Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Flash burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flash burn is any burn injury caused by intense flashes of light, high voltage electric current, or strong thermal radiation. These may originate from, for example, a sufficiently large BLEVE, a thermobaric weapon explosion or a nuclear blast of sufficient magnitude. Damage to the eye(s) caused by ultraviolet rays is known as photokeratitis.

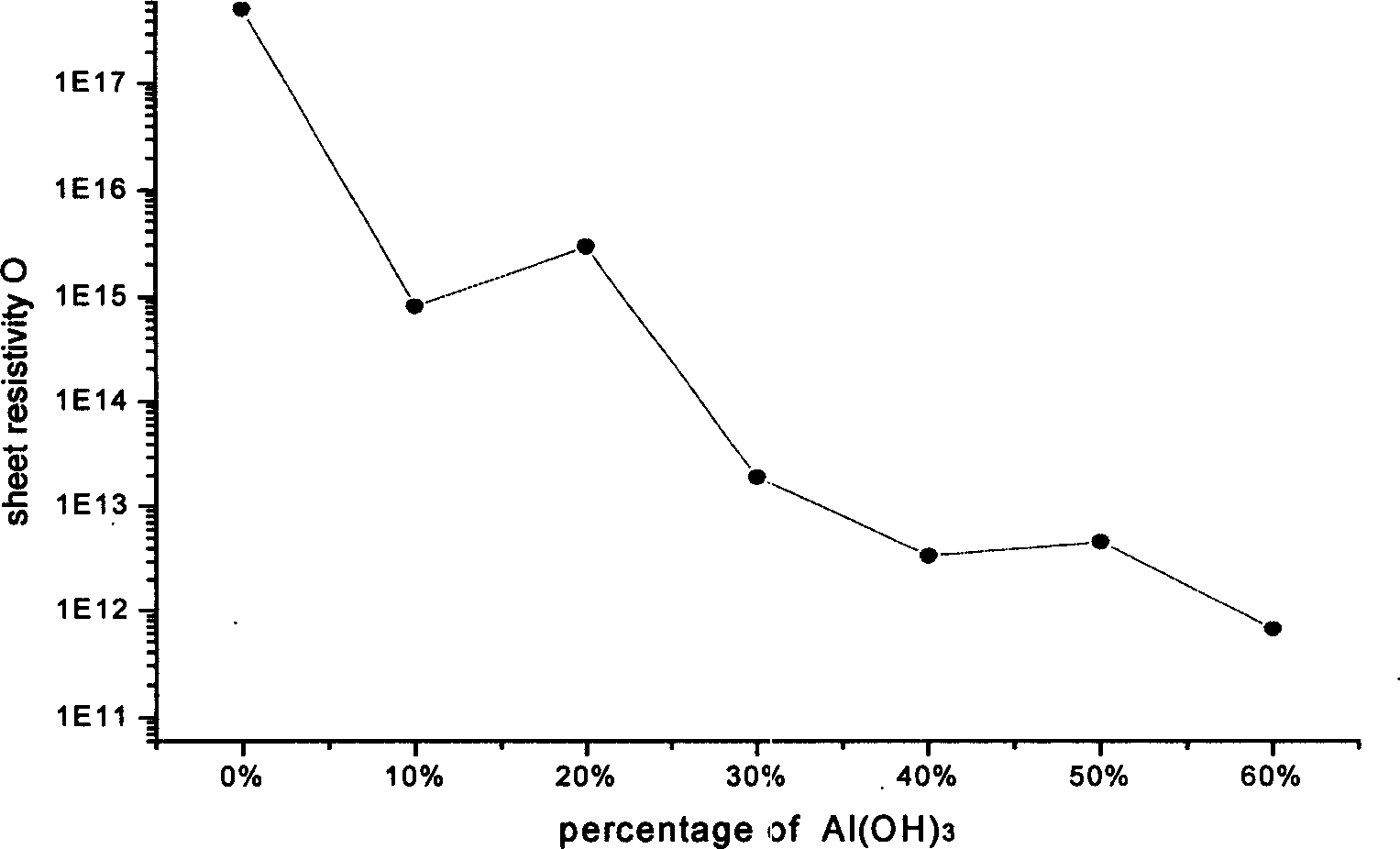

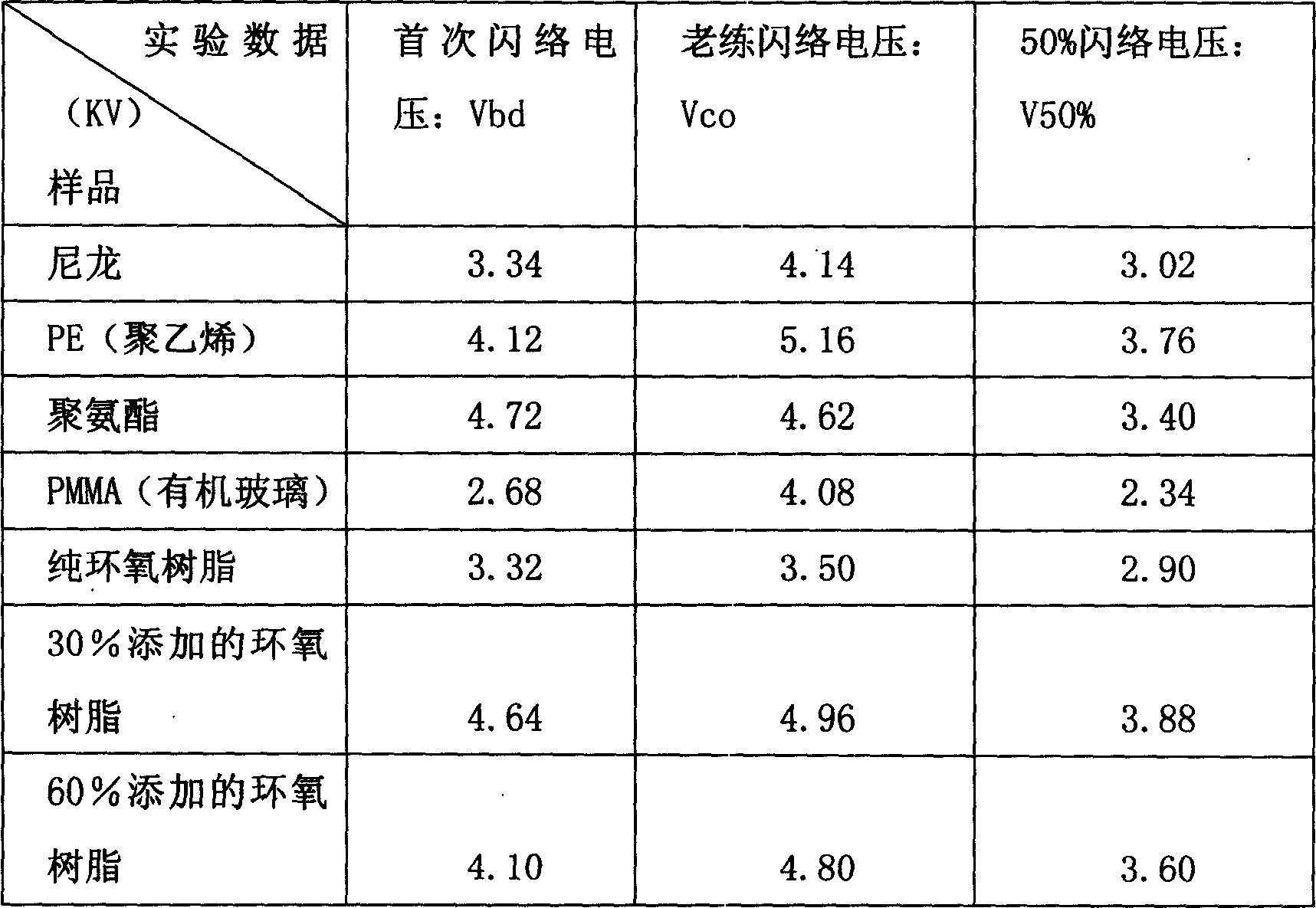

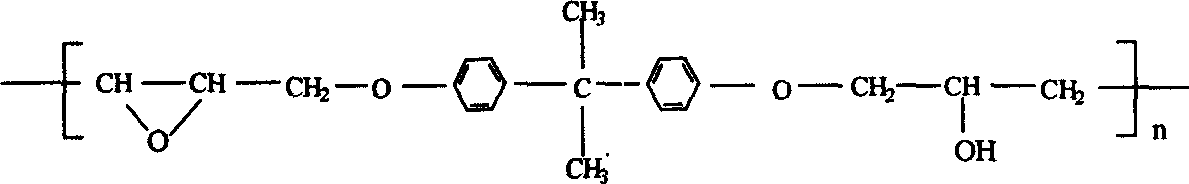

Vacuum insulator coating capable of increasing flashover voltage and method of preparation thereof

InactiveCN1604237AExcellent tracking resistanceImprove thermal conductivityPlastic/resin/waxes insulatorsFirming agentHigh surface

This invention relates to a vacuum isolation sub-coating and its process to improve the surface flashover voltage, wherein, the coating is composed of epoxide resin, aluminum hydroxide, modified synthesized amine firming agent, butyl epihydrin aether thinner. The process comprises the steps of materials, bacon, vacuum, mixture, heating and solidifying and cooling and demoulding Comparing with current material, the coating in this invention has higher surface flashover voltage and high flash burn endurance.

Owner:XI AN JIAOTONG UNIV

Preparation method of kieselguhr composite adsorbent

InactiveCN102527343ANo secondary pollutionSimple production processOther chemical processesWater/sewage treatment by sorptionSorbentBiological activation

The invention relates to a preparation method of a kieselguhr composite adsorbent. The method comprises the following steps of: crushing kieselguhr, modifying the kieselguhr through flash burning in a flash-burning kiln, and adding a foaming agent into the modified foaming agent; mixing in a high-speed mixer and adding chitosan solution; granulating with a granulator; and heating and foaming the obtained granules in an oven to obtain the finished product. In the invention, a flash-burning method is adopted for activation and modification, the sintering is uniform, the time of the flash-burning method is short, and the production efficiency is high. Chitosan has a very good chelation effect on heavy metal ions; the adsorption specific surface area is increased after foaming; since the particle sizes of the granulation are different, the densities of the finished products are different such that some of the adsorbents float on the water surface, and some are dispersed in water, and a great quantity of dye, ammonia nitrogen, surfactant and the like in the dyeing and finishing waste water can be adsorbed; and a large flocculation is formed after the adsorption, being favorable for post-processing. The kieselguhr is rich in resources and cheap; and as a low-temperature foaming agent is adopted, the foaming energy consumption and the cost of the adsorbent are low. The kieselguhr composite adsorbent is non-toxic and harmless, secondary pollution is prevented, the production technology is simple, and the cost is relatively low.

Owner:JILIN UNIV +1

Direct flash-burning molding preparation method from ceramic powder raw material

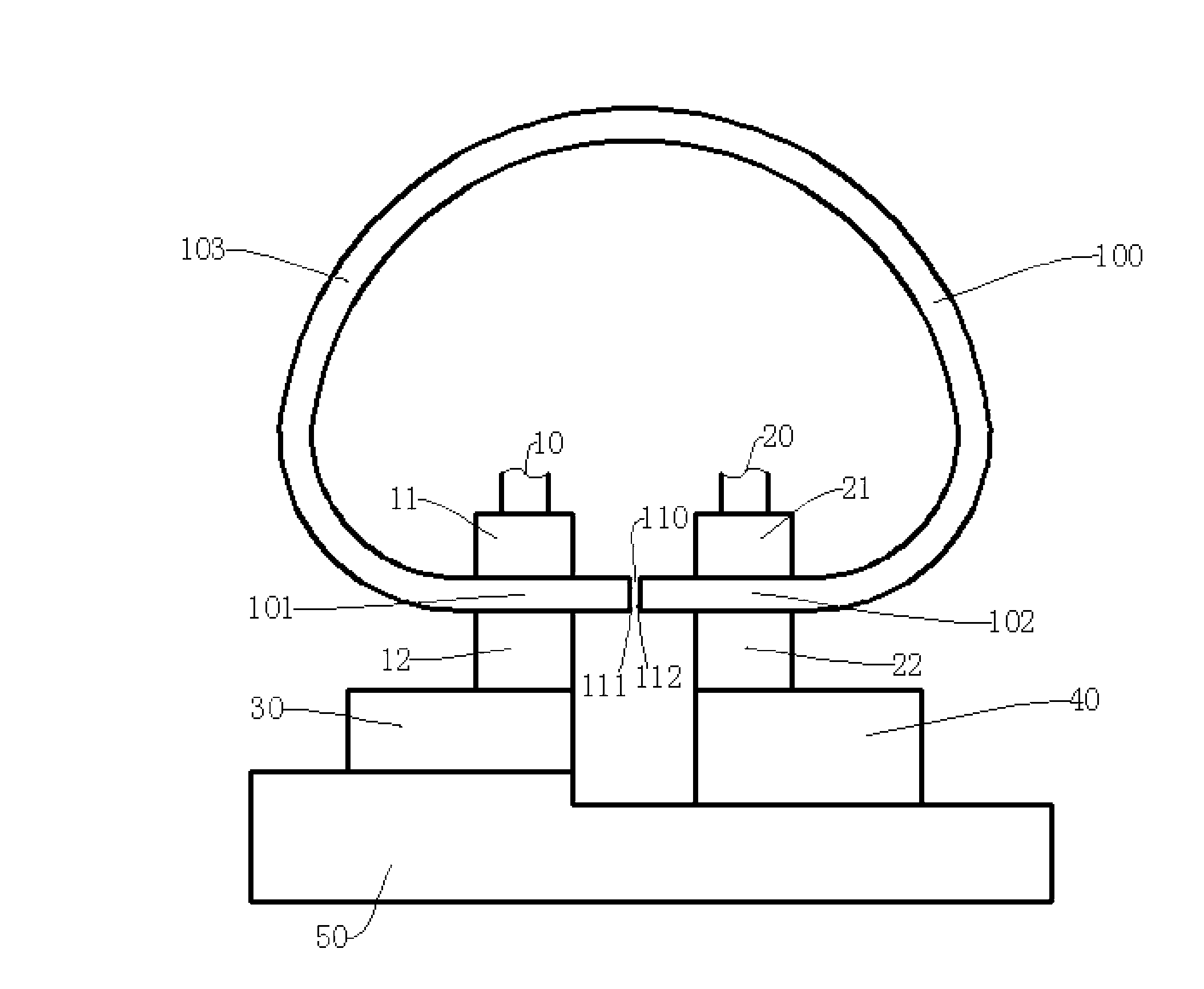

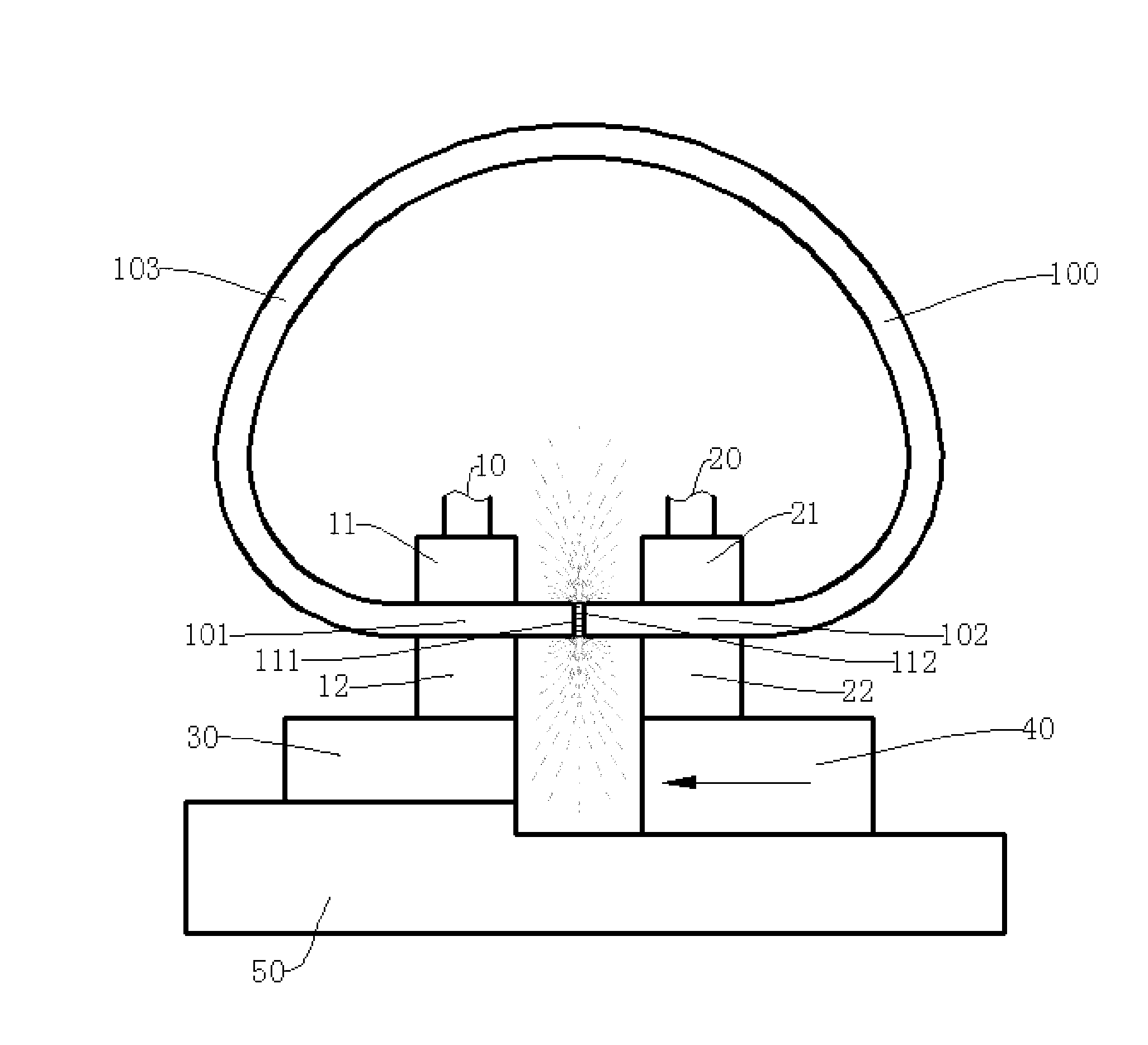

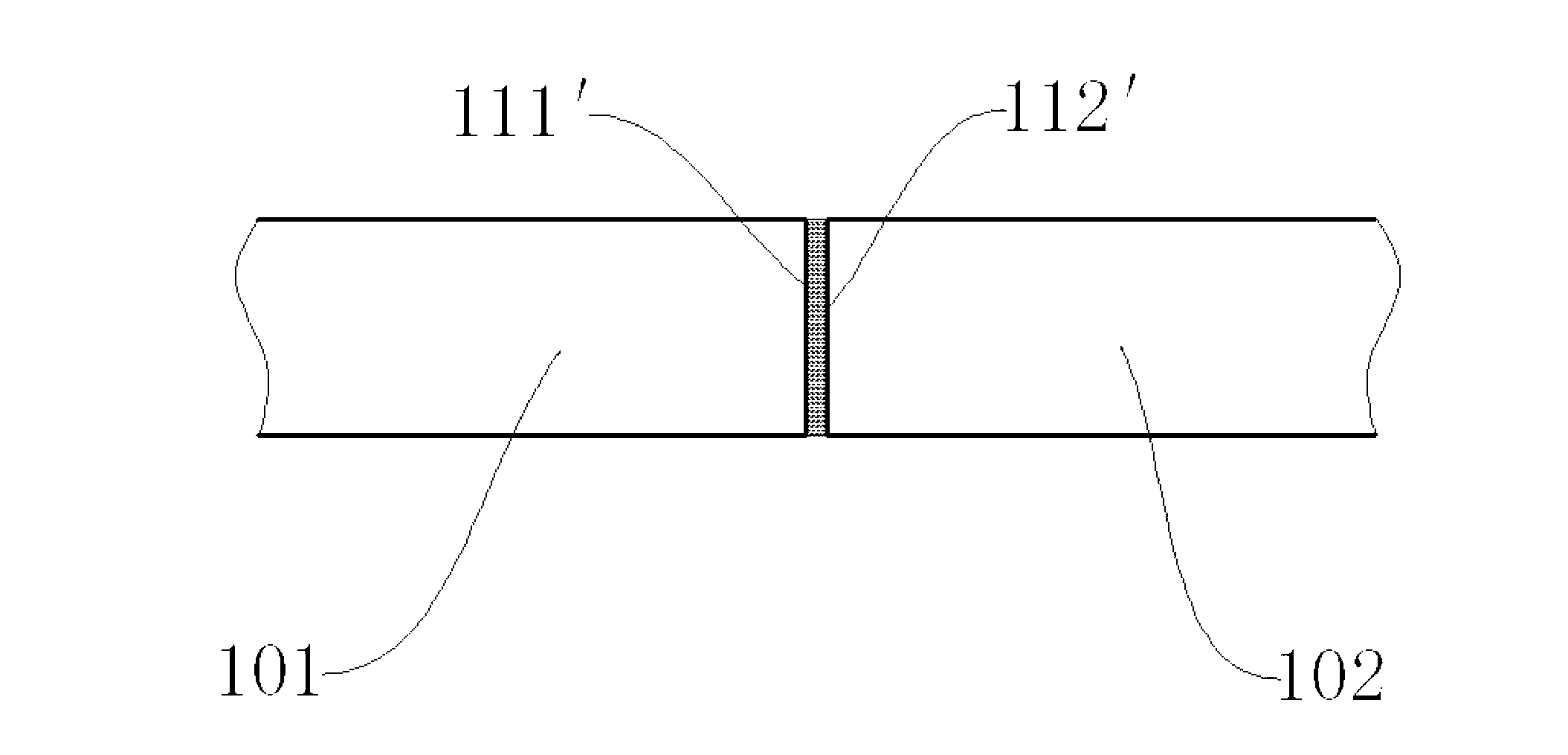

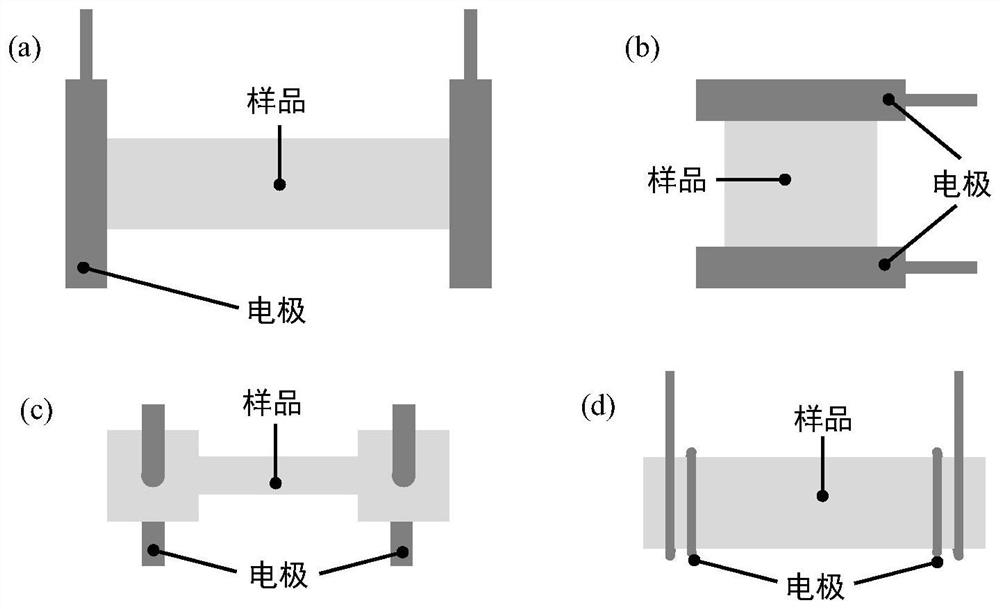

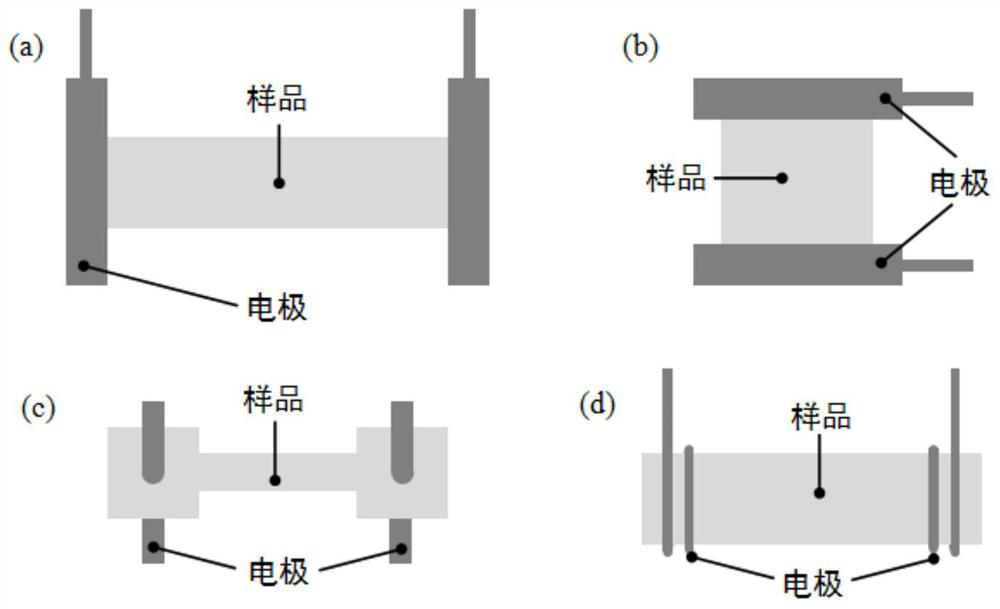

The invention provides a direct flash-burning molding preparation method from a ceramic powder raw material. The method comprises the following steps: (1) pouring a raw material into a die, vibratingto flatten the surface of the raw material; (2) putting the die into ceramic powder raw material direct molding flash-burning equipment, applying pressure of 40-50MPa to lead the ceramic powder raw material at the center of a heat area; (3) opening an assistant heat power supply (which is a conductive heat power supply), heating to 900-1000 DEG C at a speed of 100-110 DEG C / min or until a flashingphenomenon happens; (4) opening a high-voltage direct-current flash-burning power supply, supplying direct-current electricity to two sides of a sample, linearly increasing voltage of about 200V / cm until the flashing phenomeon happens; (5) controlling the current to be reduced to 1000A or less, and keeping the current to be constant, and lasting for 20-50 seconds; (6) cooling to room temperatureto obtain a compact sintering body; and (7) grinding and polishing the sintering body to obtain a required product.

