Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Benzene synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

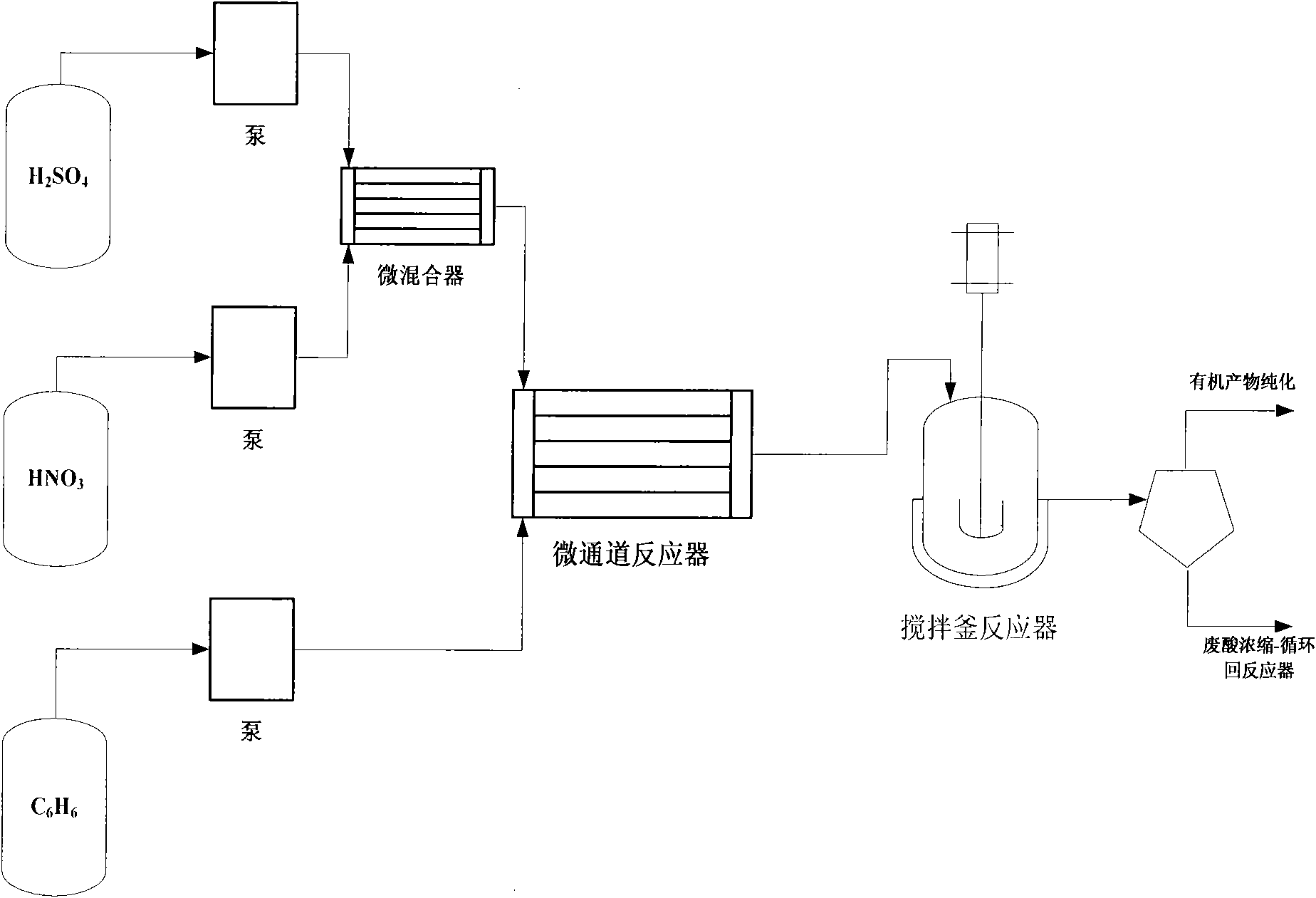

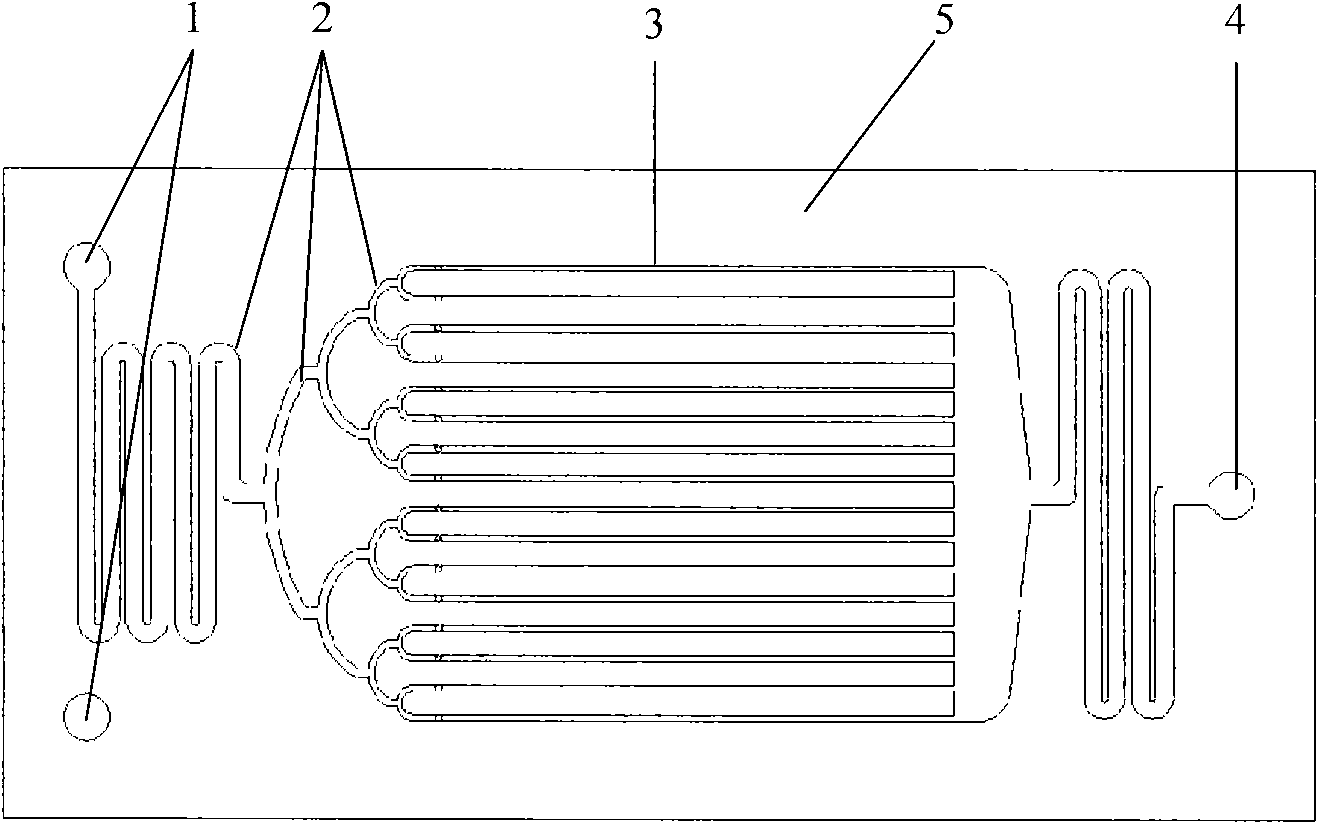

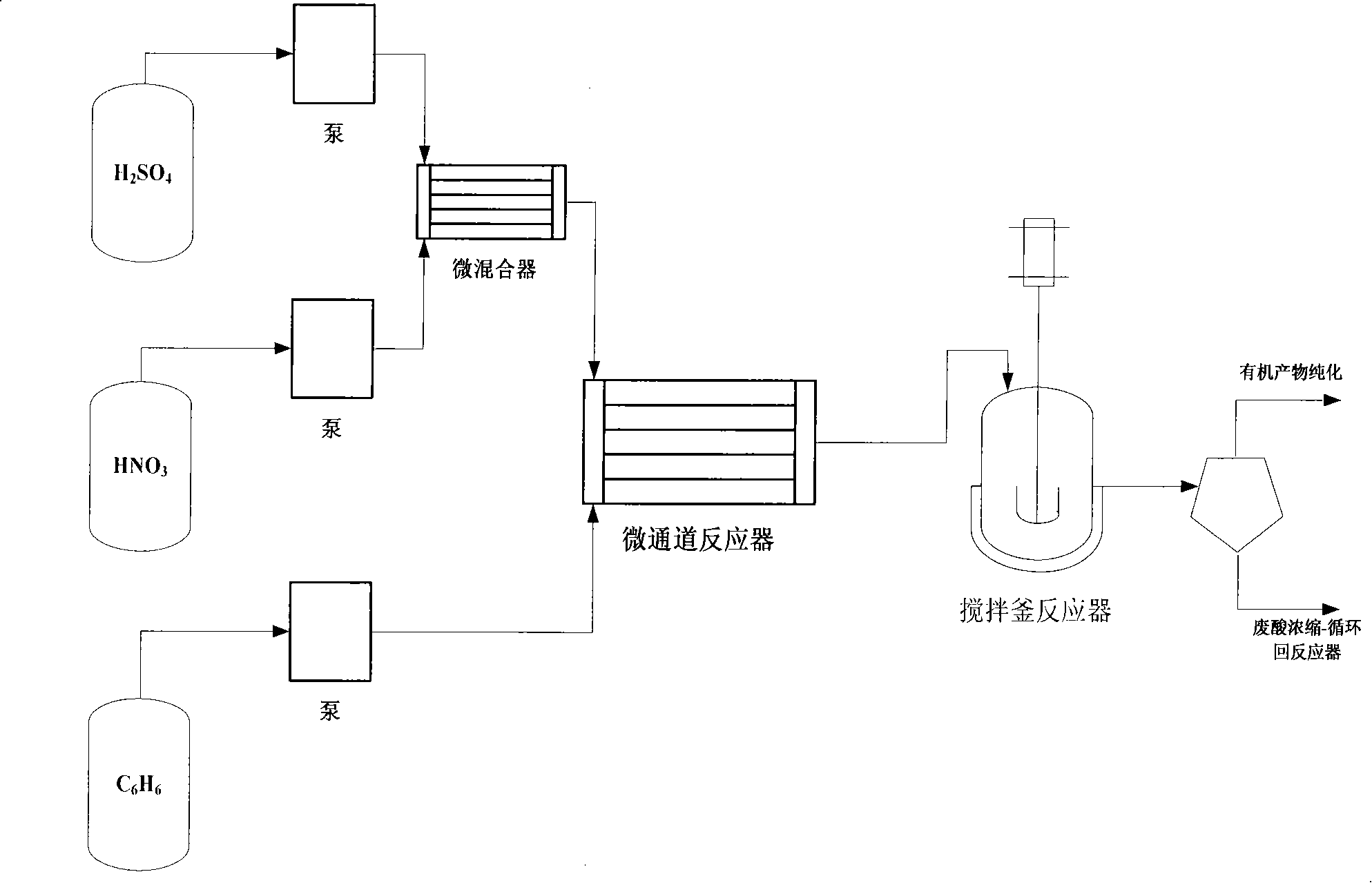

Synthetic method and special equipment for nitrobenzene

InactiveCN101613285AHigh selectivityImprove transfer characteristicsNitro compound preparationBenzeneNitration

The invention relates to a combined nitrification method for synthesizing nitrobenzene and a combined device of a micro-reactor and a stirring reactor. During the synthesis, benzene and mixed acid of nitric acid and sulfuric acid are taken as initial materials, are conveyed to two inlets of the micro-reactor through a metering pump respectively, are premixed in micro-channels, and perform partialnitration reaction at the same time; and a first-stage nitration product with high dispersion state is produced at an outlet of the micro-reactor. The first-stage nitration product continuously flowsinto a stirred tank nitration reactor to continue to react. The method and the device perform continuous operation under the condition of the mixed acid with high water content and have safe process,the conversion rate of the benzene is 99.85 percent (mol), and the selectivity of a product, namely the nitrobenzene is 99.8 percent (mol).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Technique for producing ethyl benzene

InactiveCN101450882AEasy to separateInhibit cokingHydrocarbon from oxygen organic compoundsHydrocarbonsEvaporationReaction temperature

The invention provides a method for generating ethyl benzene through ethanol and benzene subjected to a catalytic dehydration reaction, and in particular to a method for taking discarded crop straw fermentation ethanol as a raw material to be synthesized with benzene. The method comprises the following steps: mixing the reaction raw materials in a fixed-bed reactor with the mol ratio of benzene to ethanol of 6:1, adding the mixed raw materials into a heating furnace for evaporation, then adding the raw materials into the fixed-bed reactor so as to be contacted with a catalyst containing a ZSM-5 molecular sieve, carrying out the reaction under at the reaction temperature of 250 to 550 DEG C, the reaction pressure of 0.1 and 3.0 MPa, a ethanol weight airspeed of between 1 and 10h<-1> so as to generate a reaction mixture containing ethyl benzene, and returning the unreacted benzene to the reactor after separation. Compared with the prior method of synthesizing the ethyl benzene through ethene and the benzene, the method has higher economic benefits in a high oil price era; in addition, the method has few reaction side products which can be easily separated. The method has a simple process and can be applied to the industrial production of the ethyl benzene.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

Preparation method of shape-selective catalyst used for p-dialkyl benzene synthesis process

ActiveCN102513144BHigh selectivityHigh catalytic activityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationWater bathsBenzene synthesis

The invention relates to a preparation method of a shape-selective catalyst used for a p-dialkyl benzene synthesis process, and relates to the technical field of preparation of a high-performance catalyst for an alkylation process. The preparation method comprises the steps of: weighing a metal nitrate, adding to absolute ethanol at a mass ratio of metal nitrate to absolute ethanol being 1:10 for completely dissolving, then adding a complex ligand at a molar ratio of the complex ligand to metal ions in the metal nitrate being (1:1)-(3:1), uniformly stirring, adding a microporous molecular sieve at a mass ratio of the metal ions in the metal nitrate to the microporous molecular sieve being (1:100)-(1:10), uniformly stirring, standing at room temperature for 24h, drying in a 60 DEG C water bath, then transferring to an oven, drying at 120 DEG C for 6h, baking in a muffle furnace, heating to 550 DEG C at a speed of 10 DEG C / min, and maintaining the temperature for 6h to obtain the required shape-selective catalyst. The preparation method is simple and low in cost; and the obtained shape-selective catalyst has high shape selective performance.

