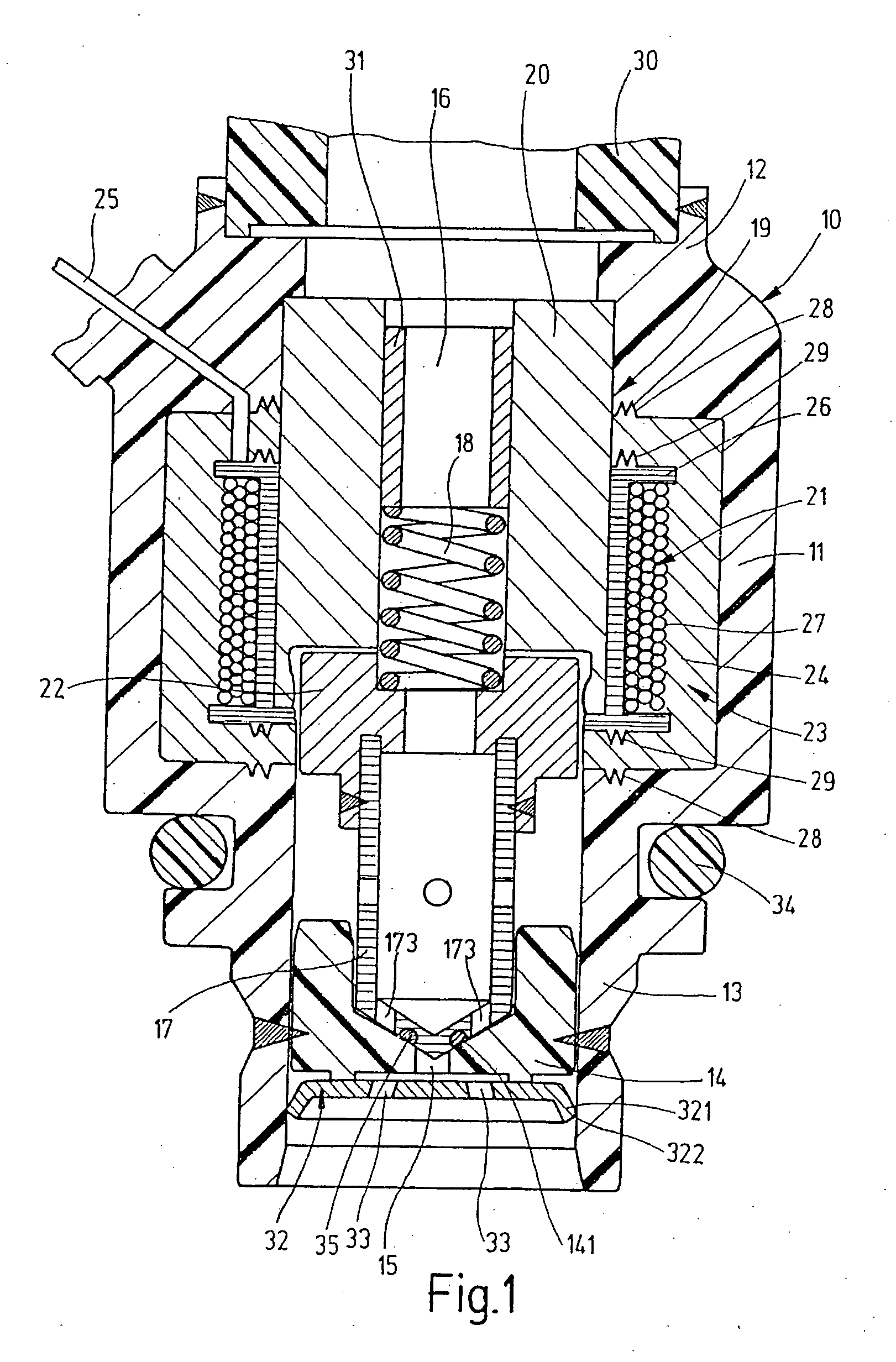

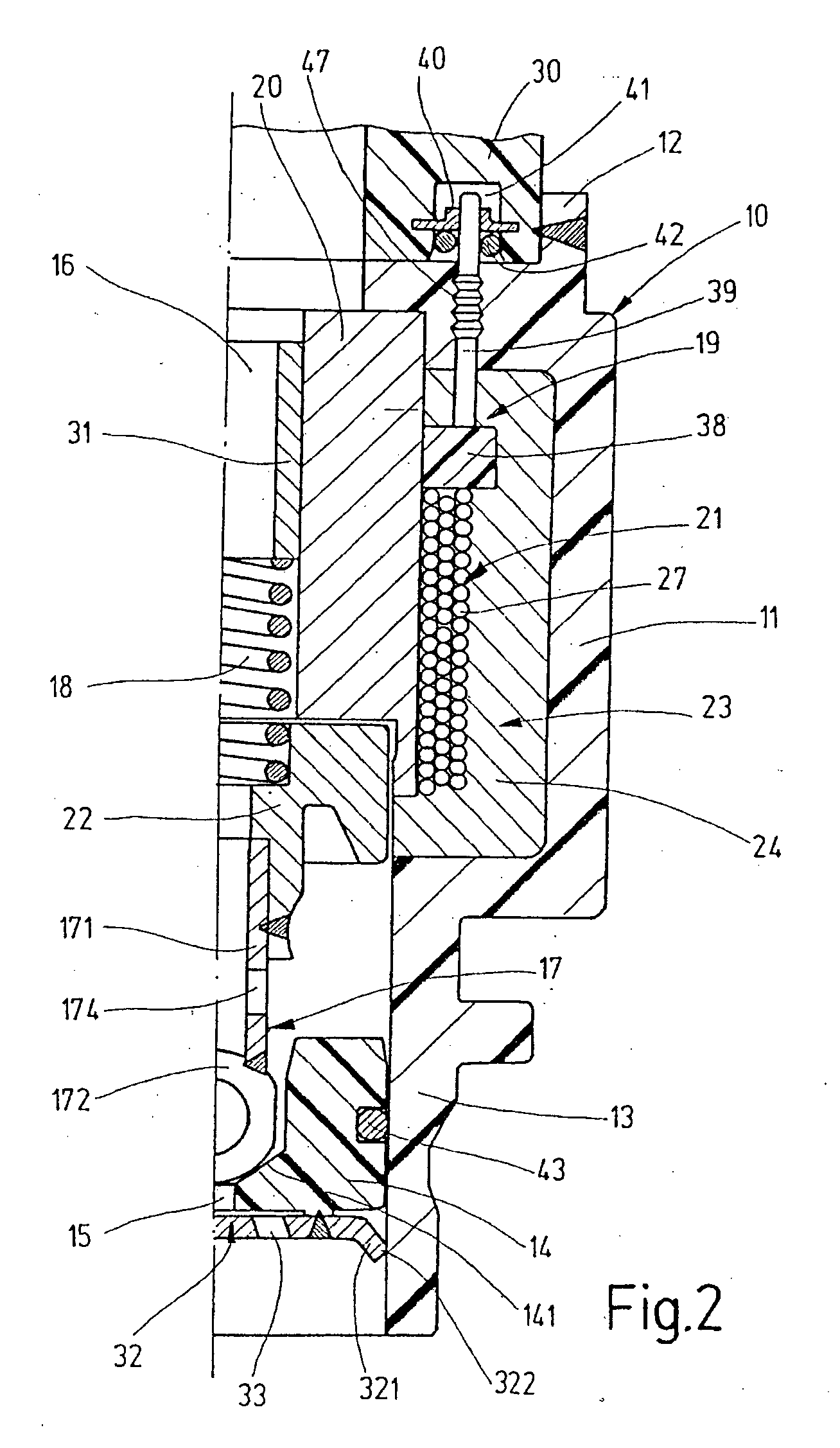

Injection Valve for Fuel Injection

InactiveUS20080061171A1Less complicated and cost-effective manufactureSimple methodOperating means/releasing devices for valvesSealing arrangements for enginesEngineeringFuel supply

A fuel injection valve has a connection piece for a fuel-supply line, a valve-seat support having a valve-seat body provided with a valve opening, a solenoid for activating a valve member, which controls the valve opening, and a plastic extrusion coat enclosing the connection piece, the solenoid and the valve-seat support. To achieve a cost-effective manufacture by requiring fewer components for the injection valve and providing a reduction in the assembly costs, the connection piece and the valve-seat support are made of plastic and designed as one-piece plastic housing together with the plastic extrusion coat. The yoke element for closing the magnetic circuit of the solenoid, which extends across the magnetic core and magnetic armature, is a magnetic material extrusion coat, which encloses the solenoid coil and adjoins the magnetic core in a gapless manner and ends in front of the magnetic armature with a gap clearance.