Owner:苏州山人纳米科技有限公司

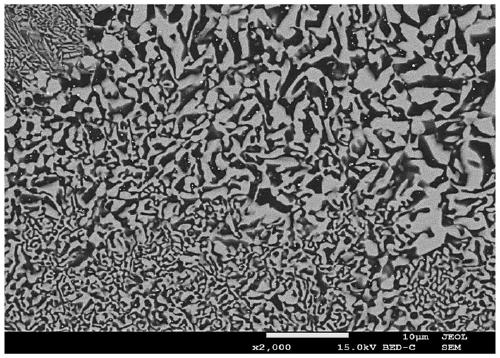

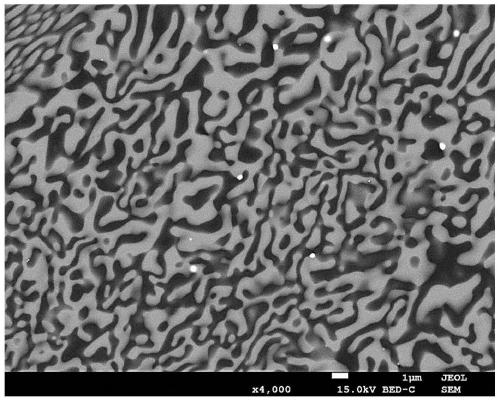

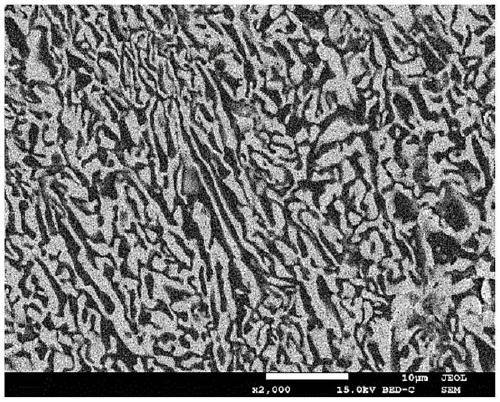

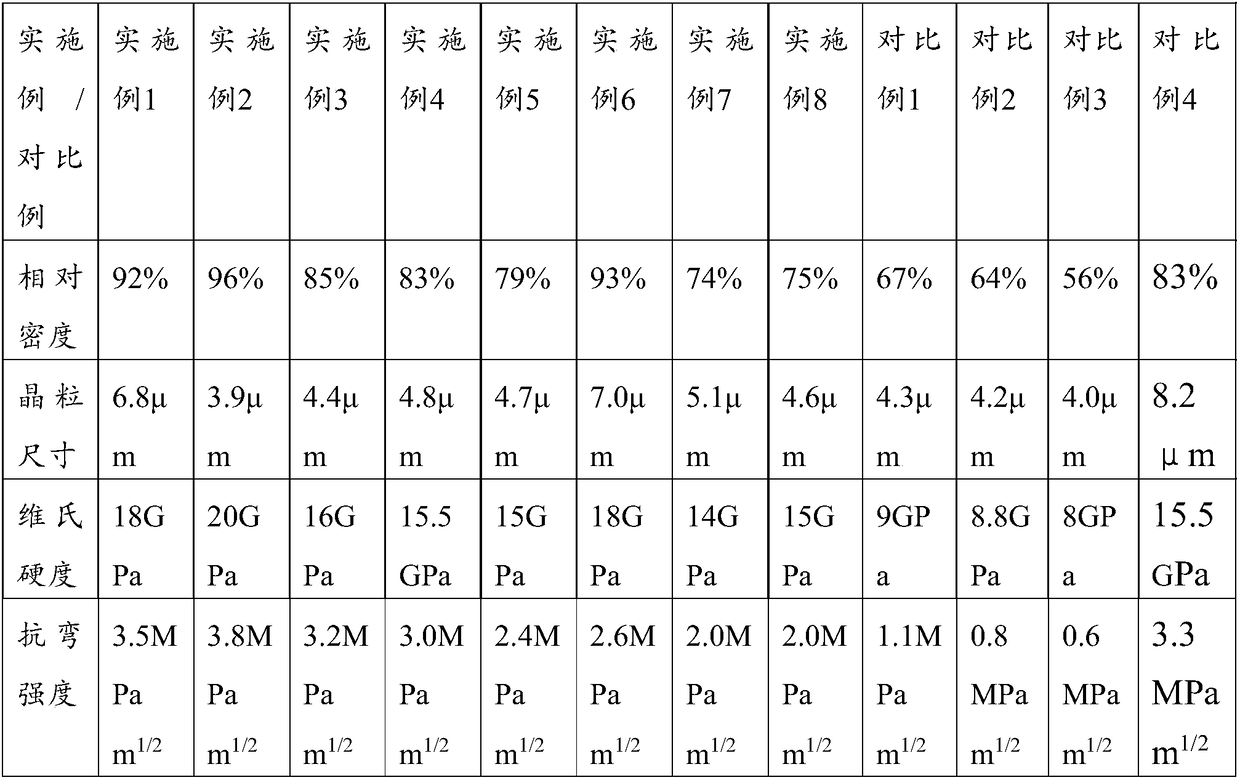

Method for preparing oxide eutectic ceramic through flash firing

The invention discloses a method for preparing oxide eutectic ceramic through flash firing. The method comprises the following steps: a) weighing ceramic powder according to a designed formula; b) carrying out ball milling, drying, granulation and compression molding treatment, and then carrying out heat treatment on the obtained green body at 0.5 Tm for 2 h; c) connecting the sample with a platinum electrode in a sintering furnace, and heating to a set temperature of 0.7-0.9 Tm; d) after the preset temperature is reached, performing heat preservation for a certain time; e) connecting a platinum electrode with a power source, presetting the electric field intensity as 100 to 1000 V / cm and the current density as 10 to 500 mA / mm<2>, and outputting an electric field to the sample, wherein theelectric field intensity is kept constant till the flash burning phenomenon occurs, and at the moment, the power source is converted into a constant-current state from a constant-voltage state; f) ina constant current state, carrying out heat preservation on the system for 1-60 minutes under a preset current density to obtain the oxide eutectic ceramic. Through coupling of an electric field anda temperature field, an oxide ceramic is promoted to rapidly form an eutectic structure below the eutectic temperature, and by adjusting sintering parameters, the morphology of the eutectic ceramic can be regulated and controlled. And the obtained eutectic structure is small in size and excellent in mechanical property.