Owner:溧阳常大技术转移中心有限公司

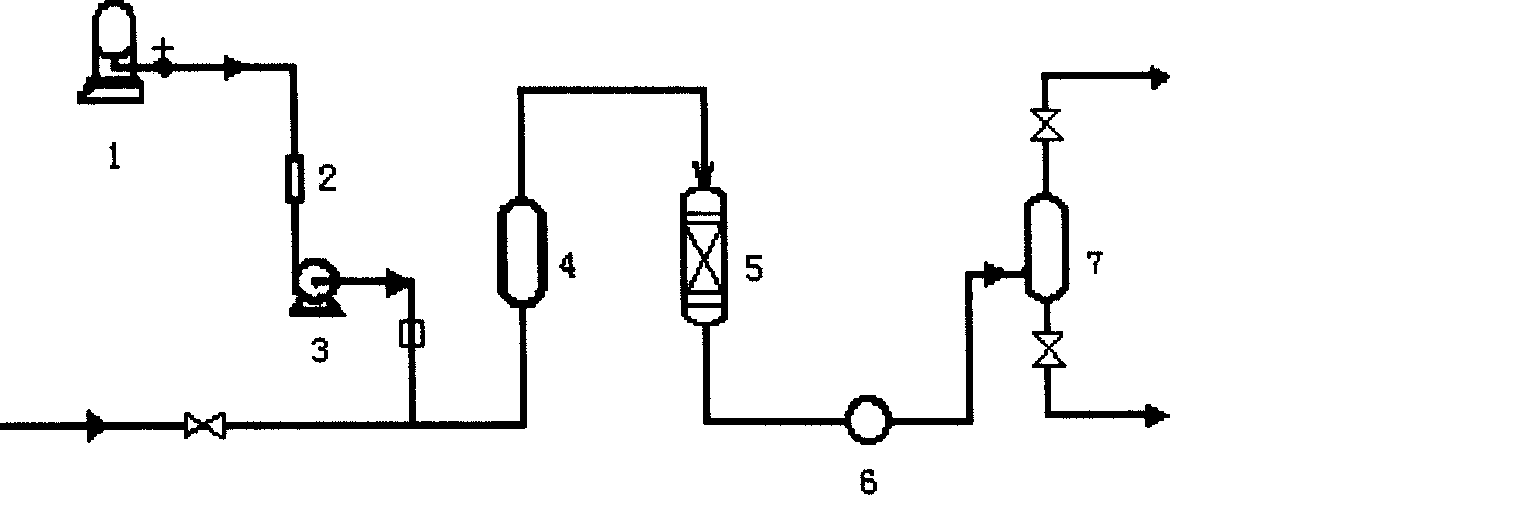

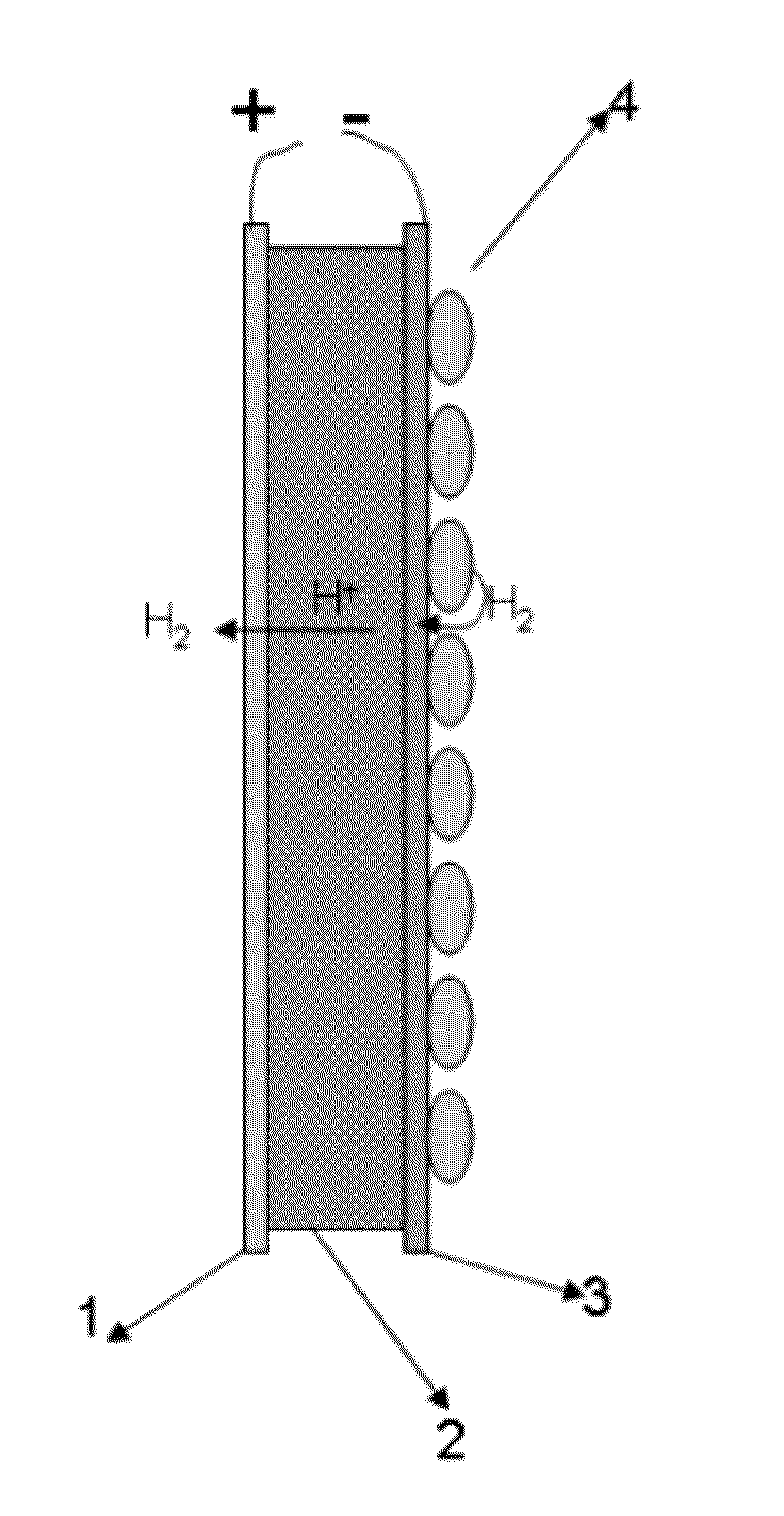

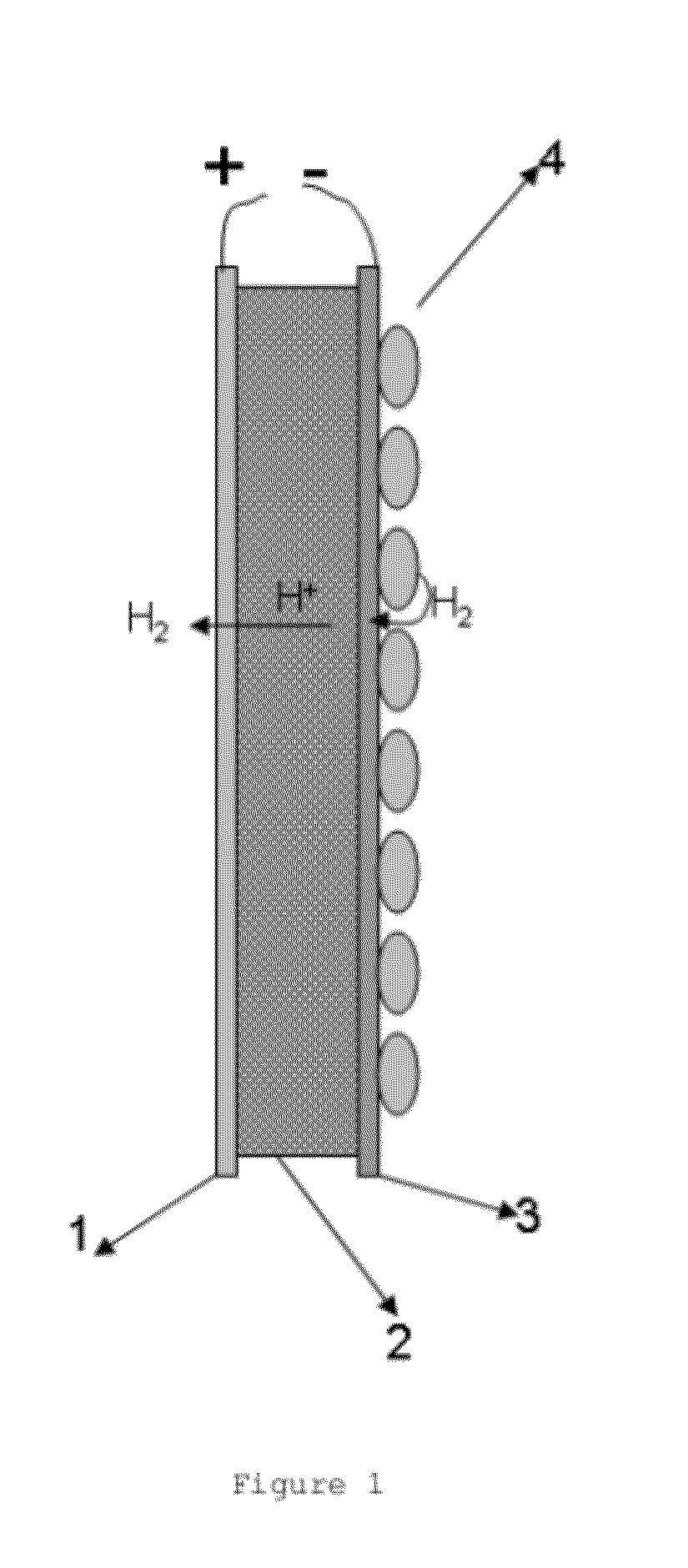

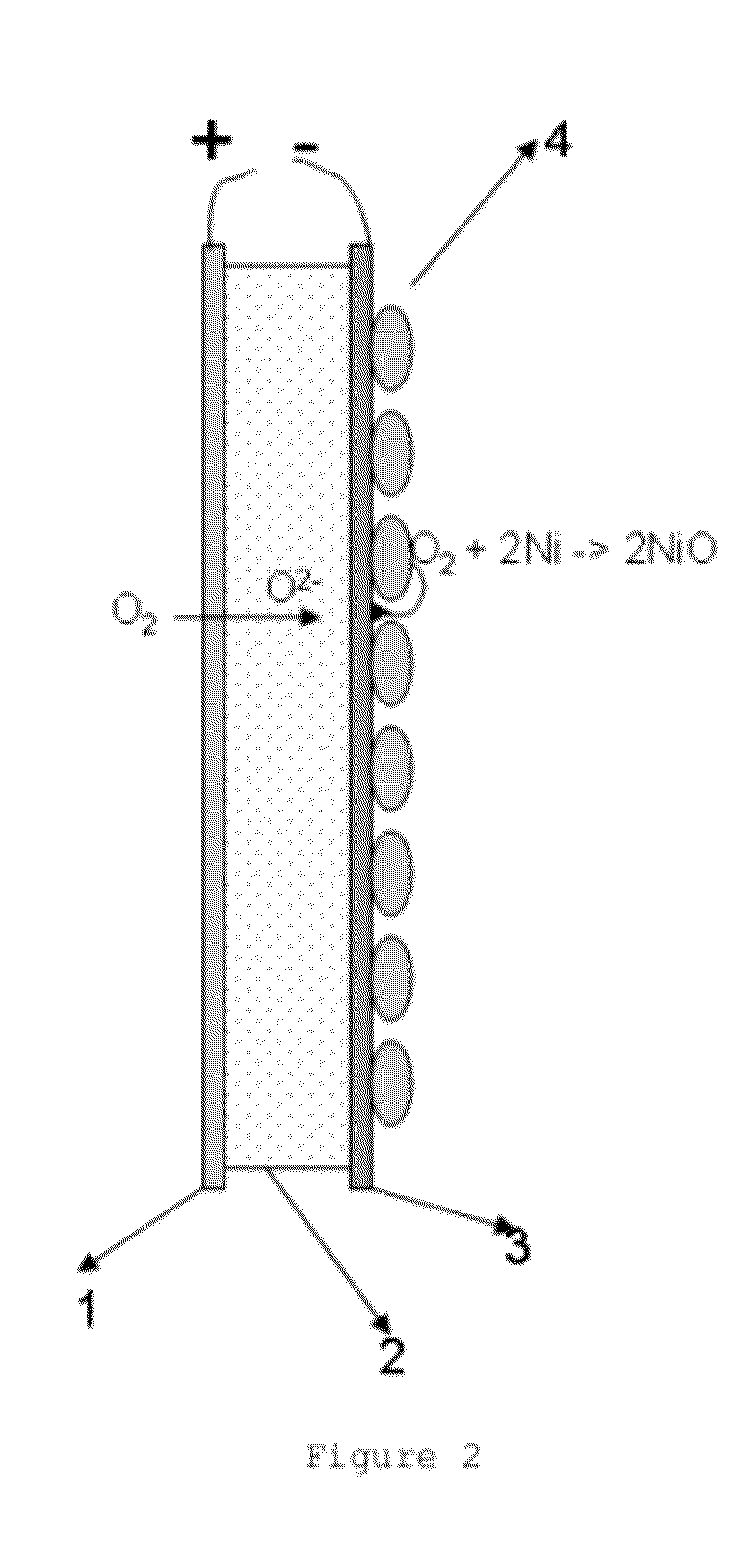

Hydrogen or oxygen electrochemical pumping catalytic membrane reactor and its applications

InactiveUS20120273366A1Increase productionCellsFinal product manufactureChemical reactionChemical reactor

The disclosed subject matter includes a new type of chemical reactor, described as hydrogen or oxygen electrochemical pumping catalytic membrane reactor. This new type of reactor is suitable for increasing the selectivity and the conversion rate of dehydrogenation, hydrogenation, deoxidation and oxidation reactions and namely in the direct amination reaction of hydrocarbons. This reactor can be used for the production of several chemical compounds, such as the direct amination of hydrocarbons and in particular for the synthesis of aniline from benzene. The disclosed subject matter includes a device and process wherein hydrogen is removed by electrochemical pumping of the hydrogen formed or by oxygen pumping so, as hydrogen is formed, it is oxidized. This new reactor exhibits benzene to aniline conversion higher than 40%.