Owner:ROBERT BOSCH GMBH

Production method for solid castoff composite multi-story building template

InactiveCN101429813AAvoid the disadvantages of prone to dentsGood dimensional stabilitySolid waste managementLaminationSurface finishSurface layer

The invention provides a method for preparing a solid waste composite multi-layer building formwork. The method comprises the following steps: wood powder, wood chips or sawdust and waste plastic are extruded and made into a wood plastic mixture which is used as an intermediate material of a product; the waste plastic and pulverized fuel ash are extruded and made into a plastic ash mixture which is used as a surface layer material of the product; and then a mold pressing or coextrusion method is adopted to obtain a novel composite board product with a wood plastic material as an intermediate layer and a plastic ash material as two outer layers. The compression strength of the prepared product can reach between 22 and 36MPa, the bending strength is between 15 and 28MPa, the bending modulus is between 450 and 980MPa, the breaking elongation rate is between 80 and 300 percent, the oxygen index is more than or equal to 25, the usage temperature is between 20 DEG C below zero and 55 DEG C, and the product has good mildew proofing, aging resistance, photodegradation resistance, wear resistance, corrosion resistance, and surface finish; and as a building formwork, the product can be repeatedly used for more than 20 times.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Antibacterial engineering plastic and its preparing method

InactiveCN101070424AHas antibacterial propertiesHas antibacterial functionTemperature controlAntioxidant

The invention discloses an antibacterial engineering plastics and preparation methods, its composition by weight ratio (%):Engineering Plastics 83-92% ; antimicrobial agent 0.3-1%; toughener 6-10%; dispersant 0.5-1% white oil 0.5- 2% ;antioxidant 0.2-0.6% and other additives 0.1-3 %.The invention using engineering plastics PC, PC / ABS alloy as the mainstay and high temperature processing can be added containing silver ion antimicrobial agent, plasticizer, antioxidants and other chemicals, by melt blending, extrusion and granulation. The function of these engineering plastics is to maintain lasting antibacterial, keep a good performance of the materials' physical and mechanical and have a simply process. The process of manufacturing the antibacterial engineering plastics have some steps as following.First of all, raw materials will be mixed according to the above ratio, and then enter the plastic extrusion machine, the temperature controlled at 220 -250 degree C and then granuled to get the antibacterial engineering plastics.

Owner:SHENZHEN KEJU NEW MATERIAL

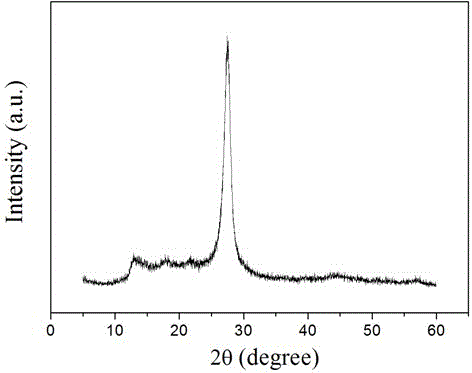

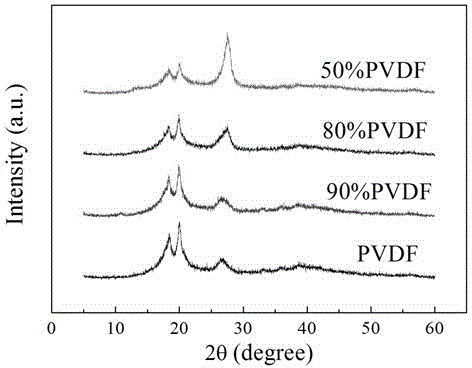

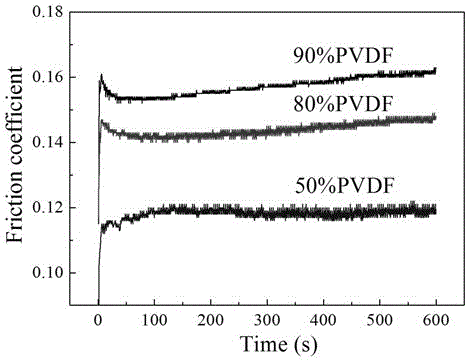

Graphite-like carbon nitride/polyvinylidene fluoride composite material and preparation method thereof

InactiveCN104017313AImprove tribological performanceImprove the interface binding forceChemical stabilityMechanical property

