Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "5-sulfoisophthalic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

5-Sulfoisophthalic acid sodium salt 95% CAS Number 6362-79-4. Linear Formula NaO 3 SC 6 H 3-1,3-(CO 2 H) 2. Molecular Weight 268.18 . EC Number 228-845-2. MDL number MFCD00007495. PubChem Substance ID 24848537

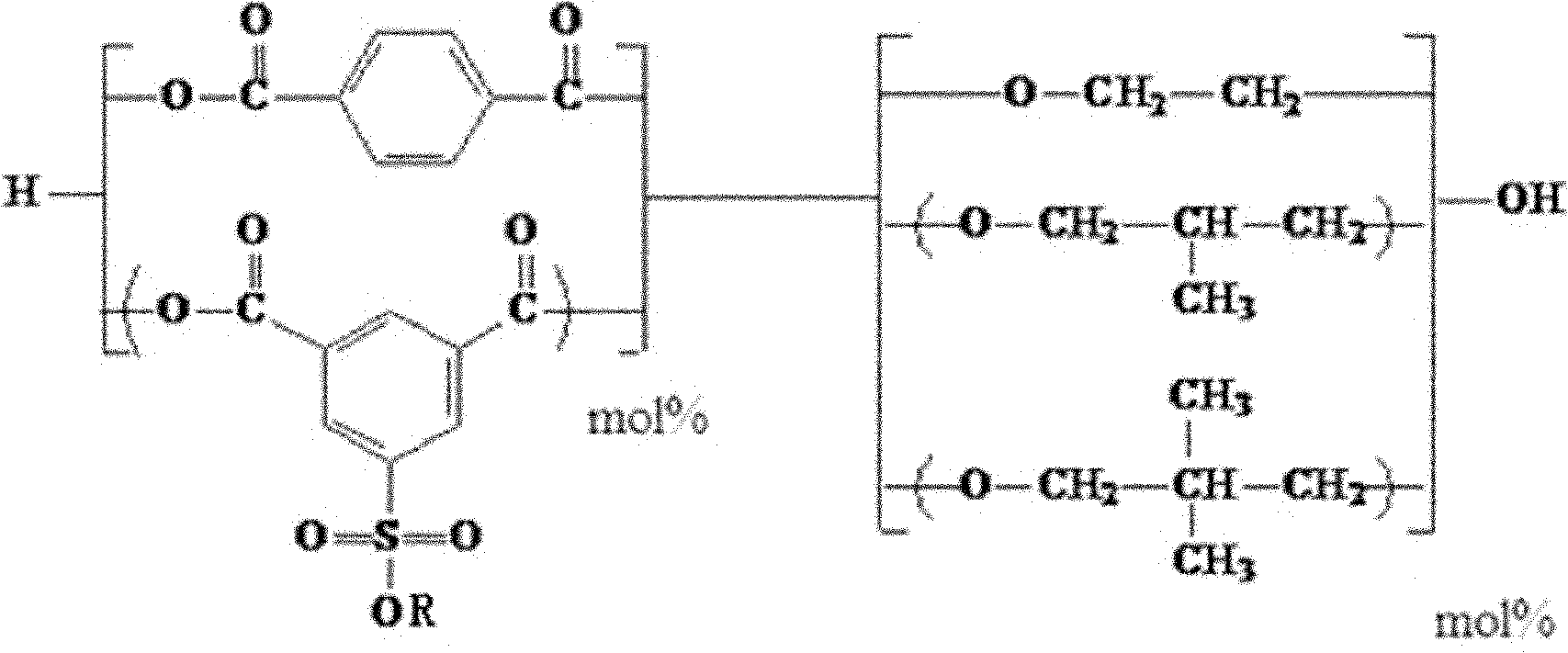

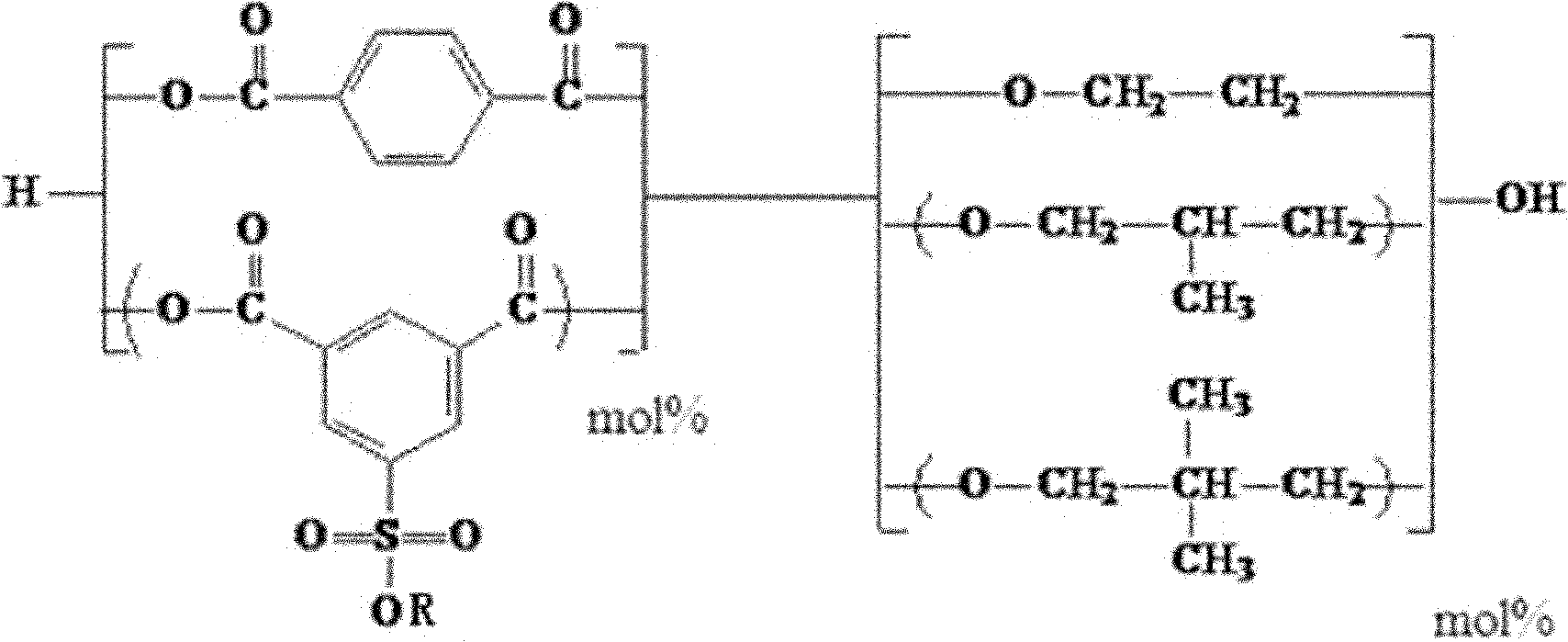

Polyester chip modified by blend with side chain aliphatic diol and preparation method thereof

InactiveCN102120816ALow costEase of industrial productionMonocomponent polyesters artificial filamentDisperse dyeSide chain

The invention relates to a polyester chip modified by the blend with side chain aliphatic diol and a preparation method thereof. The polyester chip is copolymerized by the following monomers: (1) terephthalic acid; (2) ethylene glycol; (3) sodium or potassium 5-sulfoisophthalic acid dibasic ester; and (4) the blend of 2-methyl-1,3-propanediol and 2,2-dimethyl-1,3-propanediol. The preparation method comprises the following steps: adding terephthalic acid and ethylene glycol in a first esterification kettle, adding catalyst and stabilizer simultaneously to perform esterification reaction, transferring the material to a second esterification kettle, injecting the blend of 2-methyl-1,3-propanediol and 2,2-dimethyl-1,3-propanediol to perform esterification with sodium or potassium 5-sulfoisophthalic acid dibasic ester; and (2) transferring the material to a polycondensation kettle, discharging, pelletizing and drying. The modified polyester chip of the invention is used to prepare the cationic or disperse dye atmospheric deep dyeing copolyester fiber; and the method is simple, has low cost and is suitable for industrial production.

Owner:DONGHUA UNIV

Aliphatic-aromatic polyesters, and articles made therefrom

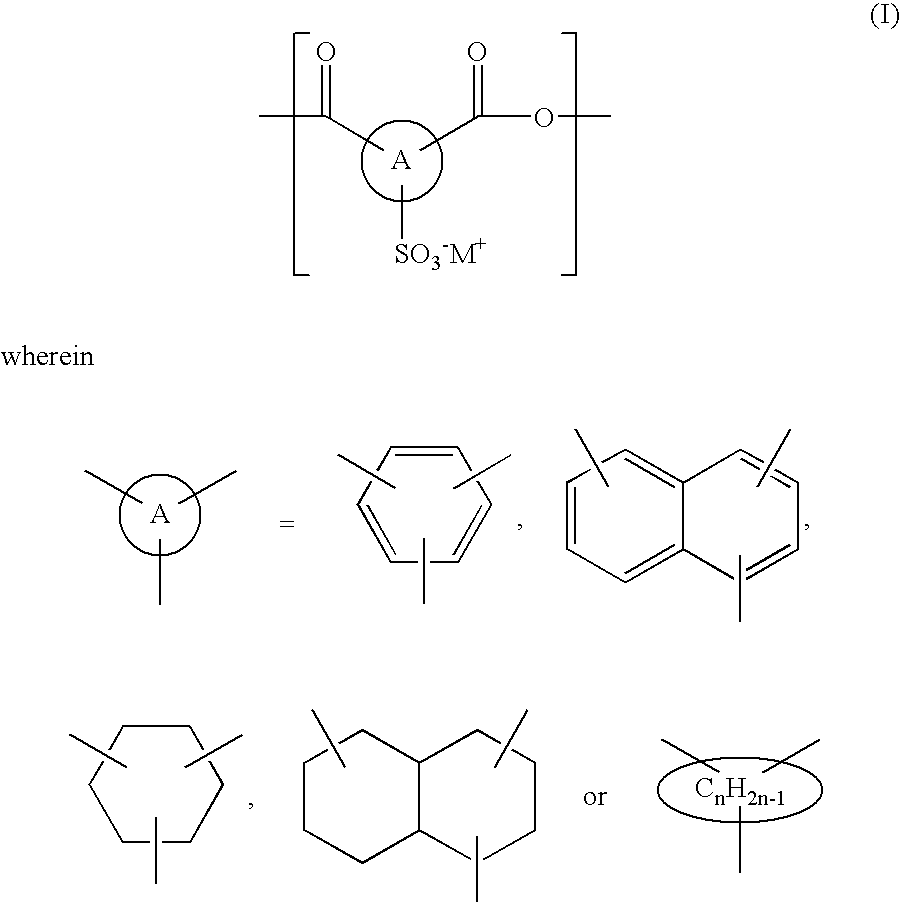

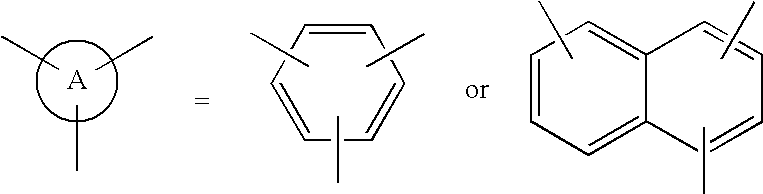

Sulfonated aliphatic-aromatic polyester compositions having improved thermal properties, and articles such as films, coatings and laminates, produced from the sulfonated aliphatic-aromatic polyester compositions, are provided. Some of the films are biocompostable. Films made from the sulfonated aliphatic-aromatic copolyesters can be used to make shaped articles, such as sheets, thermoformed containers, and coatings for, for example, films and other substrates. The sulfonated aliphatic-aromatic copolyesters are produced from a mixture of aromatic dicarboxylic acids, aliphatic dicarboxylic acids, certain glycols, and components containing alkali metal or alkaline earth metal sulfonate groups, such as a metal 5-sulfoisophthalic acid derivative.