Owner:CUF - QUIMICOS INDIS

Preparation method of shape-selective catalyst used for p-dialkyl benzene synthesis process

ActiveCN102513144AHigh selectivityHigh catalytic activityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationWater bathsMuffle furnace

The invention relates to a preparation method of a shape-selective catalyst used for a p-dialkyl benzene synthesis process, and relates to the technical field of preparation of a high-performance catalyst for an alkylation process. The preparation method comprises the steps of: weighing a metal nitrate, adding to absolute ethanol at a mass ratio of metal nitrate to absolute ethanol being 1:10 for completely dissolving, then adding a complex ligand at a molar ratio of the complex ligand to metal ions in the metal nitrate being (1:1)-(3:1), uniformly stirring, adding a microporous molecular sieve at a mass ratio of the metal ions in the metal nitrate to the microporous molecular sieve being (1:100)-(1:10), uniformly stirring, standing at room temperature for 24h, drying in a 60 DEG C water bath, then transferring to an oven, drying at 120 DEG C for 6h, baking in a muffle furnace, heating to 550 DEG C at a speed of 10 DEG C / min, and maintaining the temperature for 6h to obtain the required shape-selective catalyst. The preparation method is simple and low in cost; and the obtained shape-selective catalyst has high shape selective performance.

Owner:溧阳常大技术转移中心有限公司

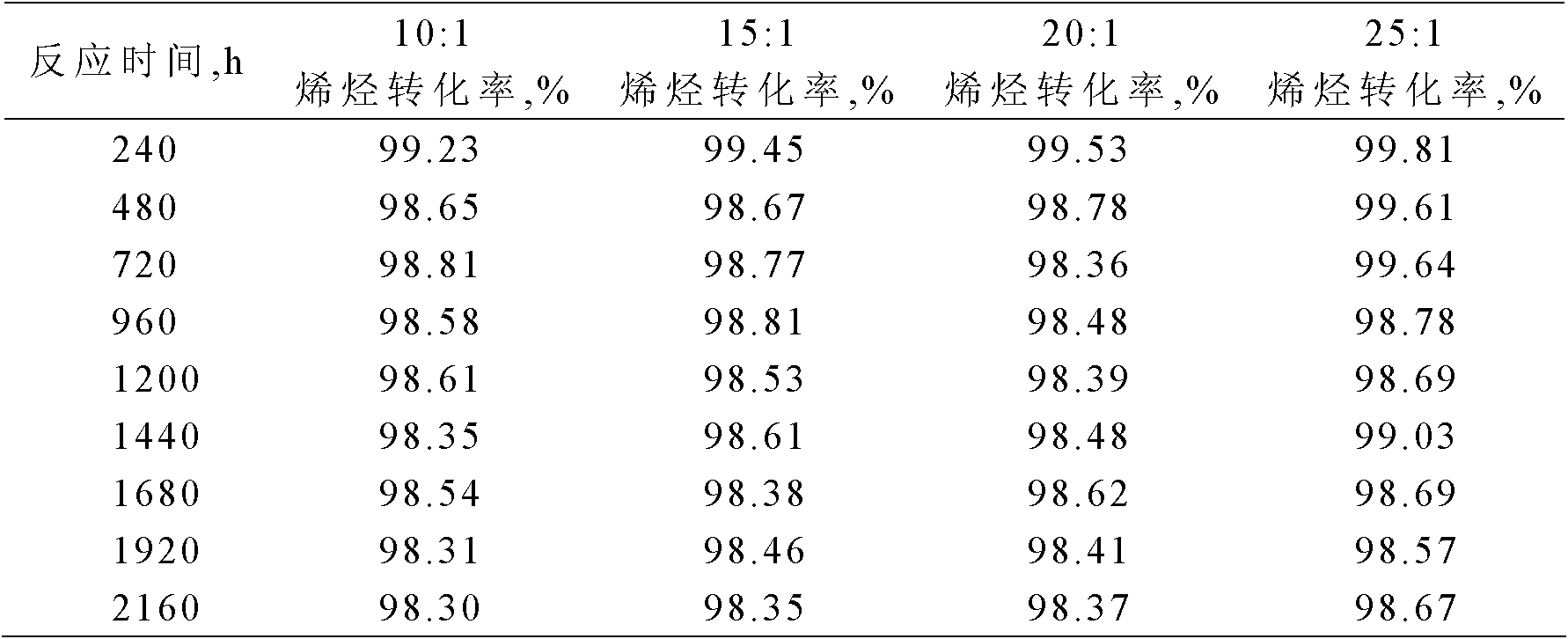

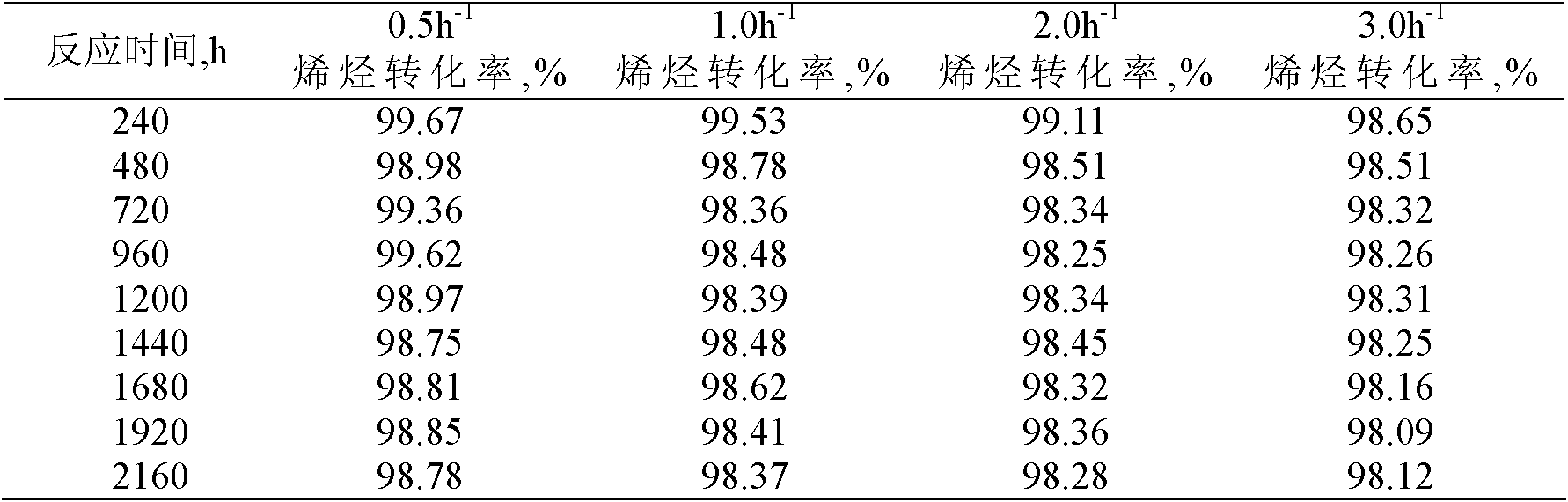

Linear alkyl benzene synthesis method

InactiveCN103130596AGood activity and stabilityImprove conversion ratePhysical/chemical process catalystsHydrocarbon from saturated and unsaturated hydrocarbon additionAlkyl transferSynthesis methods

The present invention relates to a linear alkyl benzene synthesis method, which comprises: adopting linear olefin containing 10-14 carbon atoms and benzene as raw materials, conveying into a reactor, and carrying out an alkylation reaction under a catalysis effect of a solid superacid Ni / SO42--SnO2 catalyst to obtain the linear alkyl benzene, wherein the reaction conditions comprise that: a temperature is 10-300 DEG C, a pressure is 0.1-10 MPa, an amount ratio of the benzene to the olefin material is 2-100:1, and a fed material total mass space velocity is 0.1-20 h<-1>. The synthesis method has the following characteristics that: the adopted reactor reaction is stably performed, and an olefin conversion rate is high.

