Treatment method of SOFC (solid oxide fuel cell) multi-layer co-fired material

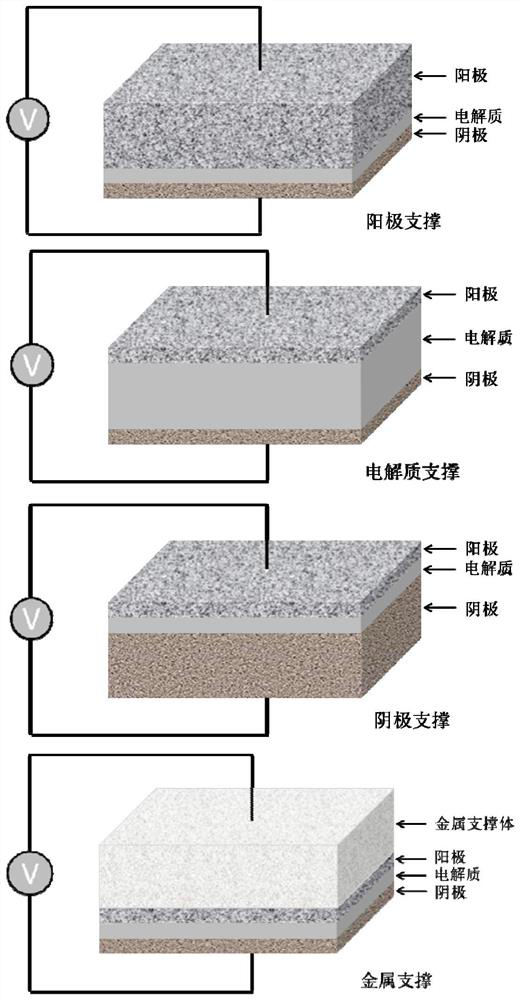

A treatment method and co-firing technology, applied in fuel cells, electrical components, electrochemical generators, etc., can solve the problems of easy delamination, cracking and difficulty in meeting life requirements of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

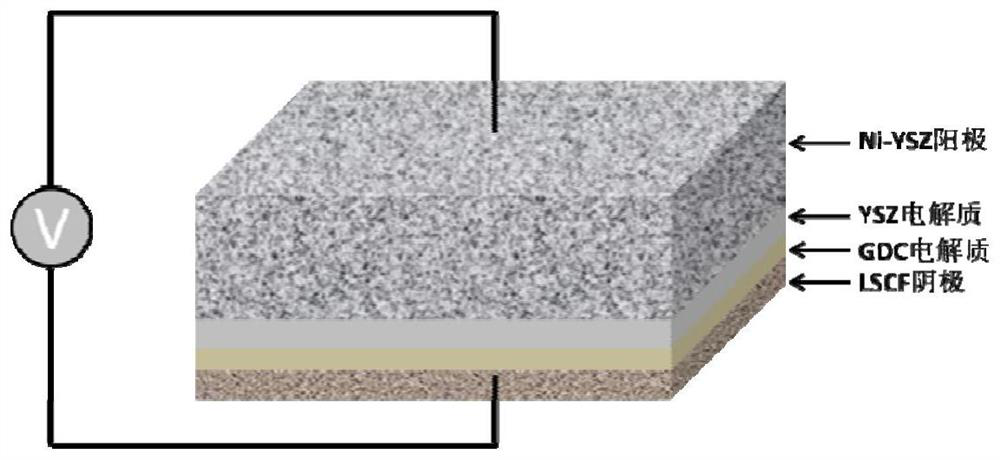

[0029] This example deals with a multi-layer co-fired material for a solid oxide fuel cell, such as image 3 shown, the material is La 1-x Sr x Co 1-y Fe y O 3 (LSCF) as the cathode, YSZ and GDC as the electrolyte, and Ni-YSZ as the anode.

[0030] The LSCF and Ni-YSZ were coated with platinum electrodes, and the electrodes were sintered as specified for different platinum pastes. The combination of electrode and material is good. Multilayer co-fired ceramics with platinum electrodes on the surface are connected in series in a circuit and placed in a sintering furnace.