Owner:SOUTHWEST JIAOTONG UNIV

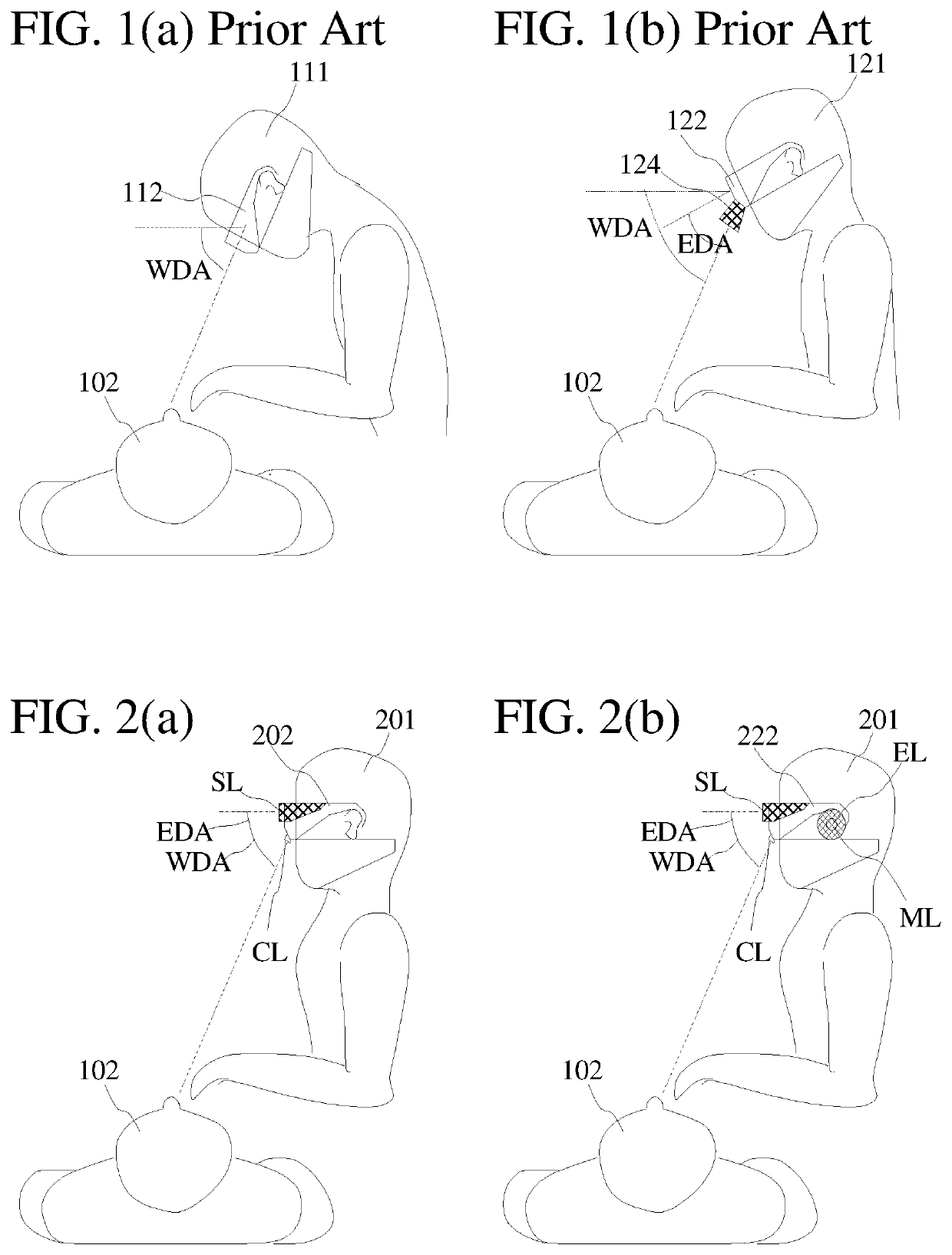

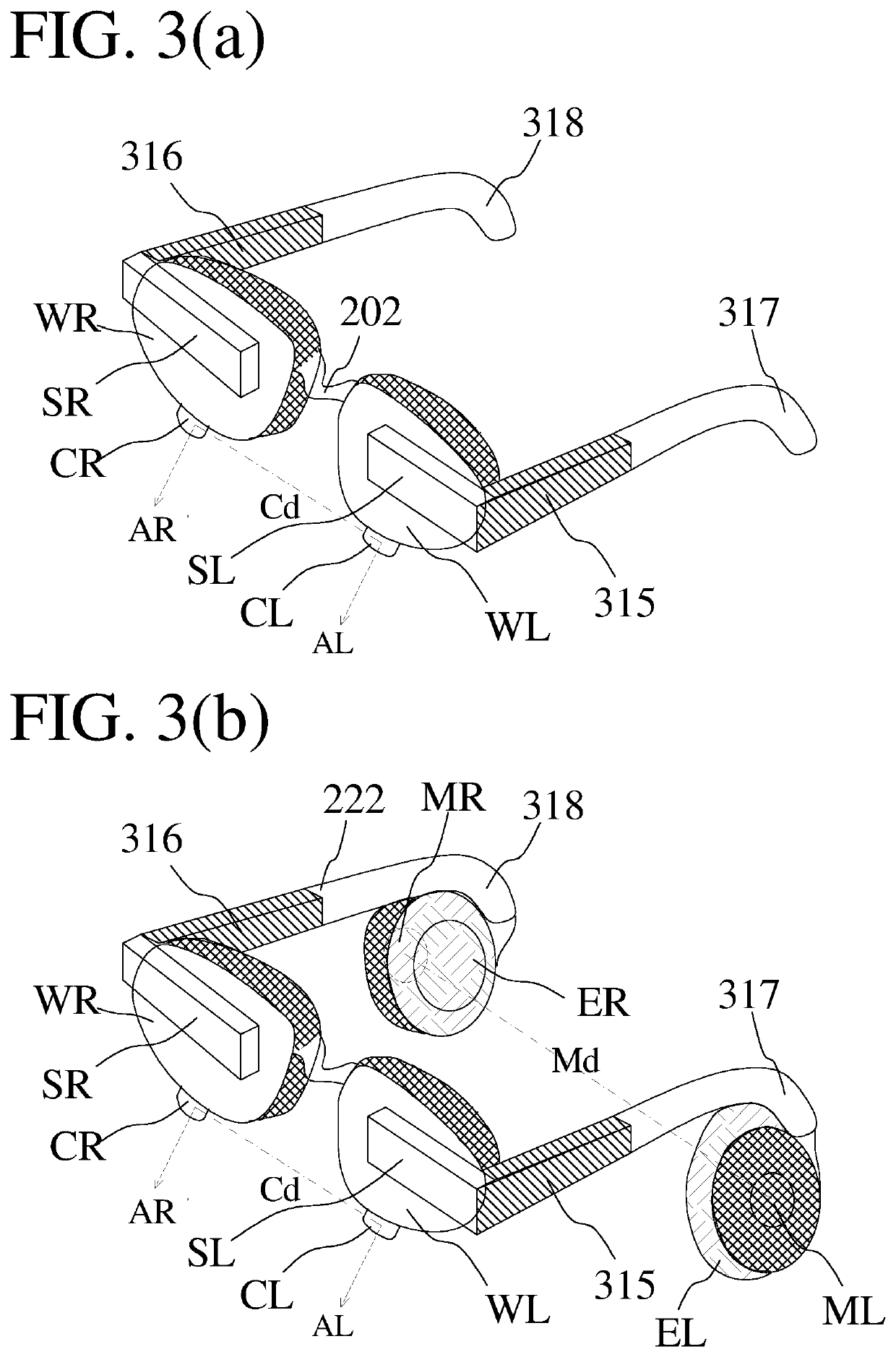

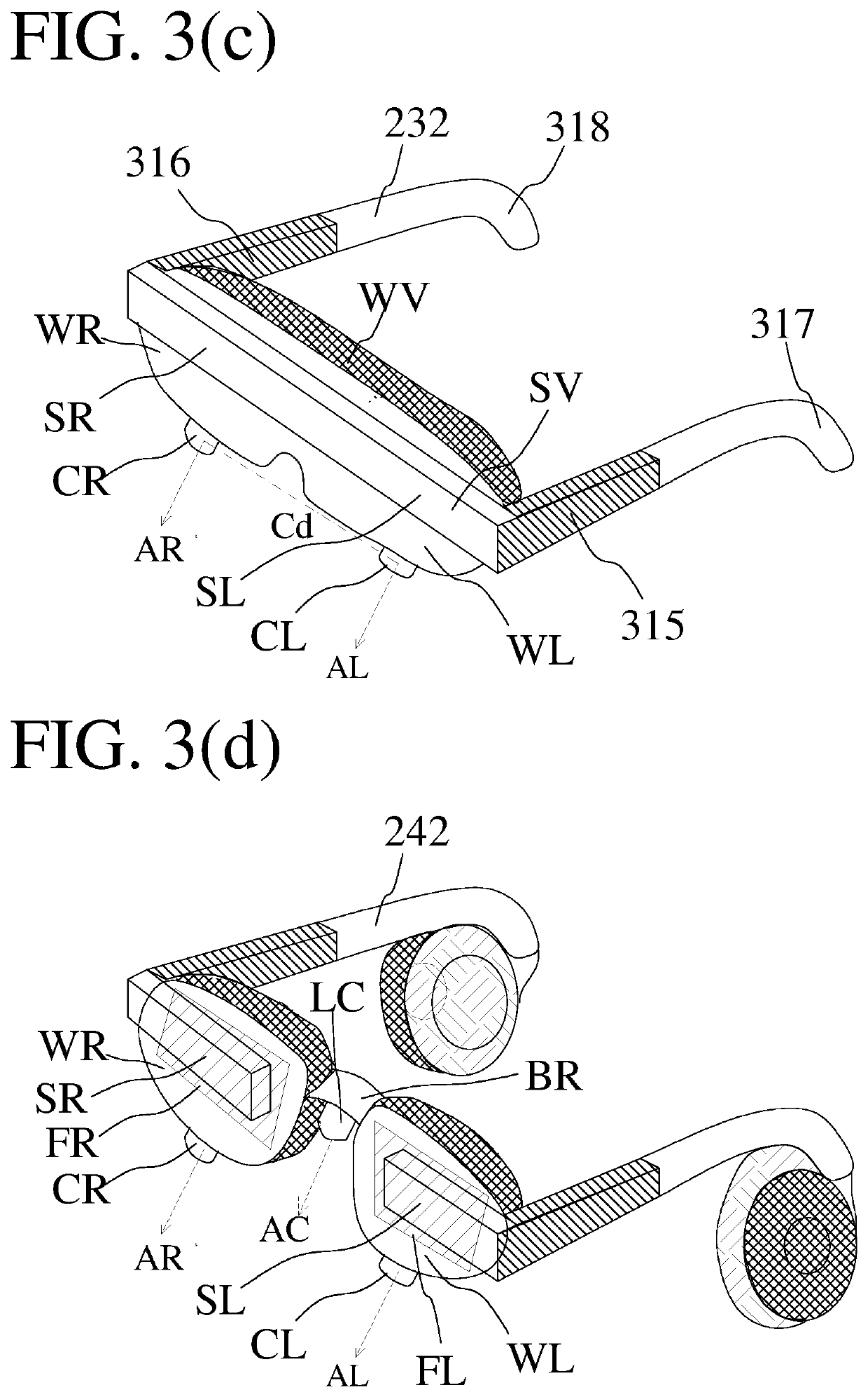

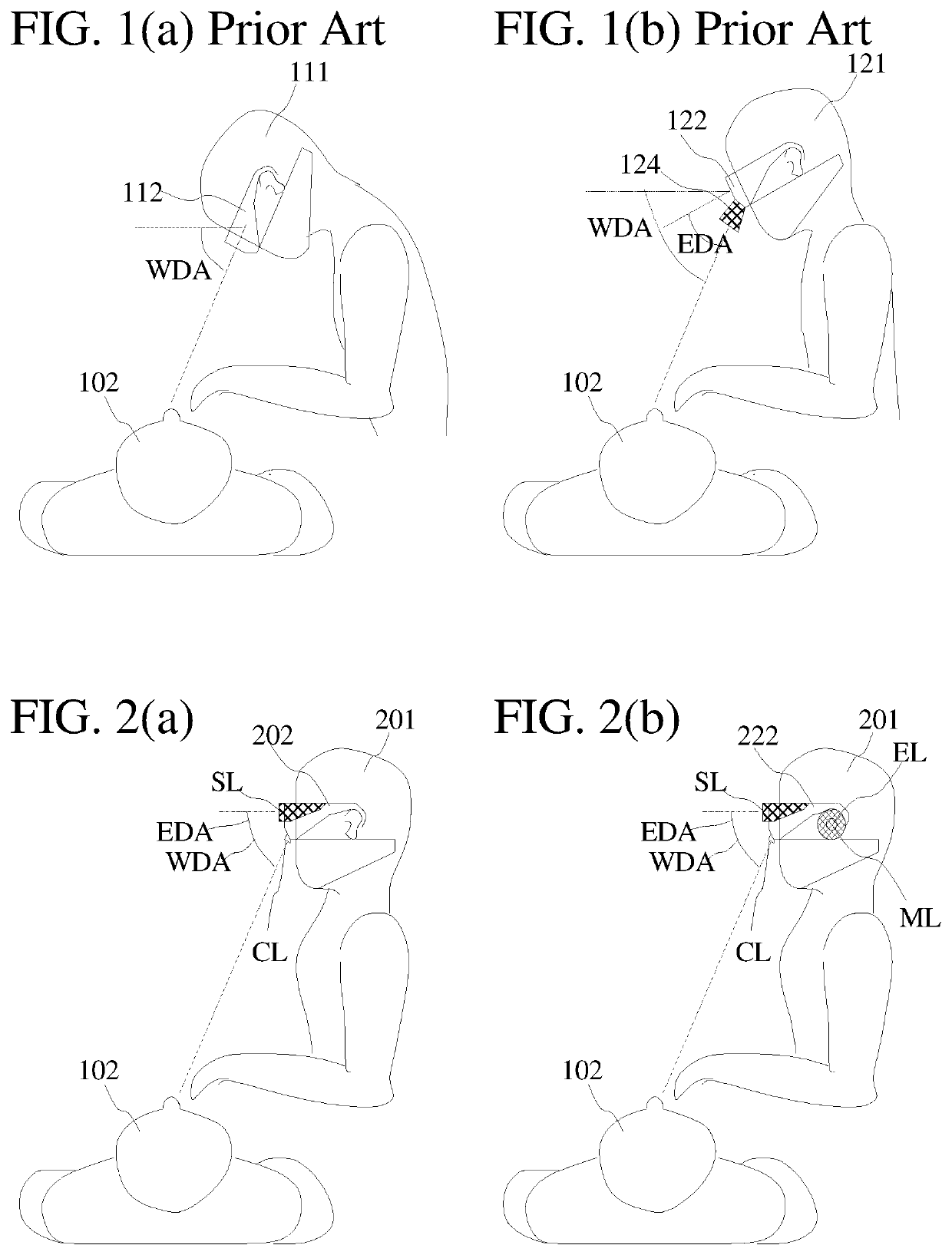

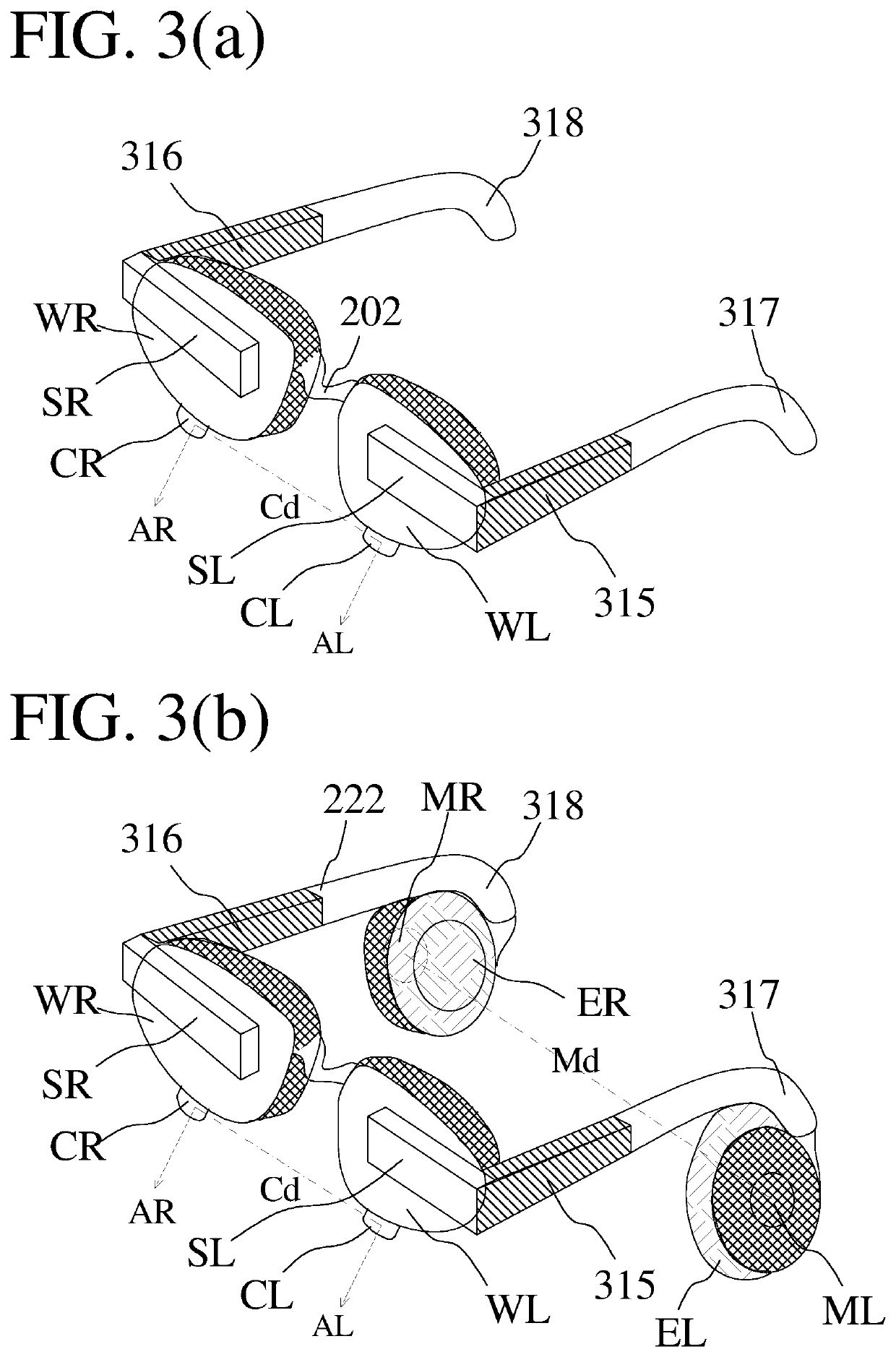

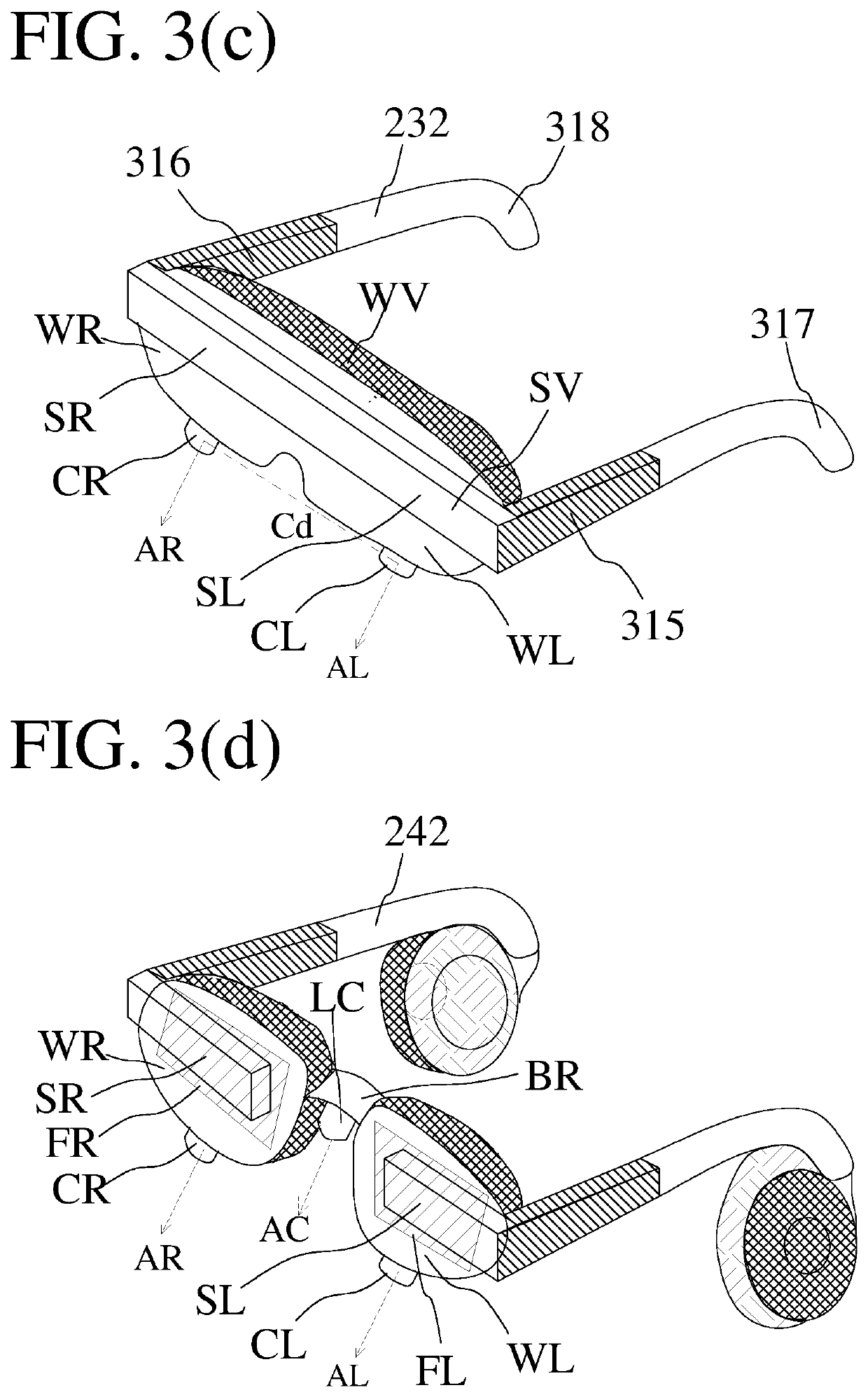

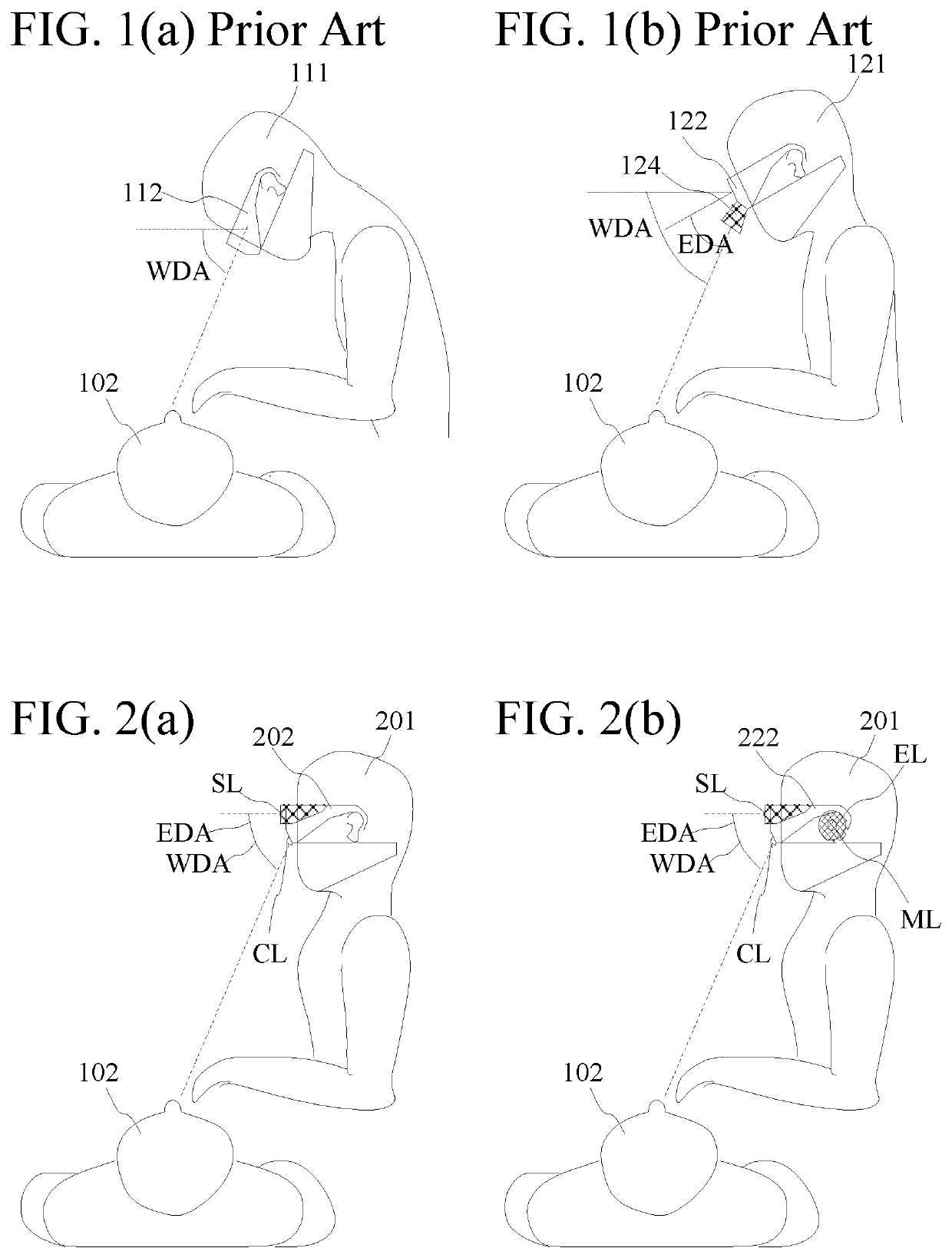

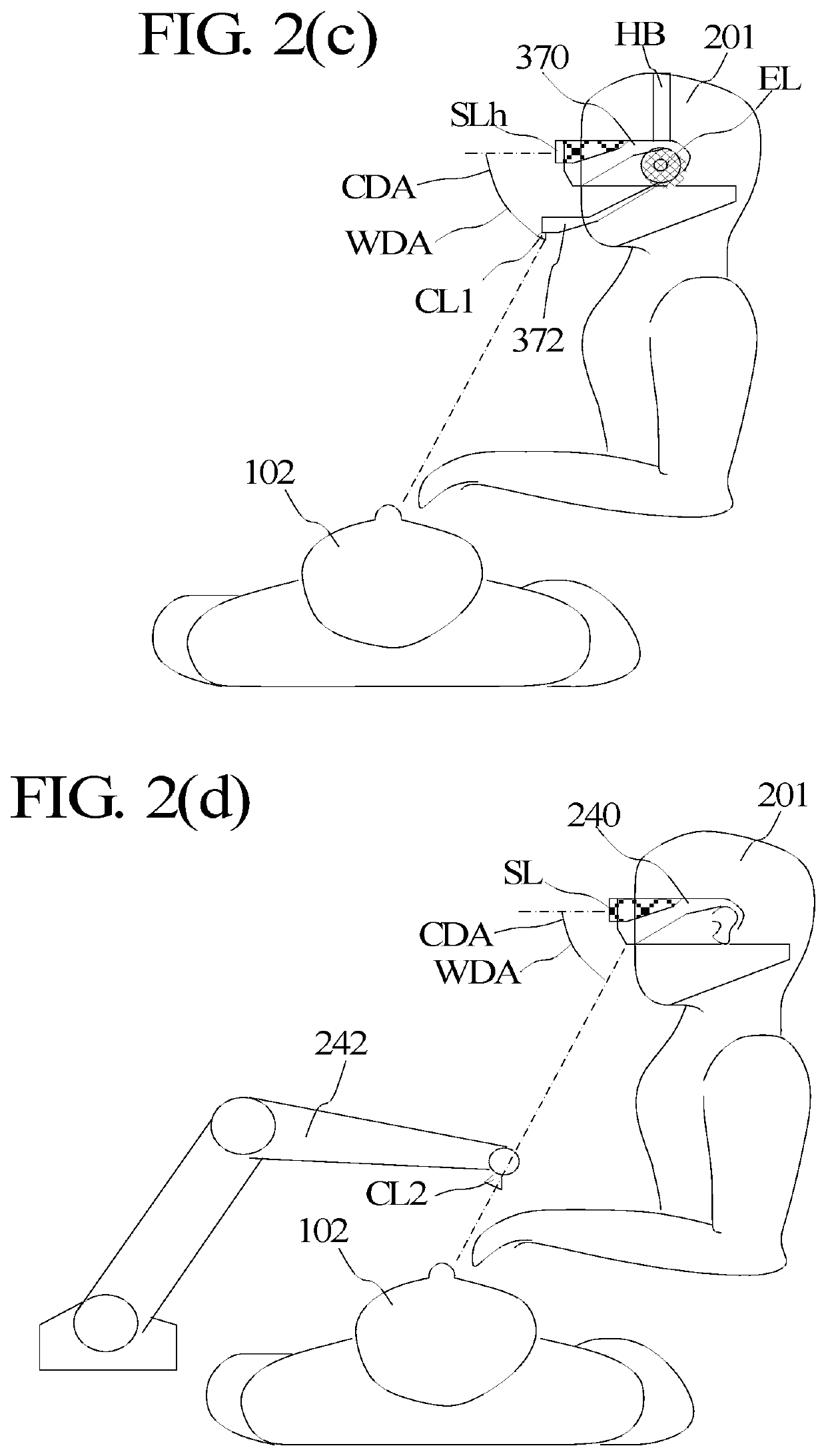

Ergonomic protective eyewear

ActiveUS20210067764A1Provide capabilityDisplay imageGogglesNon-optical adjunctsEngineeringHuman engineering

Using two or more cameras attached to the eyewear, three-dimensional views with accurate and natural depth perception of the working area can be displayed for users, so that the user can maintain healthy sitting or standing posture while working on patients or objects located below horizontal eye level. Additional functions including eye protection, zoom-in, zoom-out, on-off, lighting control, overlapping, and teleconference capabilities are also supported using electronic, video and audio devices attached to the eyewear. The eyewear can also comprise a face shield designed to protect the user from hazardous droplets, aerosols, harmful wavelengths of light, heat, sparks, flash burn, debris and / or flying objects.

Owner:SHAU ALEXANDER +1

Fuel produced from waste polyurethane foams and processing method of fuel

The invention discloses a fuel produced from waste polyurethane foams. The fuel is characterized by comprising 60%-70% by weight of waste polyurethane foam powder and 30%-40% by weight of agricultural waste particles containing cellulose and xylogen. A processing method of the fuel produced from the waste polyurethane foam comprises the following steps of: (1) crushing the waste polyurethane foams by using a crushing machine, wherein the diameter of meshes of a crushing screen of the crushing machine is not greater than 2mm; and (2) mixing the crushed waste polyurethane foams and the agricultural waste particles containing the cellulose and the xylogen, pouring the mixture into a forming machine, adding water weight of which is 5% of total weight of the mixture into the forming machine, completely mixing the mixture, and heating and squeezing to form the fuel. The fuel disclosed by the invention has the advantages of no flash burn, high compression ratio as well as stability and sufficiency in combustion.

Owner:NANJING HUANWU RESOURCES RECYCLING TECH

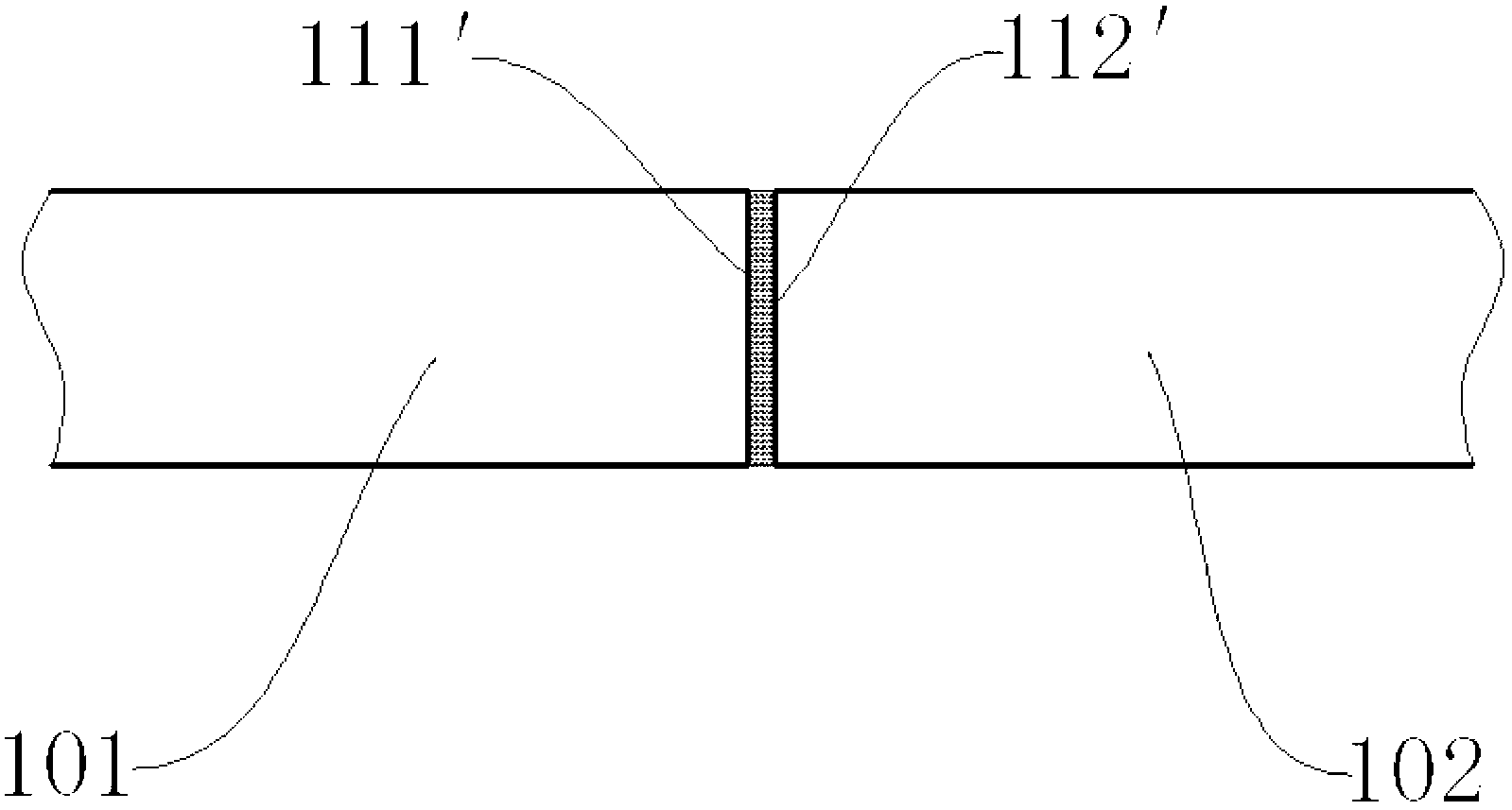

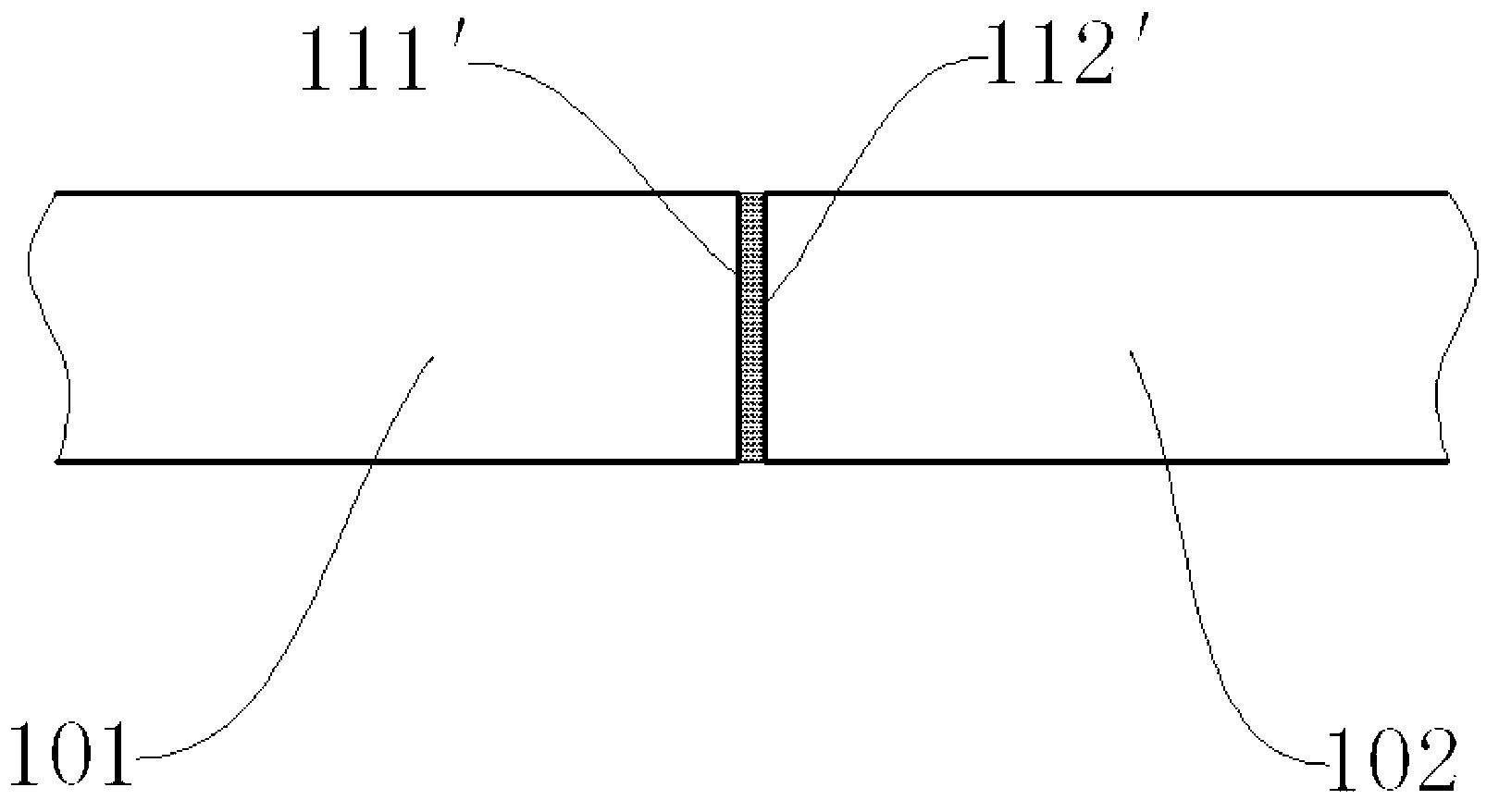

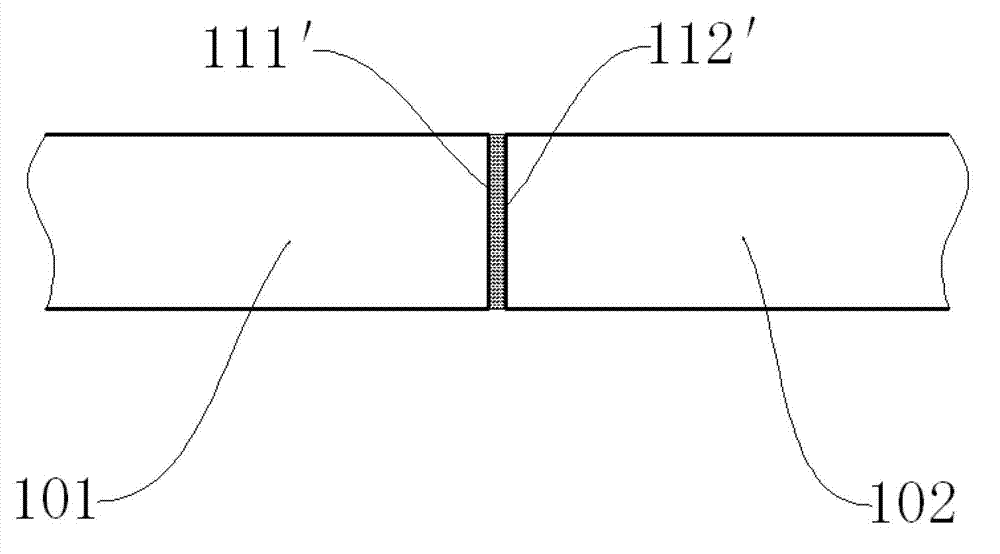

Flash welding forming method of constructional steel thin-wall ring member

The invention discloses a flash welding forming method of a constructional steel thin-wall ring member, which comprises the steps of: loading a D type ring blank with an opening in a welder, starting the welder to close the opening of the preheated ring blank, applying a 7-18V voltage between two poles of the welder to ensure that the left end face and the right end face of the opening of the ring blank are heated and molten through a flash current with the current density of 15A / mm<2>-220A / mm<2> to form a lintel, exploding to form a flash, wherein the flash burning loss speed of the ring blank is 3.6mm-7.2mm / s; driving the right end face of the ring blank to make an accelerated feeding movement towards the left end face at an initial speed of 2.5mm / s-4.0mm / s and an acceleration of 1.0mm / s<2>-2.0mm / s<2> so as to ensure that the distance between the left end face and the right end face is not more than 7mm; and after the flash is completed, driving a right straight side of the ring blank to move at a high speed towards a left straight side of the ring blank to ensure that the left end face and the right end face collide with each other under the action of an upsetting force of 9kN-15kN to form the flash welding thin-wall ring member, and keeping the pressure for 10s-30s under the action of the upsetting force. The method can ensure that the flash process is continuously and stably carried out, thereby improving the weld quality.

Owner:GUIZHOU ANDA AVIATION FORGING

Flash welding forming method of iron-based superalloy thin-wall ring member

The invention discloses a flash welding forming method of an iron-based superalloy thin-wall ring member, which comprises the steps of: loading a D type ring blank with an opening in a welder, starting the welder to close the opening of the preheated ring blank, applying a 7-18V voltage between two poles of the welder to ensure that the left end face and the right end face of the opening of the ring blank are heated and molten through a flash current with the current density of 30A / mm<2>-200A / mm<2> to form a lintel, exploding to form a flash, wherein the flash burning loss speed of the ring blank is 2.4mm-4.8mm / s; driving the right end face of the ring blank to make an accelerated feeding movement towards the left end face at an initial speed of 1.2mm / s-2.4mm / s and an acceleration of 0.4mm / s<2>-0.8mm / s<2> so as to ensure that the distance between the left end face and the right end face is not more than 8mm; and after the flash is completed, driving a right straight side of the ring blank to move at a high speed towards a left straight side of the ring blank to ensure that the left end face and the right end face collide with each other under the action of an upsetting force of 12kN-17kN to form the flash welding thin-wall ring member, and keeping the pressure for 15s-25s under the action of the upsetting force. The method can ensure that the flash process is continuously and stably carried out, thereby improving the weld quality.

Owner:GUIZHOU ANDA AVIATION FORGING

Flash welding forming method of aluminum alloy thin-wall ring member

ActiveCN102935551AImprove performanceWelding/soldering/cutting articlesResistance welding apparatusFlash weldingMaterials science

The invention discloses a flash welding forming method of an aluminum alloy thin-wall ring member, which comprises the steps of: loading a D type ring blank with an opening in a welder, starting the welder to close the opening of the preheated ring blank is closed, applying a 7-18V voltage between two poles of the welder to ensure that the left end face and the right end face of the opening of the ring blank are heated and molten through a flash current with a current density of 20A / mm<2>-150A / mm<2> to form a lintel, exploding to form a flash, wherein the flash burning loss speed of the ring blank is 6.0mm-10.0mm / s; driving the right end face of the ring blank to make an accelerated feeding movement towards the left end face at an initial speed of 4.0mm / s-6.0mm / s and an acceleration of 2.0mm / s<2>-4.0mm / s<2> so as to ensure that the distance between the left end face and the right end face is not more than 5mm; and after the flash is completed, driving a right straight side of the ring blank to move at a high speed towards a left straight side of the ring blank to ensure that the left end face and the right end face collide with each other under the action of an upsetting force of 6kN-11kN to form the flash welding thin-wall ring member, and keeping the pressure for 10s-20s under the action of the upsetting force. The method can ensure that the flash process is continuously and stably carried out, thereby improving the weld quality.

Owner:GUIZHOU ANDA AVIATION FORGING

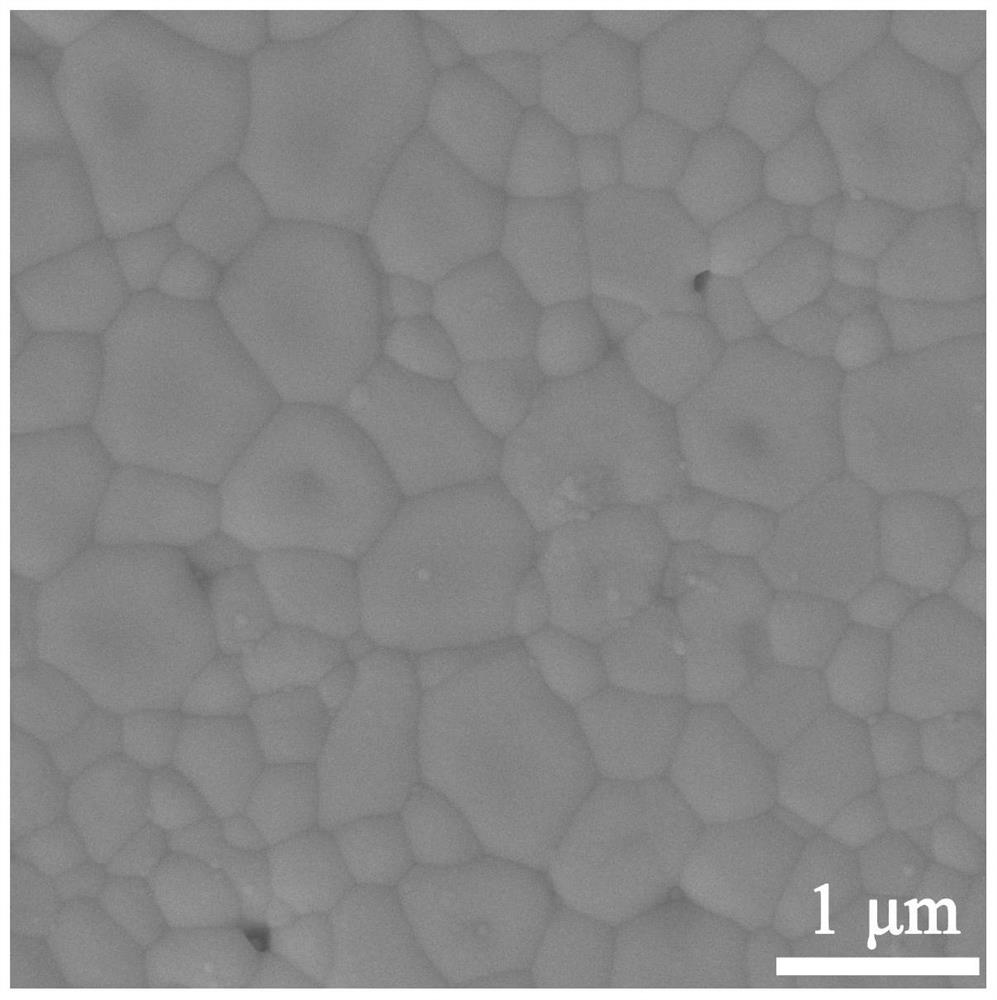

Zirconium boride based ceramic and preparation method thereof

ActiveCN108358646AGood compactness and high temperature resistanceTo achieve the effect of sintering compactCeramic sinteringBoride

The invention relates to the field of ceramic materials, in particular to a zirconium boride based ceramic and a preparation method thereof. The preparation method of the zirconium boride based ceramic provided by the invention comprises the following steps: step one, preparing zirconium boride pelleting balls through a pelleting technology under alkaline conditions, and mixing the zirconium boride pelleting balls with zirconium dioxide powder to obtain zirconium boride and zirconium dioxide composite powder; and step two, carrying out glue removal on the zirconium boride and zirconium dioxidecomposite powder, carrying out spark plasma sintering, and carrying out flashing burning with the help of an external electric field to obtain the zirconium boride based ceramic. Zirconium dioxide with a three-dimensional network structure is distributed around zirconium boride, and the temperature in the flash burning process is higher than the temperature inside a furnace, so that the temperature required for sintering densification of the zirconium boride based ceramic is reached, and flash burning of the zirconium boride based ceramic is realized. According to the method, the zirconium boride based ceramic can be prepared quickly, and the zirconium boride based ceramic is good in densification performance and high in high-temperature resistance and can be widely applied to the fieldsof heating elements, aerospace devices, and the like.

Owner:GUANGDONG UNIV OF TECH

Flash welding shaping method for nickel-based high-temperature alloy thin-wall ring

The invention discloses a flash welding shaping method for a nickel-based high-temperature alloy thin-wall ring. The method comprises the following steps of: placing a D-shaped ring blank into a welding machine, closing the opening of the D-shaped ring blank, applying a voltage of 7-18V to the space between the two poles of the welding machine, heating and melting the left and right end faces of the opening of the ring blank through the heating of flashing current of which the current density is 30-200 A / mm<2> to form a lintel, and exploding to form flash; under the condition that flash burning loss speed of the ring blank is 2.0-4.0mm / s, driving the right end face of the ring blank to feed at an increasing speed to the left end face at the initial speed of 1.0-2.0mm / s and the acceleration of 0.4-0.8mm / s<2> to ensure that the distance between the left and right end faces is less than or equal to 8 millimeters; and after flashing is completed, driving the right side straight edge of the ring blank to move towards the left side straight edge of the ring blank at a high speed, colliding the left and right end faces under the action of an upsetting force of 13-18KN to form a flash welding thin-wall ring, and maintaining pressure for 15-25 seconds under the action of the upsetting force. According to the method, a flashing process can be performed continuously and stably, so that the welding seam quality is improved.

Owner:GUIZHOU ANDA AVIATION FORGING

Flash welding shaping method for Beta-phase titanium alloy thin-walled ring

ActiveCN102962568AImprove performanceWelding/soldering/cutting articlesResistance welding apparatusPower flowBeta phase

The invention discloses a flash welding shaping method for a Beta-phase titanium alloy thin-walled ring. The flash welding shaping method includes the following steps: a D-shaped ring blank is loaded into a welding machine, the opening of the ring blank is closed, and a voltage of 7V to 18V is applied between both electrodes of the welding machine, so that a left end surface and a right end surface of the opening of the ring blank are heated to be melted by flash current with the current density of 20A / mm<2> to 180A / mm<2> to form lintels which explode to generate flashes; the flash burning speed of the ring blank is 2.8mm / s to 5.6mm / s, and the right end surface of the ring blank is driven to be fed toward the left end surface at the initial speed of 1.8mm / s to 2.6mm / s and the acceleration of 0.5mm / s<2> to 1.0mm / s<2> until the distance between the left end surface and the right end surface is less than or equal to 10mm; after flashing is finished, a right straight side of the ring blank is driven to move toward a left straight side of the ring blank at high speed, the left end surface and the right end surface collide with each other under the action of the upsetting force of 11KN to 17KN, so that the flash-welded thin-walled ring is formed, and moreover, under the action of the upsetting force, the pressure is kept for 20s to 30s. The method can ensure that the flashing process can continuously and stably go on, thus increasing the welding quality.

Owner:GUIZHOU ANDA AVIATION FORGING

Oxide composite nuclear fuel pellet and preparation method thereof

InactiveCN112358308AHigh densityShorten sintering holding timeNuclear energy generationReactor fuel susbtancesUranium oxideThorium oxide

The invention provides a preparation method of an oxide composite nuclear fuel pellet, and belongs to the technical field of nuclear material preparation. The preparation method comprises the following steps: 1) preparing mixed powder: putting oxide nuclear fuel powder and filler powder into a ball-milling tank, adding zirconium dioxide grinding balls, mixing and carrying out ball milling; 2) compression molding: carrying out compression molding on the ball-milled mixed powder, and demolding to obtain an oxide composite nuclear fuel blank; 3) flash burning: electrifying the oxide composite nuclear fuel blank body, applying constant electric fields to two ends of the blank body, simultaneously raising the temperature, and carrying out flash burning when the flash burning temperature is met,wherein the current is a constant current of 0-700mA / mm < 2 >, the field intensity is 0-300V / cm, the flash burning temperature is 25-1000 DEG C, and the flash burning time is 0-600s; and after flashburning is completed, cooling and demolding and obtaining the oxide composite nuclear fuel pellet. According to the method, the constant direct-current electric field is applied to the two ends of theblank by utilizing a flash burning technology, so that the sintering temperature of uranium dioxide or thorium dioxide can be remarkably reduced, the sintering time is shortened and the density of the material is improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Flash-burning preparation method of rare-earth oxide transparent ceramic scintillator

The invention provides a flash-burning preparation method of a rare-earth oxide transparent ceramic scintillator. The method comprises the following steps: (1) pouring mixed rare-earth oxide granulating powder into a mold for dry pressing; (2) degreasing and sintering to obtain a biscuit; (3) heating the biscuit in a tube furnace to 900-1000 DEG C; (4) clamping two sides of the biscuit with an electrode material, introducing direct current, controlling voltage to linearly increase from 0V at a speed of 20-100V / s until a flash phenomenon happens at about 60-100V; (5) controlling the current toreduce to 1000A or lower, and keeping the current to be constant, and lasting for 20-50 seconds; (6) cooling to room temperature to obtain a rare-earth oxide transparent ceramic scintillator; and (7)grinding and polishing the scintillator to form a transparent ceramic scintillator body.

Owner:苏州山人纳米科技有限公司

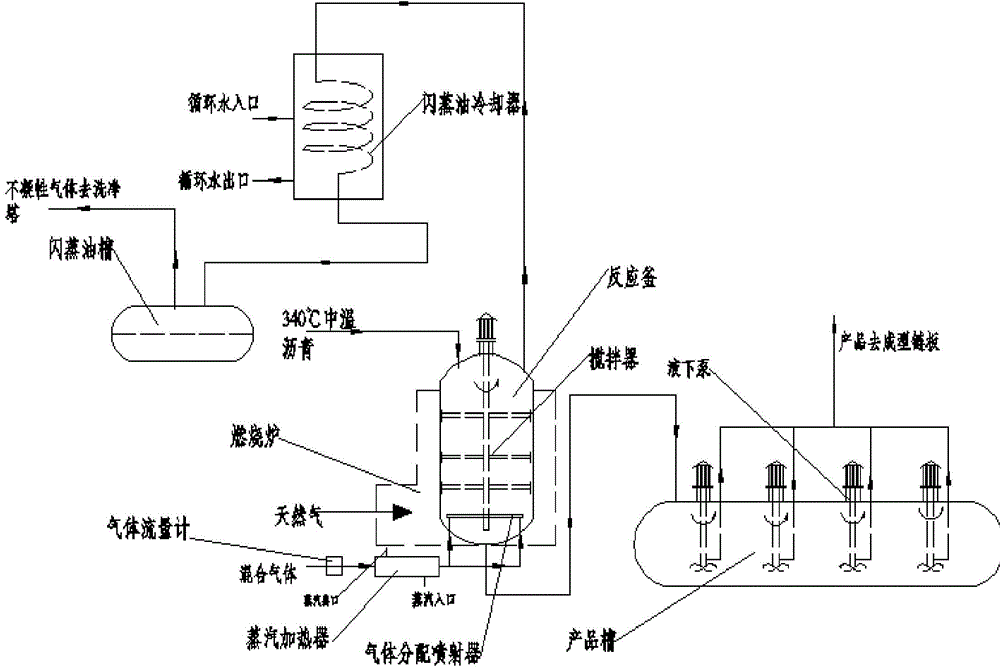

Manufacturing technique of industrial binder asphalt

ActiveCN104830362AReduce consumptionWon't flashWorking-up pitch/asphalt/bitumen by chemical meansNitrogenReaction temperature

The invention relates to a manufacturing technique of novel industrial binder asphalt, which comprises the following steps that asphalt is fed into a reaction kettle; a stirrer is started; with the temperature in the reaction kettle controlled at 300-360 DEG C, high temperature polycondensation is performed to synthesize the industrial binder asphalt; at the same time, a mixed gas of nitrogen and oxygen is injected to the reaction kettle from the bottom of the reaction kettle; free radicals in the asphalt are oxidized by oxygen in the mixed gas in a reaction process to improve the molecular weight of the asphalt; and light ingredients in the asphalt are brought out by the left mixed gas, and are called flash oil. According to the technique, the mixed gas of nitrogen and oxygen is introduced to the reaction kettle, and the reaction temperature can be reduced to around 300 DEG C from the traditional over 400 DEG C, so that energy is saved, the cost is lowered greatly, and a synthetic product is high in quality. In addition, the mixed gas is introduced to participate in the reaction, so that a situation that no flash burn or explosion of the flash oil occurs is ensured, and the safety of technological operation is improved accordingly.

Owner:WUHAN UNIV OF SCI & TECH

Radioactive waste organic solvent tributyl phosphate pyrolyzing furnace ash treatment method

ActiveCN109824355ARealize local materialsIncrease in sizeRadioactive decontaminationRadioactive wasteSolvent

The invention discloses a radioactive waste organic solvent tributyl phosphate pyrolyzing furnace ash treatment method which is characterized in that calcium pyrophosphate, calcium hydroxide, uranyl nitrate and calcium fluoride serve as raw materials and are ball-milled and dried to prepare powder, the powder is pressed on a tablet press and a cold isostatic press and pretreated to prepare a greenbody, and the green body is sintered by a flash burning technology to prepare a fluorapatite ceramic solidified body. The flash burning technology is applied to treatment of radioactive waste organicsolvent tributyl phosphate pyrolyzing furnace ash, and the prepared fluorapatite ceramic solidified body has the advantages of high mineralogical phase purity and compactness, low leaching rate and the like. Compared with existing other radioactive waste organic solvent tributyl phosphate pyrolyzing furnace ash treatment methods, the flash burning treatment method has the advantages of simple equipment, time-saving property, high efficiency, high technical controllability, economical efficiency, energy conservation, high practicability and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Cold chain equipment

PendingCN110482039AAdaptablePrevent solidificationLarge containersTank wagonsCold chainThermal insulation

The invention discloses cold chain equipment. The cold chain equipment comprises a container body, a refrigerating machine and a lithium battery. An inner cavity of the container body is divided intoa heat insulation freight house and an installation area through a plate type heat insulation wall. The refrigerating machine and the lithium battery are arranged in the installation area, the refrigerating machine is kept to be communicated with the heat insulation freight house, and the lithium battery is electrically connected with the refrigerating machine. According to the cold chain equipment, a lithium battery power supply mode is adopted, the fuel oil solidification or flash burn risk is completely avoided, the cold chain equipment has the advantages of being simple in structure and easy to achieve, and the heat insulation refrigerating performance of the heat insulation freight house is effectively ensured.

Owner:CHINA RAILWAYS CORPORATION +2

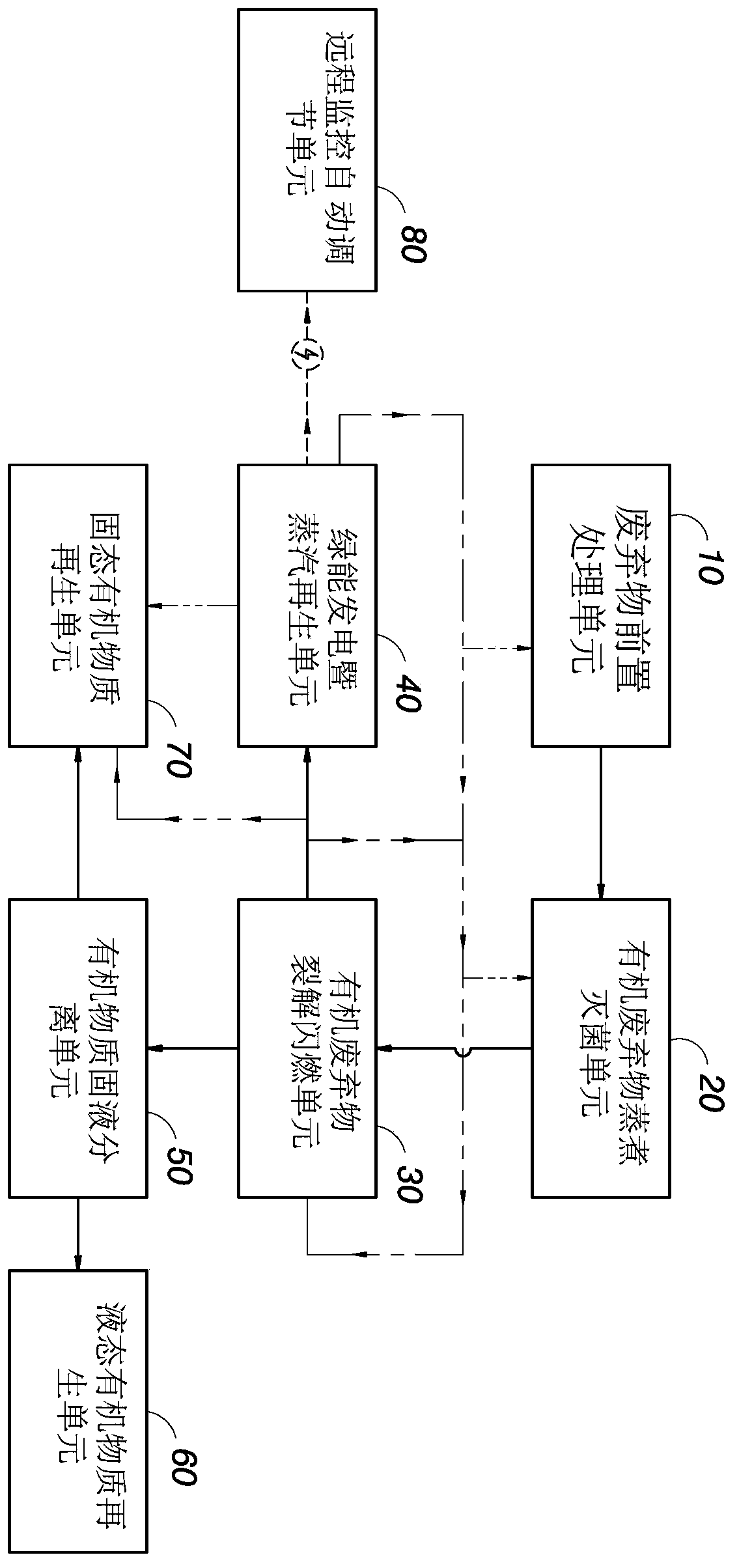

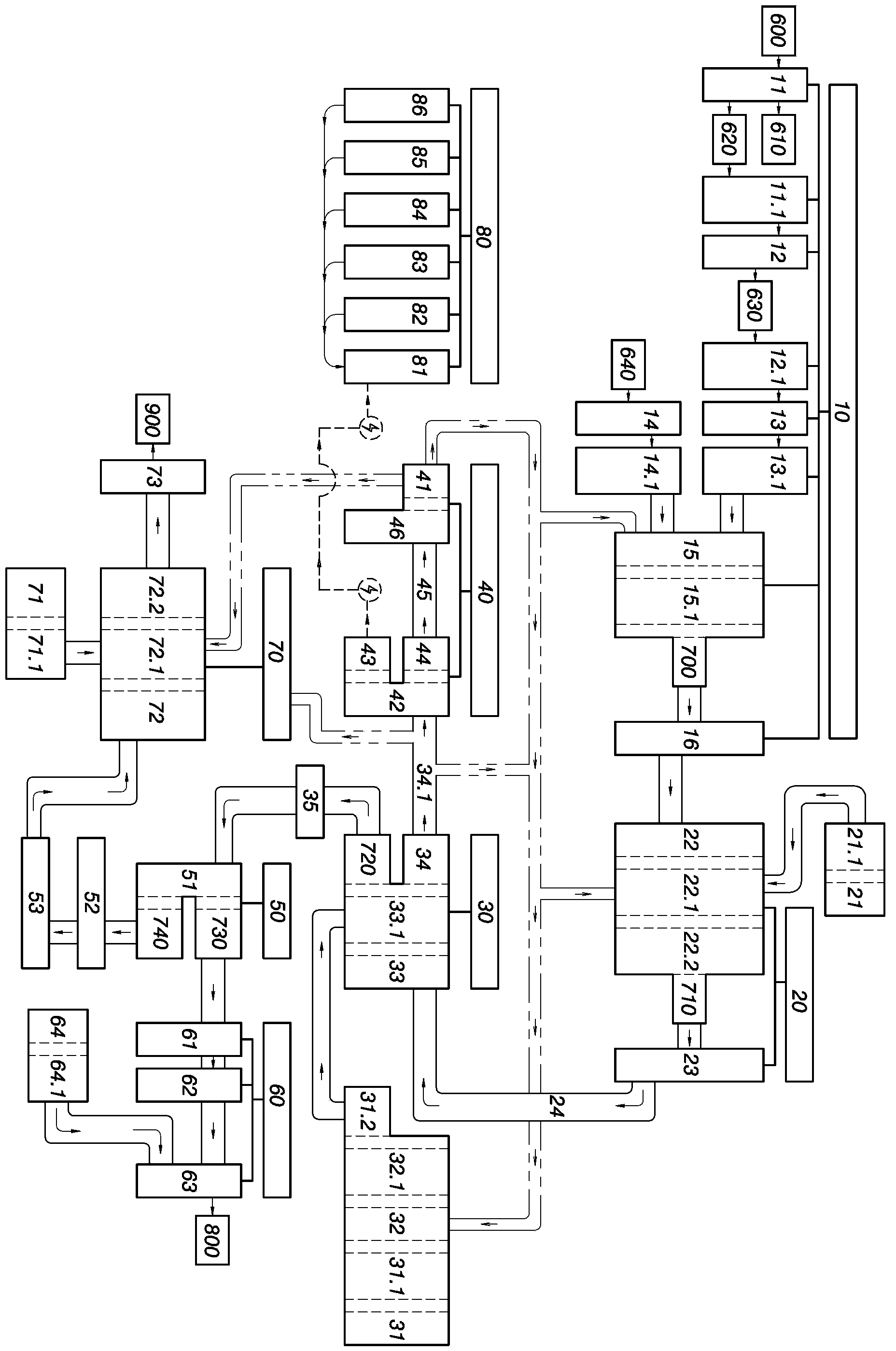

Organic matter cracking flash burning energy-saving regeneration treatment system

ActiveCN103506367AReduce processingEffective generationWaste processingSolid waste disposalEnvironmental resistanceSludge

The present invention relates to an organic matter cracking flash burning energy-saving regeneration treatment system. With the system, family kitchen waste, industrial waste, sewer sludge, agricultural waste, animal husbandry excreta and other organic waste can be re-prepared into liquid state regeneration organic matters and solid state regeneration organic matters through a waste pre-processing unit, an organic waste cooking sterilization unit, an organic waste cracking flash burning unit, a green energy electricity generation and steam regeneration unit, an organic matter solid-liquid separation unit, a liquid state organic matter regeneration unit and a solid state organic matter regeneration unit so as to be adopted as organic fertilizers or animal husbandry feeds, such that green energy sources can be effectively produced, purposes of resource recovery, environment purification, energy saving and carbon reduction can be achieved, organic waste can be recycled, the total treatment amount of burying and burning waste can be reduced, and environmental protection benefits can be improved.

Owner:王孝伦

Ergonomic protective eyewear

Using two or more cameras attached to the eyewear, three-dimensional views with accurate and natural depth perception of the working area can be displayed for users, so that the user can maintain healthy sitting or standing posture while working on patients or objects located below horizontal eye level. Additional functions including eye protection, zoom-in, zoom-out, on-off, lighting control, overlapping, and teleconference capabilities are also supported using electronic, video and audio devices attached to the eyewear. The eyewear can also comprise a face shield designed to protect the user from hazardous droplets, aerosols, harmful wavelengths of light, heat, sparks, flash burn, debris and / or flying objects.

Owner:SHAU ALEXANDER +1

Flash welding forming method of stainless steel thin-wall ring member

ActiveCN102935553AImprove performanceWelding/soldering/cutting articlesResistance welding apparatusPower flowFlash welding

The invention discloses a flash welding forming method of a stainless steel thin-wall ring member. The method comprises the steps of: loading a D type ring blank with an opening in a welder, starting the welder to close the opening of the preheated ring blank, applying a 7-18V voltage between two poles of the welder to ensure that the left end face and the right end face of the opening of the ring blank are heated and molten through a flash current with the current density of 15A / mm<2>-220A / mm<2> to form a lintel, exploding to form a flash, wherein the flash burning loss speed of the ring blank is 4.0mm-8.0mm / s; driving the right end face of the ring blank to make an accelerated feeding movement towards the left end face at an initial speed of 3.0mm / s-5.0mm / s and an acceleration of 1.0mm / s<2>-2.0mm / s<2> so as to ensure that the distance between the left end face and the right end face is not more than 7mm; and after the flash is completed, driving a right straight side of the ring blank to move at a high speed towards a left straight side of the ring blank to ensure that the left end face and the right end face collide with each together under the action of an upsetting force of 11kN-16kN to form the flash welding thin-wall ring member, and keeping the pressure for 10s-30s under the action of the upsetting force. The method can ensure that the flash process is continuously and stably carried out, thereby improving the weld quality.