Owner:PETROCHINA CO LTD +1

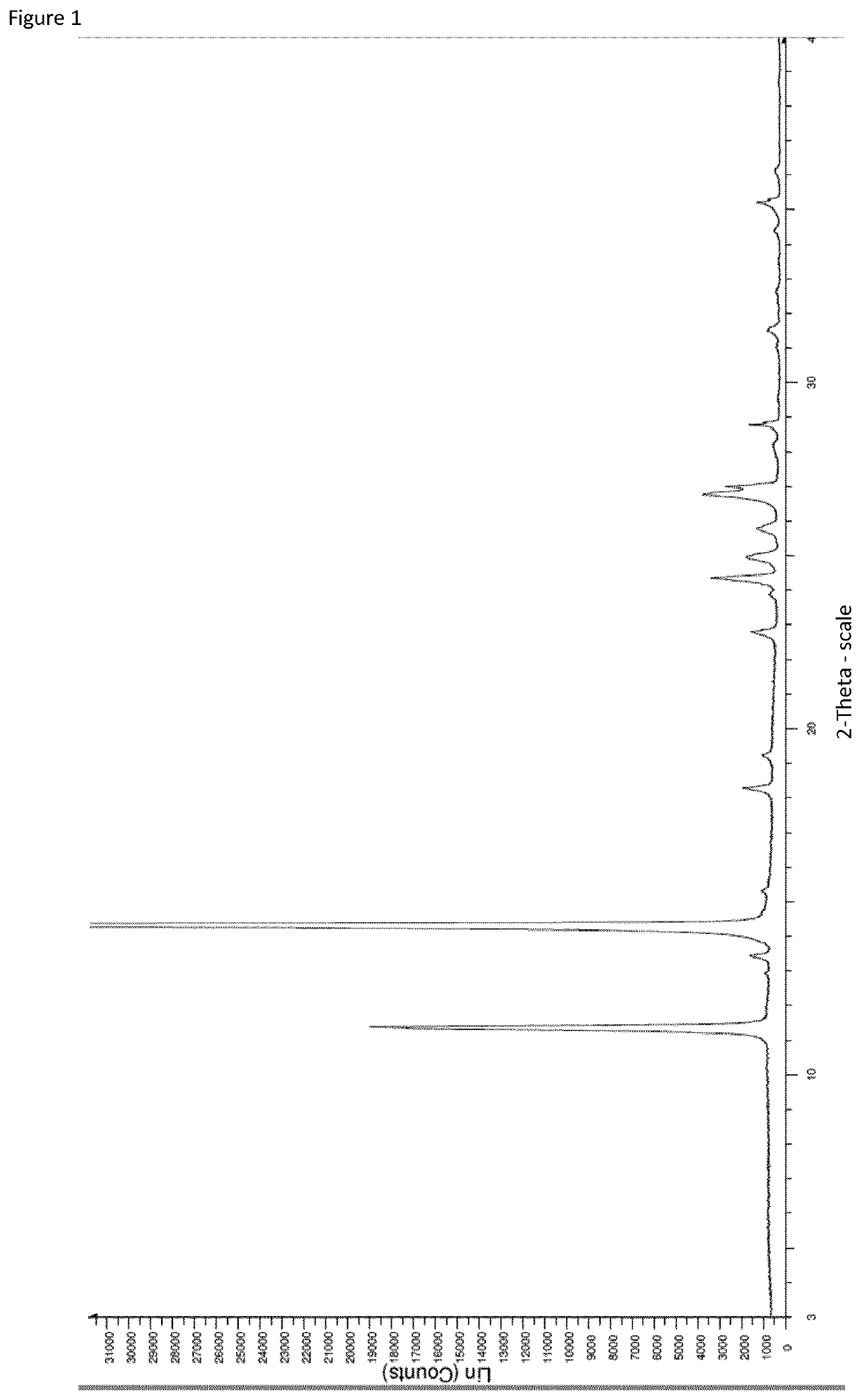

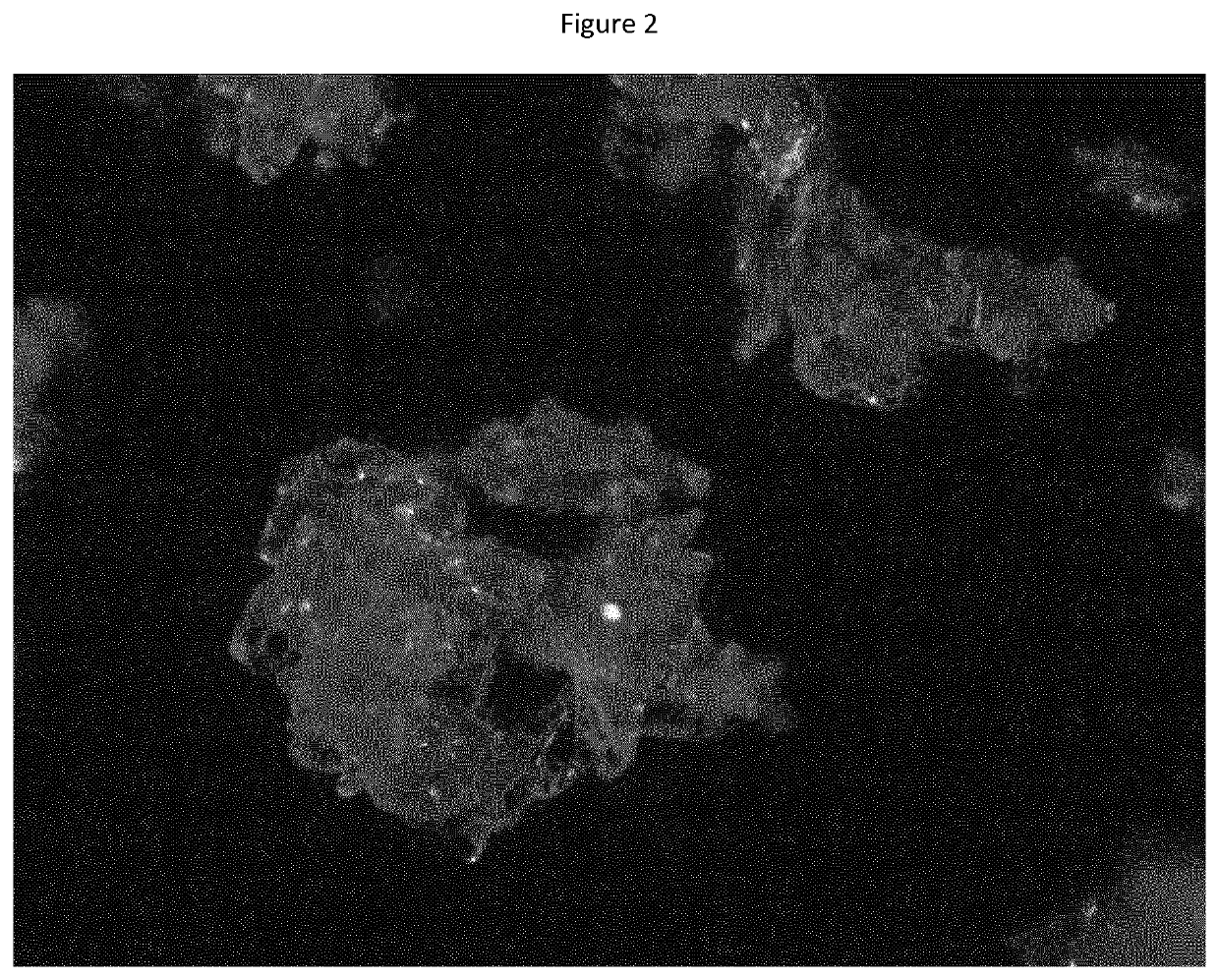

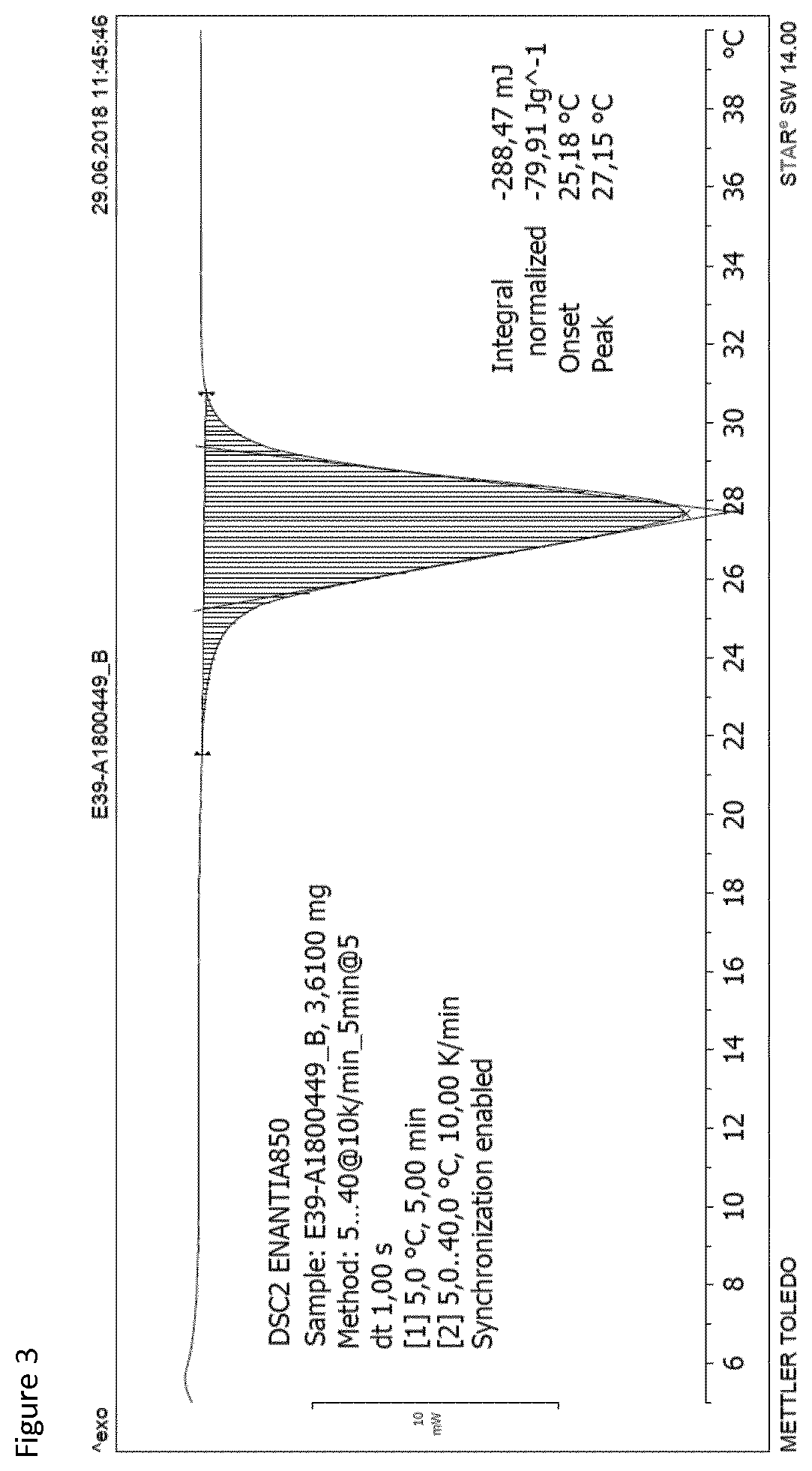

Crystalline 2-fluoro-3-nitrotoluene and process for the preparation thereof

PendingUS20210292271A1Easily handableEasily purifiableOrganic compound preparationOrganic chemistry methodsCombinatorial chemistryToluene

Owner:F I S FAB ILTALIANA SINTETICI SPA +1

Synthetic method and special equipment for nitrobenzene

InactiveCN101613285BImprove transfer characteristicsWell premixedNitro compound preparationMicroreactorNitrobenzene

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

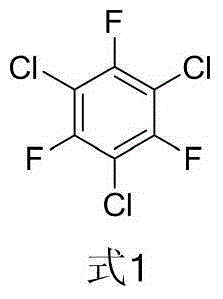

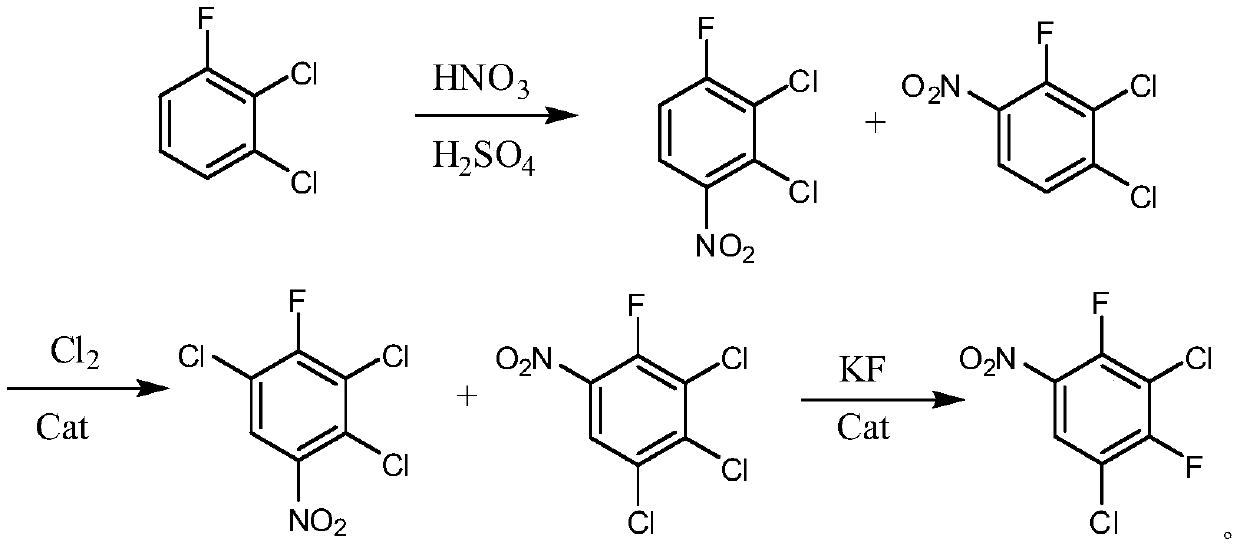

Method for synthesizing 1,3,5-trichloro-2,4,6-trifluorobenzene from 2,4-difluoro-3,5-dichloronitrobenzene

ActiveCN105130744AHigh selectivityHigh yieldHalogenated hydrocarbon preparationNitro compoundNitration

The invention discloses a method for synthesizing 1,3,5-trichloro-2,4,6-trifluorobenzene from 2,4-difluoro-3,5-dichloronitrobenzene. The method comprises performing chlorination reaction on 2,4-difluoro-3,5-dichloronitrobenzene in chlorine atmosphere to obtain a chloride, and controlling the chlorination reaction temperature to 160-195 DEG C; performing nitration reaction on the chloride in a mixed acid solution of sulfuric acid and nitric acid to obtain a nitro compound, and controlling the nitration reaction temperature to 60-110 DEG C; and performing fluorination reaction on the nitro compound with a fluoride under a waterless condition so as to obtain 1,3,5-trichloro-2,4,6-trifluorobenzene, and controlling the fluorination reaction temperature to 80-200 DEG C. The product synthesized by the method is high in selectivity, and the yield and the purity of products of all steps are relatively high, and operation is simple.

Owner:ZHEJIANG LINJIANG CHEM

Industrial production method of 1, 4-dibromo-2, 5-diiodobenzene

ActiveCN111099959AReduce usageLow reaction temperatureFinal product manufactureHalogenated hydrocarbon preparationImideTrifluoroacetic acid

The invention discloses an industrial production method of 1, 4-dibromo-2, 5-diiodobenzene, which belongs to the technical field of organic synthesis. The method comprises the step of carrying out iodination reaction at 68-72 DEG C under the action of trifluoroacetic acid and N-iodosuccinimide by using 1, 4-dibromobenzene as a raw material to obtain 1, 4-dibromo-2, 5-diiodobenzene. Compared with the existing 1, 4-dibromo-2, 5-diiodobenzene synthesis method, the method has the advantages that the use of concentrated sulfuric acid is avoided, the synthesis condition is mild, the operation is simple, the process is safe, and the industrial production is convenient.

Owner:XIAN RUILIAN NEW MATERIAL CO LTD

Bromobenzene synthesis production process

The invention relates to a bromobenzene synthesis production process, and relates to the technical field of chemical engineering. According to the invention, first, benzene and iron powder are weighed and are added into a 1000L reaction kettle. The temperature is controlled at 25-35 DEG C, and the mixture is stirred. Bromine is weighed and is dropped into the reaction kettle within 6h. When hydrogen bromide gas is produced, the temperature in the kettle is increased to 70-80 DEG C, and a constant-temperature reaction is carried out for 2h. An obtained material is washed and is allowed to stand for stratification. The obtained material is dried, and a fraction at the temperature of 155-157 DEG C is collected under normal pressure, such that a finished product is obtained. The finished product is packaged and stored. The process provided by the invention has the following advantages: preparation is convenient and simple; the process is environment-friendly and pollution-free; raw materials are easy to obtain; equipment investment is low; product purity is high; operation is convenient; the prepared bromobenzene has good application effect; and the prepared bromobenzene is safe and reliable.

Owner:安徽佑骏商品混凝土有限公司

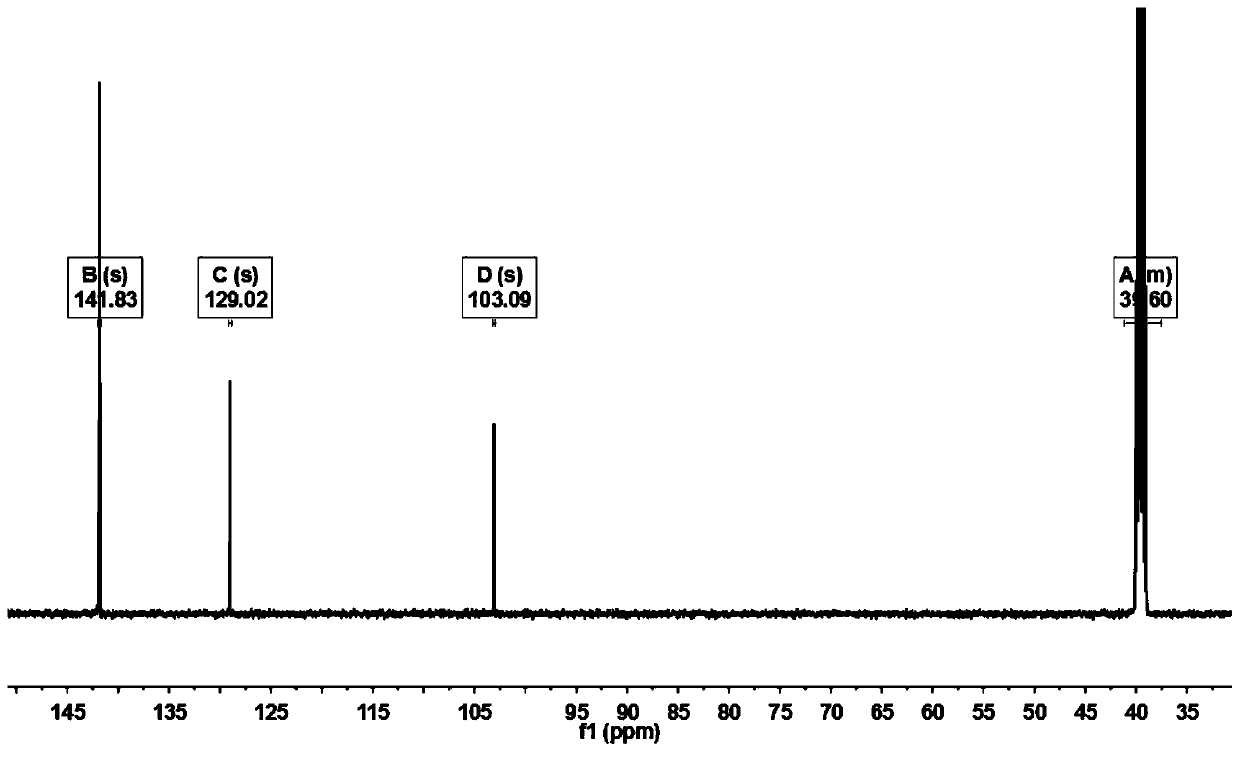

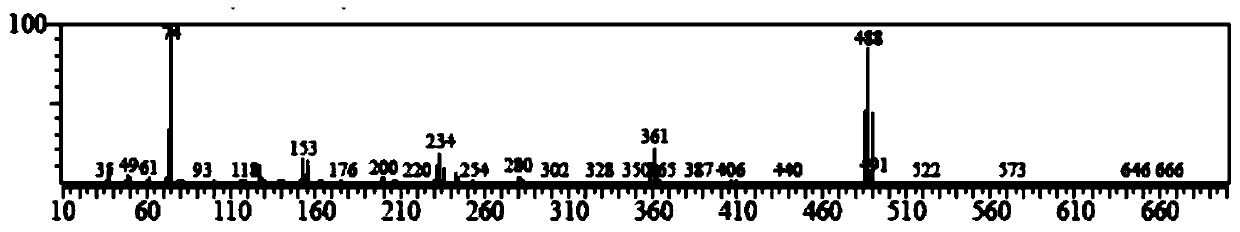

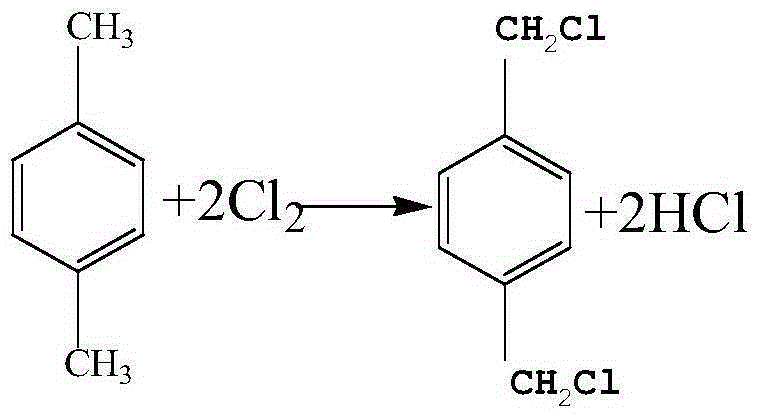

1, 4-bis(chloromethyl)benzene synthesis technology

ActiveCN105384595AHigh purityHigh yieldHalogenated hydrocarbon preparationChemical synthesisReaction rate

The invention relates to a 1, 4-bis(chloromethyl)benzene synthesis technology and belongs to the technical field of organic chemical synthesis. The technology comprises that under LED light source irradiation, p-xylene and chlorine undergo a reaction in the presence of an ionic liquid catalyst to produce a 1, 4-bis(chloromethyl)benzene reaction solution, the 1, 4-bis(chloromethyl)benzene reaction solution is cooled and separated so that a 1, 4-bis(chloromethyl)benzene crude product is obtained, and the 1, 4-bis(chloromethyl)benzene crude product is subjected to vacuum rectification so that 1, 4-bis(chloromethyl)benzene is obtained. The 1, 4-bis(chloromethyl)benzene has a melting point of 98-101 DEG C and purity of 99% or more. The 1, 4-bis(chloromethyl)benzene synthesis technology is free of any solvent, guarantees high product purity, has the characteristics of high conversion rate, fast reaction rate and low cost and is suitable for industrial production.