The invention discloses a graphite-like carbon nitride / polyvinylidene fluoride composite material and a preparation method thereof. The composite material comprises 50-99wt% of polymer matrix polyvinylidene fluoride (PVDF), and 1-50wt% of graphite-like carbon nitride g-C3N4 processed by a surface modifier. The preparation method of the composite material comprises the following steps: preparing the graphite-like carbon nitride g-C3N4, processing a packing surface, mixing two powdery raw materials in a liquid phase and carrying out quick agitation and drying treatment, hot press molding or plastic extrusion molding. Compared with a pure polyvinylidene fluoride material, the graphite-like carbon nitride / polyvinylidene fluoride composite material has the advantages that the heat stability, the chemical stability and the mechanical property of the material can be effectively improved when the tribological property is greatly improved, the coefficient of linear expansion of the material is reduced, the barrier property of the material is improved, and the graphite-like carbon nitride / polyvinylidene fluoride composite material is widely applied to the industries such as space flight and aviation, electrics, microelectronics and automobiles.

Owner:JIANGSU UNIV

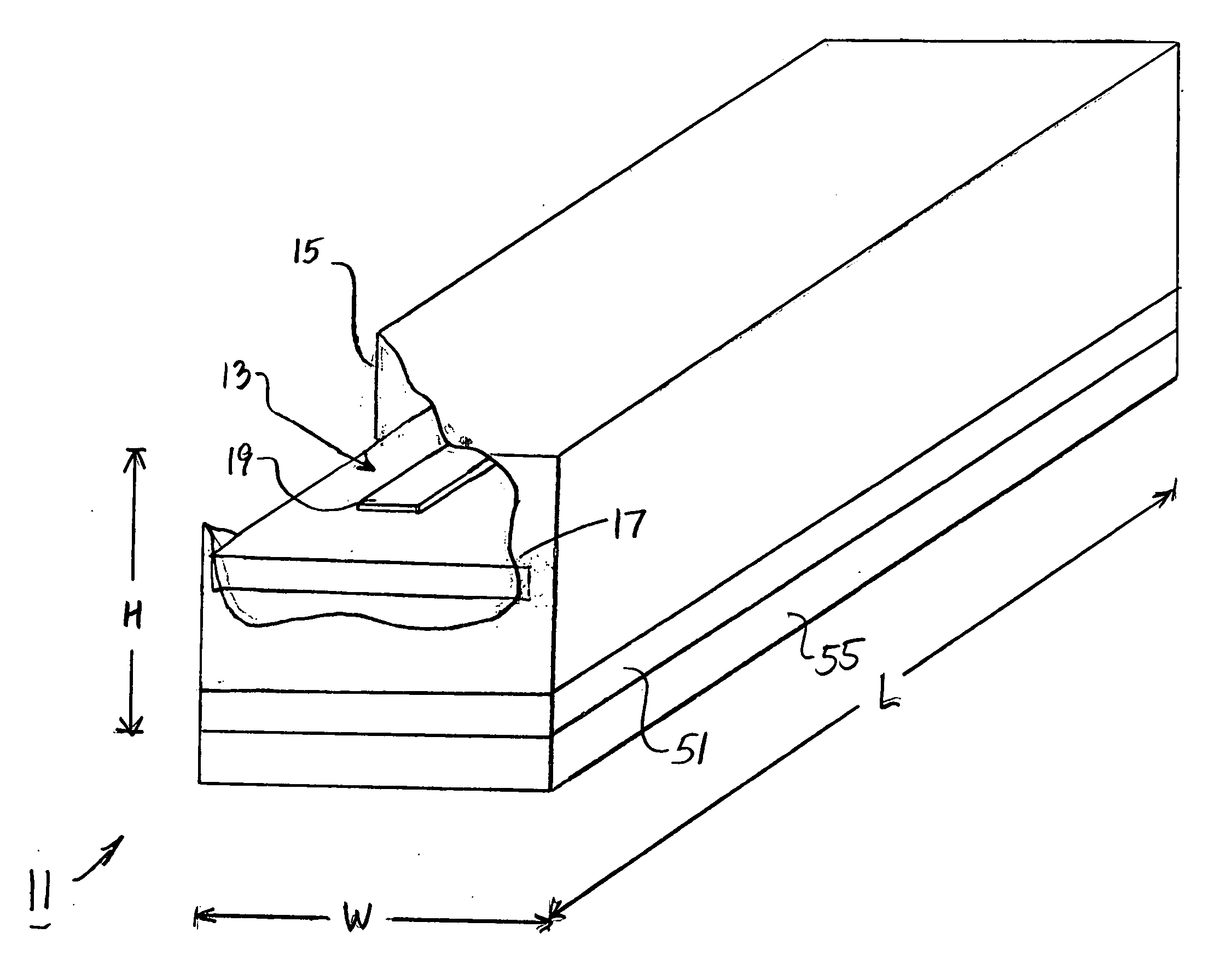

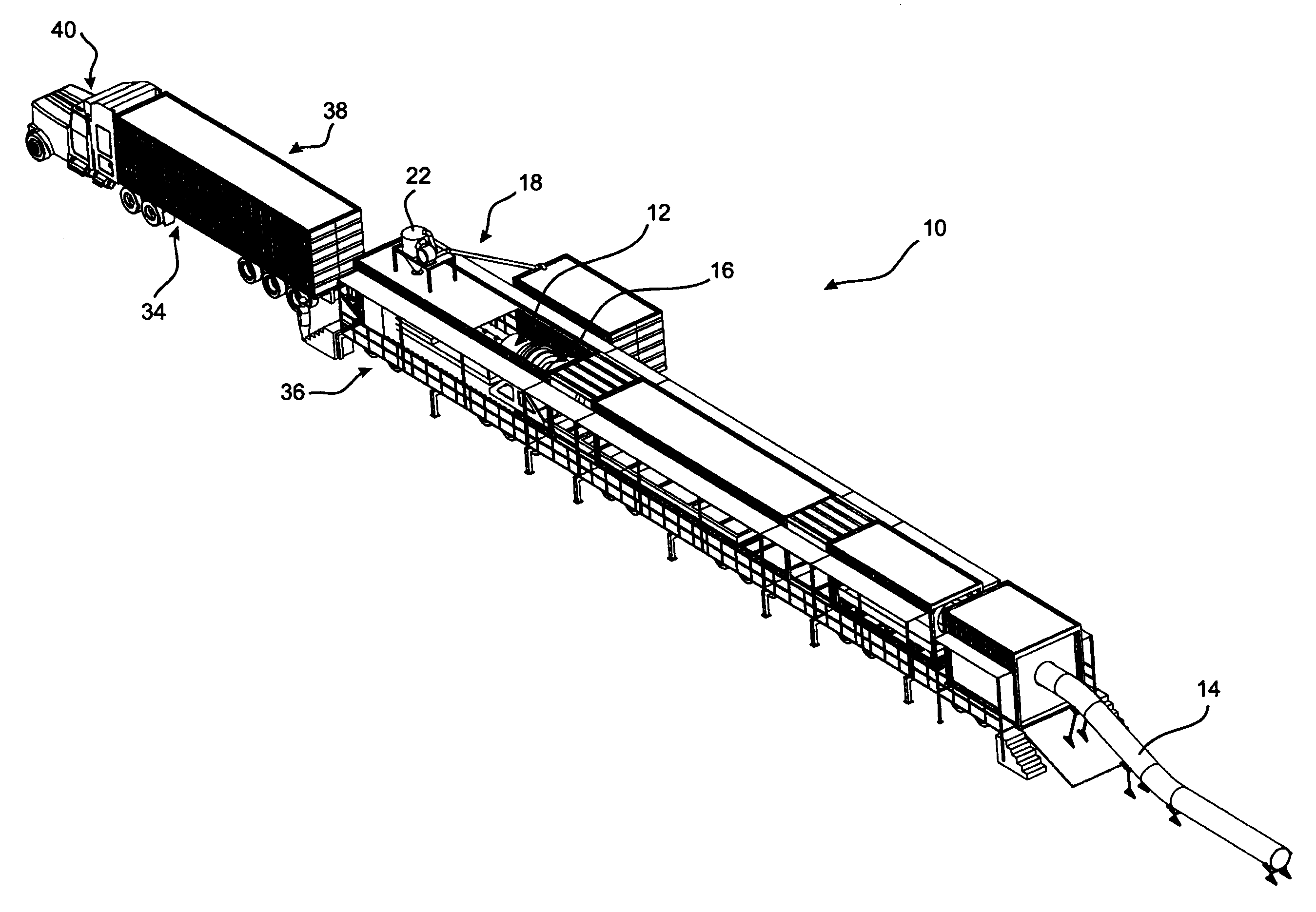

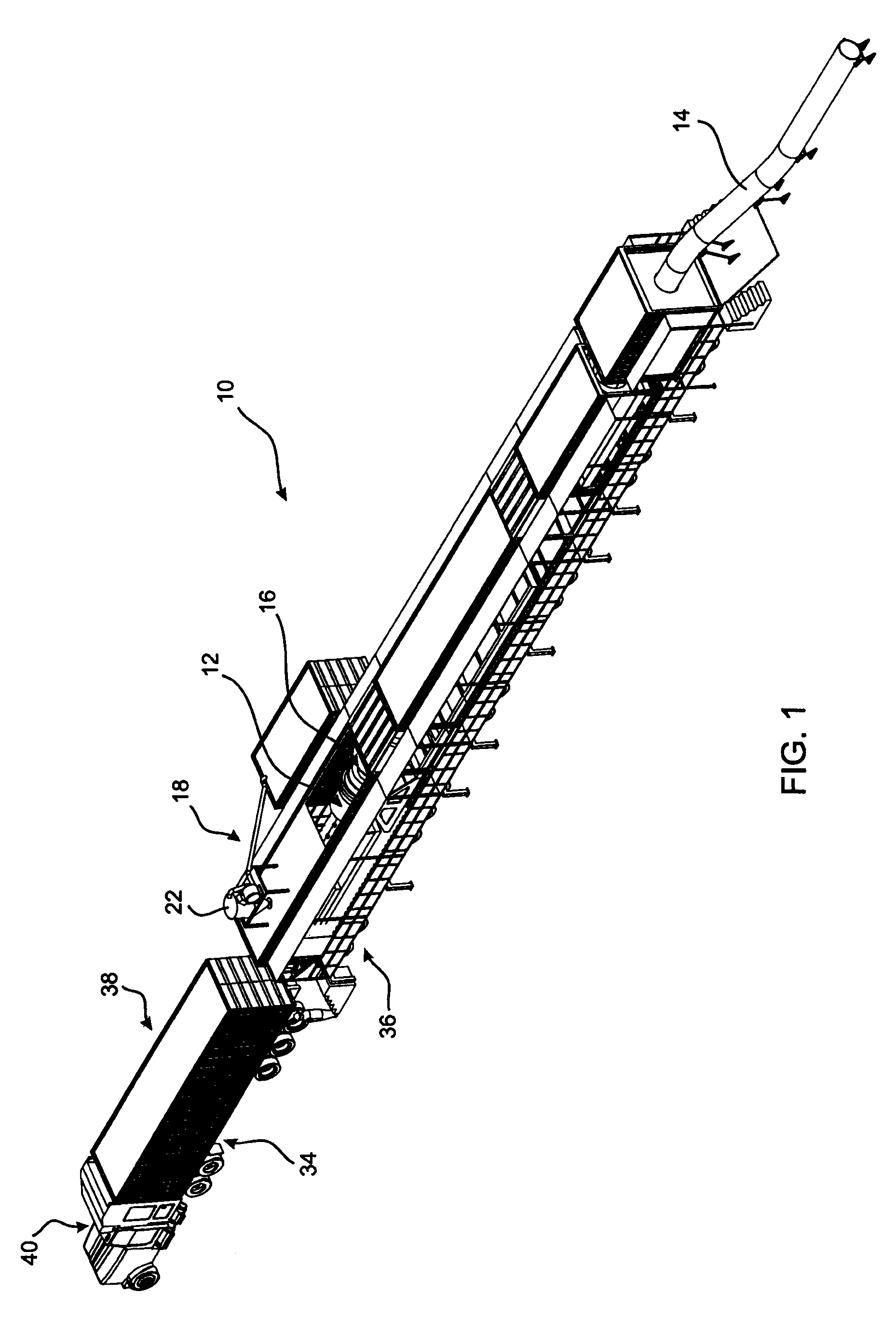

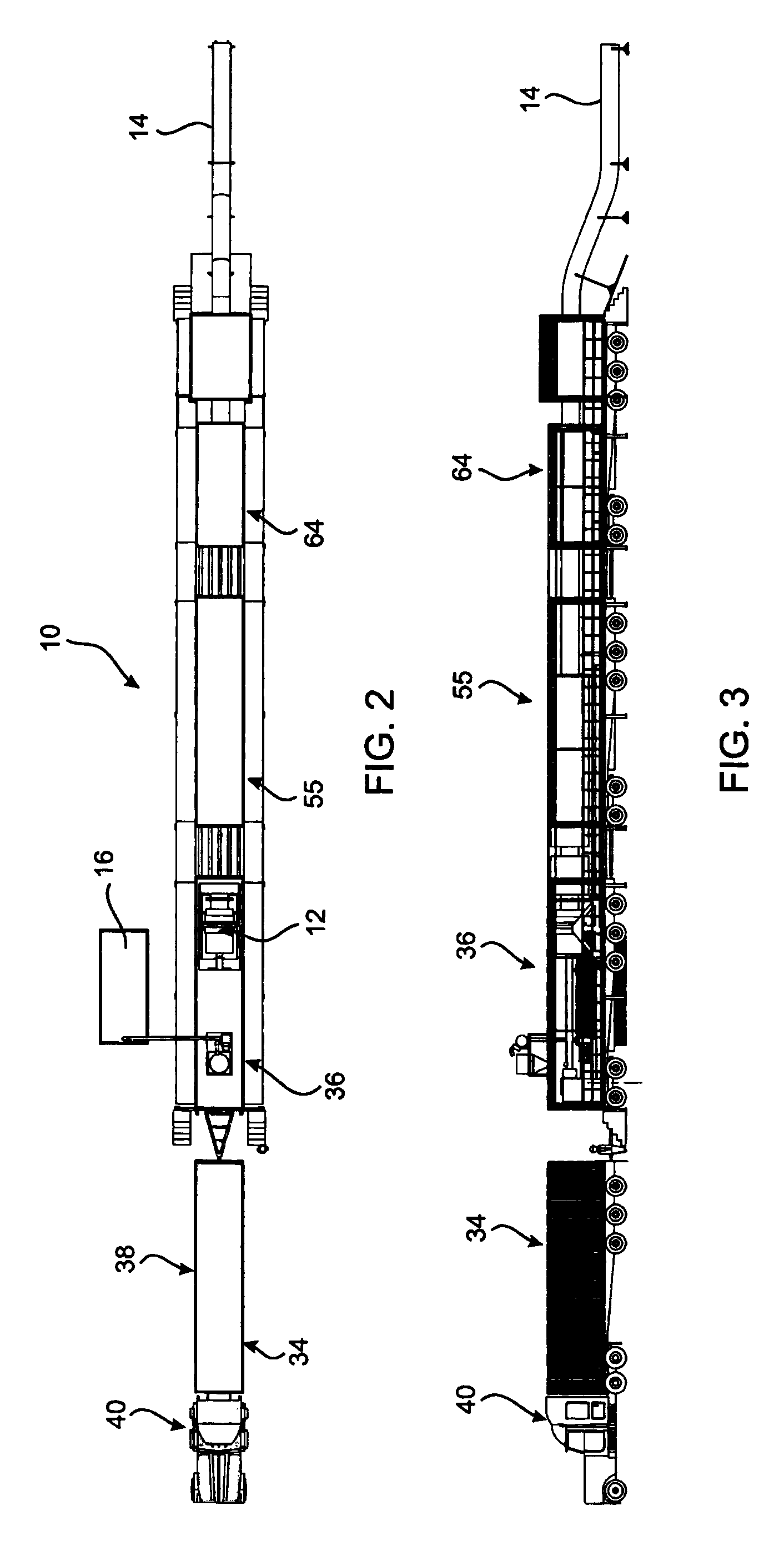

Mobile plastics extrusion plant

A mobile plastics extrusion plant 10 for manufacturing an extruded plastics product in a remote location. The mobile plant 10 comprises the following components: a transportable container 16 for storing raw plastics