Catalyst for synthesizing benzaldehyde by catalytic oxidation of toluene and preparation method thereof

A catalytic oxidation and catalyst technology, applied in catalyst activation/preparation, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve the problems of limited application and inability to greatly increase the specific surface area, and achieve inhibition of agglomeration and efficient selective catalytic oxidation. performance, scaling the effect of efficient means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

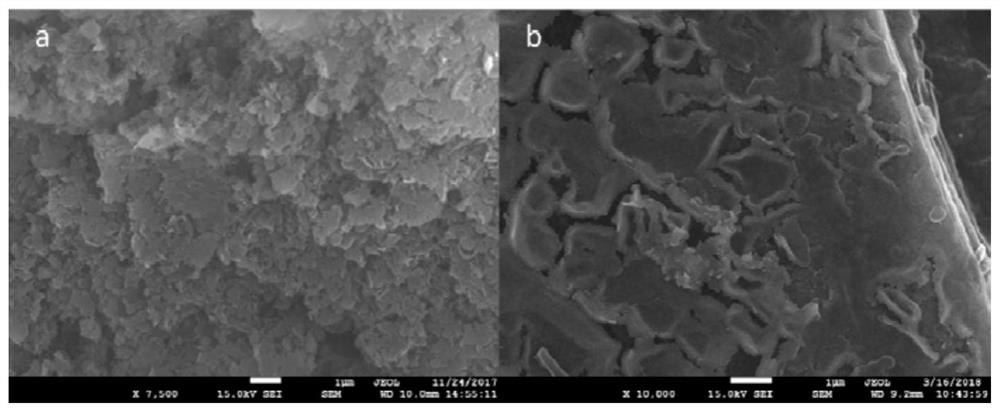

Image

Examples

Embodiment 1

[0036] A kind of embodiment of the preparation method of the catalyst of catalytic oxidation toluene synthesis benzaldehyde among the present invention, comprises the steps:

[0037] Step 1: Add 8.56g of urea and 6g of melamine into a beaker at room temperature, add 50ml of deionized water, stir the suspension for 0.5h, then transfer the suspension to a 100mL PTFE-lined stainless steel autoclave , and heated in an oven at 160°C for 12 hours. After rapid cooling to room temperature, the product was collected by vacuum filtration, washed with deionized water, and then dried at 80 °C for 10 h.

[0038] Step 2: Take the precursor treated in step 1 and place it in a corundum crucible with a cover, put it into a muffle furnace, raise the temperature from room temperature to 550°C at a heating rate of 3°C / min, and calcinate at 550°C for 4h , and then rapidly cooled to room temperature to obtain ultrathin N-doped nanosheet porous graphitic carbon nitride.

[0039] Step 3: The prepar...

example 2

[0044] A kind of embodiment of the preparation method of the catalyst of catalytic oxidation toluene synthesis benzaldehyde among the present invention, comprises the steps:

[0045] Step 1: Add 8.56g of urea and 6g of melamine into a beaker at room temperature, add 50ml of deionized water, stir the suspension for 0.5h, then transfer the suspension to a 100mL PTFE-lined stainless steel autoclave , and heated in an oven at 160°C for 12 hours. After rapid cooling to room temperature, ultrasonication was performed for 1 h with an ultrasonic power of 60W. The product was collected by vacuum filtration, washed with deionized water, and dried at 80 °C for 10 hours.

[0046] Step 2: Take the precursor processed in step 1 and place it in a corundum crucible with a cover, put it into a muffle furnace, raise the temperature from room temperature to 500°C at a heating rate of 2°C / min, and calcinate at 500°C for 3h , and then rapidly cooled to room temperature to obtain ultrathin N-dope...

Embodiment 3

[0052] A kind of embodiment of the preparation method of the catalyst of catalytic oxidation toluene synthesis benzaldehyde among the present invention, comprises the steps:

[0053] Step 1: Add 8.56g of urea and 6g of melamine into a beaker at room temperature, add 50ml of deionized water, stir the suspension for 0.5h, then transfer the suspension to a 100mL PTFE-lined stainless steel autoclave , and heated in an oven at 180°C for 24 hours. After rapid cooling to room temperature, ultrasonication was performed for 2 hours with an ultrasonic power of 80W. The product was collected by vacuum filtration, washed with deionized water, and dried at 80 °C for 10 hours.

[0054] Step 2: Take the precursor processed in Step 1 and place it in a corundum crucible with a cover, put it into a muffle furnace, raise the temperature from room temperature to 500°C at a heating rate of 5°C / min, and calcinate at 500°C for 4h , and then rapidly cooled to room temperature to obtain ultrathin N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com