Owner:GUIZHOU ANDA AVIATION FORGING

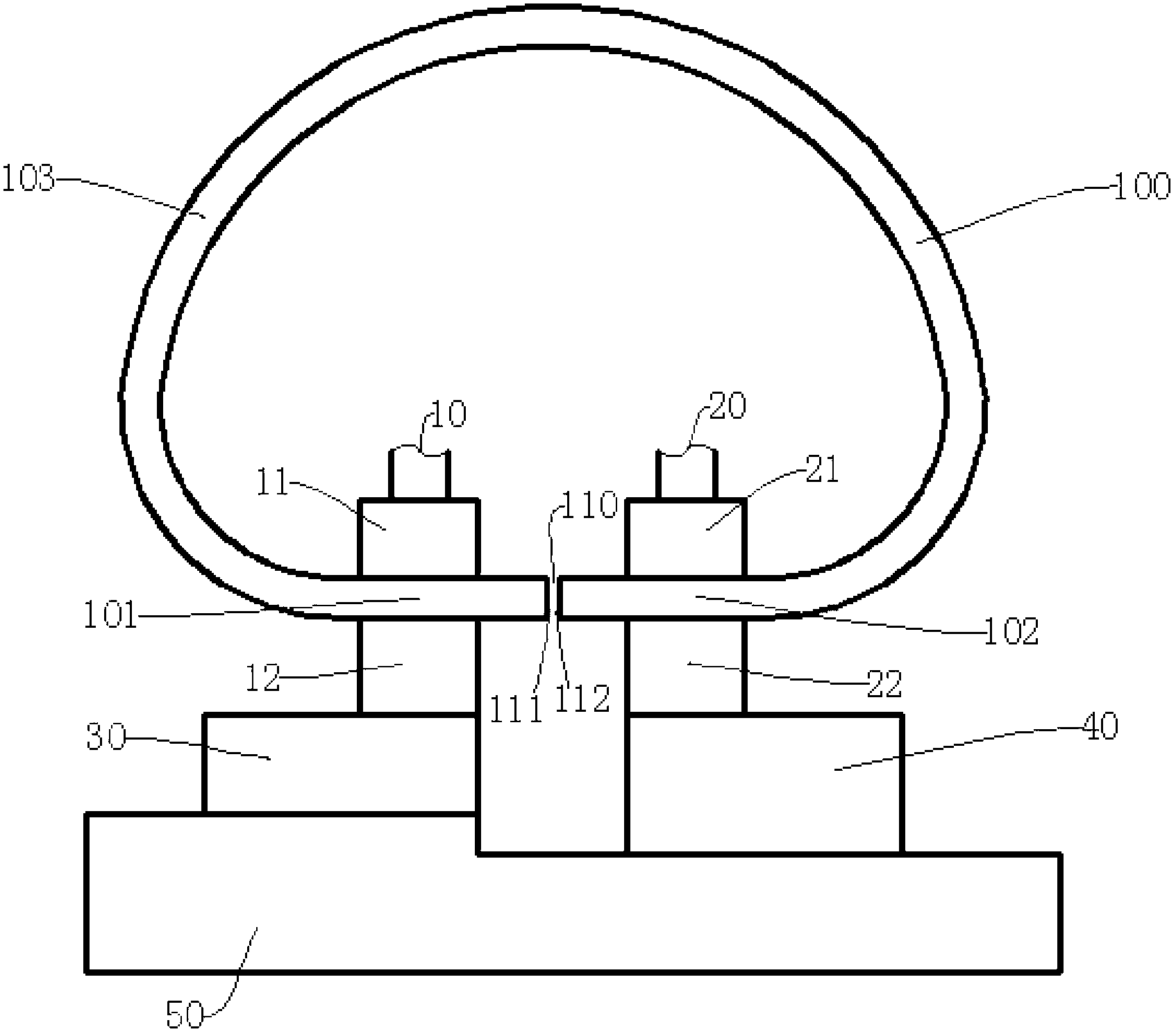

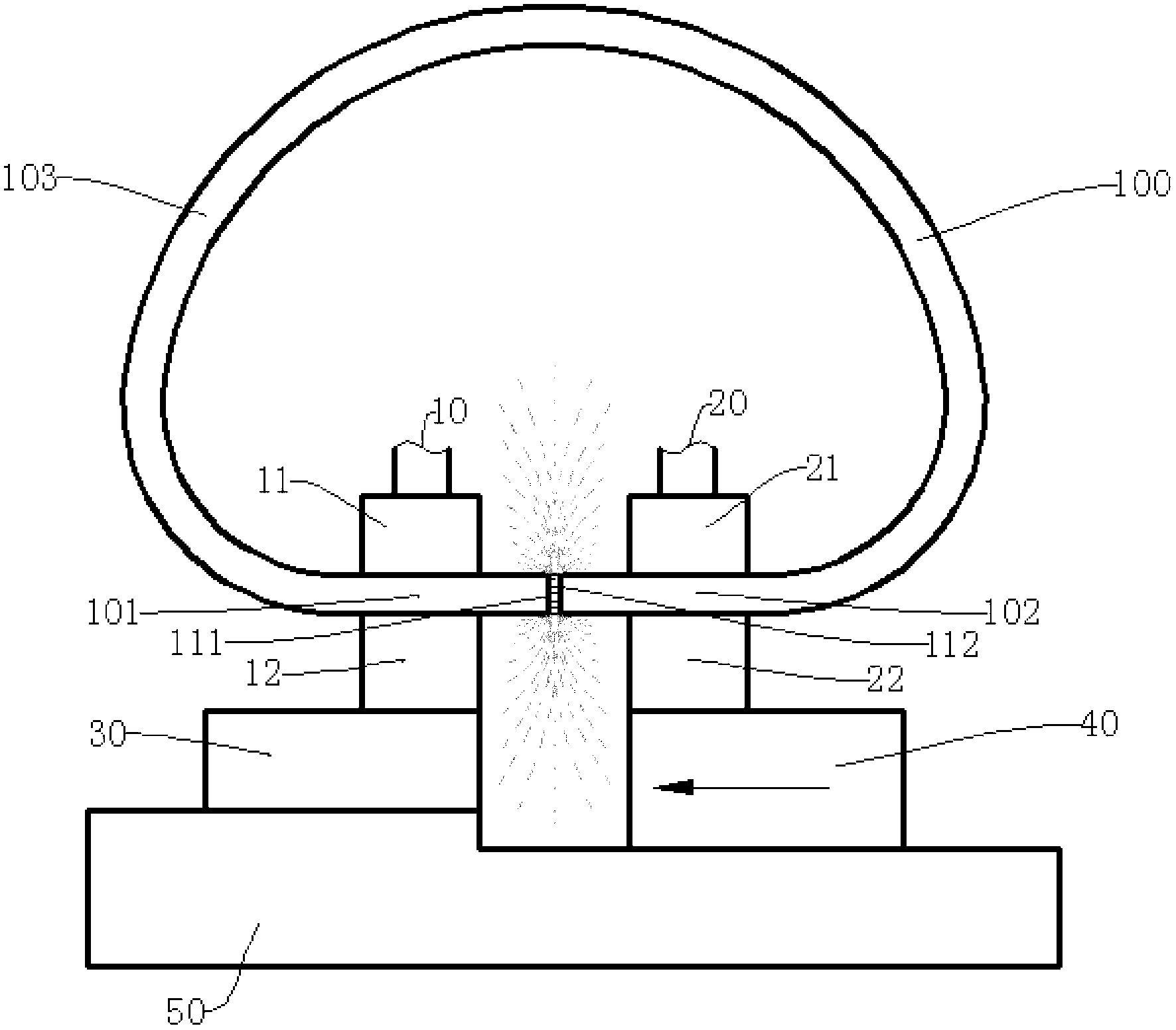

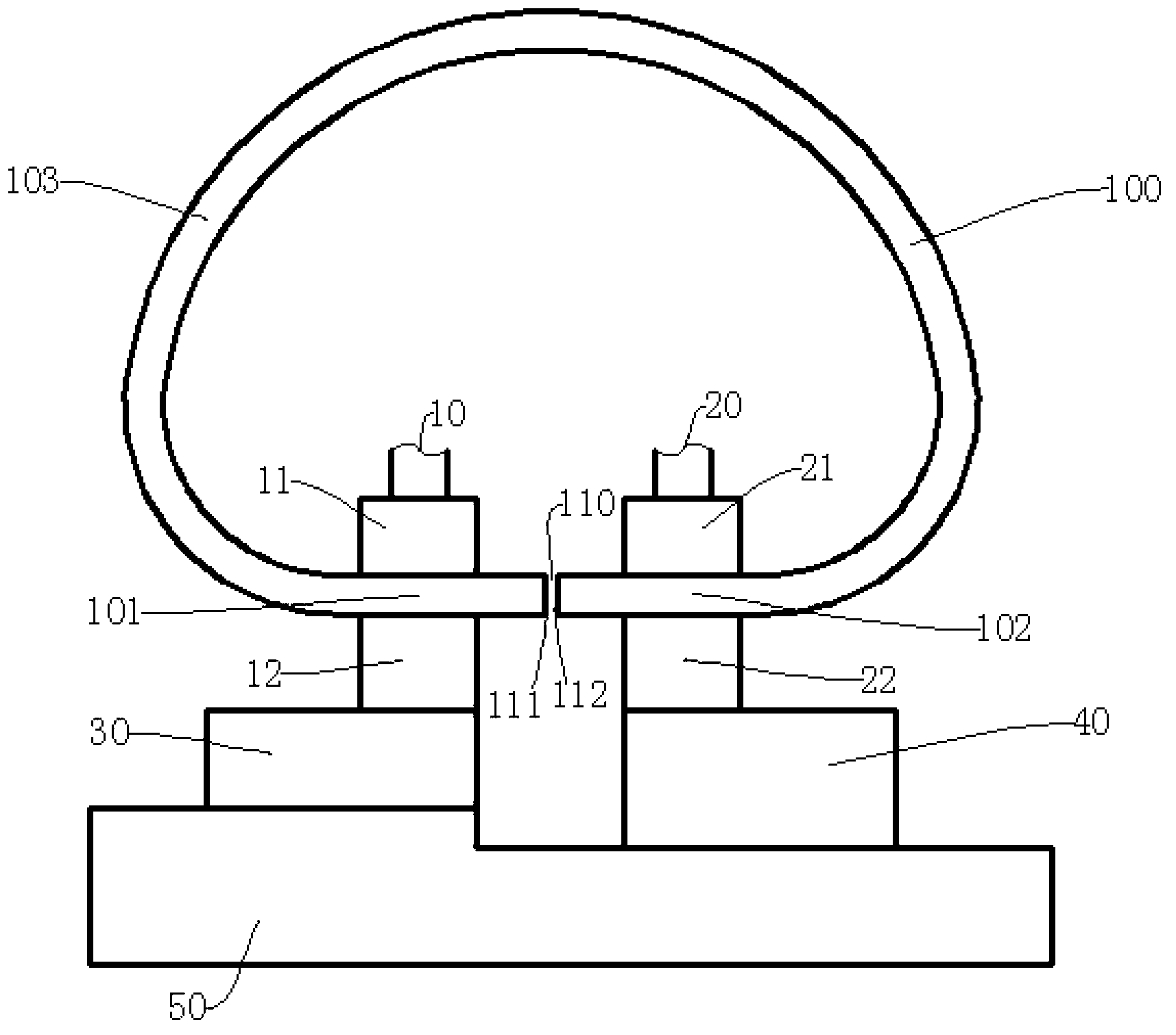

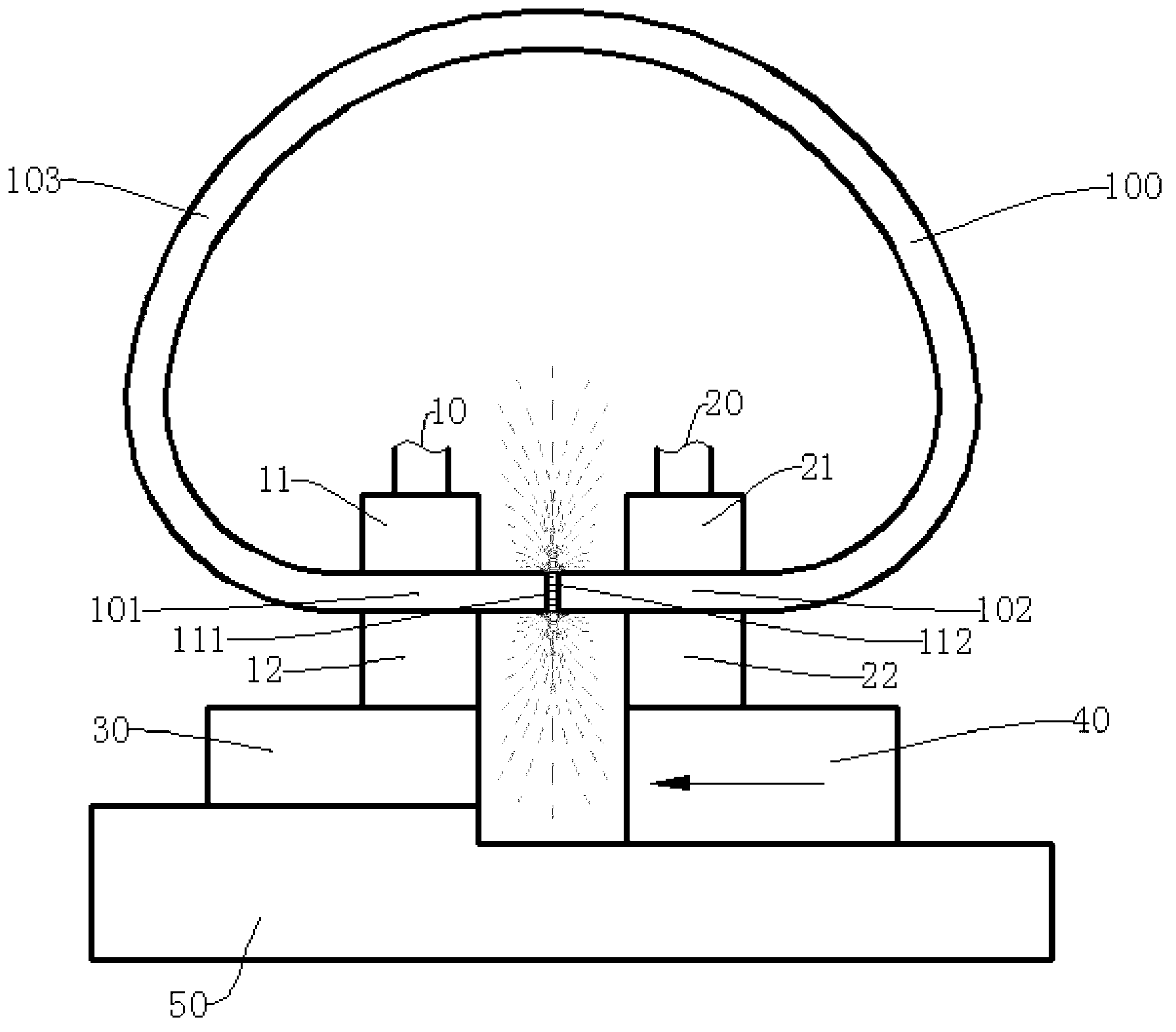

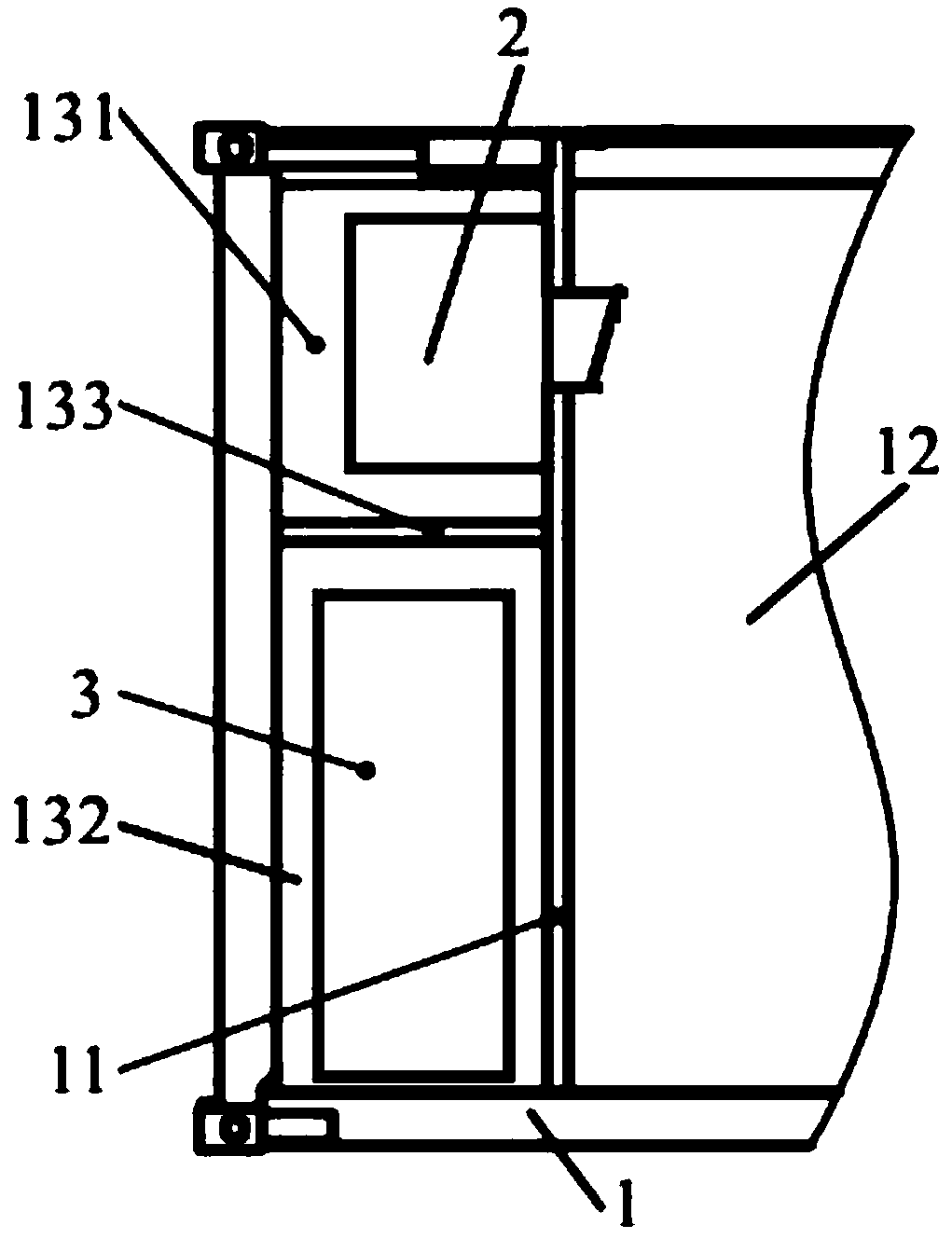

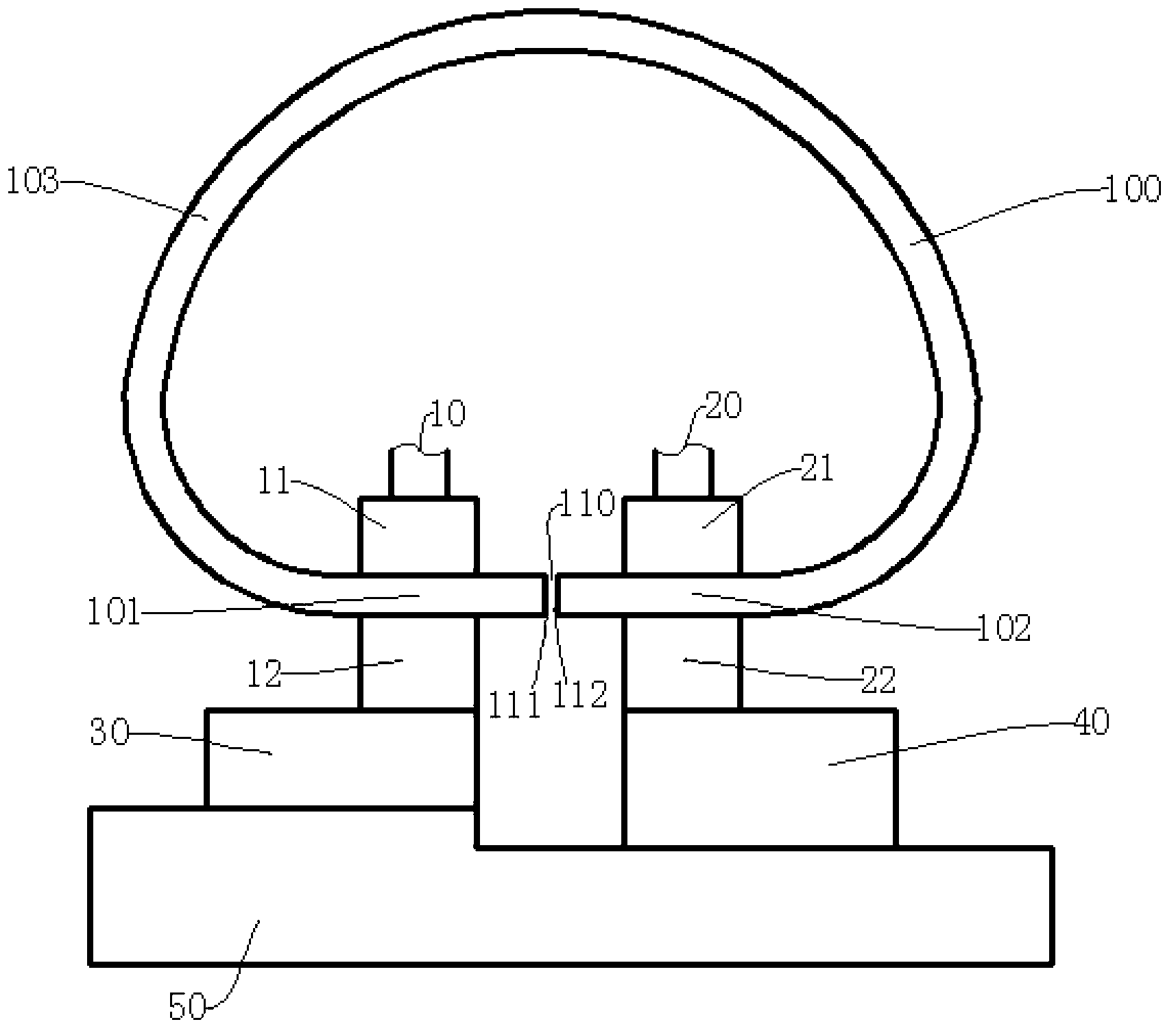

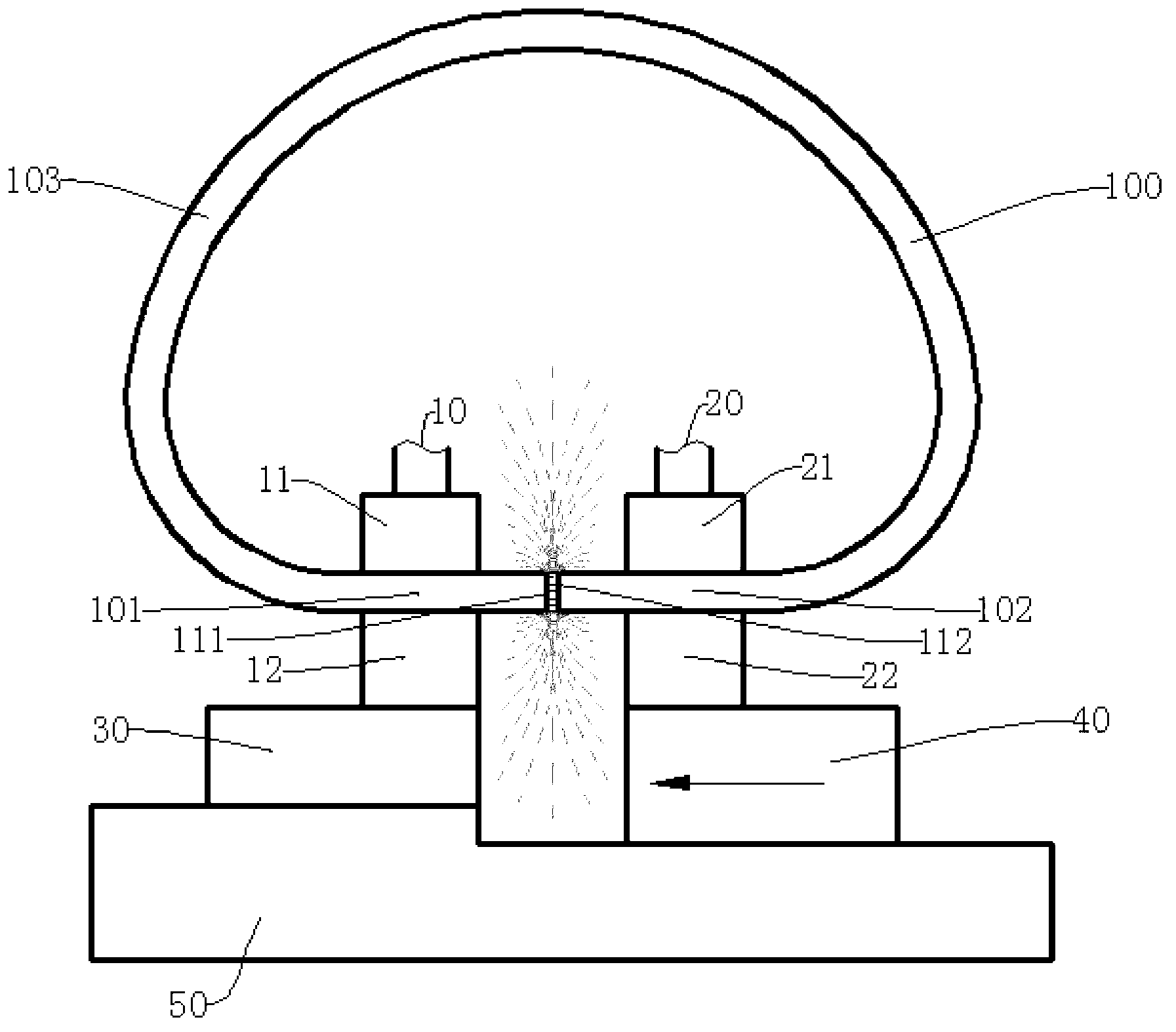

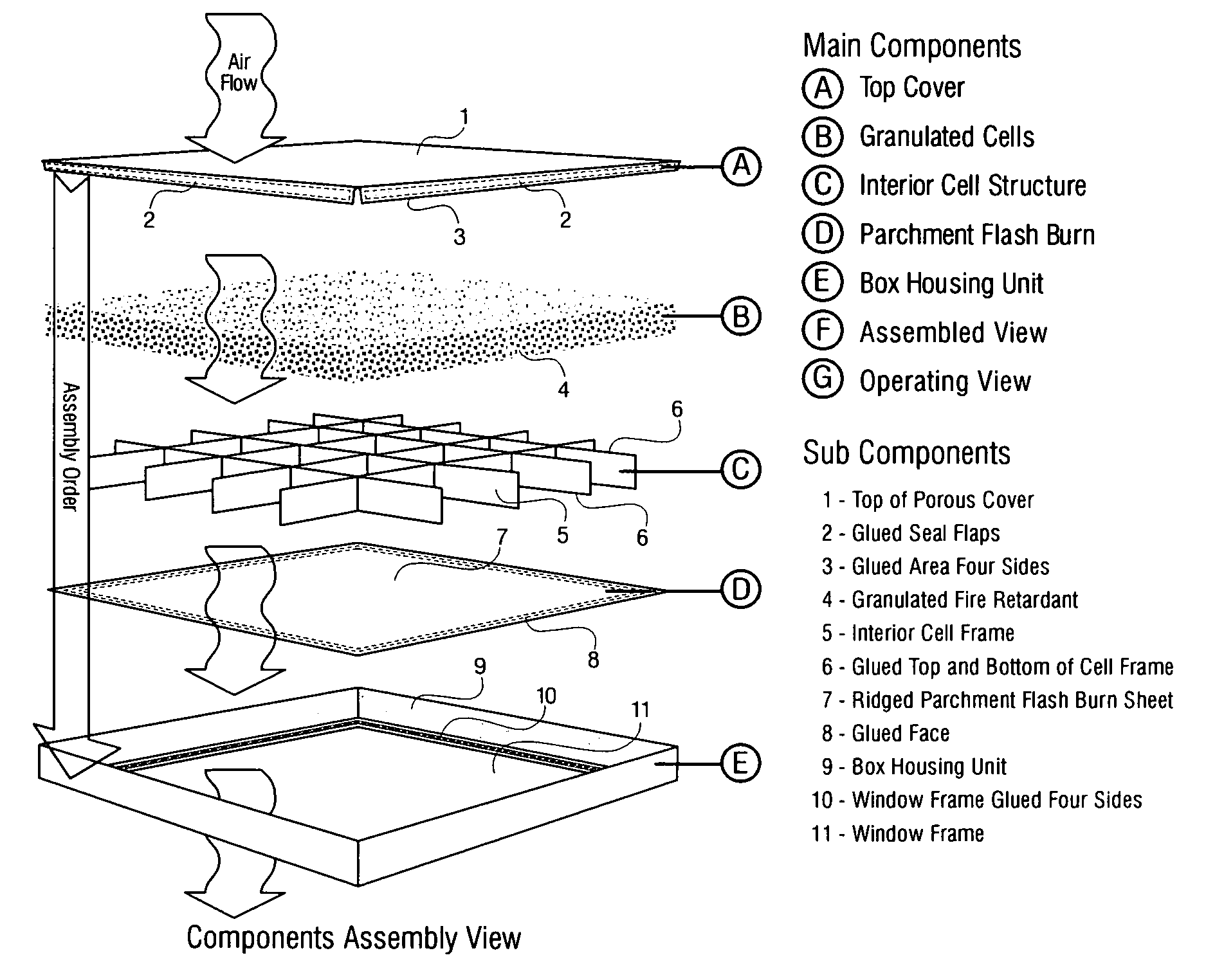

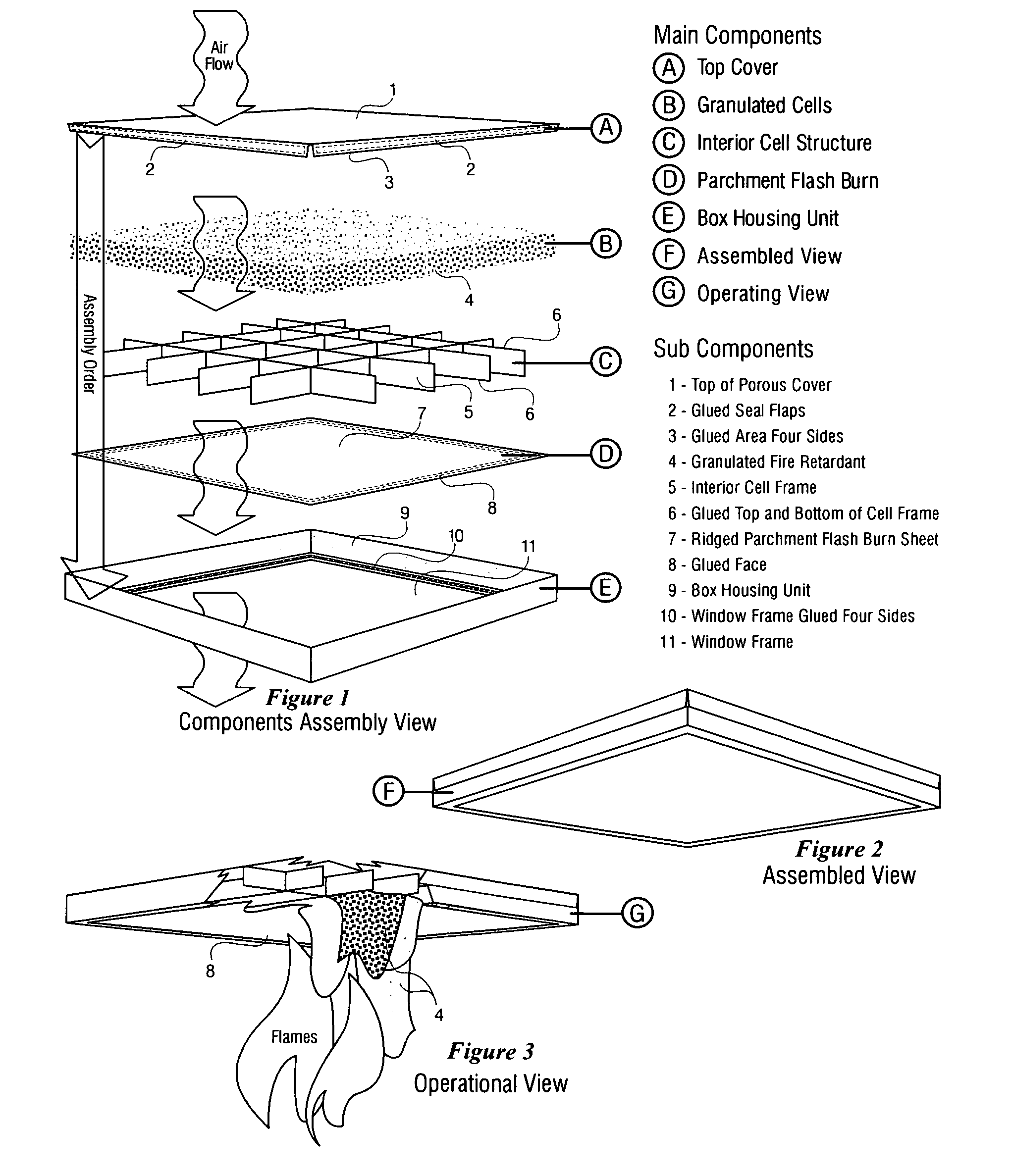

Ceiling fire extinguishing system with lost air filtration - the ceiling firefighter™

InactiveUS20110100651A1Improve insulation performanceImprove air qualityFire rescueAir filtrationSprinkler system

The Ceiling Firefighter is a Ceiling System (FIG. 2, Assembled View) designed for use within the ceilings of commercial, public and residential buildings that provides a method of mechanical fire extinguishing that offers an alternative or side by side enhancement to help overcome the nine before mentioned limitations of existing sprinkler systems. Comprised of five basic components of structure:(a) A flame resistant housing or box frame (9) whose face is set an opening or window (11), that conforms to standard ceiling system dimensions (FIG. 2, Assembled View).(b) A flash burn ridged parchment blister (7) which seals the window side of the box frame housing—secured in place with glue (8), to which its properties are measured to have a low kindling thermal range.(c) Internal glued (6) structural grid (5) whose main purpose is to reenforce both the ridged parchment flash burn blister (7) and to add overall strength to the unit itself. Secondary purpose is to minimize and limit damage to the unit's ridge parchment flash burn blister (7) to particular cells of the grid (5).