Flash welding forming method of aluminum alloy thin-wall ring member

An aluminum alloy, thin-walled ring technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of scrapped welding parts, flash stop, affecting the continuous welding and welding seam quality, etc., and achieve the effect of good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0036] The main chemical element content (percentage by weight) of the alloy is: 1.9% to 2.5% of Cu, 1.4% to 1.8% of Mg, 0.9% to 1.5% of Fe, 0.9% to 1.5% of Ni, 0.9% to 1.5% of Ni, Ti content is 0.02% to 0.10%, Mn content is 0.20%, Zn content is 0.30%, Si content is 0.35%, other elements are individually ≤0.05% and the sum is ≤0.10%, and the balance is Al.

[0037] The flash welding forming process steps of the alloy thin-walled ring are as follows:

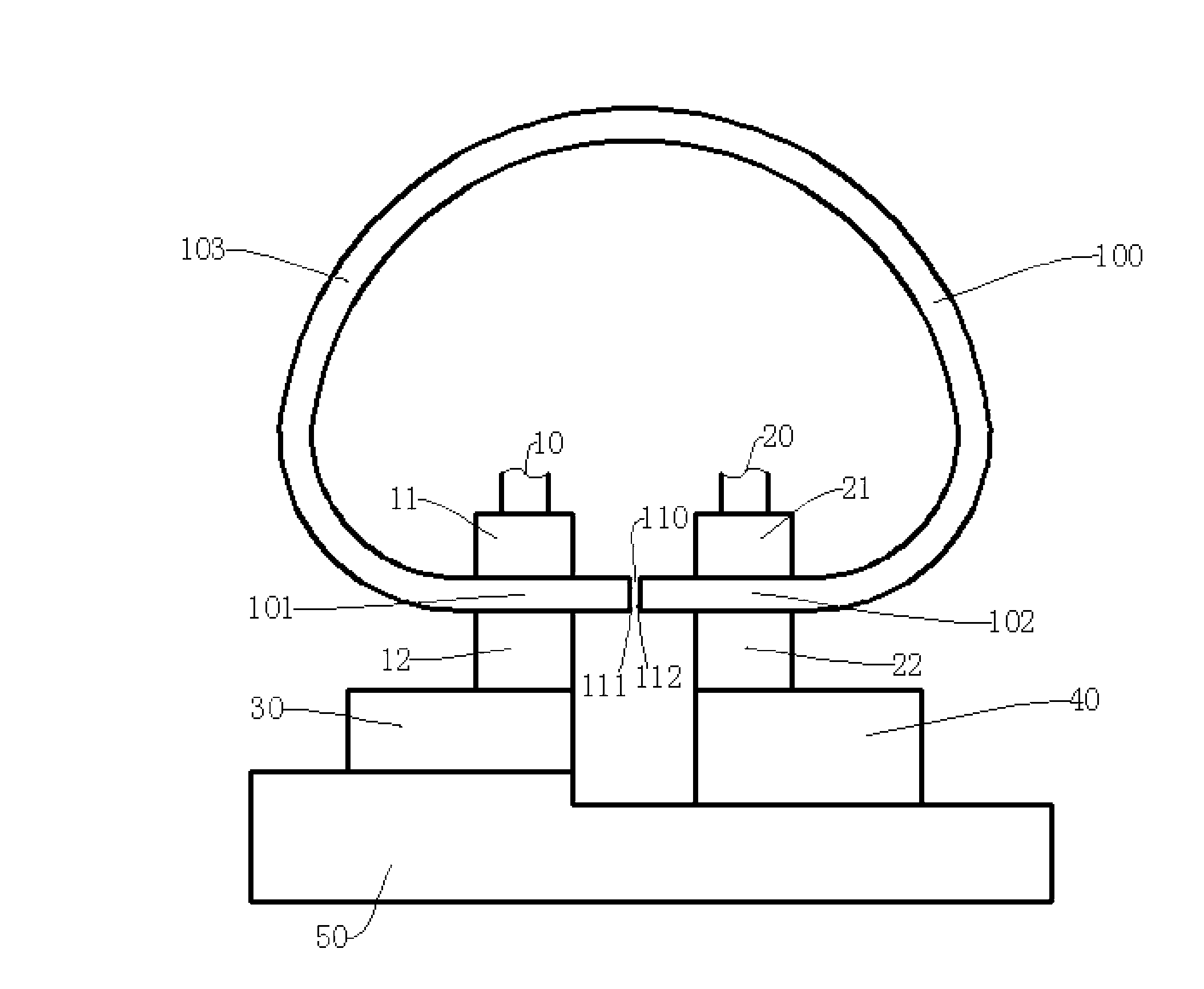

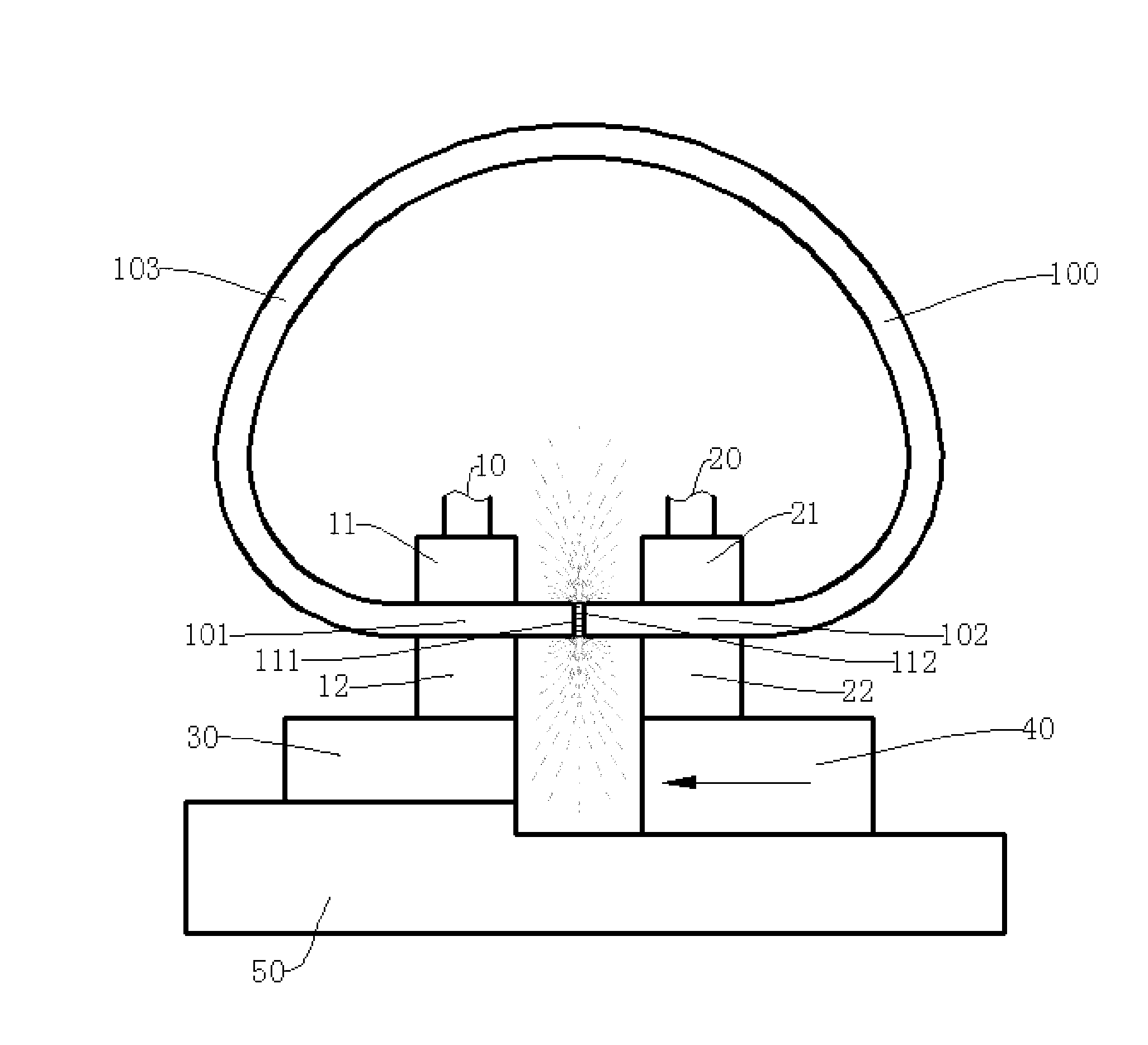

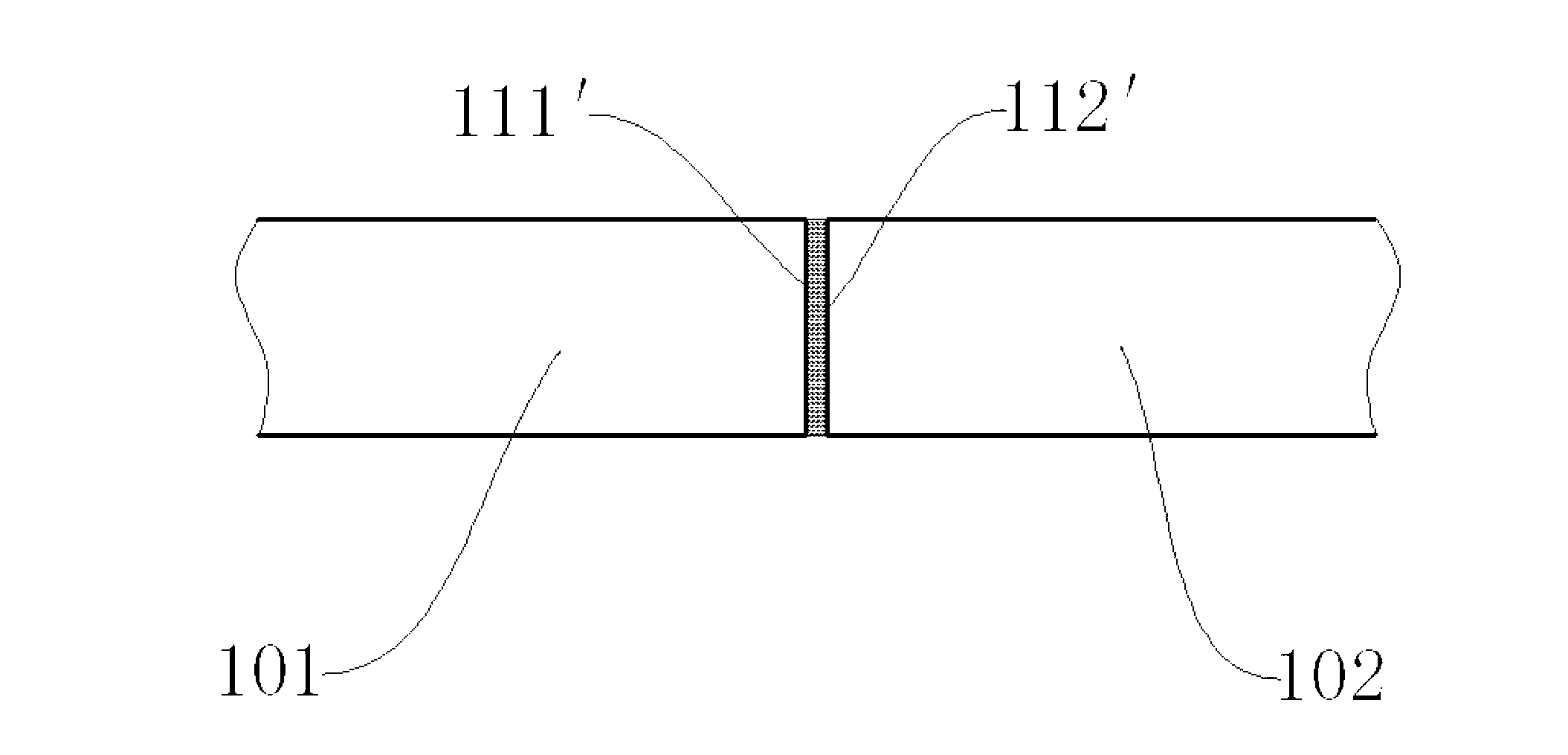

[0038] Step 1: Install the computer. Such as figure 1As shown, the 2A70 alloy D-shaped ring blank with an opening is loaded into a flash butt welding machine with a power of 1000KVA. The D-shaped ring blank is composed of a left straight side 101, a right straight side 102 and an arc-shaped side 103. The side of the opening 110 corresponding to the left straight side 101 has a left end surface 111 , and the side corresponding to the right straight side 102 has a right end surface 112 . When installing, put the left straight ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com