material prior to extrusion, and a transportable extruded product forming assembly (in the form of a die and former assembly 12) for forming an extruded plastics product from the raw plastics material. The mobile extrusion plant 10 further comprises a transportable delivery system 18 for delivering the raw plastics material from the transportable container 16 to the die and former assembly 12 whereby, in use, the entire plant can be transported to a remote location and operated to manufacture an extruded plastics product.

Owner:POLYLINE PIPE SYST LTD

RFID tag and method of manufacturing the same

ActiveUS7755484B2Improve throughputSolid-state devicesRecord carriers used with machinesEngineeringRadio frequency

A radio frequency identification (RFID) tag and method of manufacturing the same. In a preferred embodiment, the RFID tag includes a radio frequency (RF) inlay, the RF inlay including a carrier sheet, an antenna printed on the carrier sheet and a wireless communication device bonded to the antenna. The RFID tag also includes a plastic extrudate, the RF inlay being disposed within the extrudate so that the antenna and the wireless communication device are encapsulated on all sides within the extrudate. Optional metallic reflector and mounting adhesive layers may be laminated onto the underside of the extrudate. The present invention is also directed to an automated method for manufacturing the above RFID tag, such a method involving, in one embodiment, feeding a continuous supply of RF inlays into a cross-head extruder to yield a continuously extruded block and then cutting the block between successive antennae to yield a plurality of individual RFID tags.