(d) Granulated fire retardant packed within the housing box (4).(e) Top cover (1) with side flaps (2) on all four sides to be glued (3) to the outer top, outside surface main box housing (9).

Owner:DICKENS SR JAMES DANIEL +1

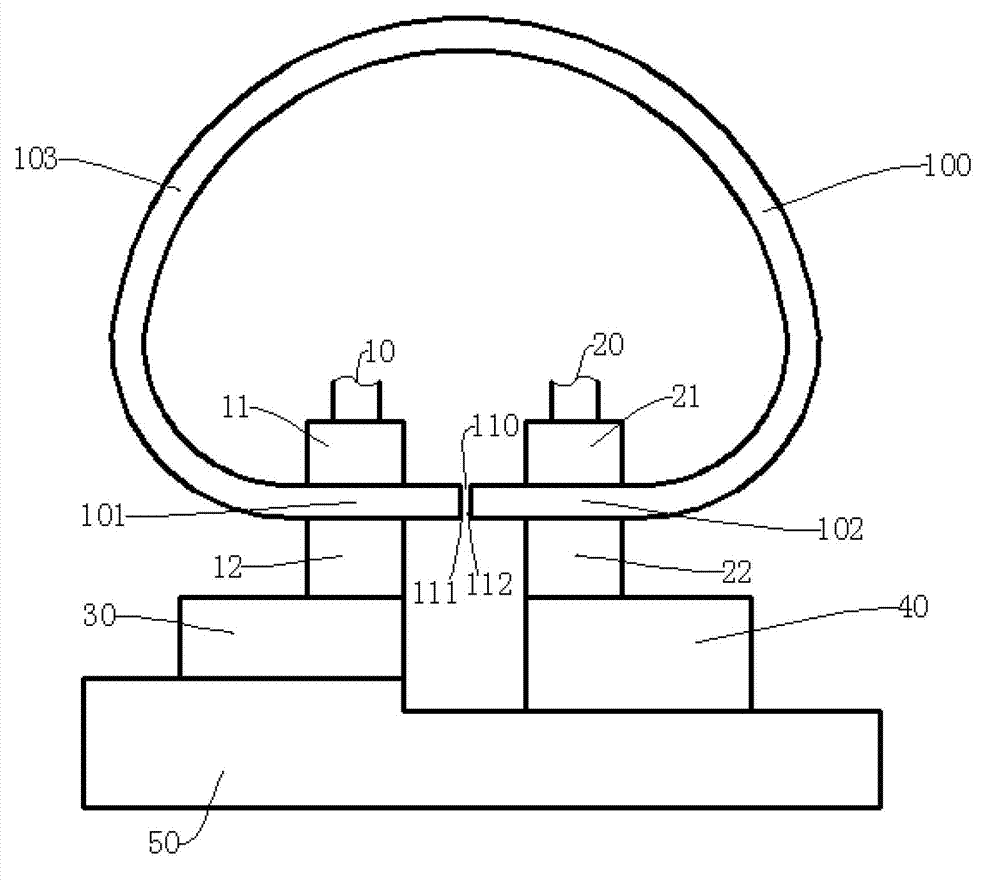

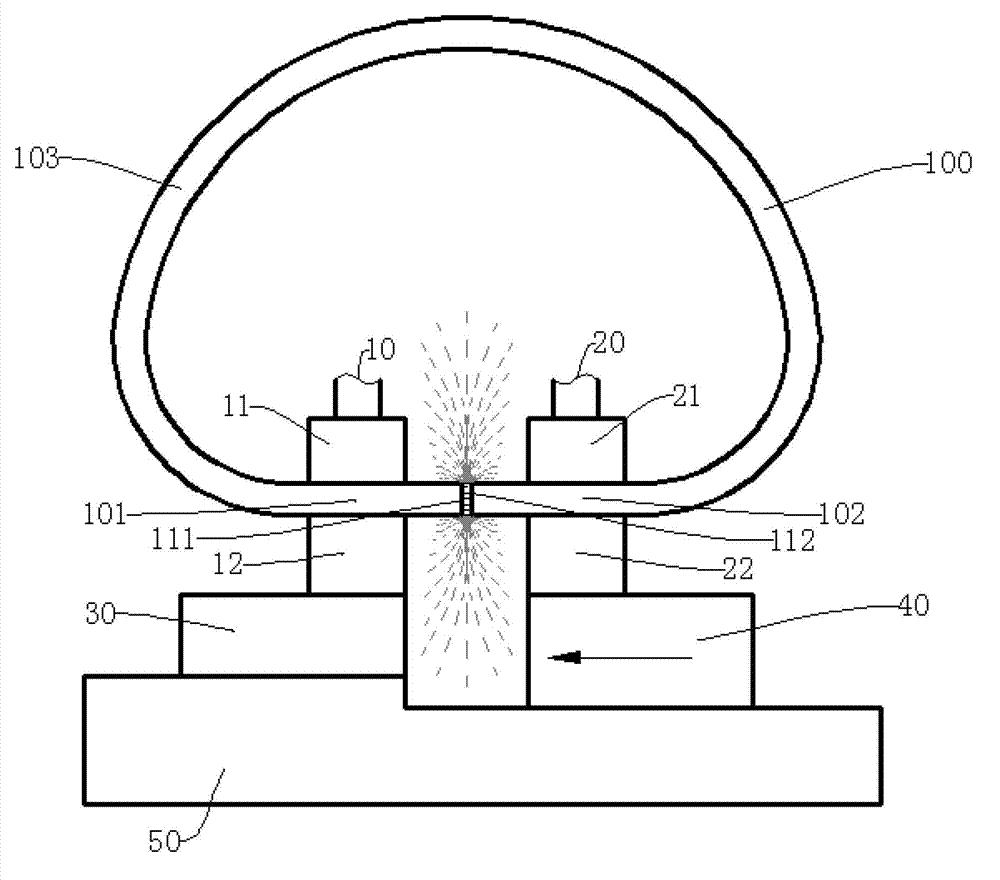

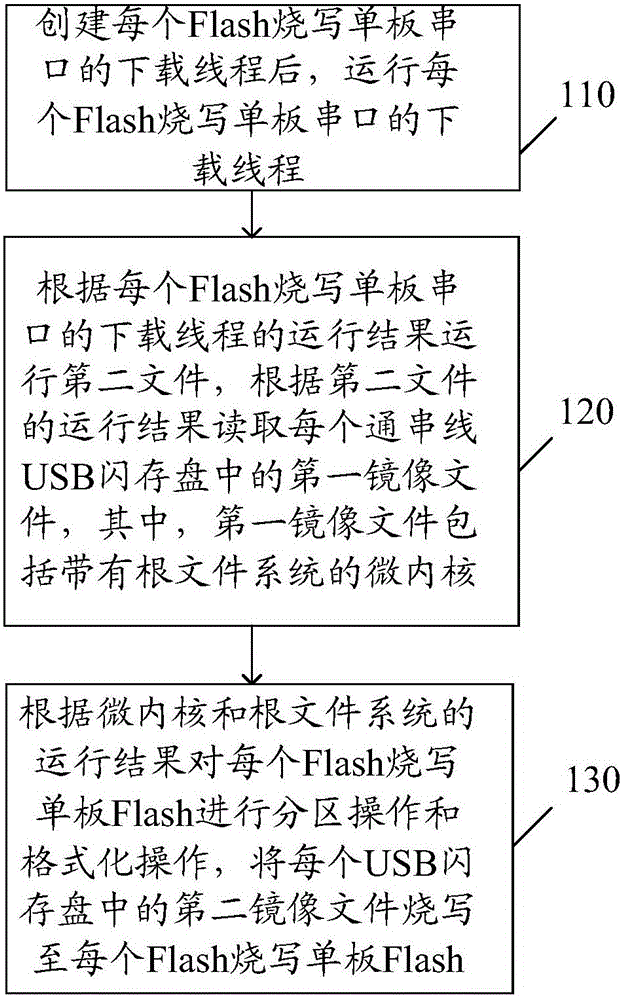

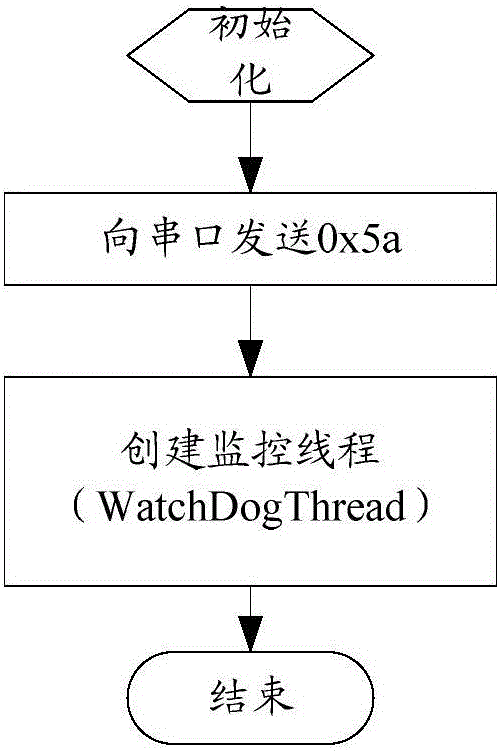

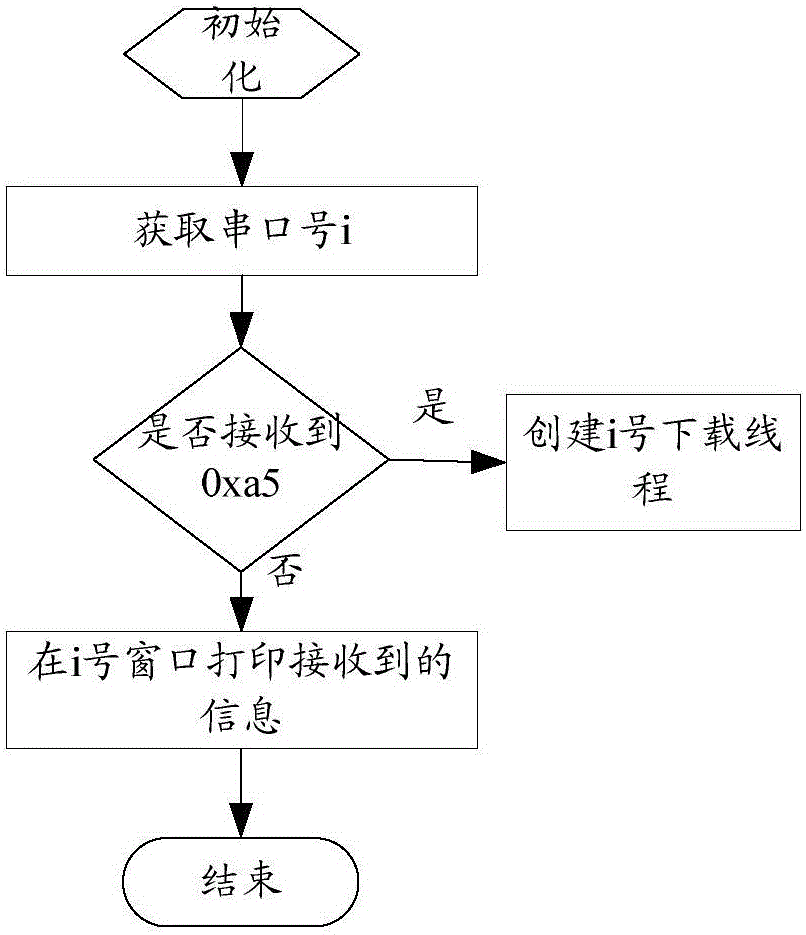

A Flash burning method, single board, upper computer and system

InactiveCN106325905AEasy to mass produceSave programming timeProgram loading/initiatingFile systemSingle plate

The invention provides a Flash burning method comprising the steps of after creating a downloading thread of each Flash burning single board serial port, operating the downloading thread of each Flash burning single board serial port; operating a second file according to the operating result of the downloading thread of each Flash burning single board serial port and reading a first mirror image file in each USB flash disk according to the operating result of the second file, wherein each first mirror image file comprises a micro-core provided with a root file system; performing partition and formatting operations on each Flash burning single board Flash according to the operating results of the micro-cores and the root file systems and burning a second mirror image file of each USB flash disk to each Flash burning single board Flash. The invention also provides a Flash burning single board, upper computer and system.