Owner:DUPONT IND BIOSCIENCES USA LLC

Method to make single-layer pet bottles with high barrier and improved clarity

InactiveUS20060246245A1Reduce yellownessEnvelopes/bags making machineryGroup 4/14 element organic compoundsPolyesterXylylene

The present invention comprises a blend of polyester and a partially aromatic polyamide with an ionic compatibilizer and a cobalt salt. This blend can be processed into a container that has both active and passive oxygen barrier and carbon dioxide barrier properties at an improved color and clarity than containers known in the art. The partially aromatic polyamide is preferably meta-xylylene adipamide. The ionic compatibilizer is preferably 5-sodiumsulfoisophthalic acid or 5-zincsulfoisophthalic acid, or their dialkyl esters such as the dimethyl ester (SIM) and glycol ester (SIPEG). The cobalt salt is selected form the class of cobalt acetate, cobalt carbonate, cobalt chloride, cobalt hydroxide, cobalt naphthenate, cobalt oleate, cobalt linoleate, cobalt octoate, cobalt stearate, cobalt nitrate, cobalt phosphate, cobalt sulfate, cobalt (ethylene glycolate), or mixtures of two or more of these. The partially aromatic polyamide is present in a range from about 1 to about 10 wt. % of said composition. The ionic compatibilizer is present in a range from about 0.1 to about 2.0 mol-% of said composition. The cobalt salt is present in a range from about 20 to about 500 ppm of said composition.

Owner:TREVIRA HLDG GMBH

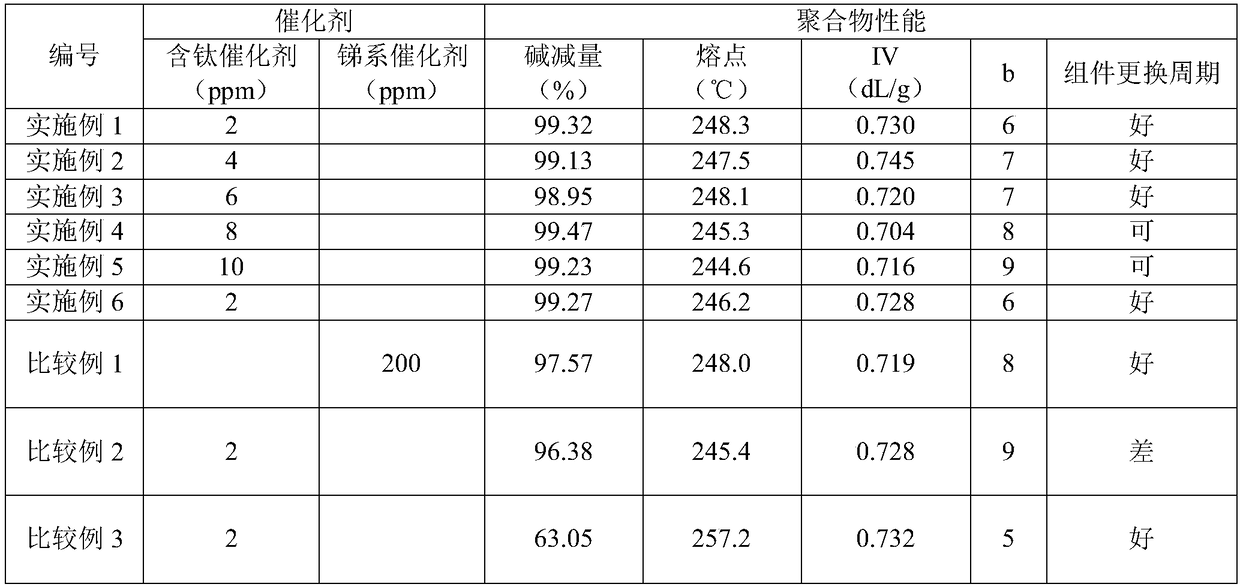

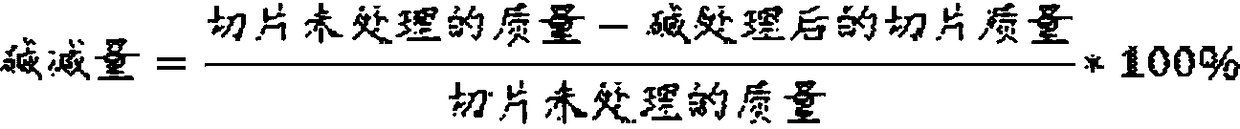

Antimony catalyst-free alkali-soluble copolyester continuously polymerizing method

InactiveCN109485841ASolve technical problems of pollutionShort service lifeMonocomponent copolyesters artificial filamentCopolyesterTitanium

The invention relates to the field of polyester synthesis and discloses an antimony catalyst-free alkali-soluble copolyester continuously polymerizing method. The antimony catalyst-free alkali-solublecopolyester continuously polymerizing method is applied to continuous polymerization of raw materials of terephthalic acid, ethylene glycol, alkali metal 5-sulfoisophthalate and polyalkylene glycol with existence of titanium-containing catalysts and stabilizer. The antimony catalyst-free alkali-soluble copolyester continuously polymerizing method involves no antinomy catalyst adding during preparation of alkali-soluble copolyester, thereby solving the technical problem of antimony pollution and being more environmentally friendly; meanwhile, for solving the technical problem of short application cycle of a spinning module during chip spinning of existing alkali-soluble copolyesters, the antimony catalyst-free alkali-soluble copolyester continuously polymerizing method introduces the copolymerization components of bishydroxyethyl isophthalate-5-sulfoisophthalic acid alkali metal salt to a pulping process to achieve dilution effects and reduce auto-polymerization and etherification, thereby being good in spinnability and effectively prolong the application cycle of the spinning module.