Owner:SHANDONG KAISHENG NEW MATERIALS

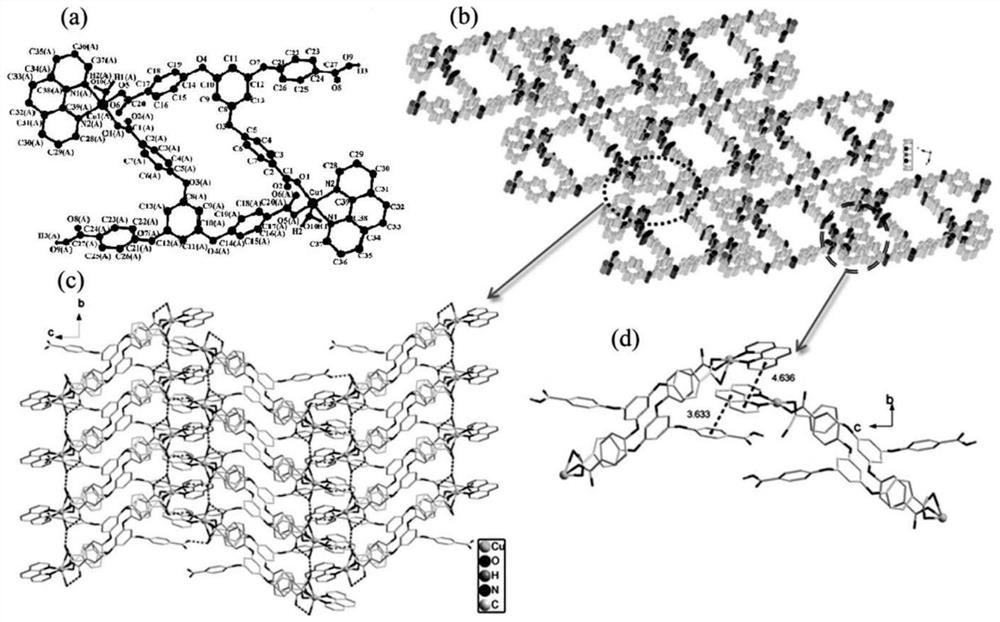

Two-dimensional supramolecular compound synthesized based on 1,3,5-tri(4-carbonylphenyloxy)benzene and method and application of two-dimensional supramolecular compound

ActiveCN113583029AImprove degradation efficiencyGroup 1/11 organic compounds without C-metal linkagesWater/sewage treatment by irradiationPhenolPhenyl group

The invention relates to treatment of dye-containing wastewater, in particular to a two-dimensional supramolecular compound synthesized on the basis of 1,3,5-tri(4-carbonylphenyloxy)benzene and a method and application of the two-dimensional supramolecular compound. The method comprises the following steps: adding 1,3,5-tri(4-carbonylphenyloxy)benzene, phenol and Cu(NO3)2.3H2O into an aqueous solution of acetonitrile, uniformly conducting stirring and mixing, transferring the formed mixture into a reaction kettle with a polytetrafluoroethylene lining, conducting heating to 110-130 DEG C, preserving heat for 60-84 hours, and conducting cooling to 20-30 DEG C at a speed of 3-8 DEG C / h to obtain the two-dimensional supramolecular compound. Compared with the prior art, the invention provides a relatively simple method for synthesizing the two-dimensional supramolecular compound, and the two-dimensional supramolecular compound synthesized by the method has relatively good degradation efficiency on dyes in water; and in addition, tests show that the two-dimensional supramolecular compound synthesized by the method is a stable and recoverable photocatalyst.

Owner:WEST ANHUI UNIV

O-bromonitrobenzene synthesis production process

InactiveCN104086433AEasy to prepareRaw materials are easy to getOrganic chemistryOrganic compound preparationO-bromonitrobenzeneChemistry

The invention provides an o-bromonitrobenzene synthesis production process, and is related to the technical field of chemical engineering. According to the invention, o-bromonitrobenzene is prepared through a synthesis reaction of a cuprous bromide solution prepared through a reduction reaction and a diazonium salt solution prepared through a diazotization reaction. The process provided by the invention has the following advantages: preparation is convenient and simple; the process is environment-friendly and pollution-free; the raw materials are easy to obtain; equipment investment is low; product purity is high; operation is easy; the prepared o-bromonitrobenzene has good application effect; and the prepared o-bromonitrobenzene is safe and reliable.