Owner:SANECHIPS TECH CO LTD

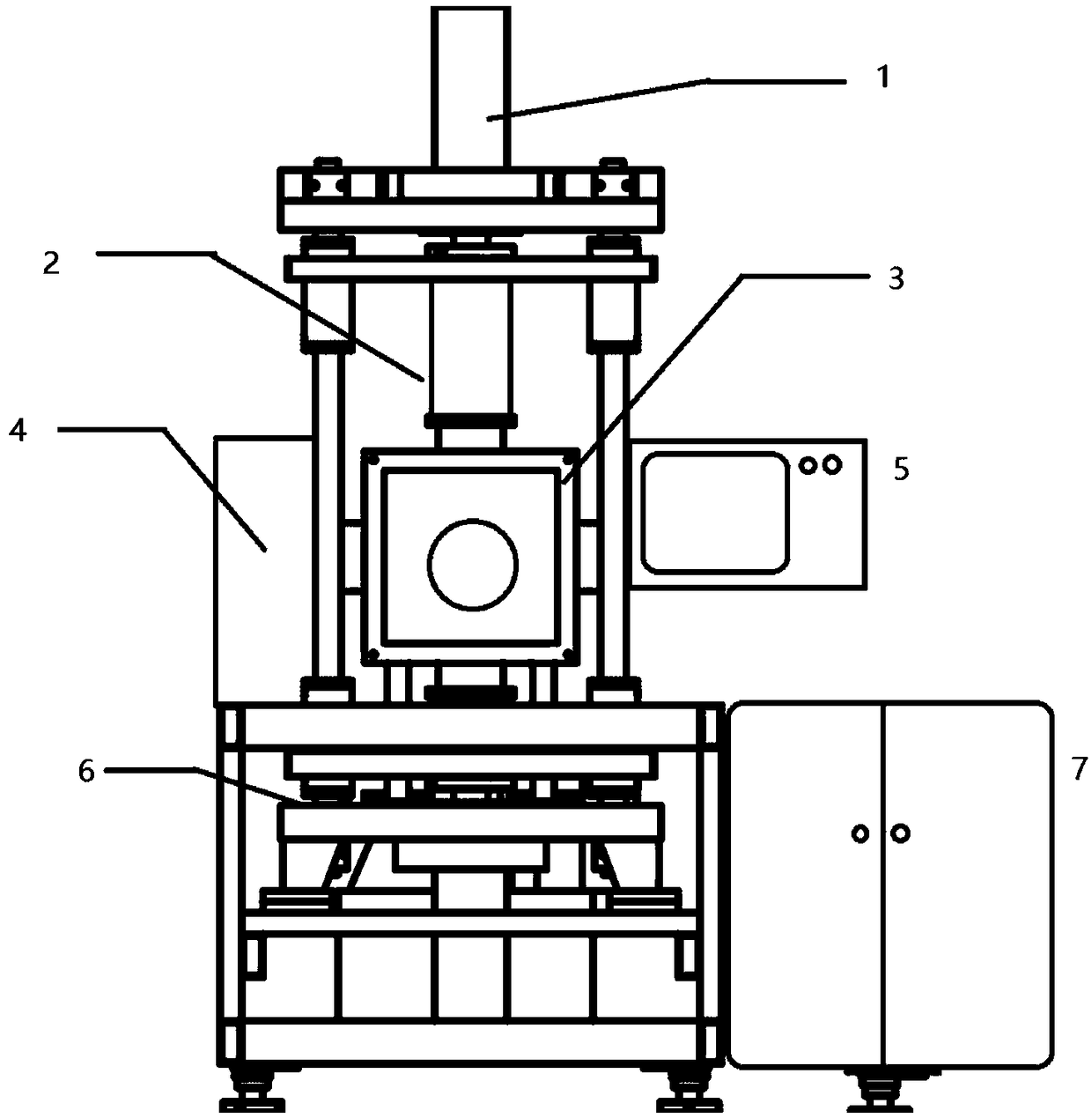

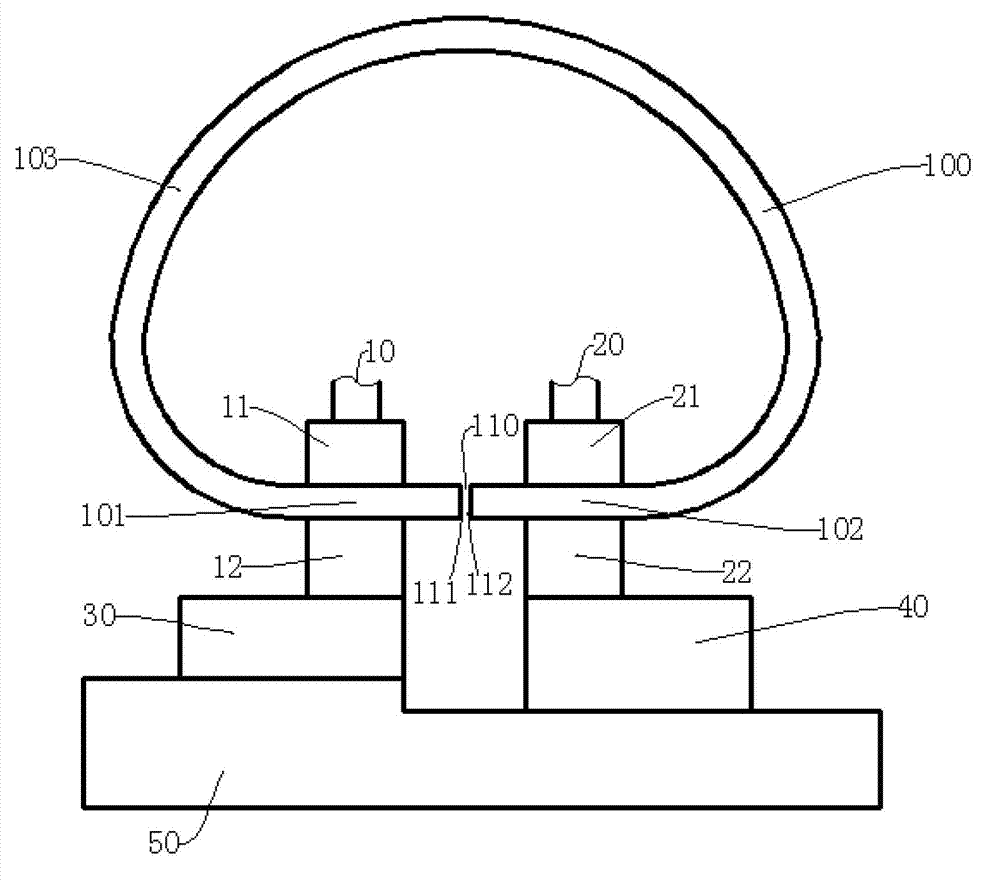

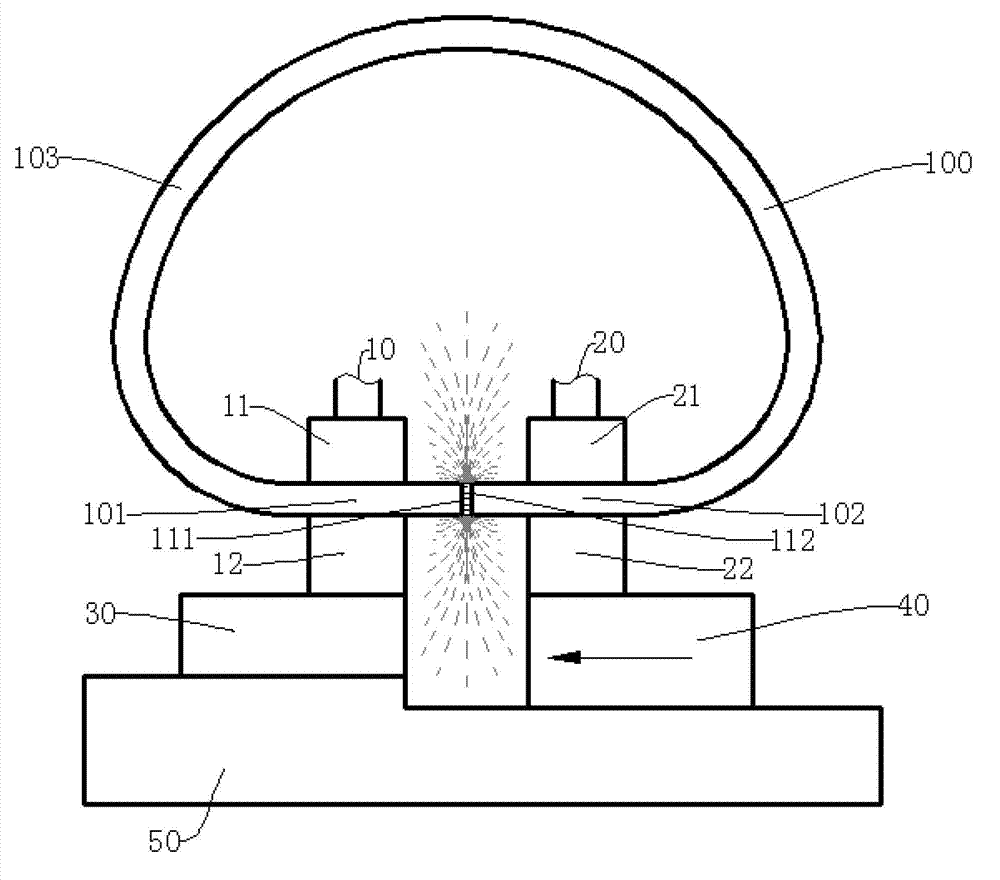

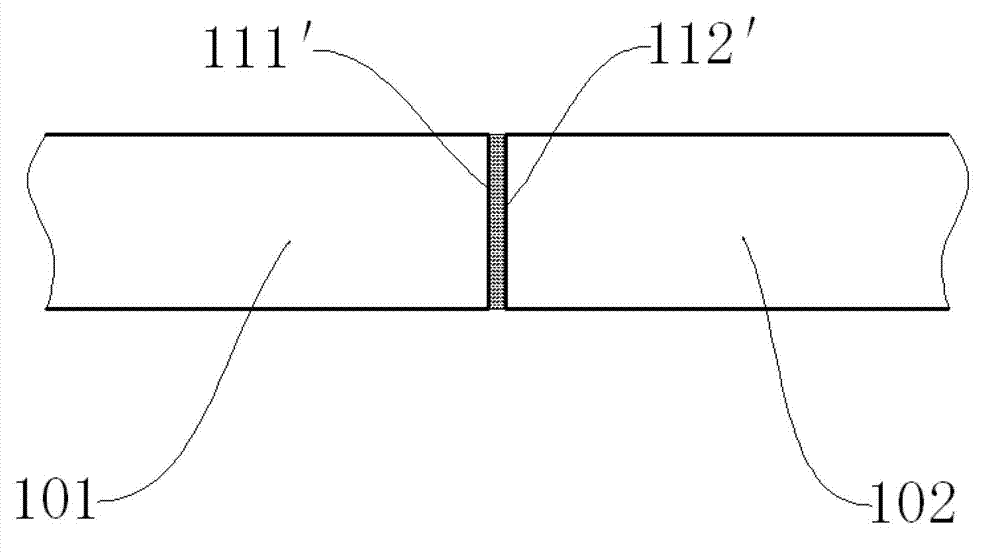

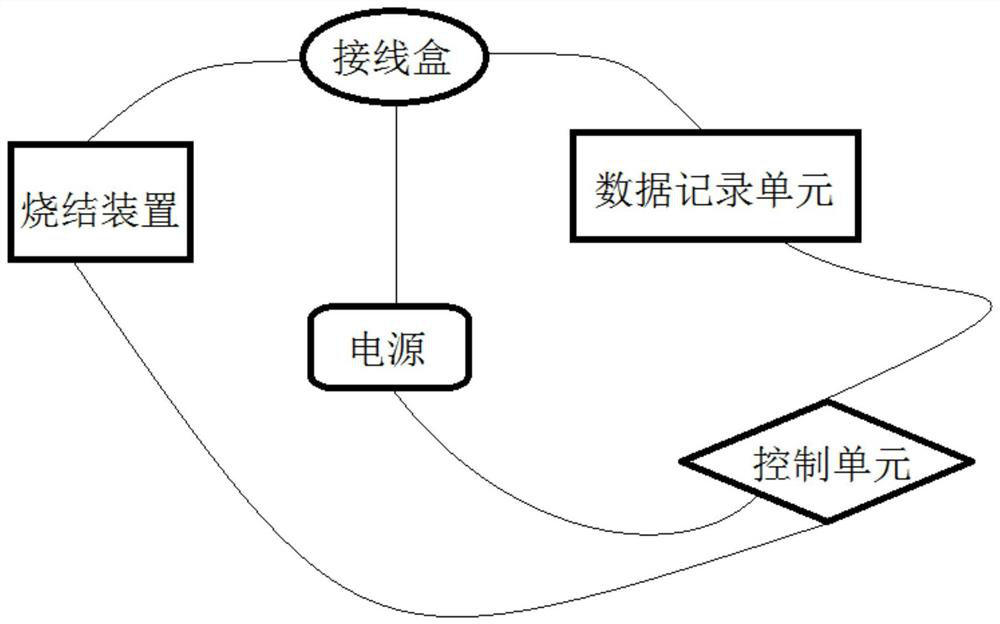

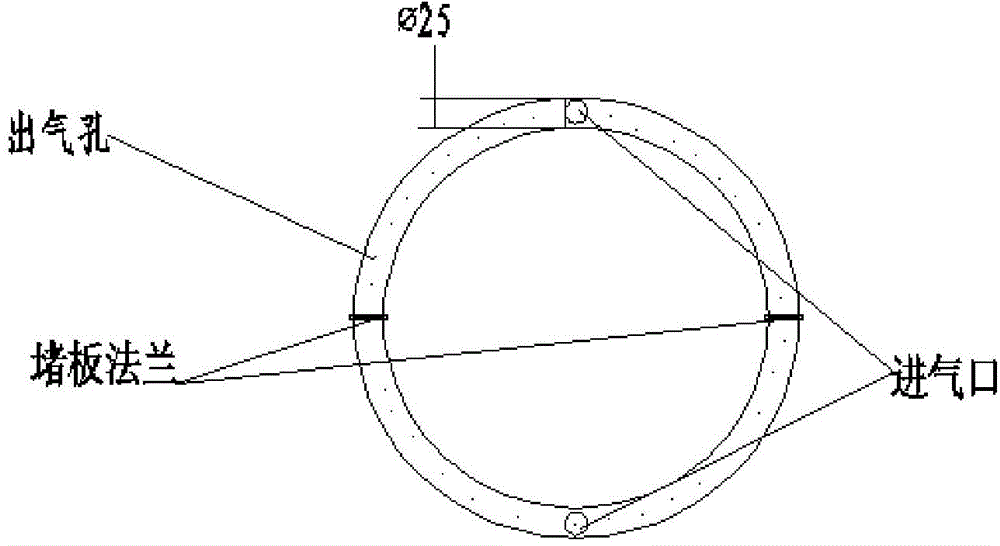

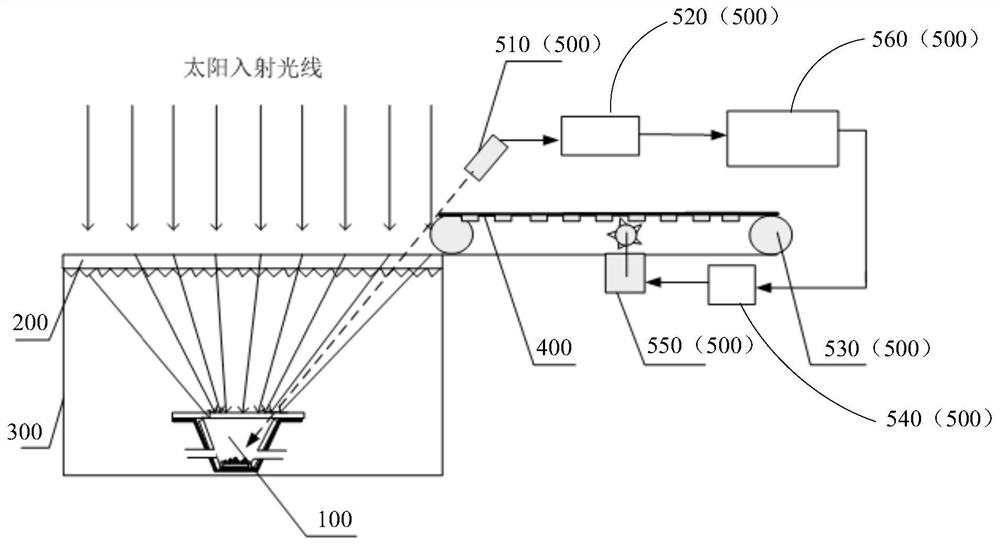

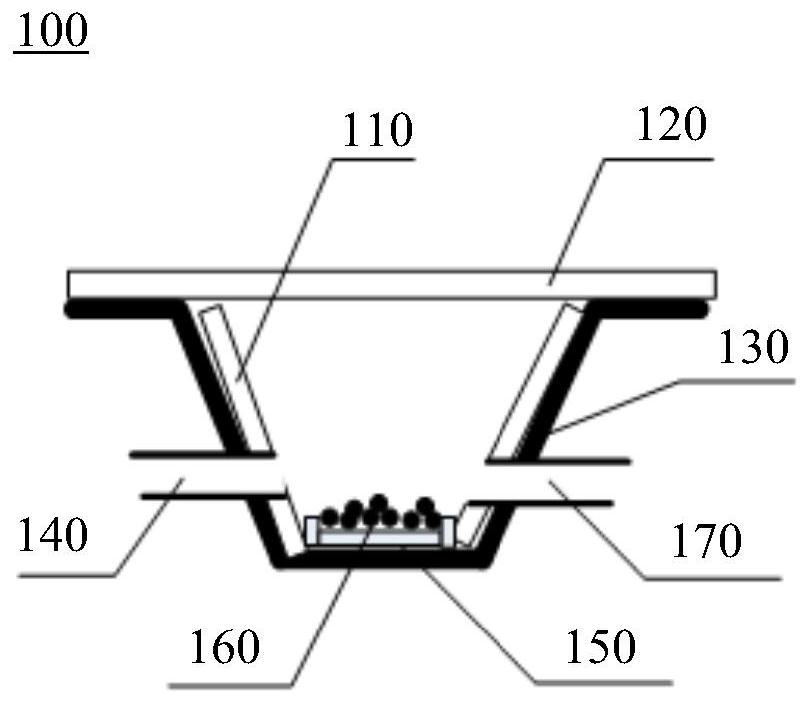

High-power condensation flash burning device

PendingCN113900459AGood flash effectEasy to controlTemperature control using electric meansMountingsEngineeringMechanical engineering

The invention provides a high-power condensation flash burning device. The high-power condensation flash burning device comprises a reaction cavity, a Fresnel condenser, a bracket, a baffle plate and a control module, wherein the Fresnel condenser is arranged at the top of the bracket; the reaction cavity is arranged at the bottom of the bracket and located on the focus of the Fresnel condenser, and a burnt object is placed at the bottom of the reaction cavity; the baffle plate is arranged above the Fresnel condenser; and the control module is connected with the baffle plate, and the control module is used for collecting a temperature signal of the burnt object and controlling the baffle plate according to the temperature signal so as to control the condensation ratio of the Fresnel condenser and adjust the heating temperature of the burnt object. According to the high-power condensation flash burning device, the flash burning process is achieved through the high-power condensation solar energy technology, energy conservation and environmental protection are achieved, the flash burning effect is good, and meanwhile flash burning can be accurately controlled through the light shielding plate.

Owner:NANJING INST OF MECHATRONIC TECH

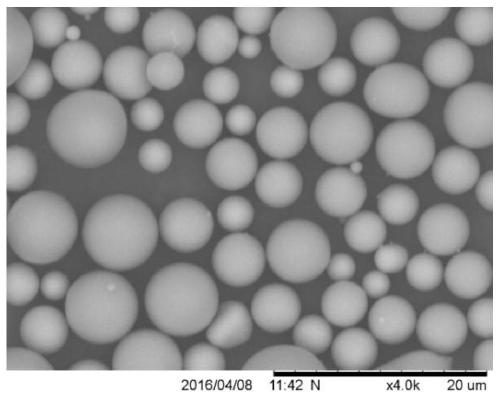

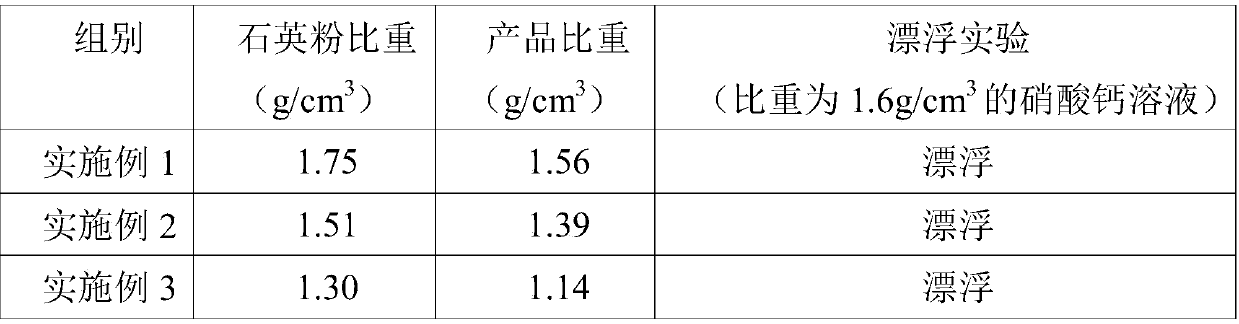

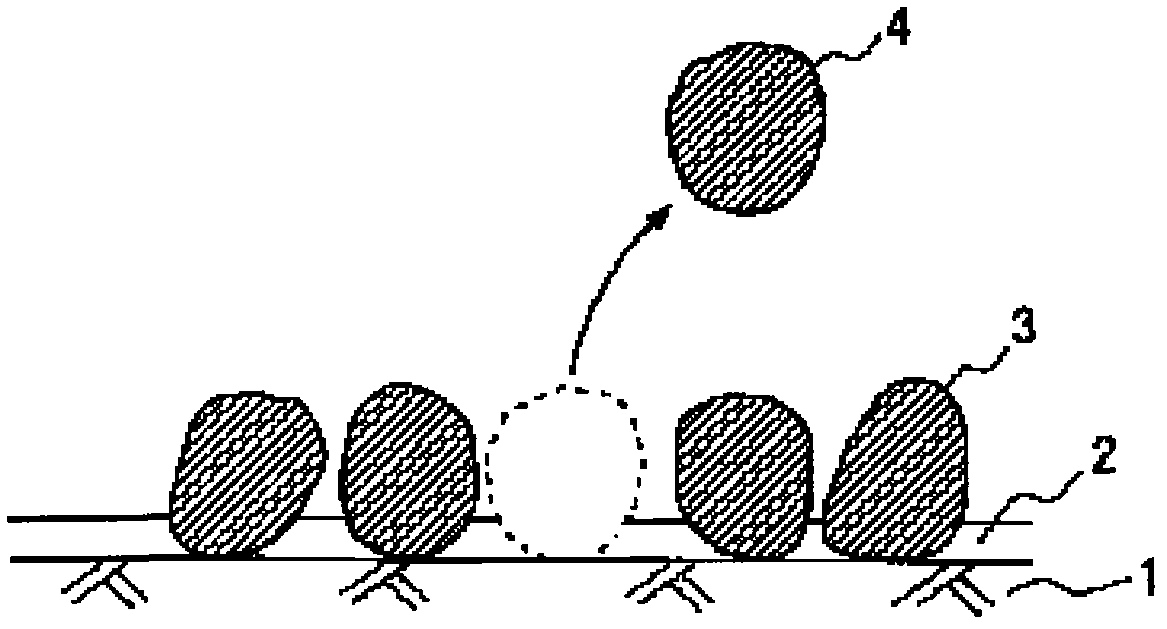

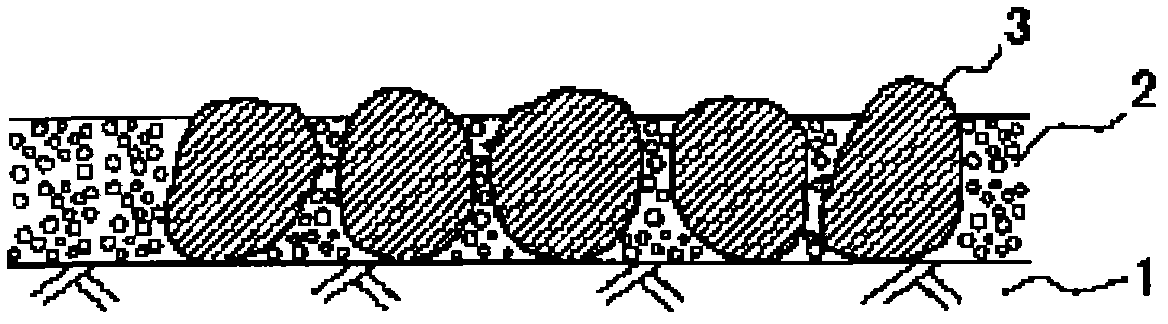

Preparation method of light spherical silica

The invention discloses a preparation method of light spherical silica, and relates to the technical field of inorganic materials. The preparation method comprises the steps that quartz mineral powdercontaining abundant fluid inclusions is screened, quartz powder with the specific gravity less than 1.8g / cm<3> is screened and used as a raw material, and the raw material is pulverized; and the pulverized raw material is introduced into a flash-burning furnace with inert gas carrier gas, airflow circulation is carried out in a spheroidized flame area, the airflow pressure intensity is adjusted,powder with the specific gravity less than 1.5g / cm<3> enters a dust collecting chamber for collecting, and the spherical closed-hole silica is obtained. The preparation method is simple in process, the prepared spherical silica has the characteristics of low specific gravity, high strength, low specific surface area, low oil absorption value, high sphericity degree and the like; and the sphericalsilica can be used as a material with low dielectric constant and low dielectric loss and is used for the field of high frequency and high speed copper clad laminates for 5G communication and the like.

Owner:ANHUI ESTONE MATERIAL TECH CO LTD

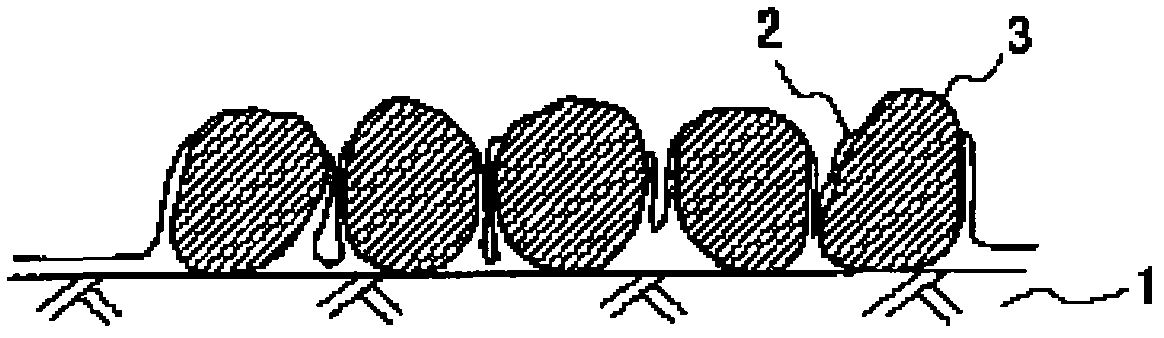

Distributed type road surface treatment construction method

InactiveCN102660916ASimple and efficient constructionAging resistanceIn situ pavingsBituminous materialsRoad surface

The invention belongs to the field of road construction and particularly relates to a distributed type road surface treatment construction method, which can fixedly bond aggregates on the road surface without using excessive asphalt material. The distributed type road surface treatment construction method comprises the process of forming an asphalt material layer in a foaming state on the road surface and the process of spreading the aggregates on the asphalt material layer in the foaming state. According to the distributed type road surface treatment construction method provided by the invention, the distributed asphalt material exists on the road surface in the state of foaming and increasing volume, therefore, even though the amount of the asphalt material does not result in flash burn phenomenon, the surface of the distributed aggregates in a large area can be fully covered, and the aggregates as well as the aggregates and the road surface can be fixedly bonded.