Owner:ZHEJIANG HENGYI PETROCHEM +1

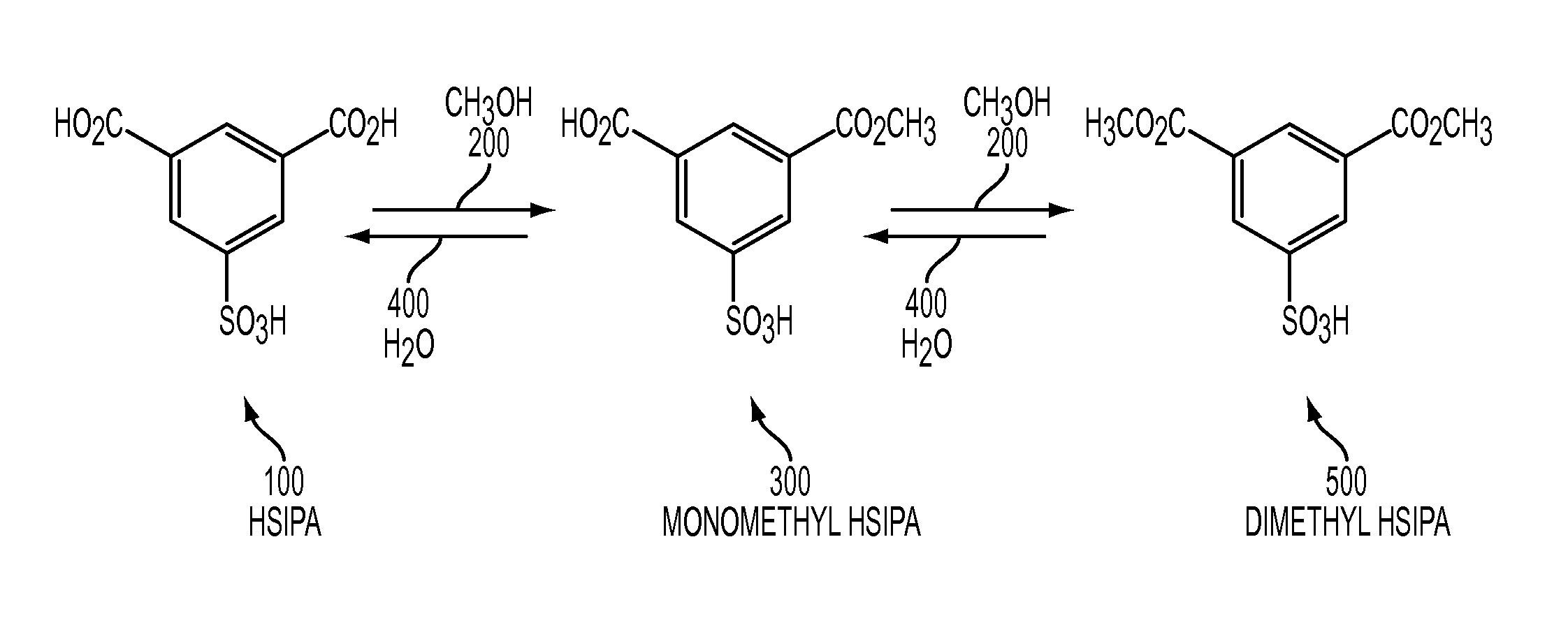

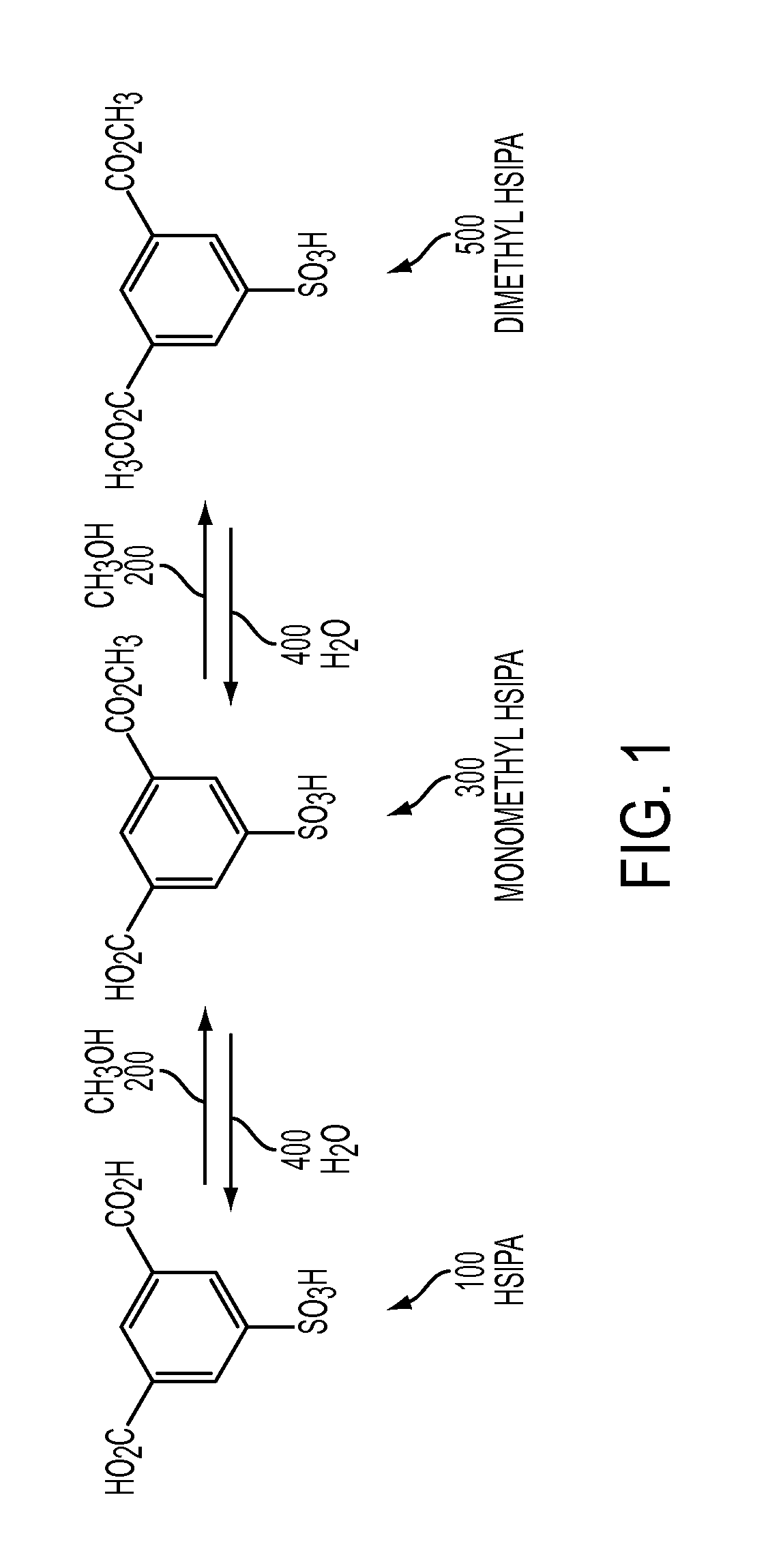

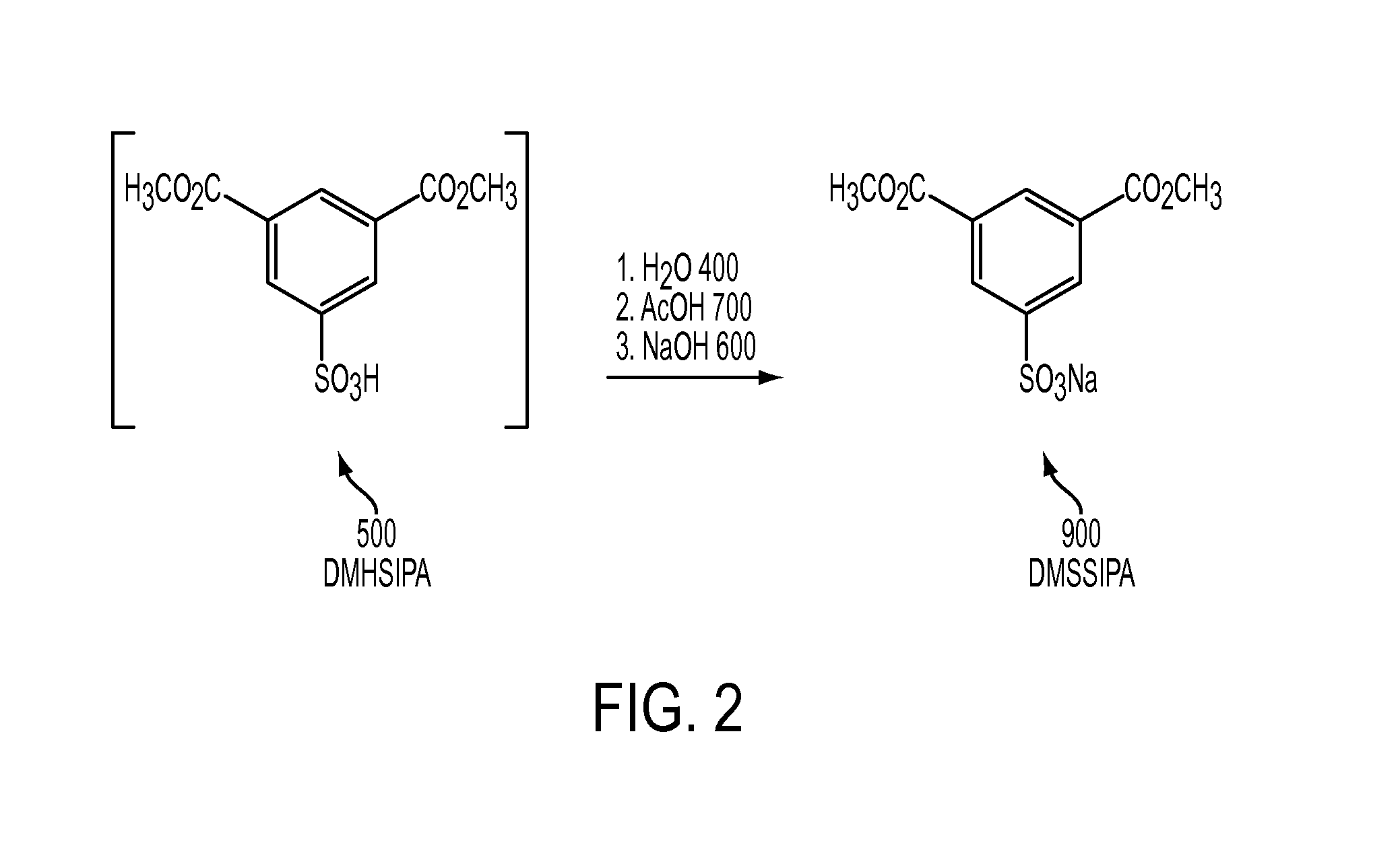

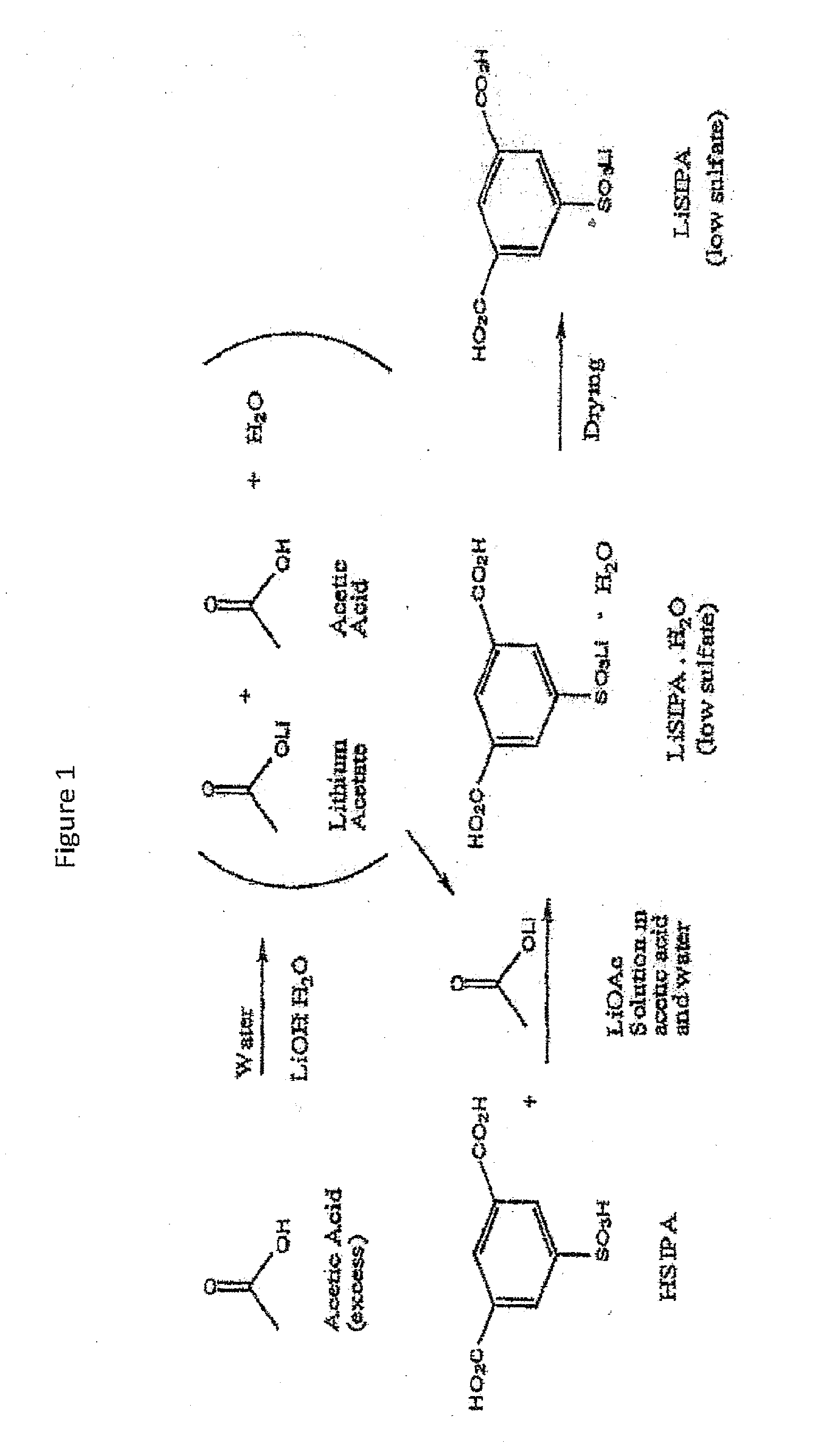

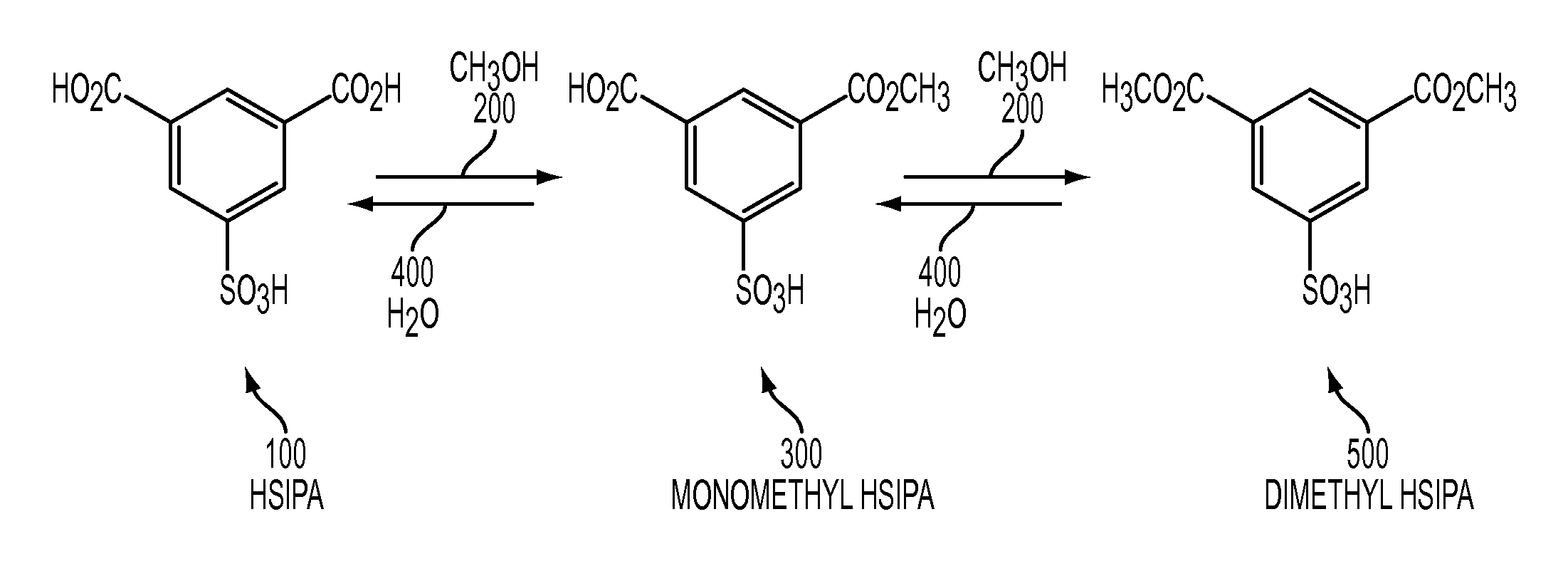