Owner:安徽佑骏商品混凝土有限公司

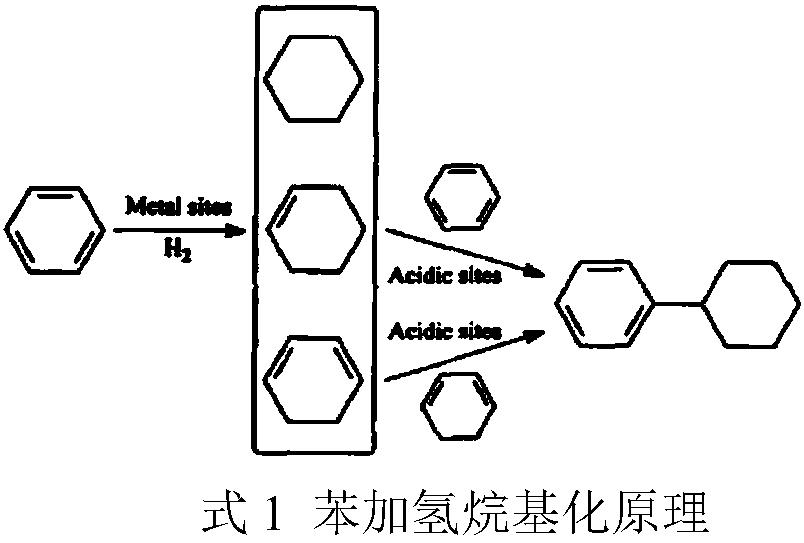

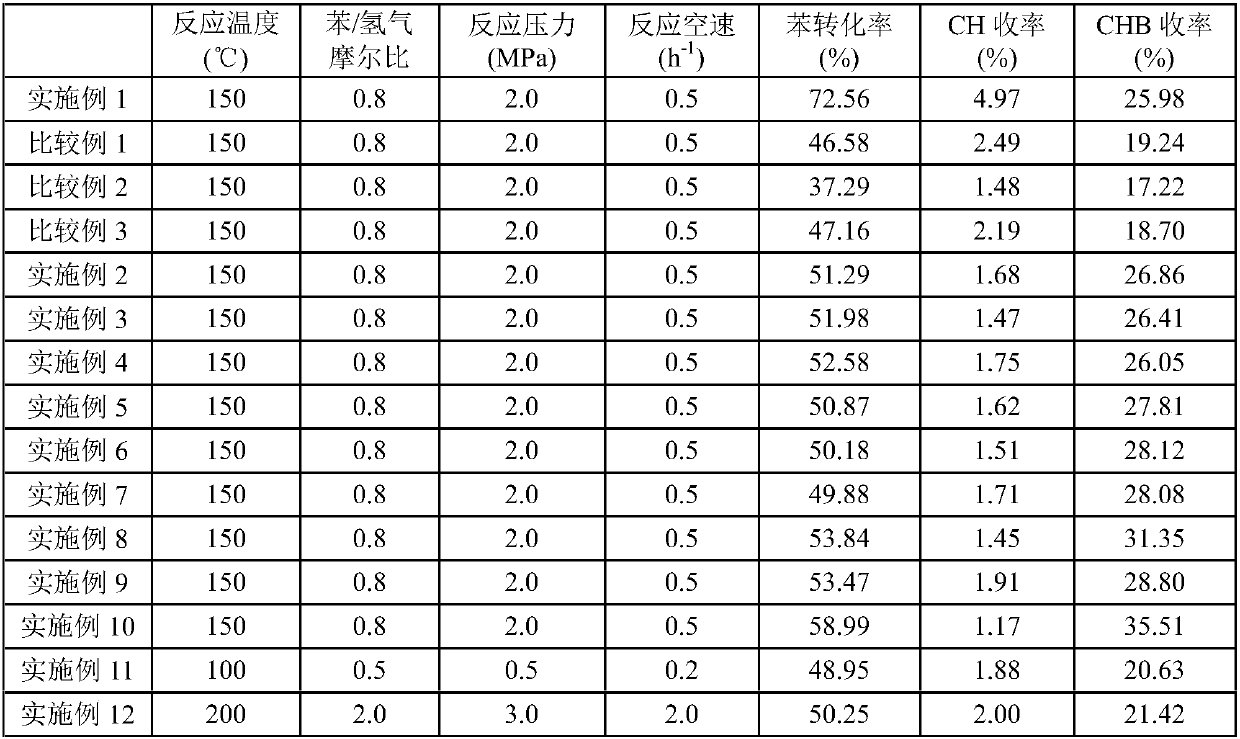

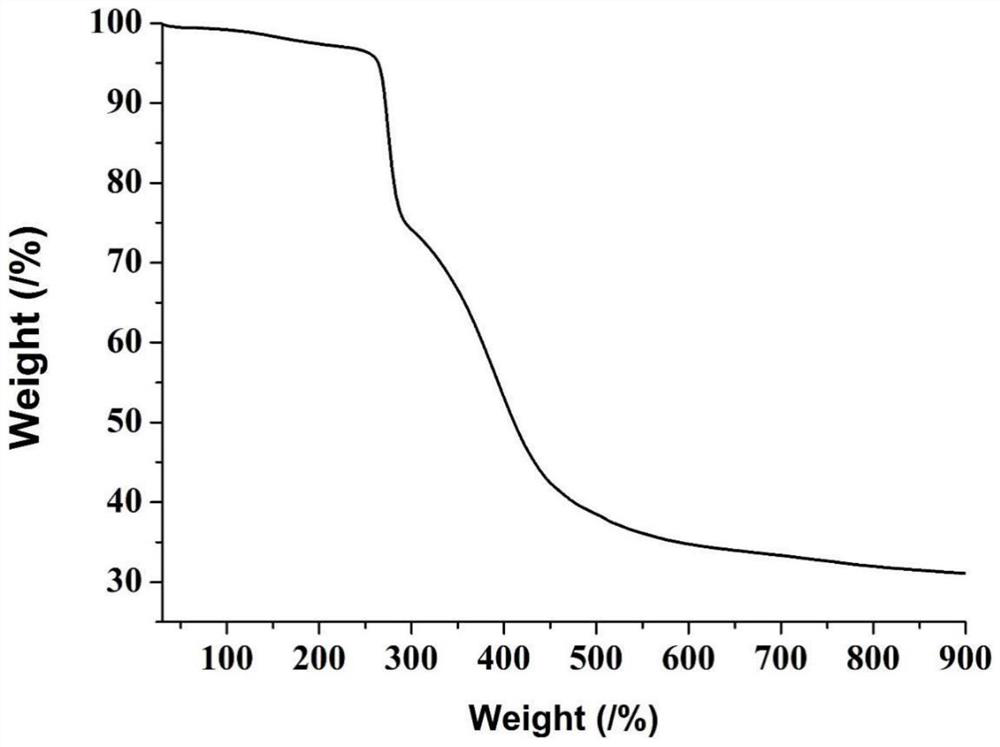

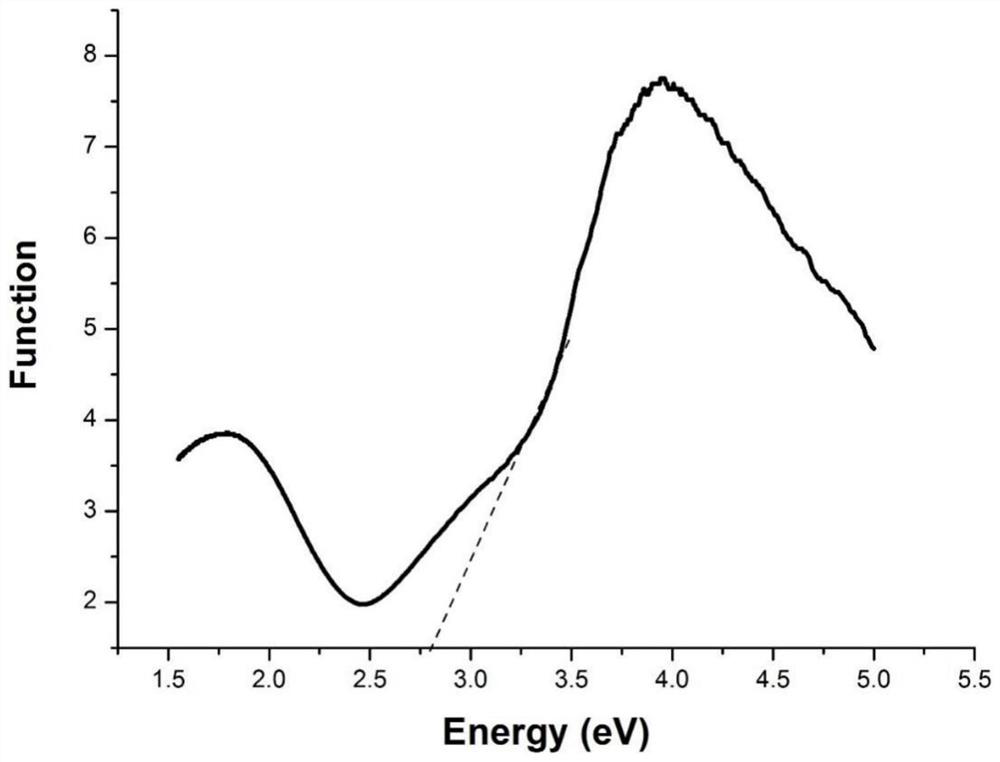

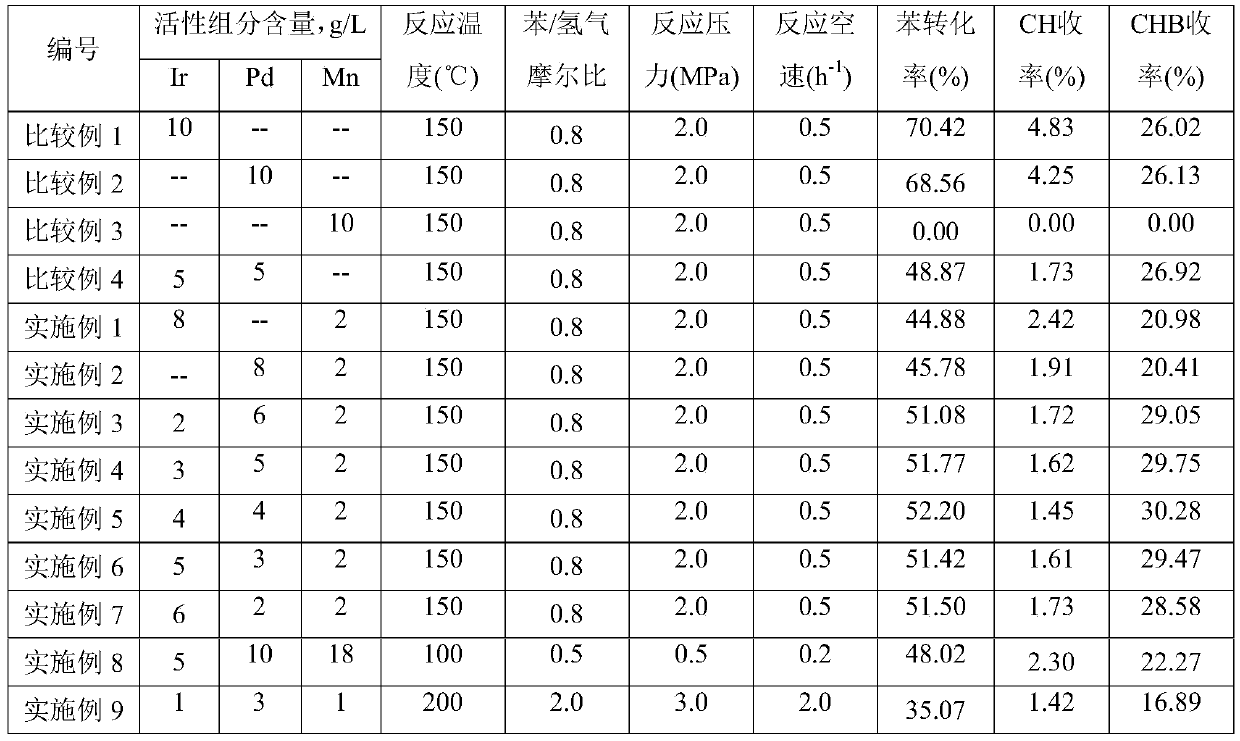

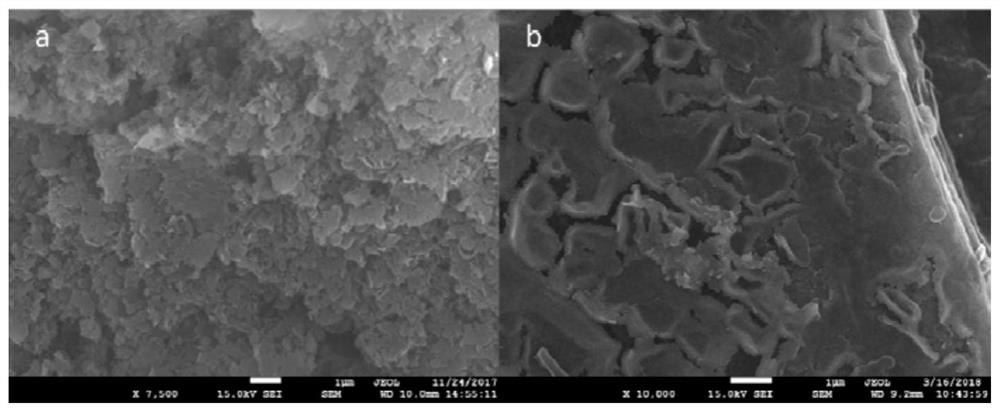

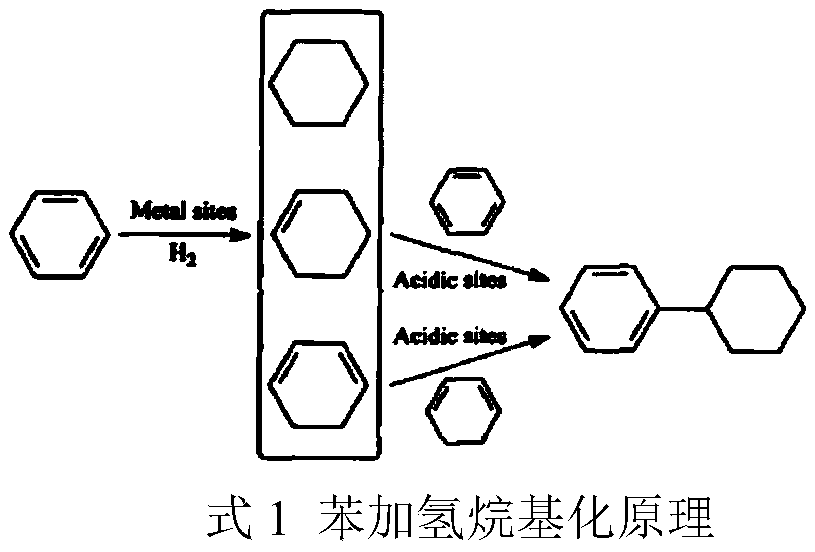

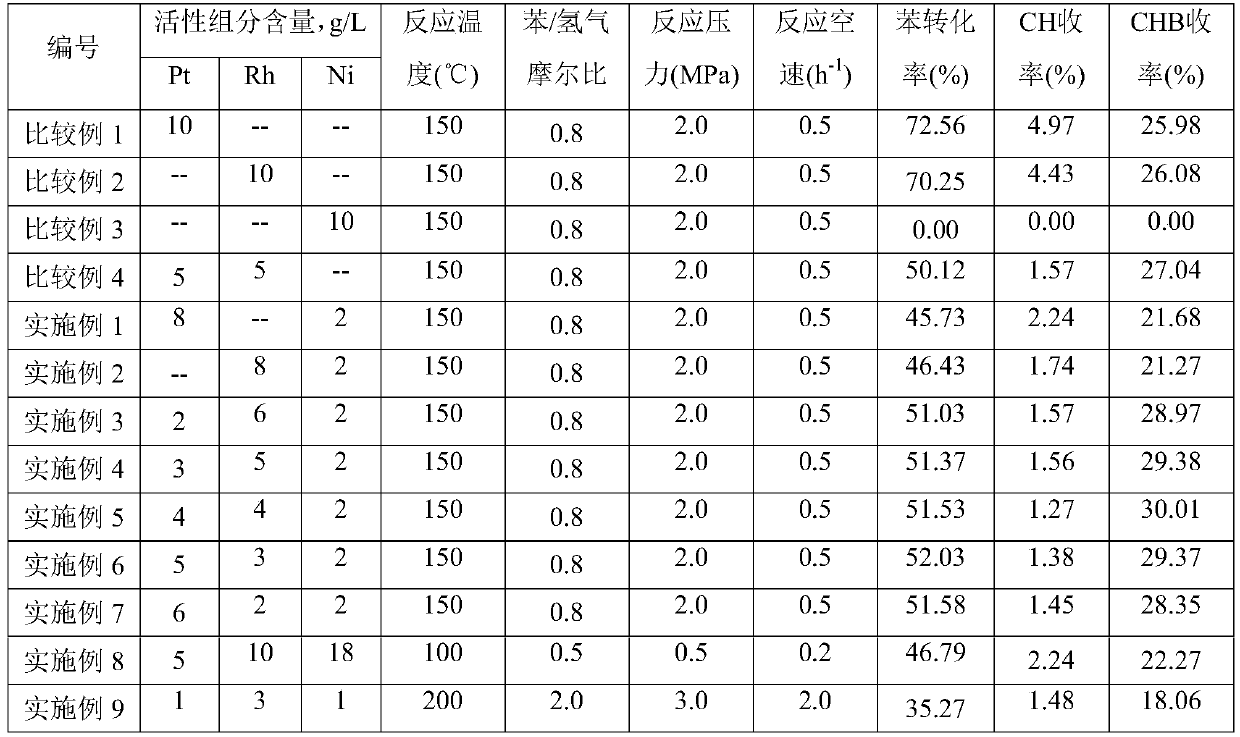

Catalyst for synthesizing cyclohexylbenzene and preparation method thereof

ActiveCN107930683BLow yieldHigh yieldMolecular sieve catalystsMolecular sieve catalystIridiumMolecular sieve

The invention relates to a cyclohexylbenzene synthesis catalyst and a preparation method thereof, and a method for one-step synthesis of cyclohexylbenzene through benzene hydroalkylation. In the priorart, the yield of the by-product cyclohexane is high and the yield of the main product cyclohexylbenzene is low in the reaction due to the catalyst. A purpose of the present invention is mainly to solve the technical problems in the prior art. The technical scheme of the present invention is that the cyclohexylbenzene synthesis catalyst is used, and comprises a carrier and an active component supported on the carrier, the active component comprises a noble metal and manganese, the noble metal comprises at least one selected from iridium and palladium, and the carrier is selected from a hydrogen-type zeolite molecular sieve. The obtained catalyst can be used for one-step preparation of cyclohexylbenzene through benzene hydroalkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for synthesizing benzaldehyde by catalytic oxidation of toluene and preparation method thereof

ActiveCN109174148BEfficient selective catalytic oxidationImprove practicalityOrganic compound preparationCatalyst activation/preparationPtru catalystBenzaldehyde

The invention discloses a preparation method of a catalyst for catalytically oxidizing toluene to synthesize benzaldehyde, which includes the following steps: (1) Dissolving melamine and urea in water, and using hydrothermal method and ultrasonic cooling to obtain a precursor; (2) High-temperature forging The precursor is burned to obtain an ultra-thin N-doped nanosheet porous graphite phase carbon nitride material; (3) the graphite phase carbon nitride obtained in step (2) is loaded with a transition metal oxide by an impregnation method to obtain the described catalyst. The ultrathin N-doped nanosheet porous graphite phase carbon nitride-supported transition metal oxide catalyst prepared by the present invention, through ultrasonic-assisted hydrothermal treatment, on the one hand inhibits the agglomeration of the nanosheets and makes the nanosheets uniformly distributed, thereby significantly increasing the On the other hand, N doping creates more nitrogen vacancies, providing more reactive sites for selective catalytic oxidation.

Owner:GUANGZHOU UNIVERSITY

Method for preparing 2, 2'-dihydroxybiphenyl by taking dibenzofuran distillate as raw material

PendingCN112341316AEasy to useGood molding effectOrganic chemistryOrganic compound preparationPotassium hydroxideDibenzofuran

The invention relates to a method for preparing high-purity 2, 2'-dihydroxybiphenyl by taking dibenzofuran distillate as a raw material and belongs to the technical field of synthesis of 2, 2'-dihydroxybiphenyl. According to the method, dibenzofuran distillate (dibenzofuran content of 70-90%) extracted from wash oil is adopted as a raw material, and solid alkali sodium hydroxide, potassium hydroxide or a mixture thereof is adopted as an auxiliary material; the raw material reacts with the solid alkali sodium hydroxide, potassium hydroxide or the mixture thereof according to a feeding ratio of1: (0.5-2). The method comprises the following steps of: adding the dibenzofuran distillate into an alkali fusion reaction kettle; performing heating to 100-140 DEG C; adding the solid alkali, and performing slow heating; and distilling and extracting light components in the heating process. Compared with products obtained by other preparation processes of 2, 2'-dihydroxybiphenyl, a product obtained by the process of the invention is purer and does not contain salt impurities, so that the purity of the product is greatly improved; a large number of raw materials are saved, resource waste is avoided; a novel material processed by using the 2, 2'-dihydroxybiphenyl is better in using effect, and the forming effect of the produced novel material is better.

Owner:河北中化鑫宝化工科技有限公司

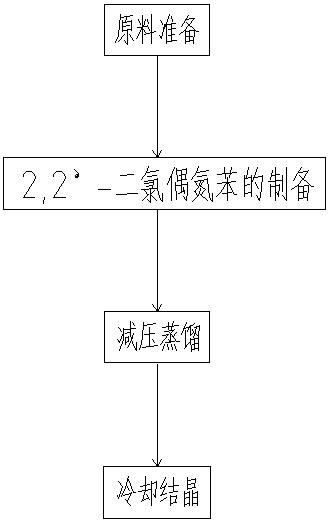

Synthesis process of 2, 2 '-dichloroazobenzene

PendingCN114315635AIncrease production rateIncrease productivityOrganic chemistryPtru catalystDistillation

The invention relates to a synthesis process of 2, 2 '-dichloroazobenzene, which is characterized in that the specific synthesis process comprises the following steps: S1, preparing raw materials; s2, preparation of 2, 2 '-dichloroazobenzene; s3, reduced pressure distillation; s4, cooling crystallization; 2, 2 '-dichloroazobenzene is continuously synthesized in the fixed bed reactor, and step-by-step molding and step-by-step molding by equipment are not needed; catalytic synthesis is carried out through the alumina-loaded ruthenium catalyst, and the production rate is increased by using the catalyst; according to the production process, 2-chloronitrobenzene and hydrogen are directly used as raw materials to directly synthesize 2, 2 '-dichloroazobenzene under the action of an aluminum oxide loaded ruthenium catalyst, the production efficiency is high, the synthesis process is simple, the production efficiency is improved, the yield of 2, 2'-dichloroazobenzene is 91%, and the liquid phase detection content is greater than 99%.