Owner:LIAONING PROVINCIAL TRANSPORTATION PLANNING & DESIGN INST

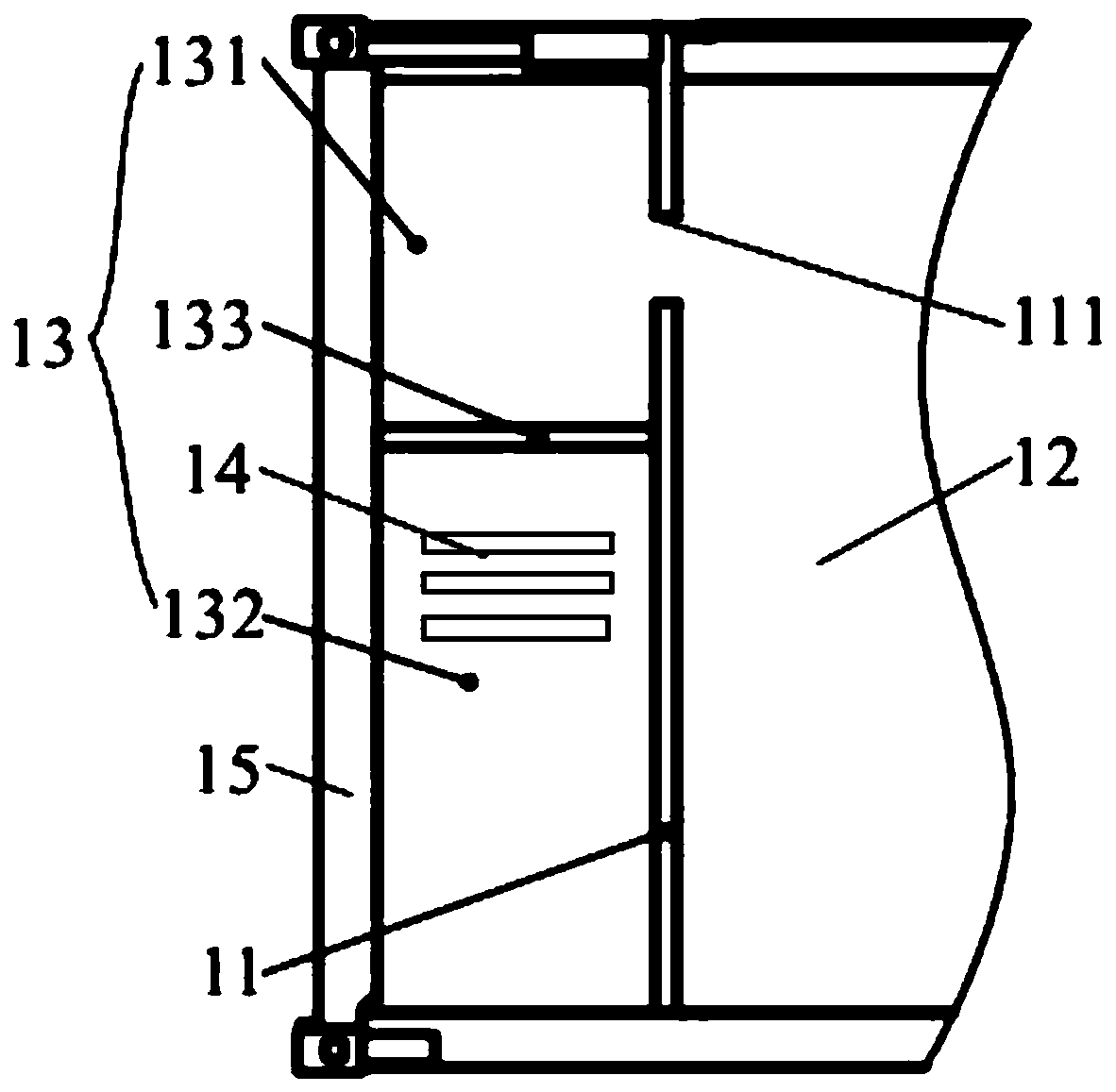

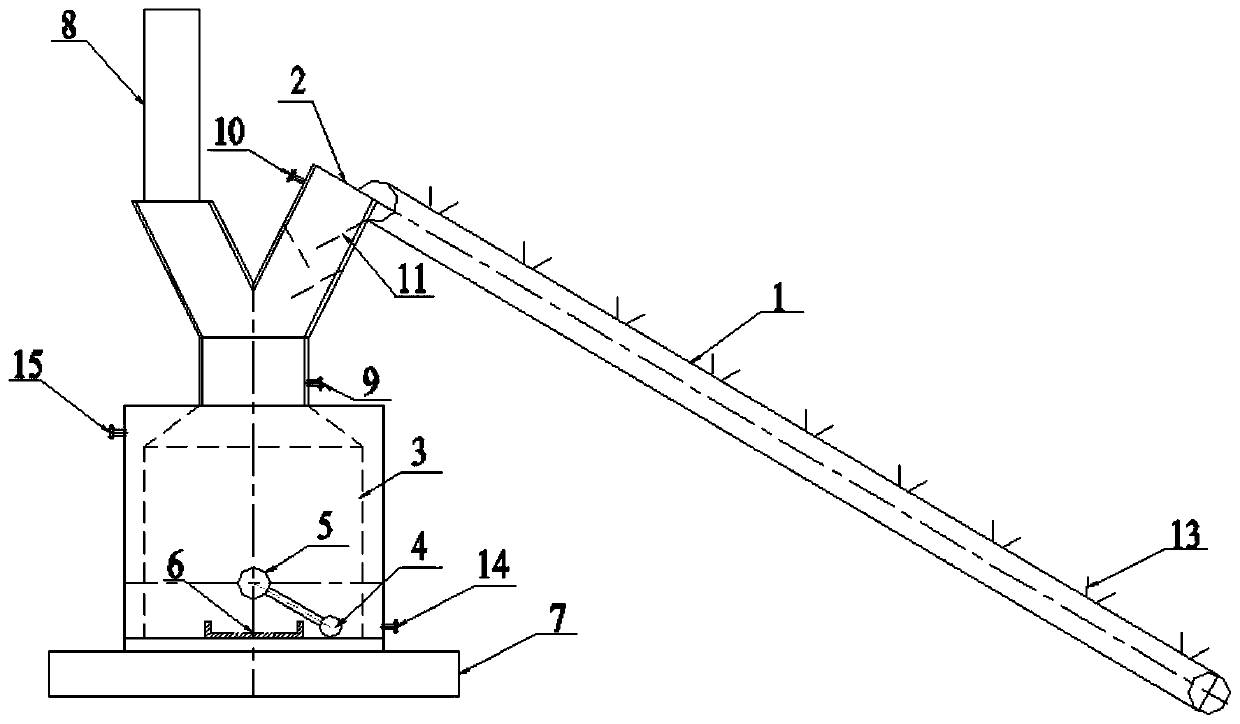

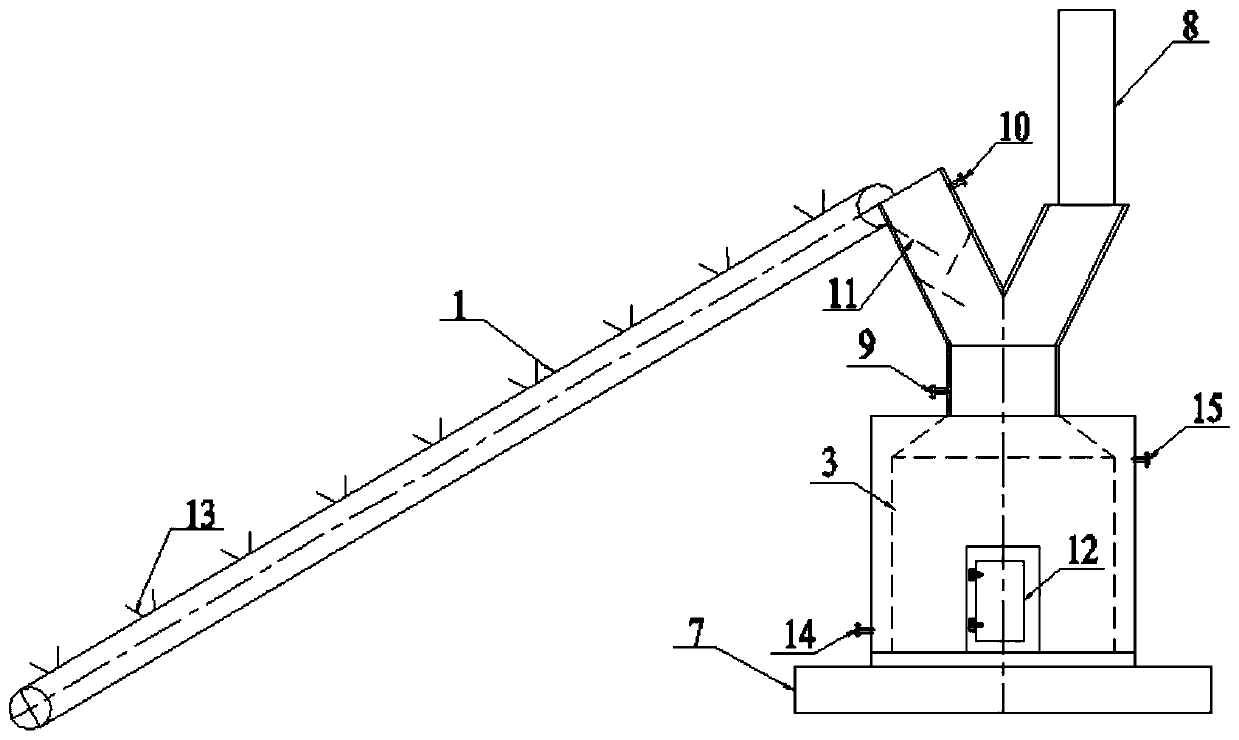

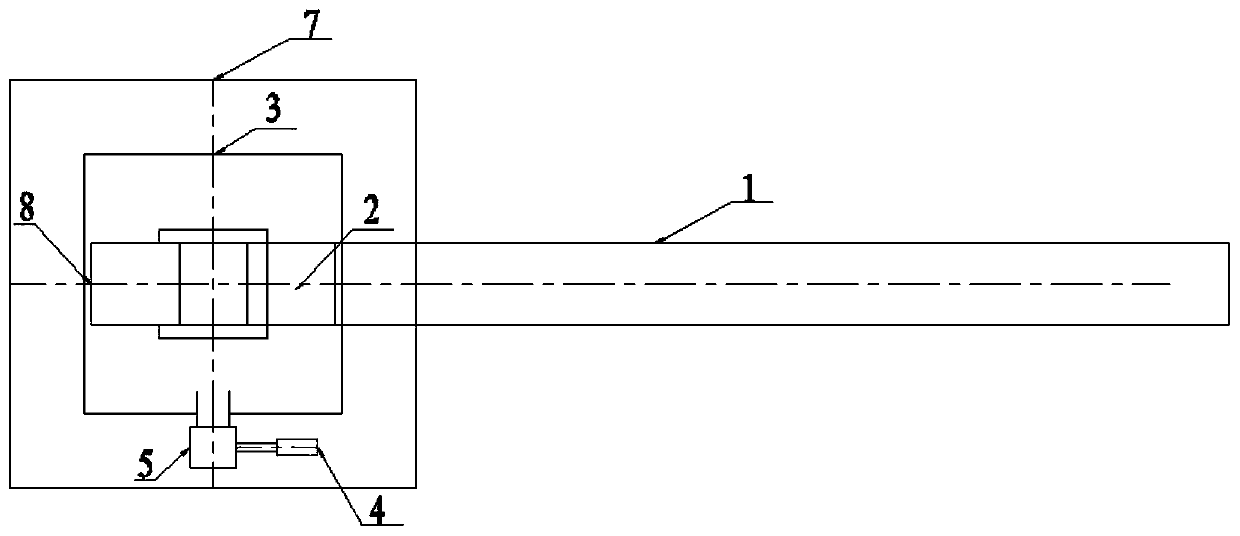

A small equivalent waste gunpowder flash burning treatment device

ActiveCN107883823BAvoid security issuesEnsuring Incineration Removal EfficiencyBlastingAir compressorBody cooling

The invention discloses a small-equivalent waste propellant flash burning treatment device. The safety treatment problem of waste propellants, used propellants, incomplete propellants and degraded propellants which are generated in the propellant and explosive scientific researching and trial-manufacturing processes is solved. The small-equivalent waste propellant flash burning treatment device mainly comprises a feed conveying device 1, a feeding port 2, an incinerator body 3, an air compressor 4, an igniter 5, an incineration disc 6, a base 7, an exhaust port 8, a feed cooling water inlet 9,a feed cooling water outlet 10, a one-way stop valve 11, an armoured door 12, a hopper13, an incinerator body cooling water inlet 14 and an incinerator body cooling water outlet 15. The small-equivalent waste propellant flash burning treatment device has the advantages that the structure is simple, the safety degree is high, the construction using cost is low, and automatic feeding and long-distance ignition can be achieved, and the small-equivalent waste propellant flash burning treatment device is suitable for airtight safety destruction of the waste propellants in scientific research testsand trial-manufacturing and production processes in the field of propellants.

Owner:XIAN MODERN CHEM RES INST

Ergonomic protective eyewear

Using a camera pointing downward, a working area below eye level can be displayed by a headwear for users, so that the user can maintain healthy sitting or standing posture while working on patients or objects located below eye level. Using two or more cameras pointing downward, three-dimensional views with accurate and natural depth perception of a working area can be displayed by a headwear for users. Additional functions including eye protection, zoom-in, zoom-out, on-off, lighting control, overlapping, and teleconference capabilities are also supported using electronic, video and audio devices associated with the headwear. The headwear can also comprise a face shield designed to protect the user from hazardous droplets, aerosols, harmful wavelengths of light, heat, sparks, flash burn, debris and / or flying objects. Contactless control devices can be used to control the functions of the headwear.

Owner:SHAU ALEXANDER YEN +1

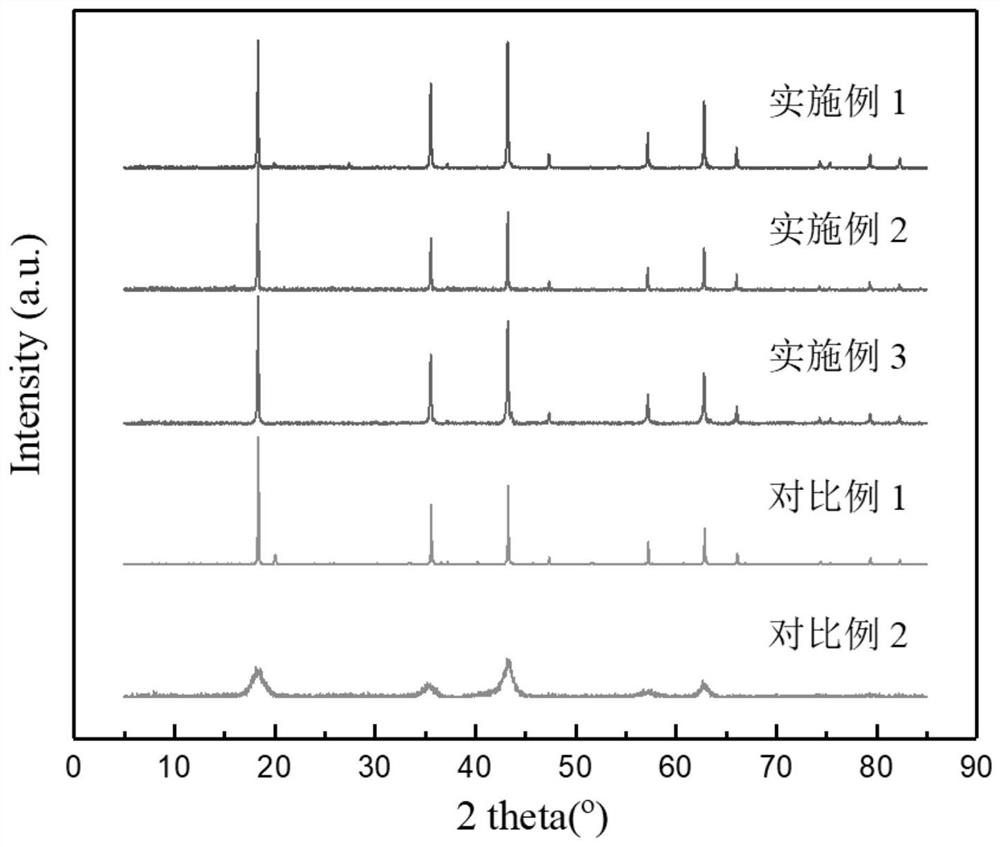

Method for rapidly preparing spinel type Li4Ti5O12 lithium titanate material at low temperature

PendingCN112374536AReduce energy consumptionUniform particle sizeAlkali titanatesCell electrodesCompression moldingHYDROSOL

The invention provides a method for rapidly preparing a spinel type Li4Ti5O12 lithium titanate material at a low temperature, and belongs to the technical field of lithium titanate preparation. The preparation method comprises the following steps of: (1) preparing flash burning precursor powder of Li4Ti5O12 by using a solid oxide mixing method, a hydrothermal method or a sol-gel method; (2) putting the flash burning precursor powder prepared in the step (1) into a mold, carrying out compression molding, demolding, and carrying out isostatic cool pressing treatment to obtain a final flash burning precursor biscuit; and (3) applying direct current to the two ends of the flash burning precursor biscuit, heating the flash burning precursor biscuit in a protective atmosphere until the flash burning is finished, starting flash burning when flash occurs, controlling the current density, controlling the flash burning for a period of time in a constant current state, stopping heating after theflash burning is completed, cooling to room temperature to obtain a Li4Ti5O12 sintered body, and crushing to obtain a spinel type Li4Ti5O12 lithium titanate powder product. According to the invention,the preparation of the precursor powder and the flash burning technology are combined, the temperature and time required by preparation are reduced, and the preparation energy consumption is saved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

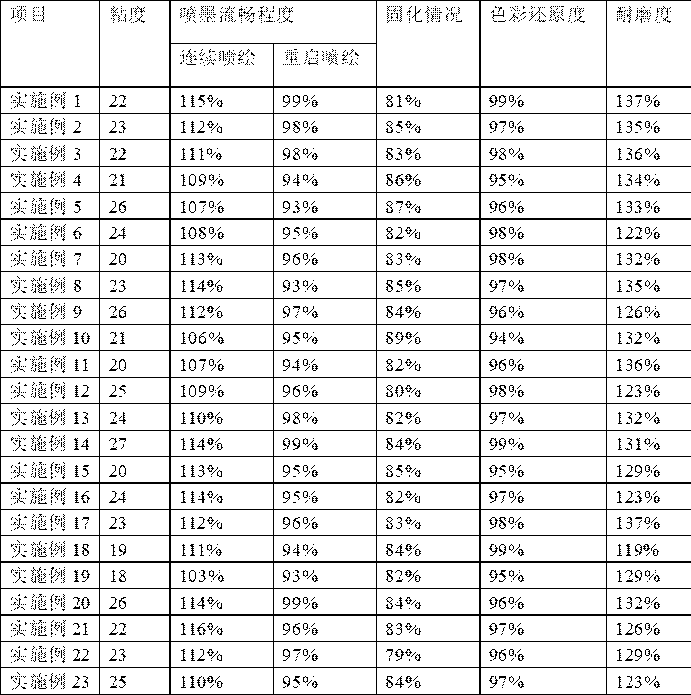

Ink solvent for glass inkjet printing

The invention relates to the technical field of jet printing, and discloses an ink solvent for glass inkjet printing, which is used for dissolving and / or swelling pigment. The ink solvent is preparedfrom resin, fuel and silicate, wherein the resin is used for immobilizing pigment onto glass; the fuel is used for carrying the pigment; the silicate is heated to be melted and softened so as to position ink on the glass; the solution which has fluidity and can be sprayed is formed. The ink solvent has the advantages that under the heating condition, the silicate molecules in the ink and the silicon dioxide or silicate molecules at the glass surface mutually disperse and permeate via the molecule thermal movement; in the heating process, the fuel for carrying the pigment can generate flash burn and produce heat, the temperature at the ink layer and glass surface is further increased, the molecule thermal movement and mutual dispersion between the ink layer and the glass surface are promoted, the positioning and fixing of jet printing patterns are accelerated, the size deviation of the jet printing patterns on the surface of a glass plate is effectively decreased, and the size and position accuracy of the patterns on the surface of the glass plate is obviously improved.

Owner:万弋林

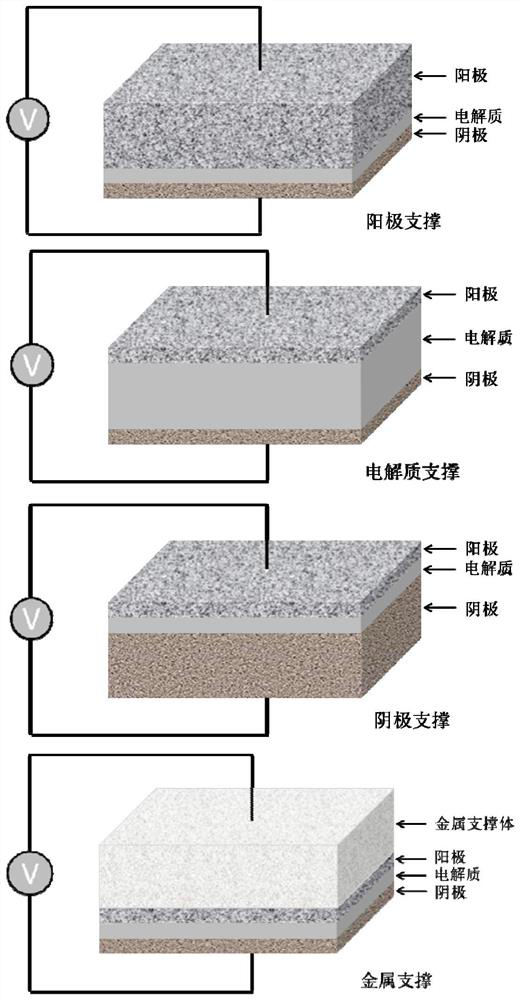

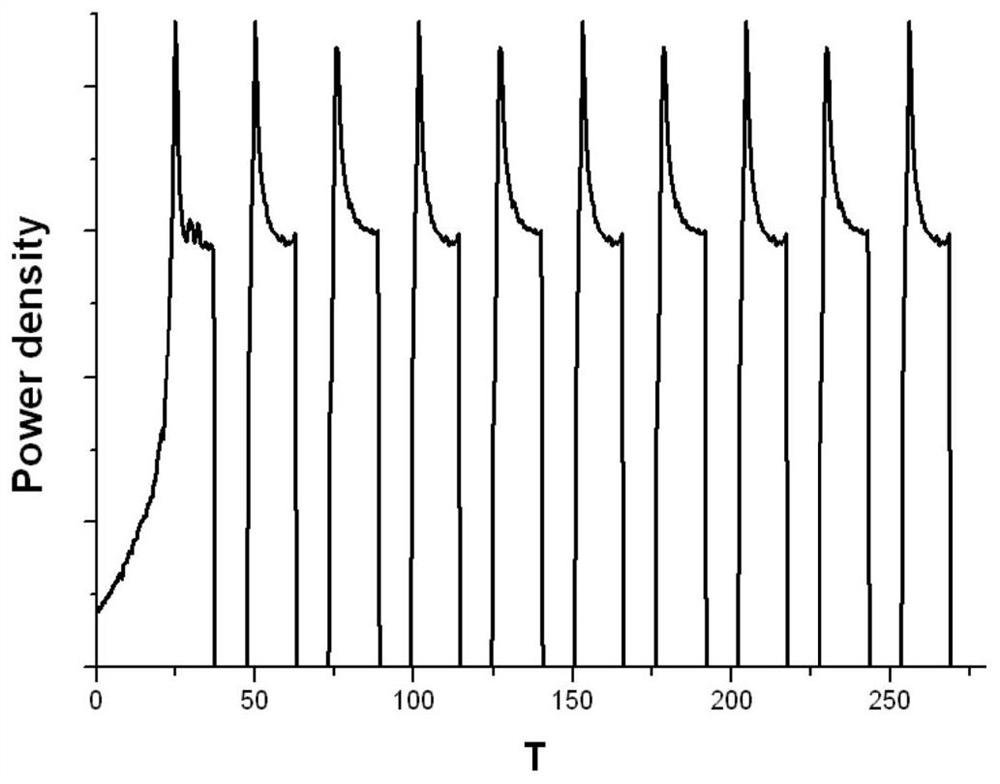

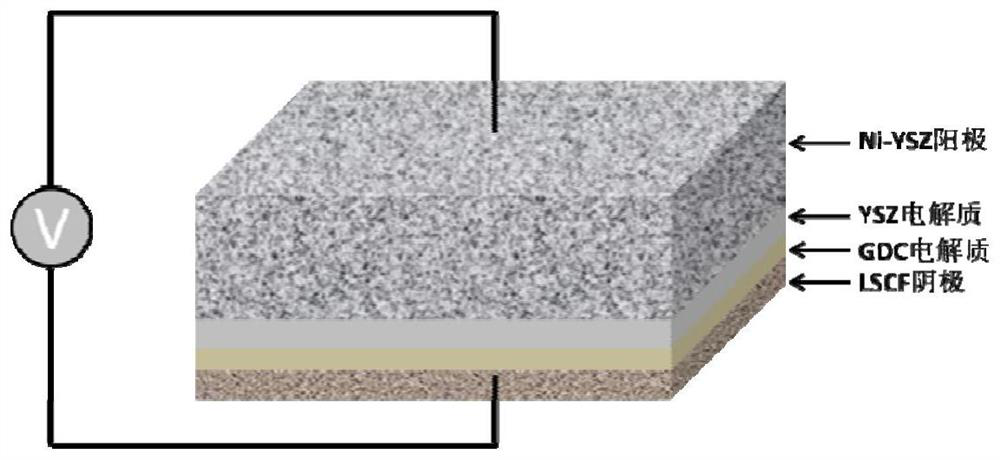

Treatment method of SOFC (solid oxide fuel cell) multi-layer co-fired material

PendingCN114649554AReduces spalling/crackingHigh bonding strengthFuel cellsFurnace temperatureHemt circuits

The embodiment of the invention discloses a treatment method of an SOFC (Solid Oxide Fuel Cell) multi-layer co-fired material, which comprises the following steps: connecting the SOFC multi-layer co-fired material in series in a circuit, placing in a sintering furnace, and heating to 400-1400 DEG C in an inert atmosphere; and applying an electric field to the SOFC multi-layer co-fired material, turning off a power supply when a flash burning phenomenon occurs, repeating for multiple times, and then reducing the furnace temperature to room temperature. According to the embodiment of the invention, the electric field is repeatedly applied to the multi-layer structure, so that the material and the structure are repeatedly subjected to the second stage (abrupt change stage) of flash burning, atoms / ions on the interface are promoted to be quickly diffused, the bonding strength of the interface is greatly improved, the stress of the interface is relieved, and the spallation / cracking of the SOFC in the use process is reduced.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com