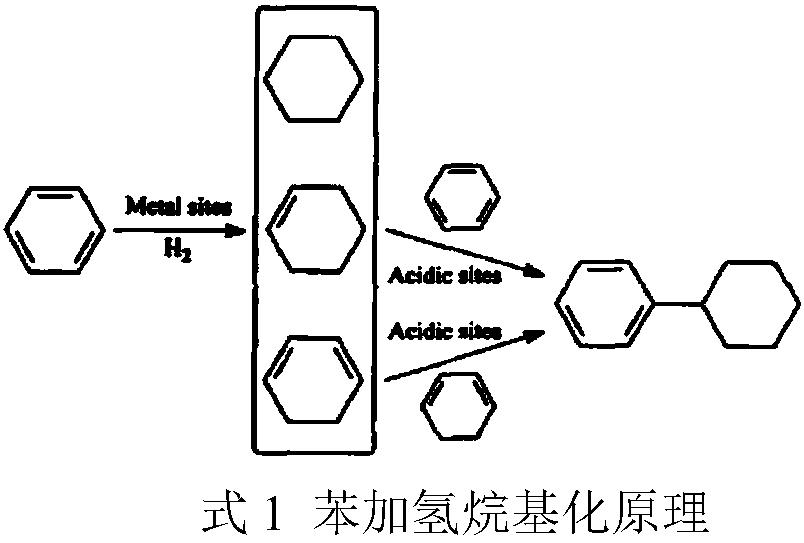

Catalyst for synthesis of cyclohexylbenzene

A cyclohexylbenzene and catalyst technology, applied in the field of catalysts for cyclohexylbenzene synthesis, can solve the problems of low yield of cyclohexylbenzene, high yield of cyclohexylbenzene, low yield of cyclohexane, etc. Yield-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Catalyst preparation

[0037] Weigh PdCl containing Pd 1.5g 2 Be dissolved in 1mol / L hydrochloric acid aqueous solution and be made into 80g solution I; Measure 0.1L diameter to be 1mm, length 5mm non-binding cylindrical hydrogen type BEA zeolite molecular sieve (the mol ratio of silicon dioxide / alumina is 40); The solution I was loaded on the hydrogen-type BEA zeolite molecular sieve, impregnated at room temperature for 12 hours, dried at 100°C for 12 hours, and calcined at 450°C for 4 hours to prepare the desired catalyst.

[0038] 2. Catalyst evaluation

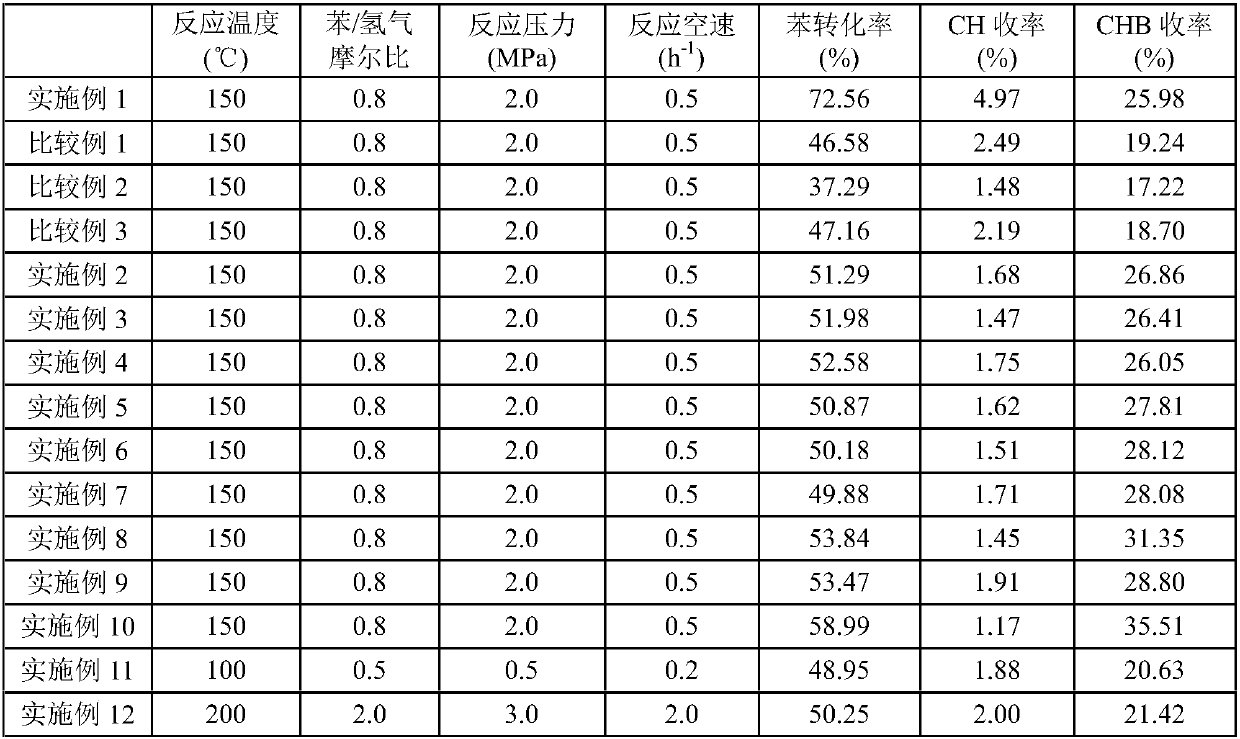

[0039] Get 10ml catalyst packing in the fixed-bed reactor, carry out activity evaluation after reduction activation, condition is as follows: the temperature of reaction is 150 ℃, and the mol ratio of benzene and hydrogen in the reaction raw material is 0.8, and the pressure of reaction is 2.0MPa (gauge pressure) , the liquid volume space velocity of the reacted raw material benzene is 0.5h -1 .

[0040] For ...

Embodiment 2

[0060] 1. Catalyst preparation

[0061] Weigh PdCl containing Pd 0.3g 2 Dissolve in 1mol / L hydrochloric acid aqueous solution and be made into 40g solution I; Weigh the La(NO 3 ) 3 ·6H 2 O and Pr(NO 3 ) 3 ·6H 2 O is dissolved in water and is made into 40g solution II; Measure 0.1L diameter to be 1mm, length 5mm cylindrical hydrogen-type BEA zeolite molecular sieve (the mol ratio of silicon dioxide / aluminum oxide is 40), solution I and The solution II was mixed evenly and then loaded on the hydrogen-type BEA zeolite molecular sieve, impregnated at room temperature for 12 hours, dried at 100°C for 12 hours, and calcined at 450°C for 4 hours to prepare the desired catalyst.

[0062] 2. Catalyst evaluation

[0063] Catalyst evaluation method see embodiment 1.

[0064] For the convenience of comparison, the composition of the catalyst is listed in Table 1, and the evaluation results are listed in Table 2.

[0065] It can be known from Example 2 and Comparative Example 1 an...

Embodiment 3

[0067] 1. Catalyst preparation

[0068] Weigh PdCl containing Pd 0.3g 2 Dissolve in 1mol / L hydrochloric acid aqueous solution and be made into 40g solution I; Weigh the La(NO 3 ) 3 ·6H 2 O and Sm(NO 3 ) 3 ·6H 2 O is dissolved in water and is made into 40g solution II; Measure 0.1L diameter to be 1mm, length 5mm cylindrical hydrogen-type BEA zeolite molecular sieve (the mol ratio of silicon dioxide / aluminum oxide is 40), solution I and The solution II was mixed evenly and then loaded on the hydrogen-type BEA zeolite molecular sieve, impregnated at room temperature for 12 hours, dried at 100°C for 12 hours, and calcined at 450°C for 4 hours to prepare the desired catalyst.

[0069] 2. Catalyst evaluation

[0070] Catalyst evaluation method see embodiment 1.

[0071] For the convenience of comparison, the composition of the catalyst is listed in Table 1, and the evaluation results are listed in Table 2.

[0072] It can be seen from the comparison of Example 3 with Compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com