Owner:JIANGSU KANGHENG CHEM

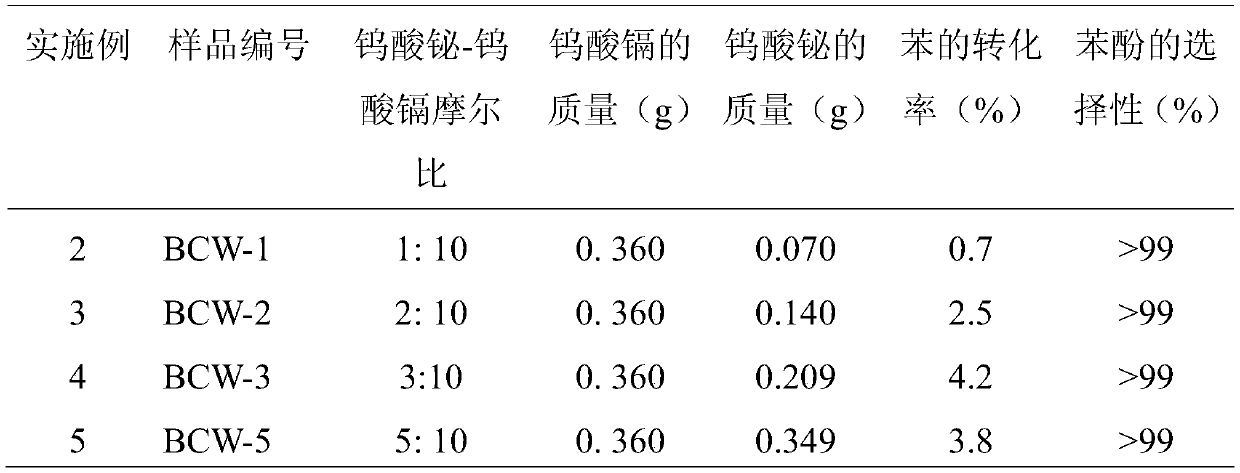

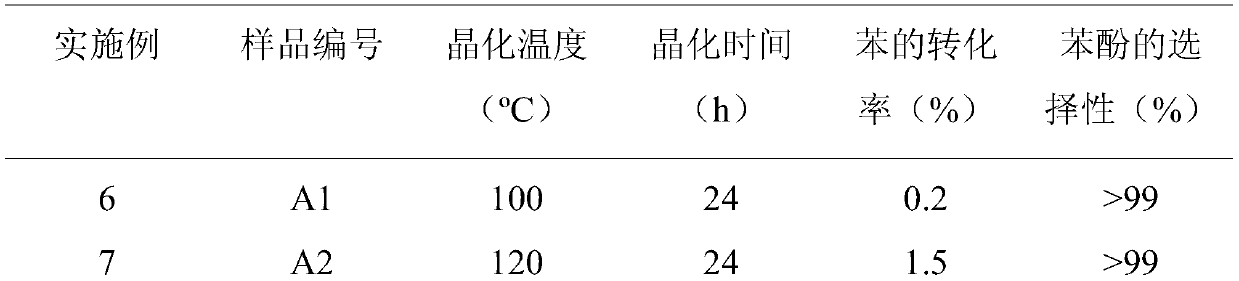

A method for the synthesis of phenol by highly selective oxidation of benzene

ActiveCN107008253BNo pollution in the processHigh selectivityOrganic chemistryOrganic compound preparationSynthesis methodsTungstate

The invention provides a method for highly selective oxidation of benzene to synthesize phenol, which method has the advantages of high selectivity, low energy consumption, and no pollution. The steps for preparing high-efficiency photocatalysts in the present invention are as follows: dissolve cadmium salt and tungstate in an amine solution, stir evenly to adjust the pH, and then undergo hydrothermal treatment, centrifugation, filtration, washing, drying and other steps to prepare cadmium tungstate; Dissolve bismuth salt and tungstate in the alcohol solution, stir and mix evenly, then add the prepared cadmium tungstate, and then proceed through crystallization, cooling, filtration, separation, drying and other steps to prepare the cadmium tungstate-bismuth tungstate composite light Catalyst: Take the cadmium tungstate-bismuth tungstate composite photocatalyst and disperse it in the solvent and reaction solution, add oxygen and light to obtain phenol. The present invention can improve the conversion rate of benzene by controlling the molar ratio of bismuth and cadmium in the catalyst, and the selectivity of the produced phenol is greater than 99%.

Owner:HUNAN UNIV

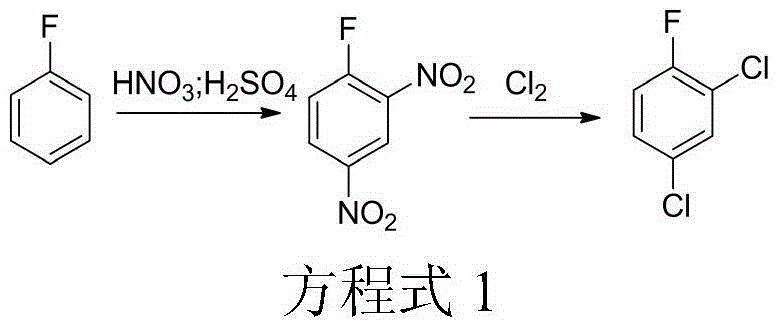

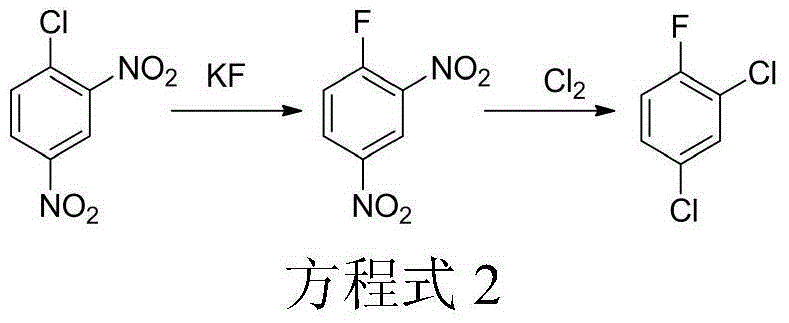

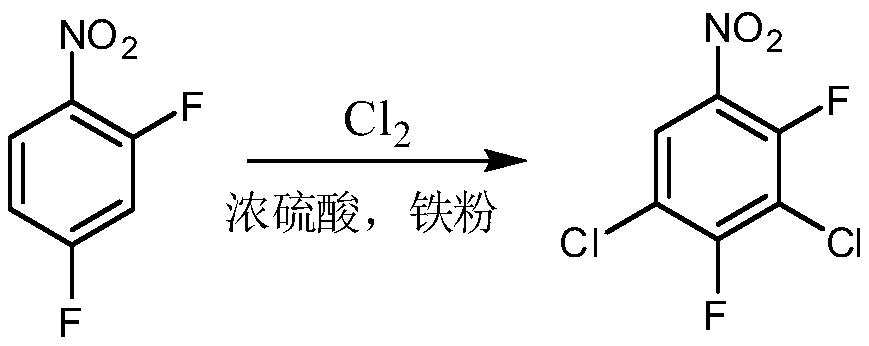

Preparation method of 2,4-difluoro-3,5-dichloronitrobenzene

ActiveCN110642720ALow yieldHigh yieldOrganic compound preparationChemical recyclingPtru catalystPotassium fluoride

The invention provides a preparation method of 2,4-difluoro-3,5-dichloronitrobenzene, which belongs to the field of pesticide intermediate preparation and solves the problem of existing synthesis of 2,4-difluoro-3,5-dichloronitrobenzene such as poor selectivity. The preparation method of 2,4-difluoro-3,5-dichloronitrobenzene comprises the following steps: S01: using 2,3-dichlorofluorobenzene as raw material, using nitric acid as nitration reagent, and obtaining nitration mixture of 2,3-dichloro-4-fluoronitrobenzene and 2-fluorine-3,4-dichloronitrobenzene; S02: under the catalysis of chlorination catalyst, introducing chlorine gas into the nitration mixture in step SO1 to obtain chlorinated mixture of 2,3,5-trichloro-4-fluoronitrobenzene and 2-fluorine-3,4,5-trichloronitrobenzene; S03: under the catalysis of a fluorination catalyst, fluorinating the chlorinated mixture in the step SO2 with potassium fluoride to obtain the 2,4-difluoro-3,5-dichloronitrobenzene. The preparation method hasthe advantages of good reaction selectivity and the like.

Owner:ZHEJIANG LINJIANG CHEM

Catalyst suitable for synthesis of cyclohexylbenzene and preparation method thereof

ActiveCN107930681BLow yieldHigh yieldMolecular sieve catalystsMolecular sieve catalystMolecular sievePlatinum

The invention relates to a catalyst for cyclohexylbenzene synthesis, and a preparation method thereof, and a method for one-step synthesis of cyclohexylbenzene through benzene hydroalkylation. In theprior art, the yield of the by-product cyclohexane is high and the yield of the main product cyclohexylbenzene is low in the reaction due to the catalyst. A purpose of the present invention is mainlyto solve the technical problems in the prior art. The technical scheme of the present invention is that the catalyst for cyclohexylbenzene synthesis is used, and comprises a carrier and an active component supported on the carrier, the active component comprises a noble metal and nickel, the noble metal comprises at least one selected from platinum and rhodium, and the carrier is selected from a hydrogen-type zeolite molecular sieve. The obtained catalyst can be used for one-step preparation of cyclohexylbenzene through benzene hydroalkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process for synthesizing 3,5-dibromonitrobenzene

InactiveCN103864622AEasy to prepareRaw materials are easy to getOrganic chemistryOrganic compound preparationBenzeneAlcohol

The invention discloses a production process for synthesizing 3,5-Dibromonitrobenzene, relating to the technical field of chemical engineering. The production process comprises the steps of performing bromination reaction to obtain crude 2,6-dibromo-4-nitrobenzene; then, preparing nitride precipitates from crude 2,6-dibromo-4-nitrobenzene which is taken as a raw material, alcohol and benzene, and carrying out elimination reaction. The production process disclosed by the invention has the beneficial effects that the preparation is convenient, simple, environment-friendly and pollution-free, materials are easily available, the equipment investment is a little, the purity is high, the production process is convenient to operate, and prepared 3,5-dibromonitrobenzene is good in use effect and is safe and reliable.

Owner:ANHUI HUARUN PAINTS

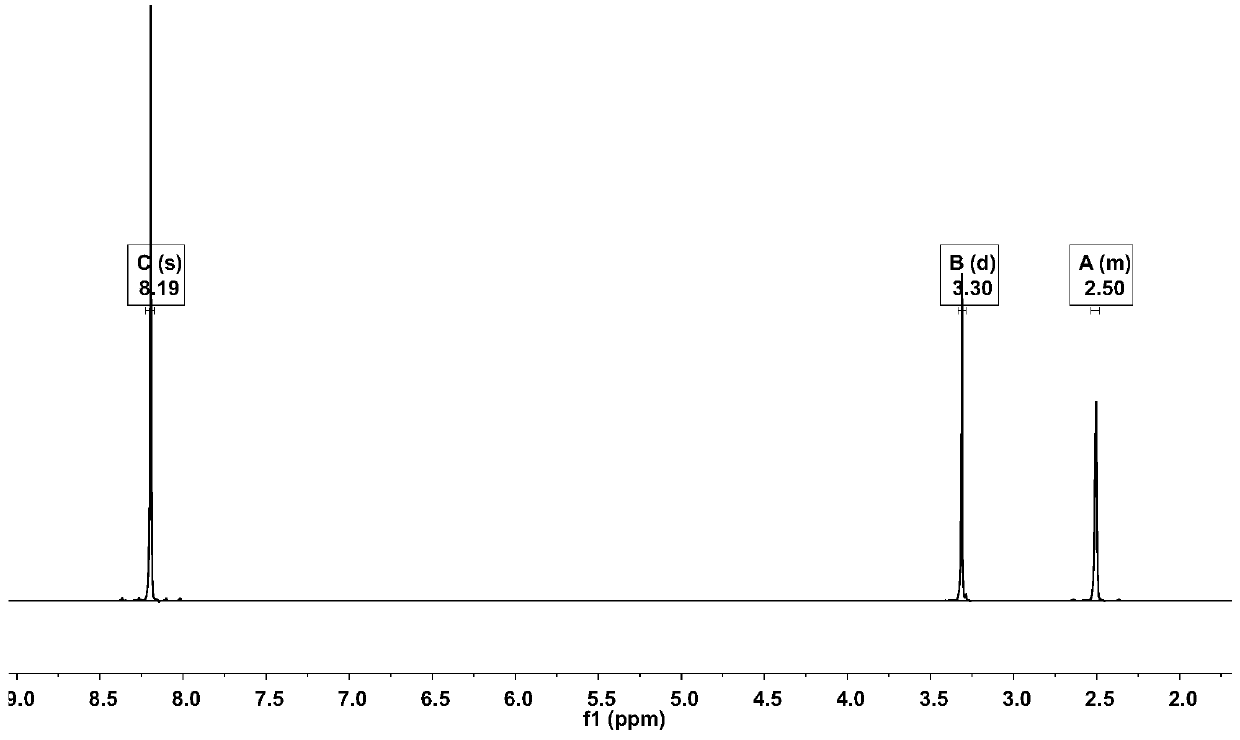

Synthesis of 1-(β-d-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene

ActiveCN104557895BHigh yieldMild conditionsOrganic chemistryBulk chemical productionBenzene synthesisStereoselectivity

Owner:JIANGSU SINOBIOPHARMA

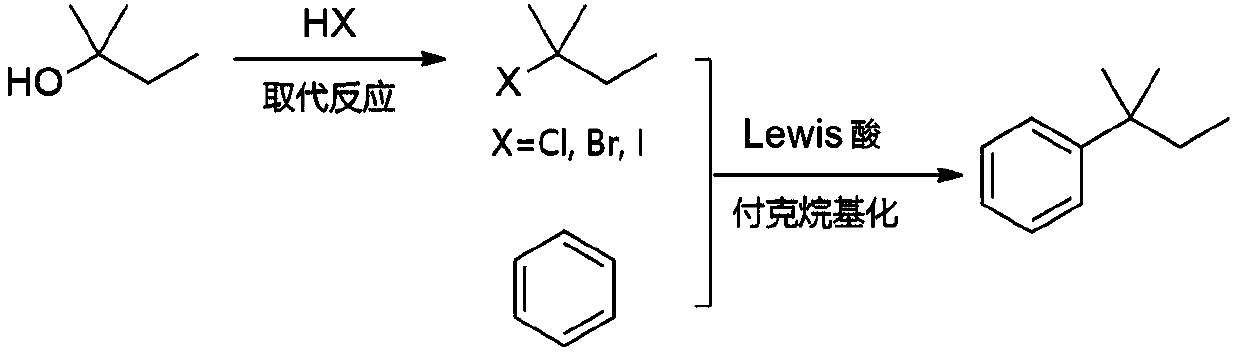

Synthesis method of tert-amylbenzene with controllable isomer content

PendingCN111217666AHigh yieldHigh selectivityCatalystsHydrocarbon preparation catalystsIsomerizationPtru catalyst

The invention provides a synthesis method of tert-amylbenzene with controllable isomer content. The synthesis method comprises the following steps: 1) carrying out a substitution reaction on tert-amylalcohol and haloid acid to obtain a halopentane intermediate; 2) carrying out a Friedel-Crafts alkylation reaction on the halopentane intermediate and benzene under the catalysis of a Lewis acid to obtain tert-amylbenzene; wherein the Lewis acid is one of ZnCl2 and FeCl3 or a mixture of the ZnCl2 and the FeCl3; the temperature of the Friedel-Crafts alkylation reaction is -10 to 40 DEG C; the vacuum degree is absolute pressure of 2-75kPa; and the reaction time is 0.5-4 h. According to the synthesis method, by setting reasonable reaction steps, controlling reaction conditions, selecting a proper catalyst and the like, the isomerization ratio is reduced, and the tert-amyl product with high yield and high selectivity is obtained.