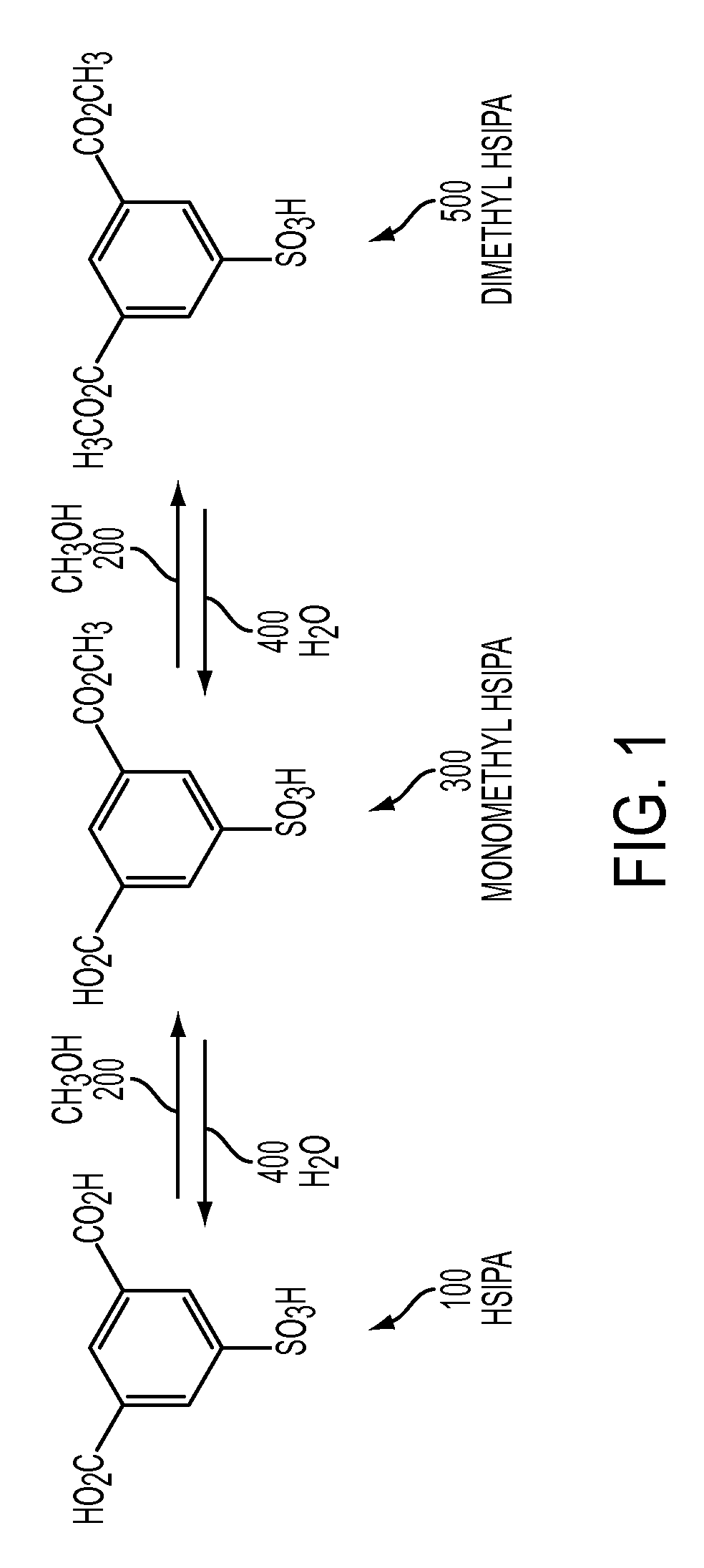

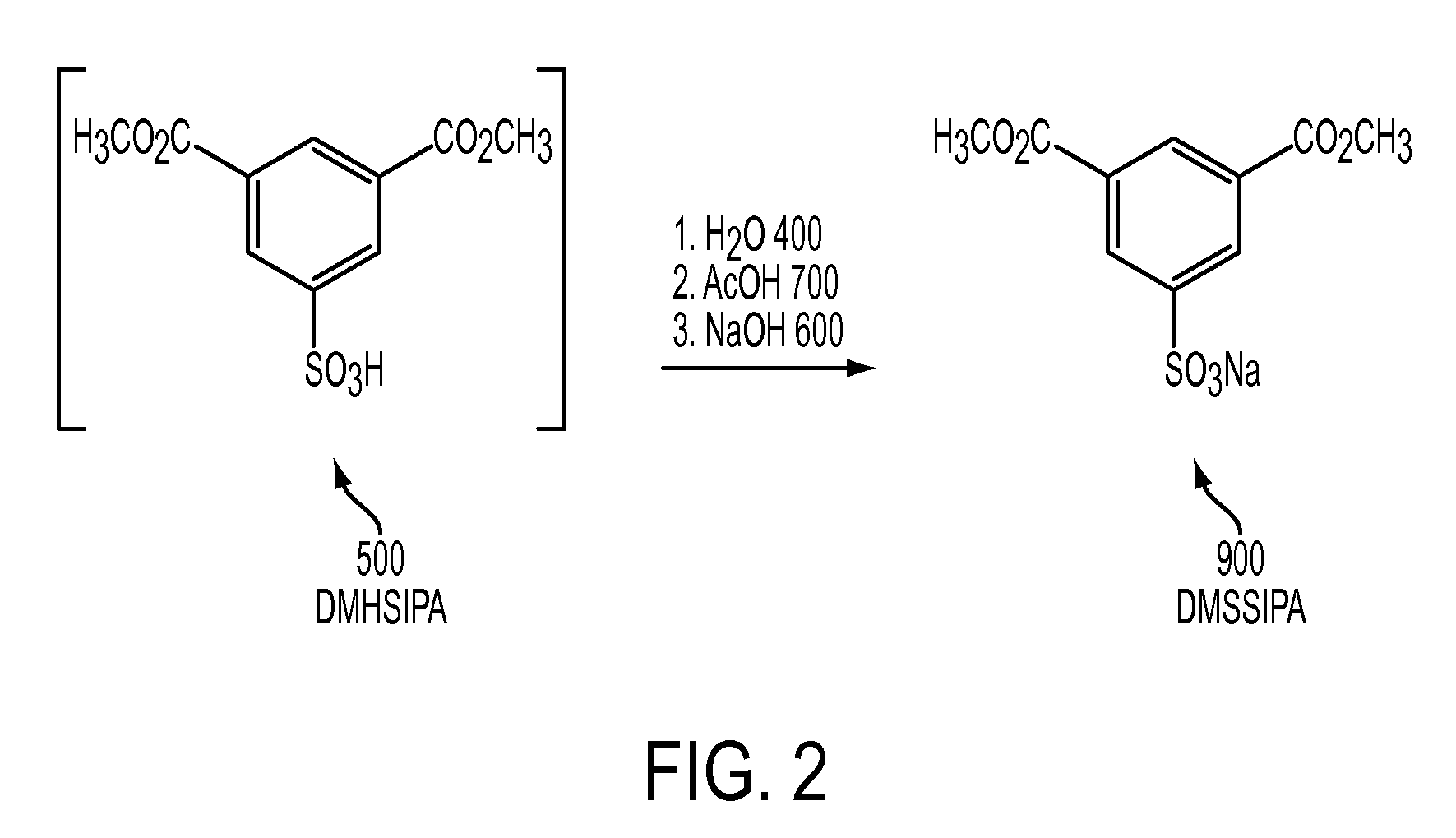

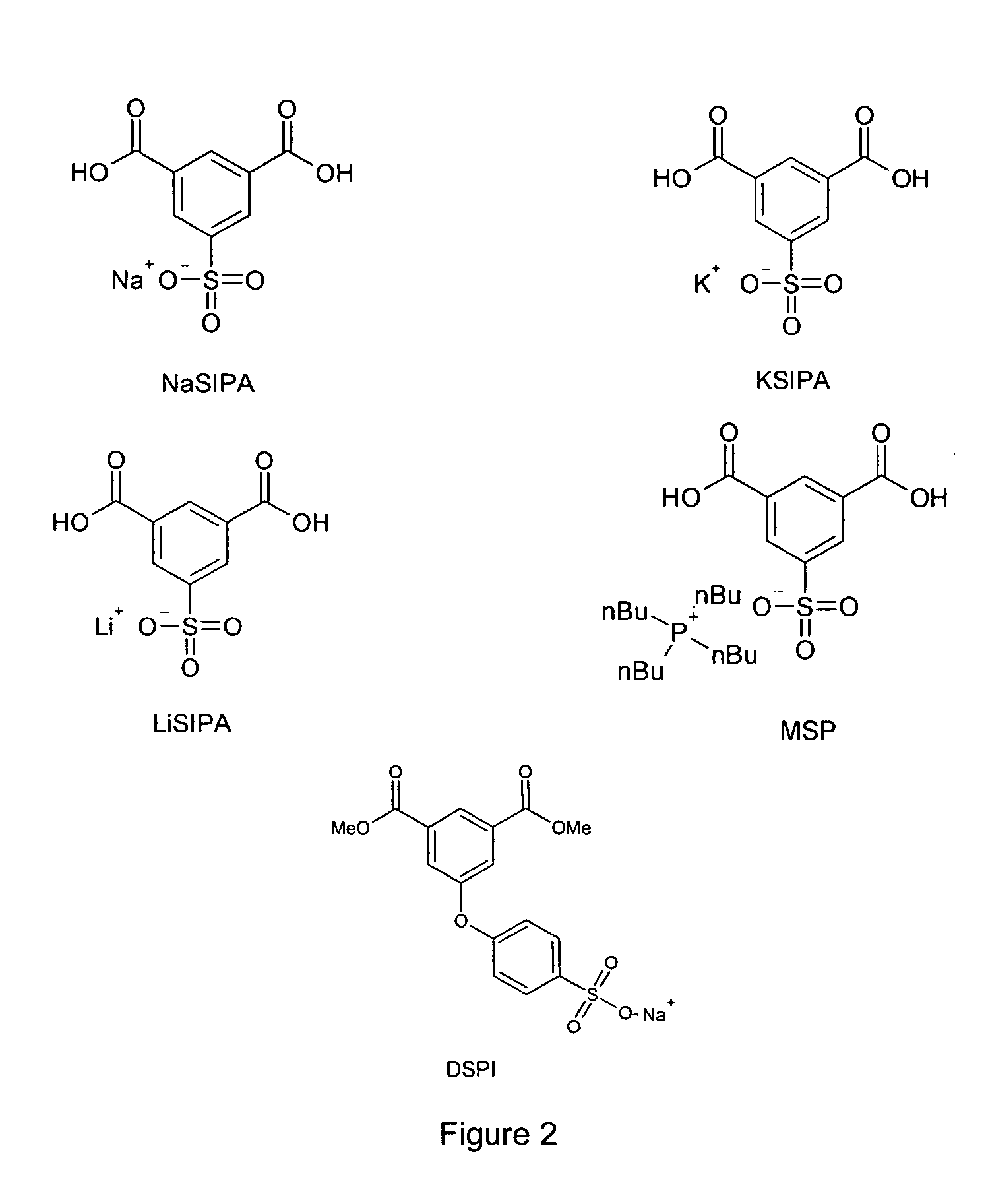

Metal salts of a dialkyl ester of 5-sulfoisophthalic acid and method of preparing same