Owner:CASCADE ENG

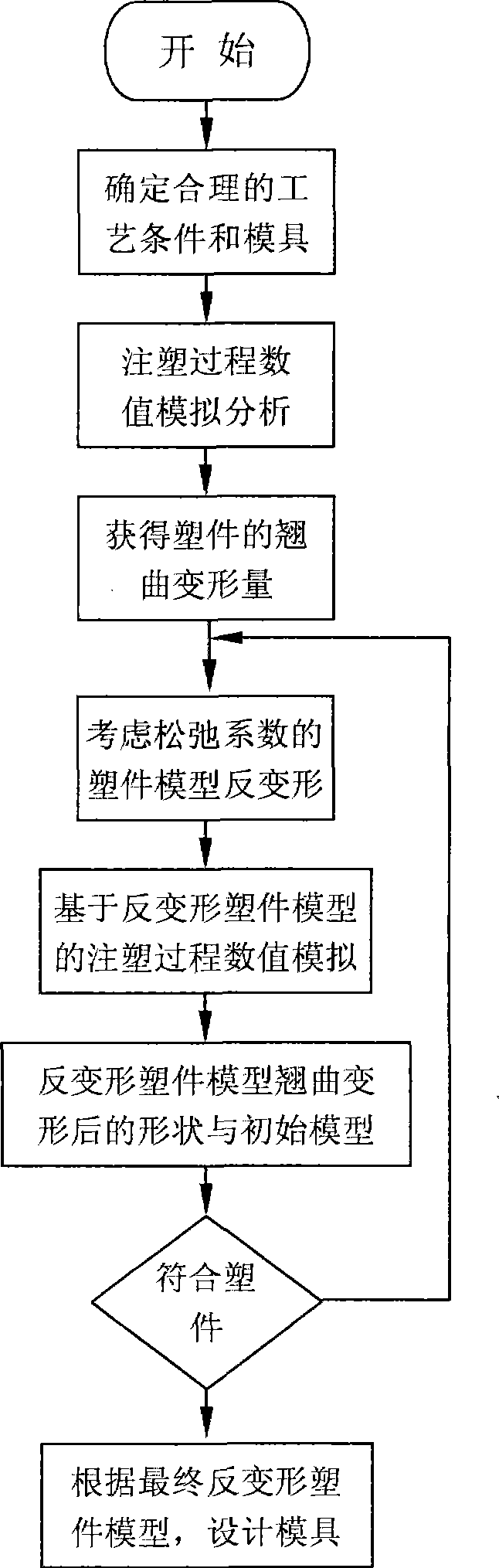

Method for designing mould cavity

InactiveCN101075269AShorten the manufacturing cycleReduce the number of trialsSpecial data processing applicationsEngineeringInjection moulding

A method for designing die cavity of mould includes utilizing value analog software to carry out value analog analysis of plastic extrusion process to obtain warping deformation distribution on plastic component after lattice node is made on initial plastic component model when process condition of preparing plastic component and mould structure are confirmed, making reverse deformation treatment on original model of plastic component according to warping deformation amount at each node position till final deformation proof model of plastic component in according with accurate requirement is obtained then designing die cavity of mould as per final deformation proof mode.

Owner:QINGDAO BEIDOUXINGKONG ELECTRONICS TECH

Quick change system for interchanging molds on extrusion blow molding machines

A quick change system and method of interchanging molds on plastic extrusion blow molding machines is disclosed wherein a universal standard subplate is provided for use with different blow molding machines on which a variety of different mold units are removably mounted on the standard subplate with the subplate establishing a preselected precisely aligned relation automatically between the mold unit and a machine platen. A quick release locking device is provided between each mold unit and a unitary standard water manifold and detabber assembly. The unitary standard assembly is provided as a one-piece component with fluid connections communicating respectively with water and air supply sources of the water manifold and detabber and which are conveniently maintained attached without being disconnected during detachment of the unitary standard assembly from the mold unit during a mold change.

Owner:HEISE INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com