3D printing material having self-cleaning antibacterial function as well as preparation method and application of 3D printing material

A 3D printing and self-cleaning technology, applied in the field of 3D printing materials and preparation, can solve the problems of adverse effects on human health, no antibacterial and antifouling self-cleaning function, easy to breed bacteria, etc., achieve good self-cleaning and antifouling performance, improve Photogenerated quantum efficiency, the effect of improving surface self-cleaning and antibacterial and antibacterial functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

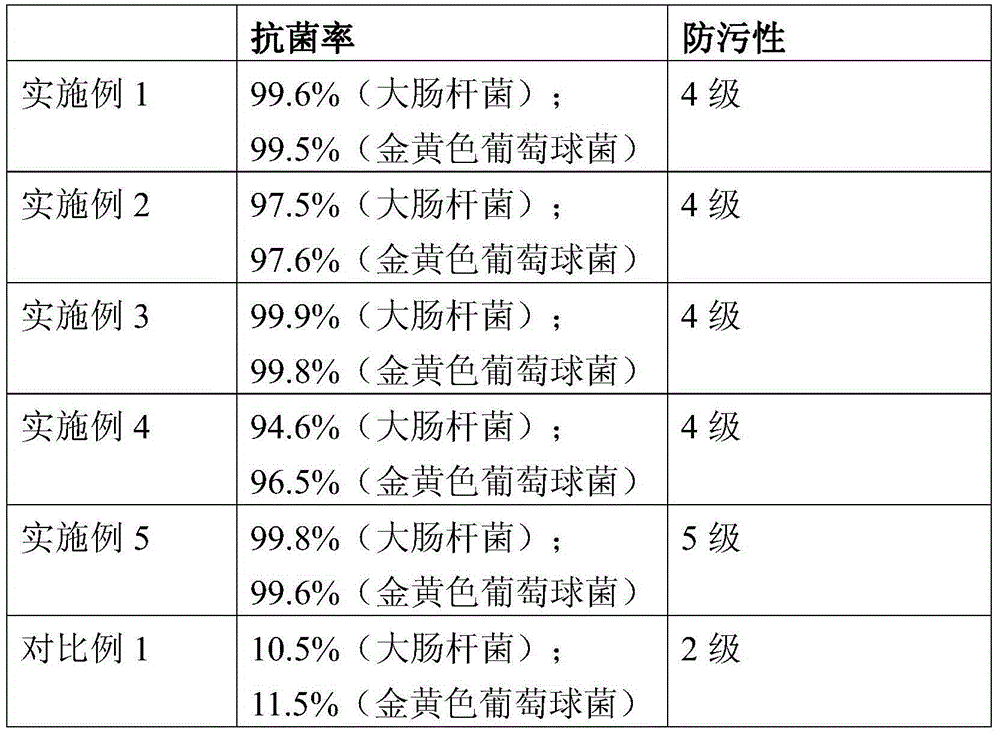

Examples

Embodiment 1

[0046] (1) Formula dosage (parts by mass): 75 parts of acrylonitrile-butadiene-styrene ternary block copolymer (ABSHAC-8250), 1.5 parts of lead chrome yellow pigment powder (average particle size: 10 μm), talcum powder (average particle size of 10 μm) 3 parts, nano-titanium dioxide (average particle size of 25 nm, anatase phase) 0.5 parts, isoprene rubber (SKI-3S) 20 parts.

[0047] (2) Preparation process: first put ABS HAC-8250 into the dryer and bake at 100°C for 3 hours to completely evaporate the water; then put each raw material into the mixer according to the formula, and set the mixer to run for 10 minutes at 100rpm; Put the uniformly mixed materials into the SJ single-screw plastic extruder. The temperature of the single-screw plastic extruder is set as: 190°C in the first zone of the machine head, 200°C in the first zone of the barrel, 207°C in the second zone of the barrel, and 207°C in the second zone of the barrel. The third zone is 201°C; the speed of the main en...

Embodiment 2

[0049](1) Formula dosage (parts by mass): 70 parts of acrylonitrile-butadiene-styrene ternary block copolymer ABS-758 (Chimei, Taiwan), 1.5 parts of iron blue powder (special for plastics, with an average particle size of 11 μm) , 3 parts of talc powder (average particle size is 10 μm), 0.5 parts of nano-silver particles (average particle size is 15 nm), 20 parts of silicone rubber (GXJ70).

[0050] (2) Preparation process: first put ABS-758 into the dryer and bake at 100°C for 2.5 hours to completely evaporate the water; then put each raw material into the mixer according to the formula, and set the mixer to run for 15 minutes at 100rpm; The uniformly mixed materials are put into the SJ single-screw plastic extruder. The temperature of the single-screw plastic extruder is set as: 190°C in the first zone of the machine head, 200°C in the first zone of the barrel, 206°C in the second zone of the barrel, and 206°C in the third zone of the barrel. zone 200°C; the speed of the mai...

Embodiment 3

[0052] (1) Formula dosage (parts by mass): 80 parts of polylactic acid PLA (2003D, NatureWorks LLC IngeoTM), 1.5 parts of iron yellow powder (special for plastics, with an average particle size of 10 μm), superfine calcium carbonate (average particle size of 0.1 μm) 3 parts, 0.5 parts of nano-titanium dioxide (model P25, Degussa), 15 parts of chlorinated butyl rubber (chlorinated butyl rubber 1240, Lanxess, Germany).

[0053] (2) Preparation process: first put PLA into the dryer and bake at 105°C for 3 hours to completely evaporate the water; then put each raw material into the mixer according to the formula, and set the mixer to run at 100rpm for 12 minutes; mix well Put the materials into the SJ single-screw plastic extruder, and the temperature of the single-screw plastic extruder is set as follows: 190°C in the first zone of the machine head, 200°C in the first zone of the barrel, 205°C in the second zone of the barrel, and 202 in the third zone of the barrel ℃; the speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com