ActiveUS20120225981A1Lithium organic compoundsSulfonic acids salts preparationMedicinal chemistryMetal salts

The claimed invention meets these and other objects by providing a method of preparing a metal salt of a dialkyl ester of 5-sulfoisophthalic acid. Broadly speaking, the method provides for the contacting of a dialkyl ester of 5-sulfoisophthalic acid with a metal cation in a buffered reaction mixture to form the metal salt of the dialkyl ester. The reaction mixture is buffered, at least in part, by the acetate of the metal cation. The method according to invention also encompasses various methods of preparing the dialkyl ester of 5-sulfoisophthalic acid.

Owner:FUTUREFUEL CHEM

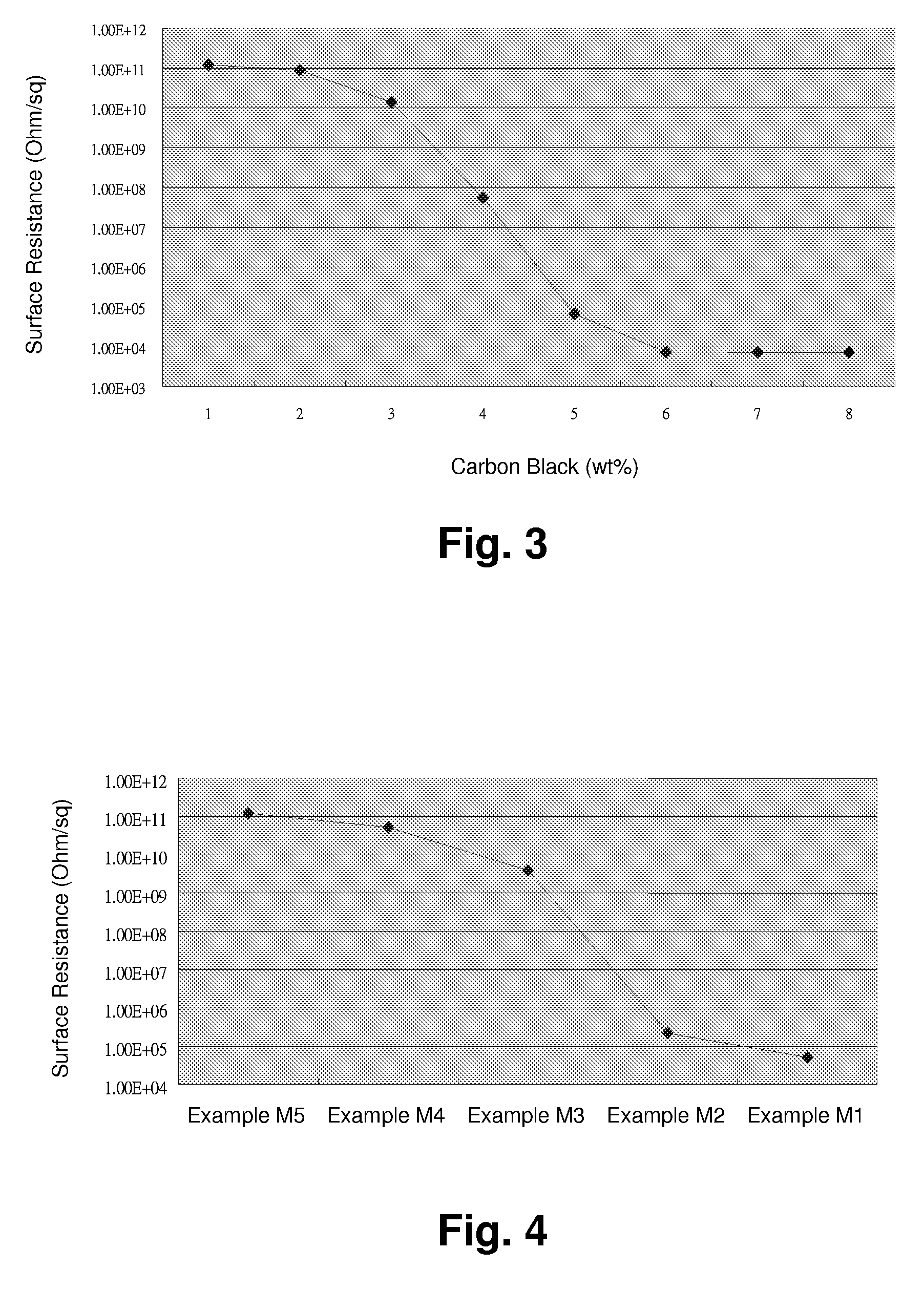

Carbon black-containing polyamide masterbatch composition and method for preparing the same

ActiveUS20100152328A1Electroconductive/antistatic filament manufactureMonocomponent copolyamides artificial filamentMasterbatchEthylene glycol bis

A carbon black-containing polyamide masterbatch composition is provided. The carbon black-containing polyamide masterbatch composition includes a polyamide compounded with an admixture of carbon black and a water-soluble polyamide. The water-soluble polyamide is a copolymer of caprolactam, ethylene glycol bis(2-aminoethyl)ether or ethylene glycol bis(3-aminopropyl)ether, and 5-sulfoisophthalic acid monosodium salt.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

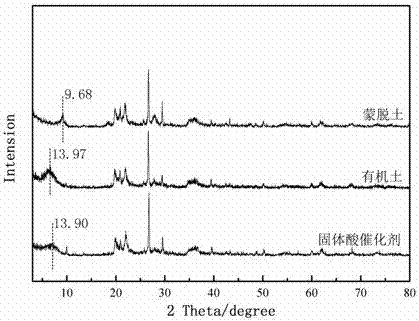

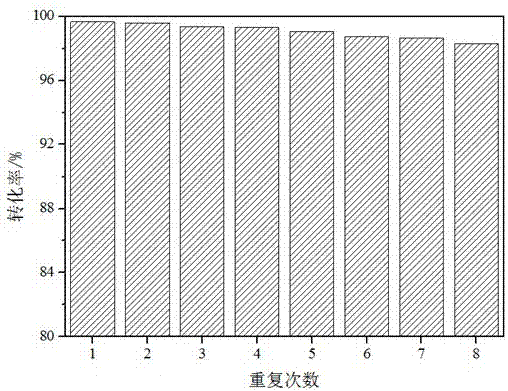

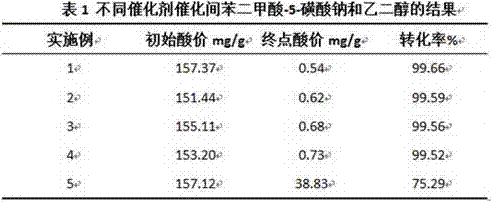

Solid acid catalyst for preparation of sodium isophthalate diethylene glycol 5-sulfonate via direct esterification and preparation and application of solid acid catalyst

ActiveCN107029758AEasy to separateImprove catalytic performanceSulfonic acid esters preparationCatalyst activation/preparationSolid acidHydrotalcite

The invention discloses synthesis and application of a solid acid catalyst and particularly relates to a solid acid catalyst for preparation of sodium isophthalate diethylene glycol 5-sulfonate via direct esterification and preparation and application of the solid acid catalyst; the solid acid catalyst comprises an inorganic lamellar structure material and an intercalation element; the inorganic lamellar structure material may be one or any of montmorillonite, mica, purified bentonite, kaolin, graphite, hydrotalcite and a tetravalent metallic insoluble salt; and the intercalation element may be one or any of Ti, O, H and C. The solid acid catalyst has high catalytic activity in the production of sodium isophthalate diethylene glycol 5-sulfonate from 5-sulfoisophthalic acid monosodium salt and diethylene glycol via direct esterification, the catalyst is easy to separate from the product after reaction, and the catalyst is reusable after being activated.

