Method for preparing methyl furoate from furfuraldehyde through oxidation and esterification

A technology of methyl furoate and oxidative esterification, which is applied in the direction of organic chemistry, can solve the problems of increased cost, inability to recycle, difficult separation of homogeneous alkali, etc., and achieve the effect of reducing loss and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

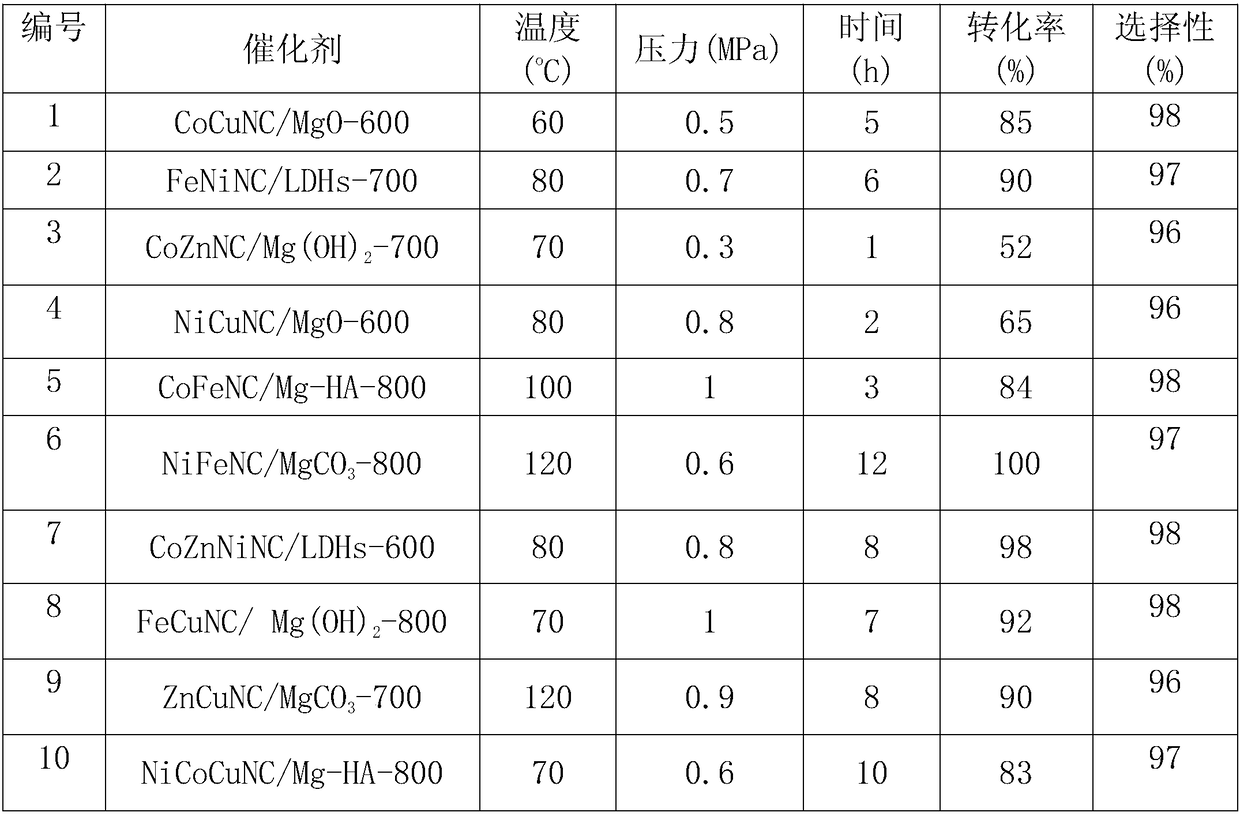

[0012] Add CoCuNC / MgO-600 (Co 3.7wt%, Cu 1.5wt%, N 1%, C 12%) catalyst, 0.5mmol furfural, and 5mL methanol into a stainless steel autoclave with polytetrafluoroethylene lining inside. The temperature was raised to a reaction temperature of 60° C. using an automatic temperature controller, and 0.5 MPa of oxygen was added to react for 5 hours. During the reaction, the pressure was kept constant. The reaction products were analyzed by GC, and the reaction results are shown in Table 1.

Embodiment 2

[0014] FeNiNC / LDHs-700 (Fe 2.6wt%, Ni 2wt%, N 3%, C 15%) catalyst, 0.5mmol furfural, and 5mL methanol were added to a stainless steel autoclave with a polytetrafluoroethylene lining inside. The temperature was raised to a reaction temperature of 80° C. using an automatic temperature controller, and 0.6 MPa oxygen was added to react for 7 hours, keeping the pressure constant during the reaction. The reaction product was analyzed by GC, and the reaction results are shown in Table 1

Embodiment 3

[0016] CoZnNC / Mg(OH) 2 -700 (Co 5wt%, Zn 1.5wt%, N 0.5%, C 10%) catalyst, 0.5mmol furfural, and 5mL methanol were added to a stainless steel autoclave with a polytetrafluoroethylene lining inside. The temperature was raised to a reaction temperature of 70° C. using an automatic temperature controller, and 0.3 MPa oxygen was added to react for 1 hour. During the reaction, the pressure was kept constant. The reaction products were analyzed by GC, and the reaction results are shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap