Method for rapidly preparing spinel type Li4Ti5O12 lithium titanate material at low temperature

A spinel type, lithium titanate technology, applied in titanate, alkali metal titanate, chemical instruments and methods, etc., can solve the problems of low preparation efficiency and lithium loss, and achieve uniform particle size and high rate performance. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

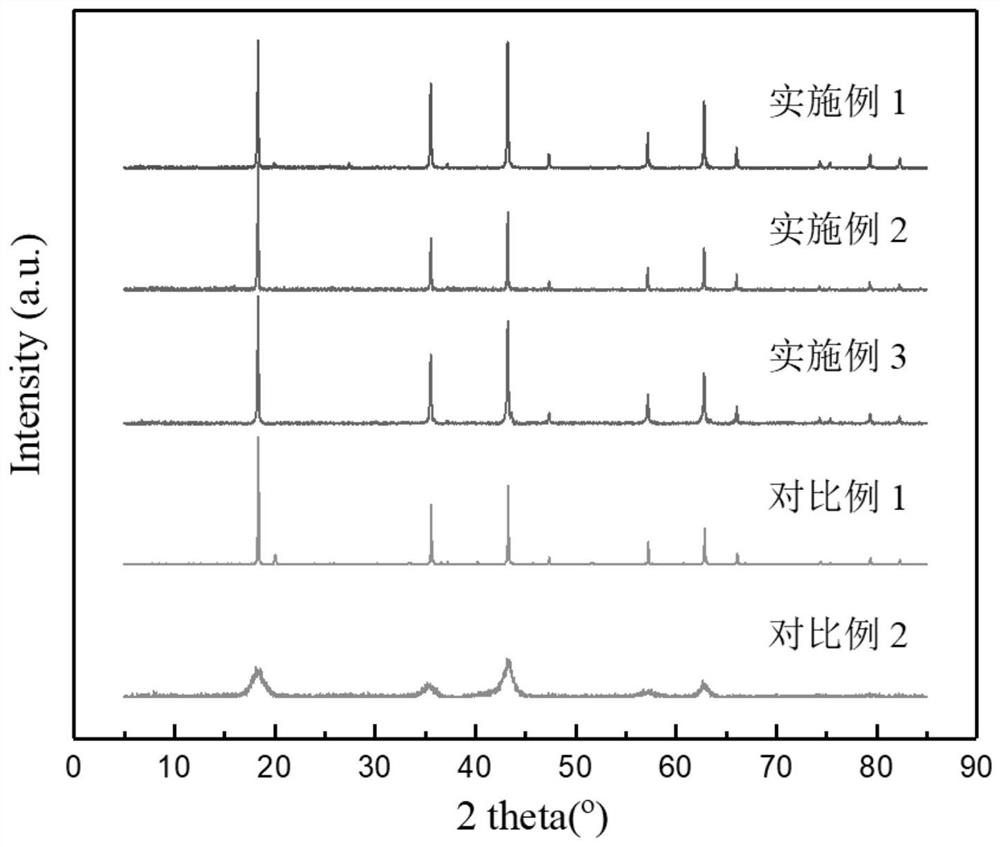

[0029] This example uses the solid oxide mixing method combined with the flash firing process to prepare spinel Li 4 Ti 5 o 12 Lithium titanate material, the specific preparation process is as follows:

[0030] Weigh 6.44g of lithium carbonate powder, 17.40g of titanium dioxide powder, and 50mL of ethanol and mix them in a 250mL zirconia ball mill jar, add 120g of zirconia grinding balls with a diameter of 3mm, and reinforce the lid; place the packaged ball mill jar on a ball mill for ball milling, set The rotation speed is 100r / min, and the ball milling time is set to 12h; the obtained mixed solution is dried in an oven after removing the solvent, and the oven temperature is set to 60°C, and then the dried material is fully ground and sieved to obtain the flash precursor powder.