Owner:UNIV OF JINAN +1

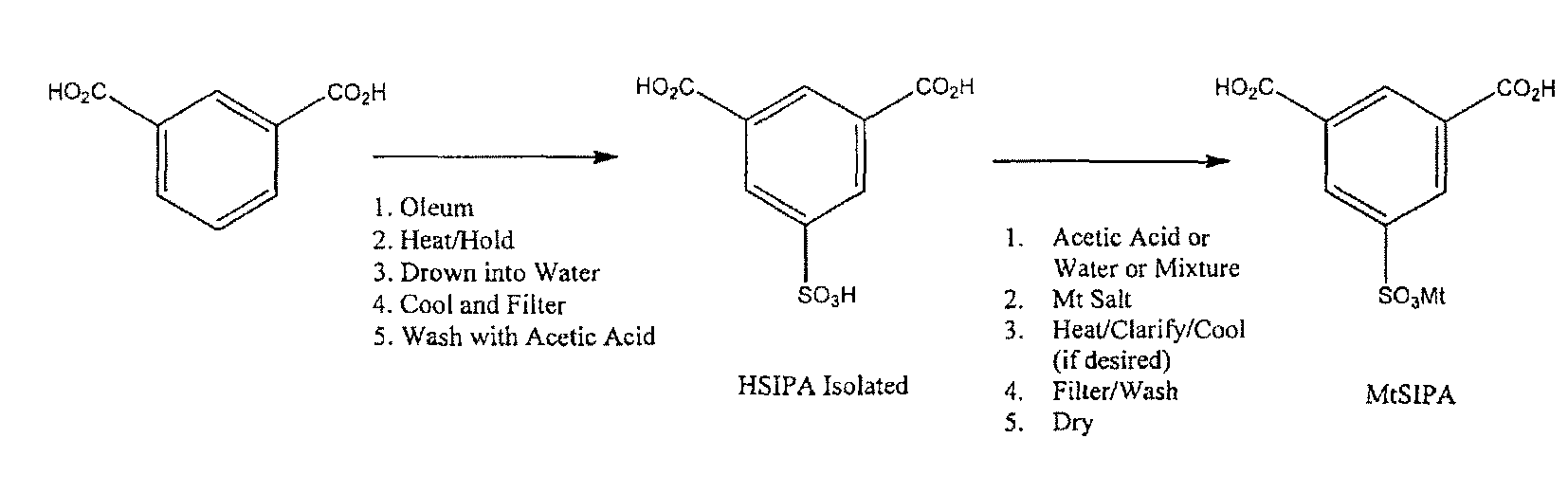

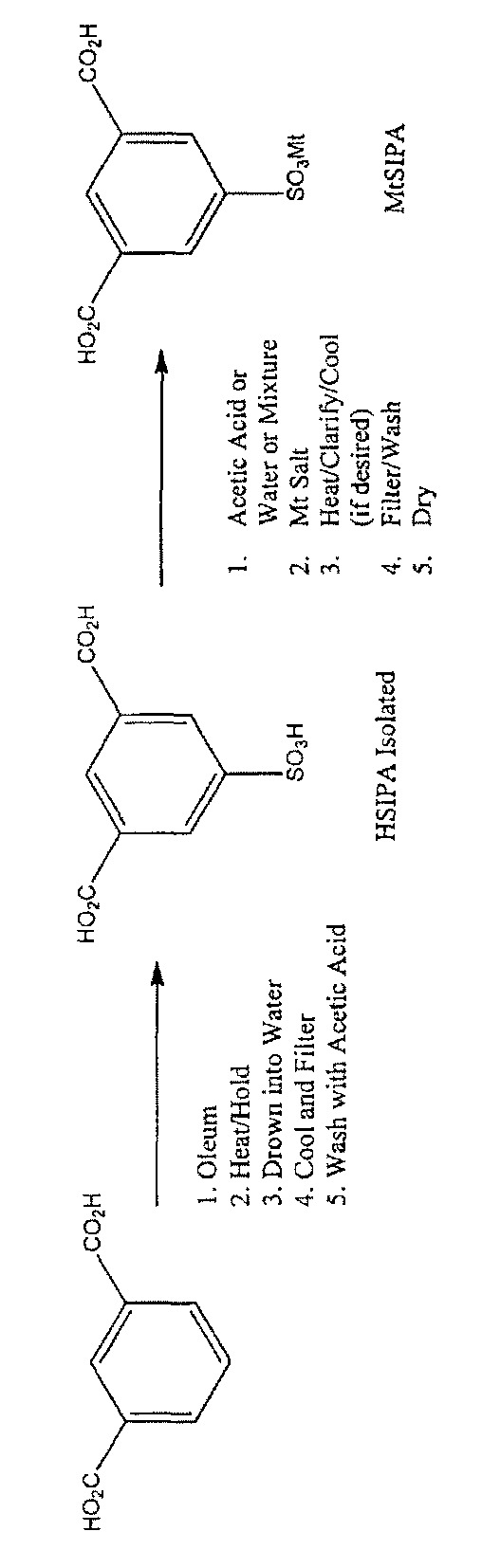

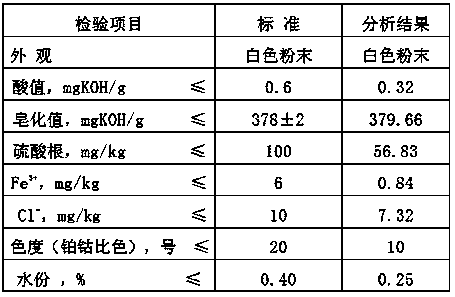

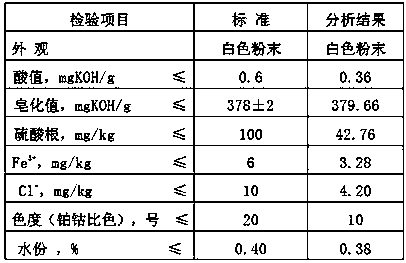

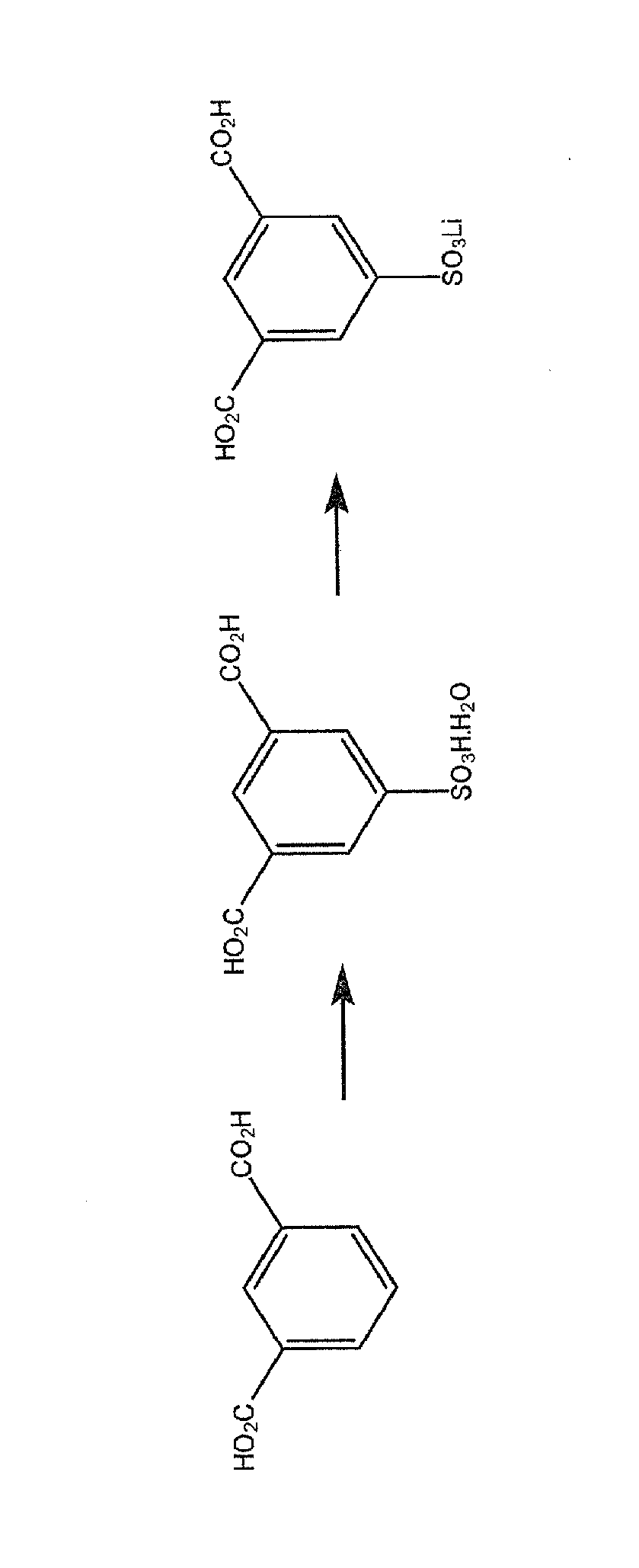

Salts of 5-sulfoisophthalic acid and method of making same

ActiveUS8772522B2Group 1/11 element organic compoundsGroup 8/9/10/18 element organic compoundsRubidiumManganese

This invention relates to methods for the production of various metal salts of 5-sulfoisophthalic acid including those where the metal cation is selected from the group consisting of silver (I), sodium, potassium, rubidium, cesium, magnesium, calcium, strontium, barium, manganese (II), iron (II), cobalt (II), nickel (II), copper (I), copper (II), zinc, yttrium, and cadmium. The methods utilize a solvent system that comprises acetic acid or water or a mixture of both. The invention also encompasses the various metal salts of 5-sulfoisophthalic acid.

