Preparation method of light spherical silica

A spherical silica, lightweight technology, applied in the direction of silica, silicon oxide, chemical instruments and methods, etc., can solve the problems of large specific surface area, high oil absorption value, insufficient strength, etc., and achieve simple process and high specific surface area Low, high sphericity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Fully investigate the formation history of quartz ore, screen out quartz ore powder containing rich fluid inclusions, use the weight liquid to classify, and screen out the specific gravity less than 1.8g / cm 3 Quartz powder; crush the raw material to particle size D 50 2 to 30 μm; the screened powder is passed into the flash furnace with argon as the carrier gas, the temperature in the high temperature area of the flash furnace is controlled at 1700°C, and four nozzles are designed to blow each other in the high temperature area to make the powder form in the high temperature area Circulation, smoldering for 30 minutes; stop calcination, control the airflow pressure to 0.4MPa, collect dust, and obtain the product spherical closed-cell silica.

Embodiment 2

[0023] The operation of embodiment 2 and embodiment 3 is the same as embodiment 1.

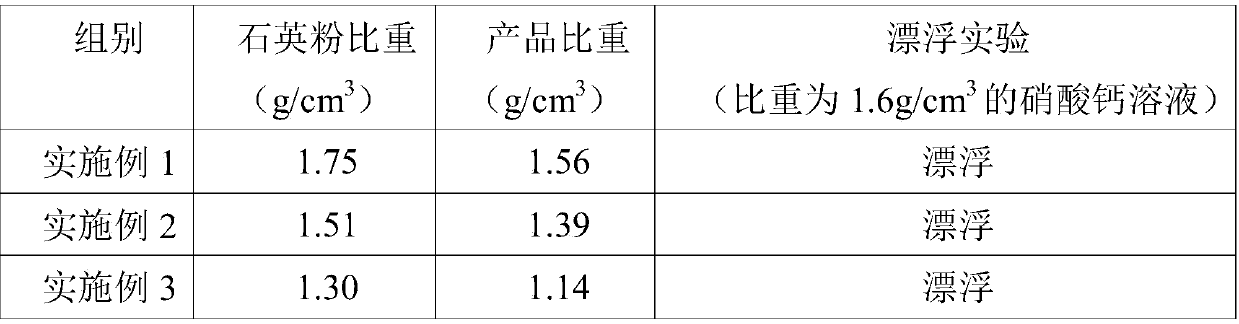

[0024] The raw material and product specific gravity data of embodiment 1-3 are as shown in table 1.

[0025] Table 1

[0026]

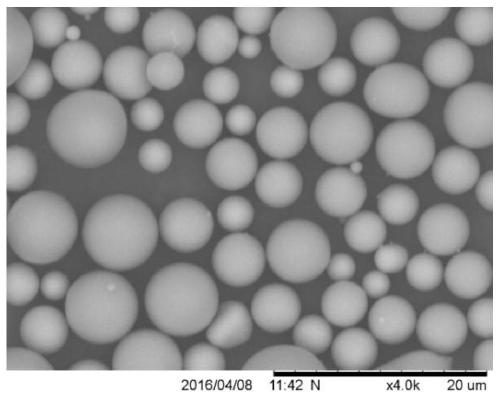

[0027] Depend on figure 1 It can be seen that the specific gravity of the prepared product is small, the sphericity is high, and the shape is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com