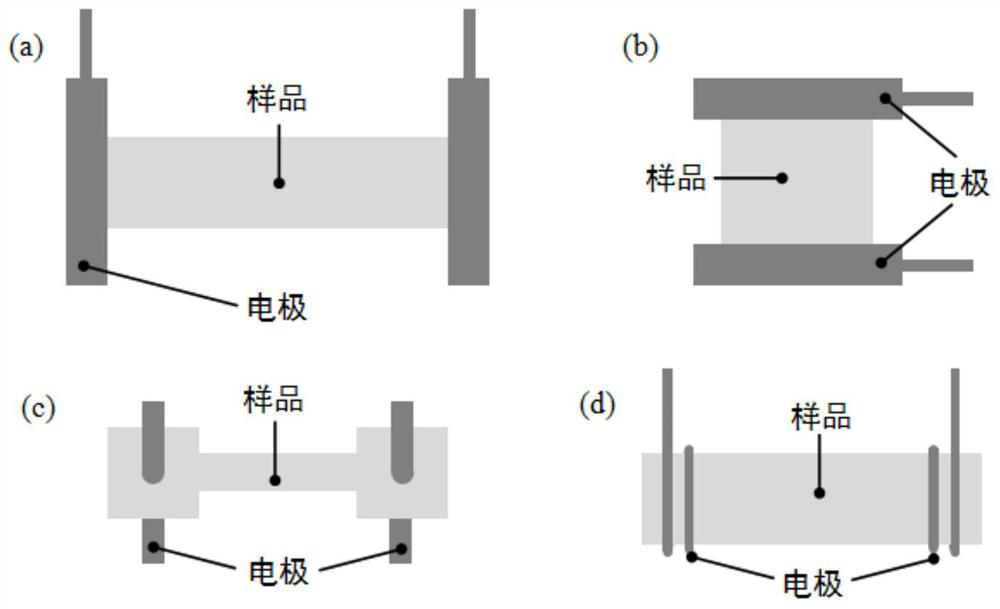

[0031] Put the flash-fired precursor powder into a cuboid cemented carbide mold, and carry out compression molding. The molding pressure is 200 MPa, and the holding time is 2 minutes; 4×4mm 2 , ...

Embodiment 2

[0035] In this example, spinel Li was prepared by hydrothermal method combined with flash firing process. 4 Ti 5 o 12 Lithium titanate material, the specific preparation process is as follows:

[0036] Dissolve 10.0g of butyl titanate in 60.0mL of ethanol to obtain a titanium source solution, and at the same time dissolve 1.62g of lithium nitrate in 60.0mL of water to obtain a lithium source solution; fully stir the titanium source solution and lithium source solution to obtain a mixed solution; mix The liquid is placed in a hydrothermal kettle, and the hydrothermal kettle containing the mixed solution is placed in an oven for hydrothermal reaction. The filling degree in the hydrothermal kettle is 60%, and the reaction temperature of the hydrothermal reaction is 180°C. The reaction time of the hydrothermal reaction at the reaction temperature is 24 hours; the hydrothermal reaction product is cooled to room temperature, dried, ground, and sieved to obtain the flash precursor ...

Embodiment 3

[0041] This example utilizes sol-gel method combined with flash firing process to prepare spinel Li 4 Ti 5 o 12 The specific preparation process of lithium titanate material is as follows:

[0042] Dissolve 2.64g of lithium acetate and 38.4g of citric acid in 75.0mL of ethanol and 5.0mL of deionized water to prepare a lithium source solution; dissolve 17.0g of butyl titanate in 100mL of ethanol to prepare a titanium source solution; vigorously stir the titanium Source solution, lithium source solution was slowly added dropwise to titanium source solution, the reaction temperature was controlled to maintain at room temperature, and a transparent sol was obtained by continuous stirring, and then aged for 24 hours to obtain a milky white wet gel; the wet gel was placed in an oven and heated at 120 Dry at a constant temperature for 18 hours at °C to obtain a xerogel, and then grind and sieve the xerogel to obtain a flash precursor powder.

[0043] Put the flash-fired precursor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com