Owner:FUTUREFUEL CHEM

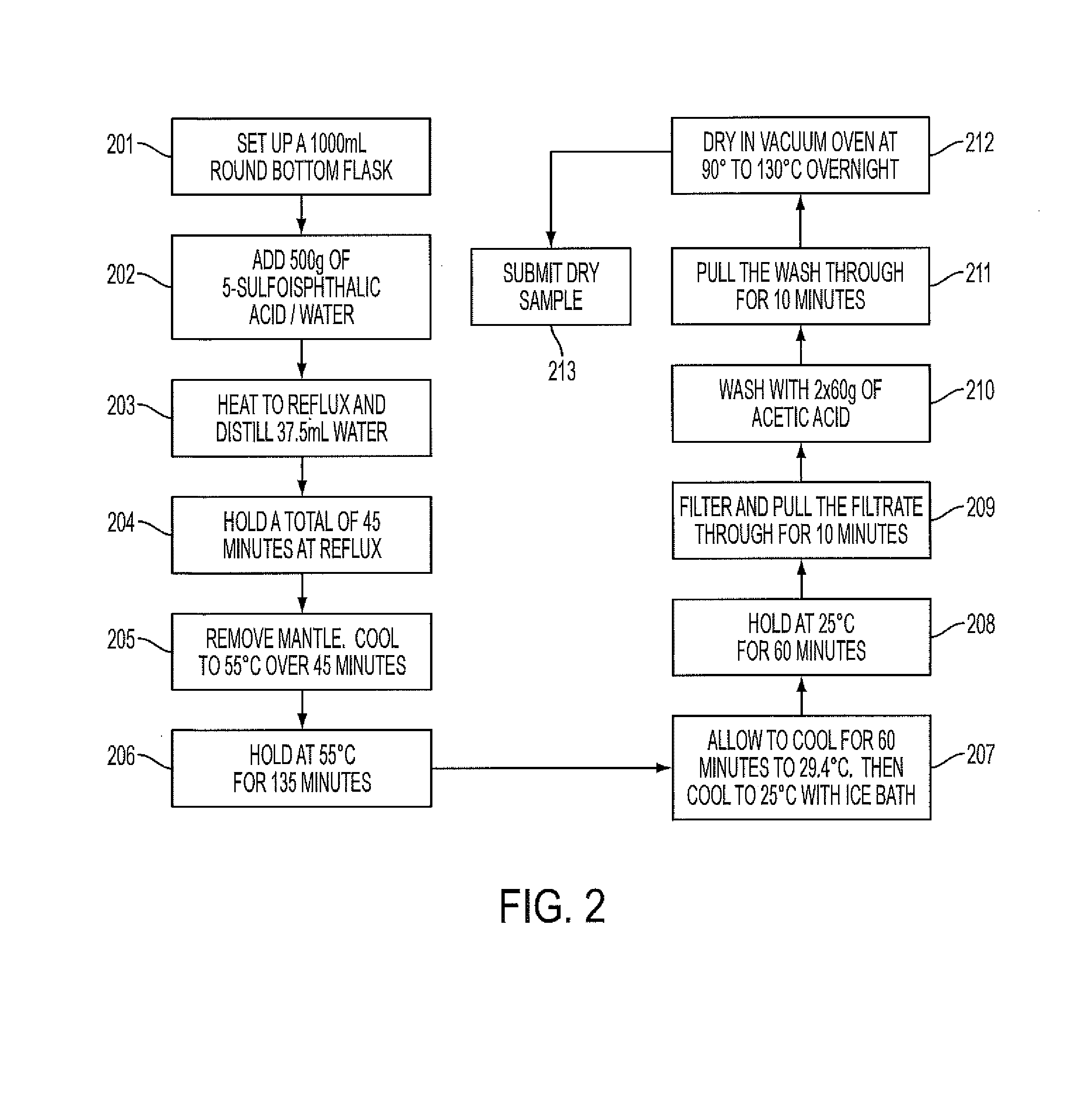

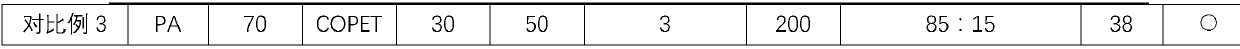

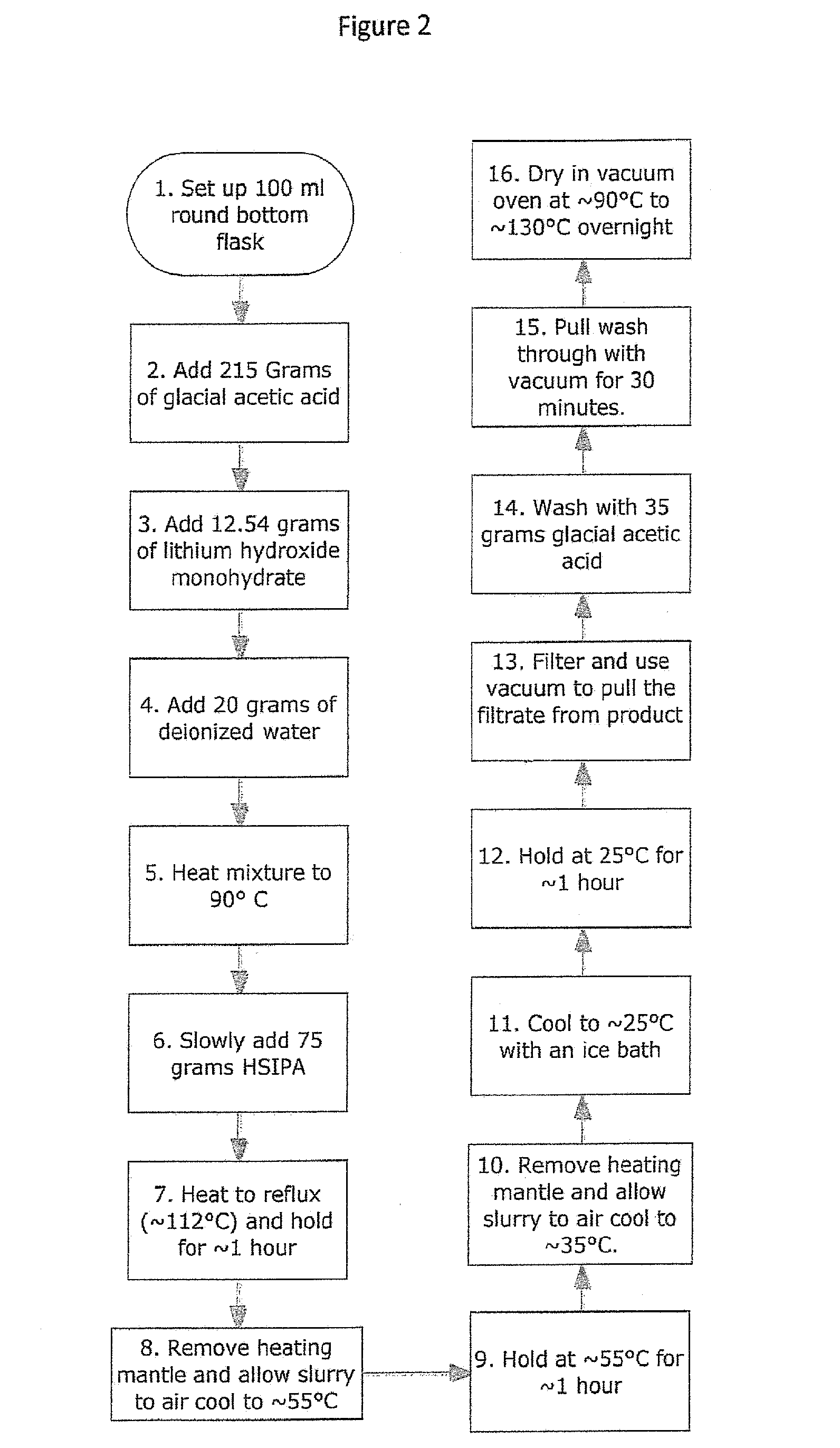

Use of an acetic acid wash to prepare low-sulfate 5-sulfoisophthalic acid, mono-lithium salt

There is disclosed a process for making a mono-lithium salt of 5-sulfoisophthalic acid (LiSIPA) having less than 500 ppm sulfate. The process uses a reaction mixture of water, a lithium cation producing compound, and 5-sulfoisophthalic acid. The reaction mixture is heated to reflux, cooled, filtered and washed with acetic acid to obtain a high quality LiSIPA having less than 500 ppm sulfate. Also disclosed is a high quality, non-purified reaction product containing a mono-lithium salt of 5-sulfoisophthalic acid and having less than 500 ppm sulfate.