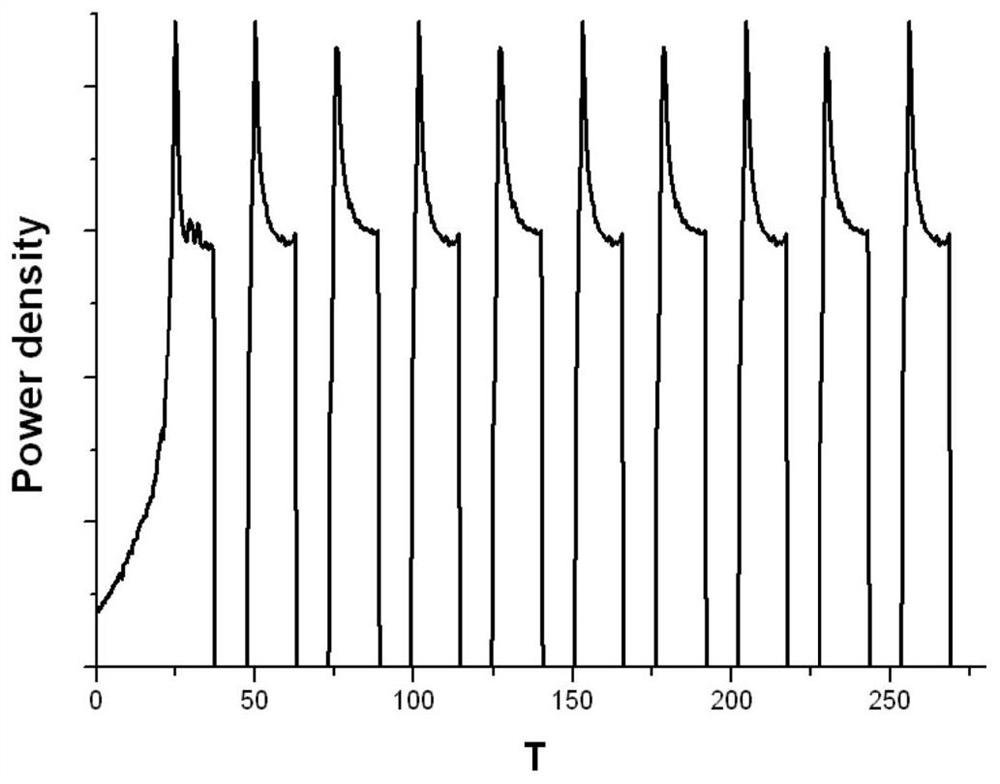

[0031] The sintering furnace was heated to 800°C and kept at a constant temperature for 10 minutes. An electric field of 100 V / cm was applied, and a voltage of 5 V was applied assuming that the thickness of the multilayer co-fired ceramic was 0.5 mm. After the electric field is applied, a flash-burn phenomenon occurs, the current increases rapidly, and the power supply automatically switches to the cur...

Embodiment 2

[0033] This example deals with a multi-layer co-fired material for a solid oxide fuel cell, such as Figure 5 shown, the multilayer material is BaCo 0.4 Fe 0.4 Zr 0.1 Y 0.1 O 3-δ (BCFZY) is the cathode, BaZr 0.1 Ce 0.7 Y 0.1 Yb 0.1 O 3–δ (BZCYYb) is the electrolyte and Ni-BZCYYb is the anode. Coat both ends with platinum electrodes and sinter the electrodes as specified for different platinum pastes. The electrode and the material are combined well. Multilayer co-fired ceramics with platinum electrodes on the surface are connected in series in a circuit and placed in a sintering furnace. Platinum electrodes can be omitted.

[0034] The sintering furnace was heated to 900°C and kept at a constant temperature for 10 minutes. An electric field of 120V / cm is applied, and if the thickness of the multilayer co-fired ceramic is 0.5mm, a voltage of 6V is applied. After the electric field is applied, a flash-burn phenomenon occurs, the current increases rapidly, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com