Owner:CHINA TIANCHEN ENG

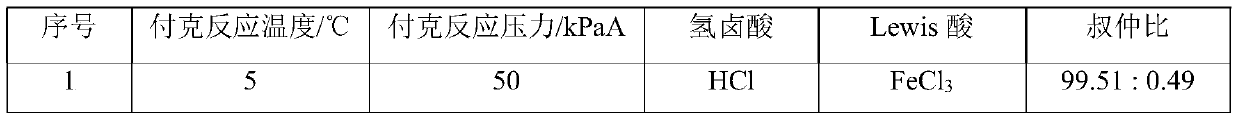

A kind of method of synthesizing 4-hydroxymethyl biphenyl

ActiveCN107602339BRaw materials are cheap and easy to getStrong price advantageOrganic compound preparationHalogenated hydrocarbon preparationOrganic synthesisGrignard reagent

The invention discloses a method for synthesizing 4-hydroxymethyl-biphenyl, belonging to the field of organic synthesis. The method comprises the steps of enabling biphenyl, which is taken as a raw material, to react with NXS to generate 4-halogenated biphenyl; then, enabling the generated 4-halogenated biphenyl to react with magnesium metal in presence of chlorinated n-butane so as to generate aGrignard reagent; then, enabling the generated Grignard reagent to react with XCH2OR, and carrying out acidic hydrolysis to obtain the 4-hydroxymethyl-biphenyl. The method has the advantages of beingeasy in obtaining of raw material, low in cost and mild in conditions, thus having a process amplification prospect.

Owner:浦拉司科技(上海)有限责任公司

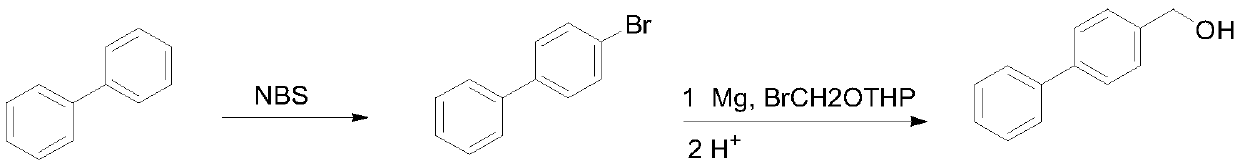

Electrode material for synthesizing p-aminophenol by electrolyzing nitrobenzene, preparation method and application thereof

PendingCN113802138AHigh yieldLess investmentElectrolytic organic productionElectrodesBetaineM-aminophenol

The invention provides an electrode material for synthesizing p-aminophenol by electrolyzing nitrobenzene, a preparation method and application thereof. The electrode material is a composite material formed by filling a copper wire cage with copper metal particles and hydrophobic particles, wherein the hydrophobic particles are copper metal particles of which the surfaces are covered with niobium (Nb) and copper (Cu) doped titanium dioxide (TiO2) films. According to the invention, the electrode material is used for electrolyzing nitrobenzene to synthesize a cathode of p-aminophenol, and a compound surfactant of polyglycerol decastearate and dodecyl dimethyl betaine is added into a catholyte, so that the method can effectively solve the problems of low solubility and slow diffusion of products, raw materials and intermediates in water and low reaction selectivity caused by excessive reduction of the intermediate benzene mass in the traditional synthesis process, has the advantages of simple process and low energy consumption, and is suitable for wide industrial application.

Owner:WANHUA CHEM GRP CO LTD

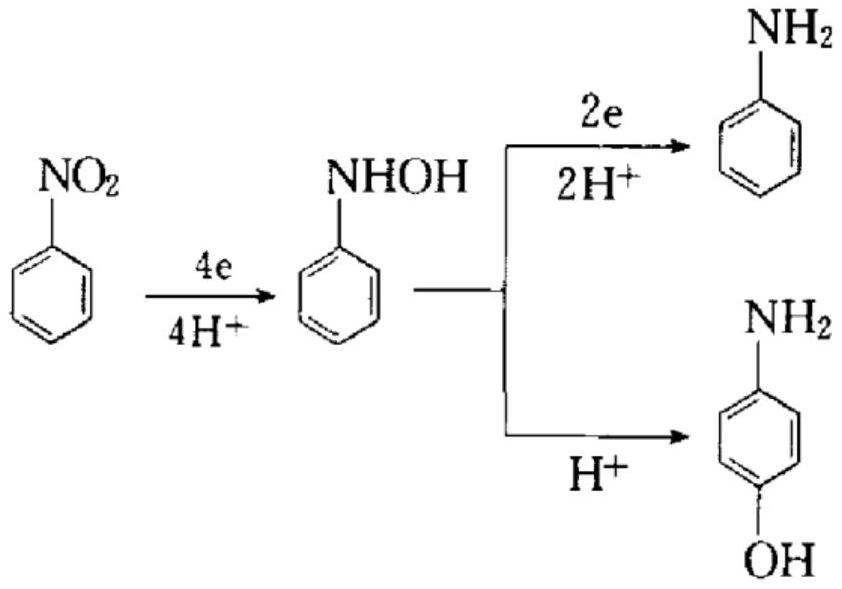

A kind of synthetic method of 1-benzyloxy-2-[2-(3-methoxyphenyl) vinyl] benzene

ActiveCN105541569BEasy to makeMild responseOrganic compound preparationGroup 5/15 element organic compoundsRoom temperatureChloride

The invention provides a method for synthesizing 1-benzyloxy-2-[2-(3-methoxyphenyl)vinyl]benzene. The method comprises the following steps: making diphenylmethoxyphosphine react with m-methoxybenzyl chloride at 55-60 DEG C to obtain m-methoxybenzyldiphenylphosphine oxide; adding a solvent and a basifier into the m-methoxybenzyldiphenylphosphine oxide; and keeping reactions at room temperature to obtain 1-benzyloxy-2-[2-(3-methoxyphenyl)vinyl]benzene. The synthesis preparation method is simple, mild in reaction and easy to implement.

Owner:苏州诚和医药化学有限公司

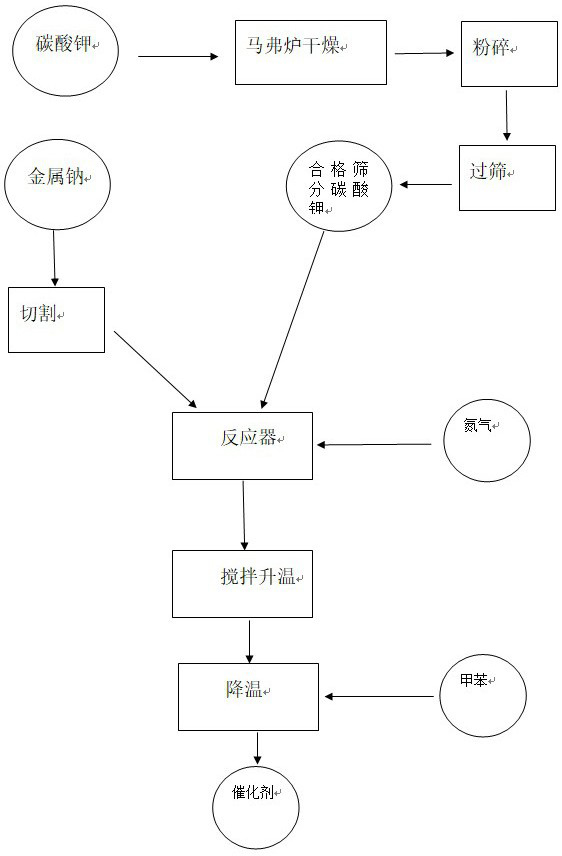

Preparation process of novel catalyst for isobutylbenzene synthesis process

InactiveCN112958128ALow priceReduce manufacturing costPhysical/chemical process catalystsPtru catalystSide chain

The invention belongs to the field of pharmaceutical chemicals, and particularly relates to a preparation process of a novel catalyst for an isobutylbenzene synthesis process. Isobutylbenzene (IBB) is a main intermediate for synthesizing a human medicine ibuprofen which is used for diminishing inflammation, relieving fever and easing pain. A main synthesis method of the isobutylbenzene is an alkylation method taking methylbenzene and propylene as raw materials, and isobutylbenzene is generated through a side chain alkylation reaction in the presence of a basic catalyst. Alkali metal needs to be used as a catalyst for the side chain alkylation reaction, at present, metal potassium catalysts or potassium-sodium alloy catalysts are usually used at home and abroad, and the production cost is greatly reduced and the economic benefit is improved by using cheaper metal sodium.The present invention uses metallic sodium and potassium carbonate to make the novel catalyst, and the catalyst is used for synthetic reaction of isobutylbenzene products.

Owner:山东新华万博化工有限公司

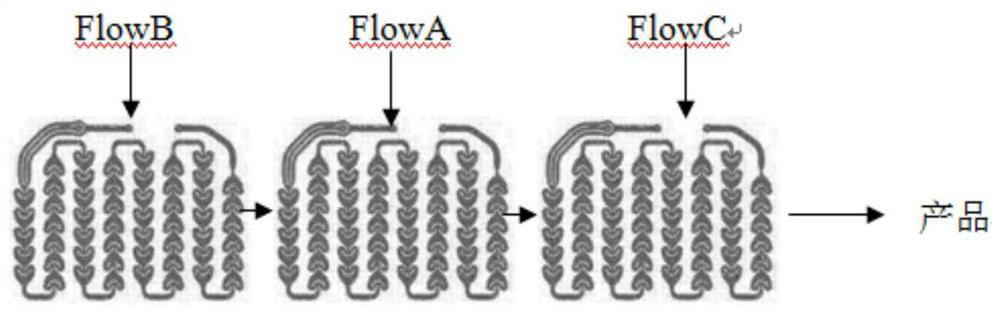

2, 5-dichloronitrobenzene and micro-channel continuous synthesis process thereof

PendingCN112778136AShort reaction timeNo refining/distillation purification requiredChemical/physical/physico-chemical microreactorsNitro compound preparationNitrobenzeneOrganic layer

The invention relates to the field of synthesis of 2, 5-dichloronitrobenzene, in particular to 2, 5-dichloronitrobenzene and a micro-channel continuous synthesis process thereof. The micro-channel continuous synthesis process of the 2, 5-dichloronitrobenzene comprises the following steps of preheating mixed acid by a micro-channel reactor preheating module, reacting the mixed acid with paradichlorobenzene in a molten state in a micro-channel reactor reaction module I, continuously reacting in a micro-channel reactor reaction module II containing sulfuric acid to obtain a reaction solution, layering, and washing and layering an organic layer by an alkali solution, thereby obtaining the product. The mixed acid is fuming nitric acid and sulfuric acid. The micro-channel continuous synthesis process of 2, 5-dichloronitrobenzene belongs to a solvent-free micro-channel process and is green and safe, the raw material conversion rate is 100 wt%, the yield is 99.5 wt% or above, the product purity is 99.9 wt% or above, and the product can be subjected to subsequent reaction without rectification and purification.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

Catalyst for synthesis of cyclohexylbenzene

ActiveCN107866273ALow yieldHigh yieldMolecular sieve catalystsHydrocarbon by addition and hydrogenationMolecular sievePtru catalyst

The invention relates to a catalyst for synthesis of cyclohexylbenzene, a preparation method thereof and a method of one-step synthesis of cyclohexylbenzene through hydroalkylation of benzene. The catalyst mainly solves the technical problems that yield of by-product cyclohexane is high and yield of main product cyclohexylbenzene is low in a reaction caused by a catalyst in the prior art. The catalyst for synthesis of cyclohexylbenzene comprises a carrier and the following active components: (1) 0.5-20g / L of Pd; and (2) 0-40g / L of at least one of lanthanoid elements, wherein the carrier is hydrogen-type zeolite molecular sieves. By employing the technical scheme, better effect is obtained, and the catalyst can be used to the one-step method of preparing cyclohexylbenzene through the hydroalkylation of benzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis of 1-(β-d-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene Synthesis of 1-(β-d-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/411b38b4-9931-4e4c-abcd-89f1519bbc0a/HDA0000662232430000011.png)

![Synthesis of 1-(β-d-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene Synthesis of 1-(β-d-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/411b38b4-9931-4e4c-abcd-89f1519bbc0a/HDA0000662232430000021.png)

![Synthesis of 1-(β-d-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene Synthesis of 1-(β-d-glucopyranosyl)-4-methyl-3-[5-(4-fluorophenyl)-2-thienylmethyl]benzene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/411b38b4-9931-4e4c-abcd-89f1519bbc0a/HDA0000662232430000031.png)

![A kind of synthetic method of 1-benzyloxy-2-[2-(3-methoxyphenyl) vinyl] benzene A kind of synthetic method of 1-benzyloxy-2-[2-(3-methoxyphenyl) vinyl] benzene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/4eed40fa-ba51-4079-b123-44f7245851f6/151230144417.png)

![A kind of synthetic method of 1-benzyloxy-2-[2-(3-methoxyphenyl) vinyl] benzene A kind of synthetic method of 1-benzyloxy-2-[2-(3-methoxyphenyl) vinyl] benzene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/4eed40fa-ba51-4079-b123-44f7245851f6/151230144602.png)