Owner:FUTUREFUEL CHEM

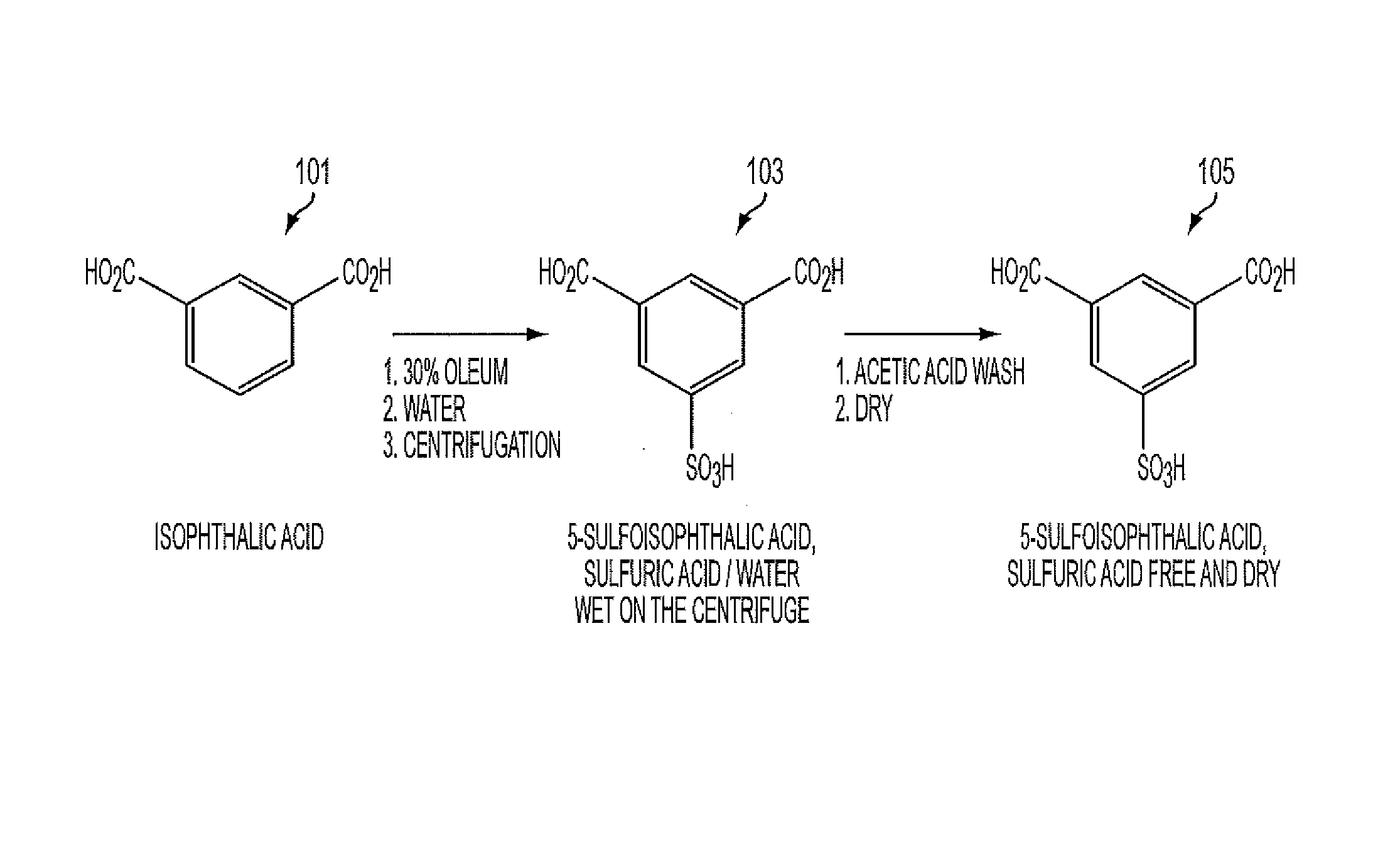

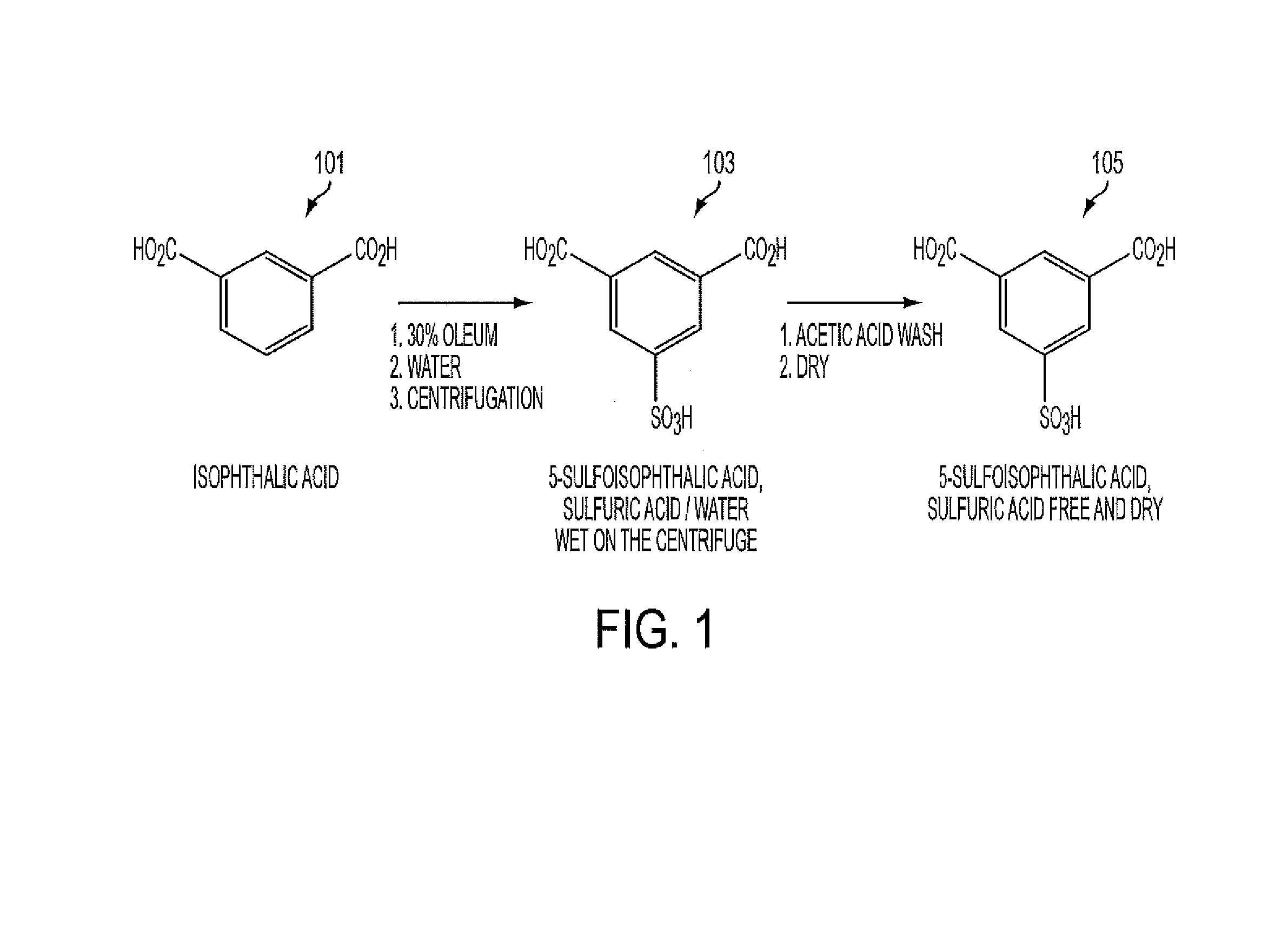

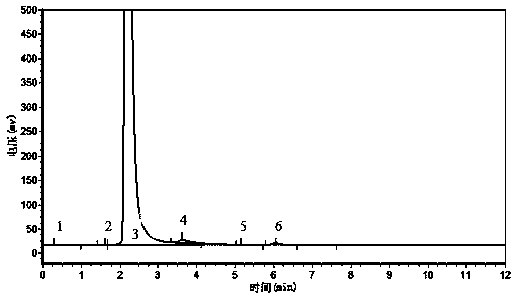

Purification of 5-sulfoisophthalic acid by the use of an acetic acid wash on a crude cake

ActiveUS8404886B2Organic compound preparationCarboxylic compound separation/purificationAcetic acid5-sulfoisophthalic acid

A method for the purification of 5-sulfoisophthalic acid wherein via the application of an acetic acid wash while said crude cake of 5-sulfoisophthalic acid is filtered.

Owner:FUTUREFUEL CHEM

Method for increasing yield of 5-sulfoisophthalic acid for synthesis of ternary monomer

The invention provides a method for increasing yield of 5-sulfoisophthalic acid for synthesis of a ternary monomer. The method comprises the following steps: feeding, filling nitrogen, performing a first-stage heating reaction, performing a second-stage heating reaction, adding remaining oleum, performing a third-stage heating reaction, and performing a negative pressure reaction. The method has the beneficial effects that the reaction time is shortened, and the reaction temperature is lowered; compared with the existing production process, the maximum reaction temperature is lowered by 30 DEGC, and the sulfonation reaction cycle is shortened by 2 hours; the loss of sulfur trioxide is reduced, the cost is reduced, and the economic benefits of the ternary monomer product can be increased;the amount of oleum is reduced, which is 5% less than that in the current process dosage, and the amount of alkali used in the subsequent neutralization process can be reduced by more than 5%, at thesame time, the reaction time of the neutralization process is shortened, the amount of cooling water is reduced, and the energy saving effect is remarkable; and the yield of 5-sulfoisophthalic acid isincreased.

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI +1

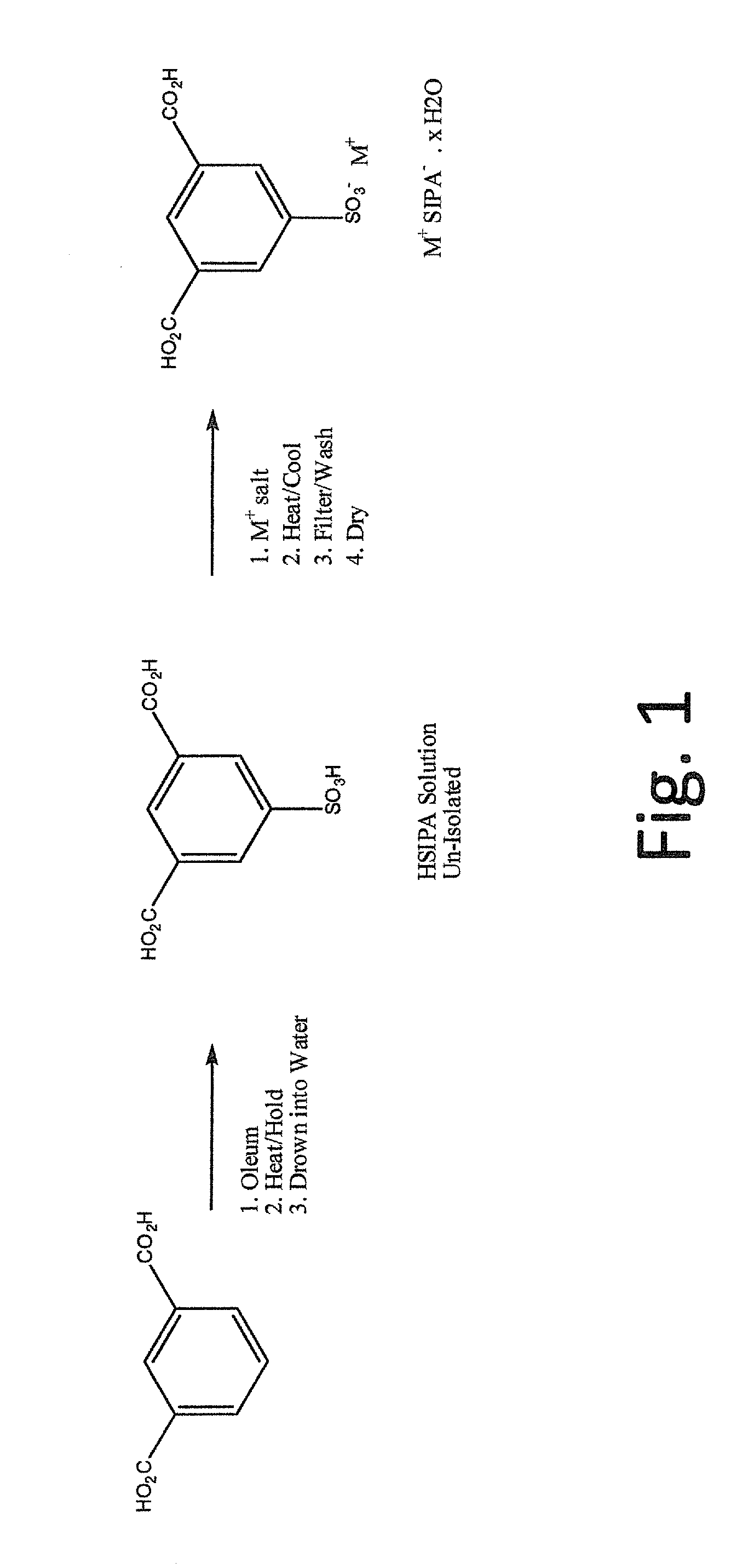

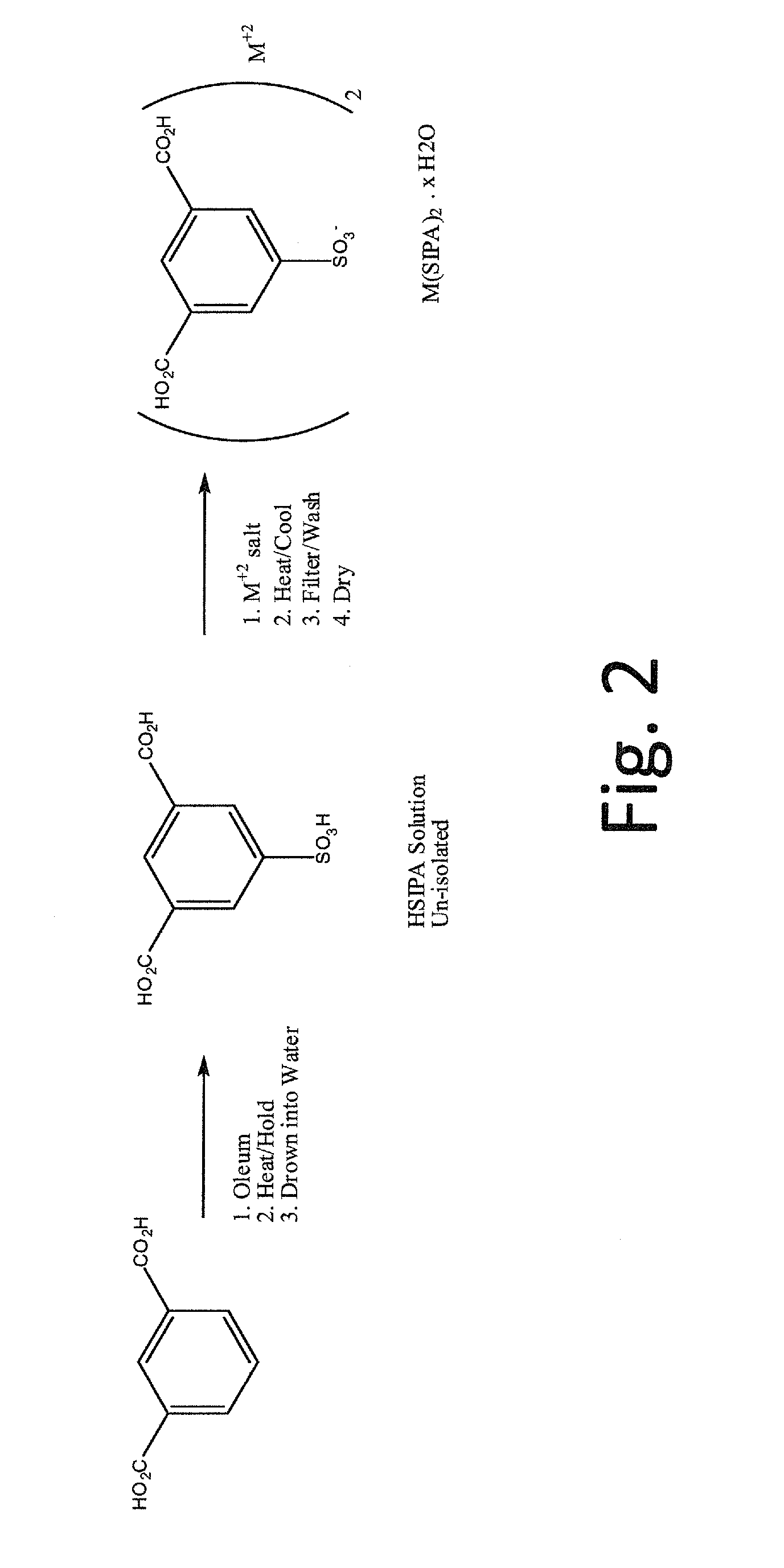

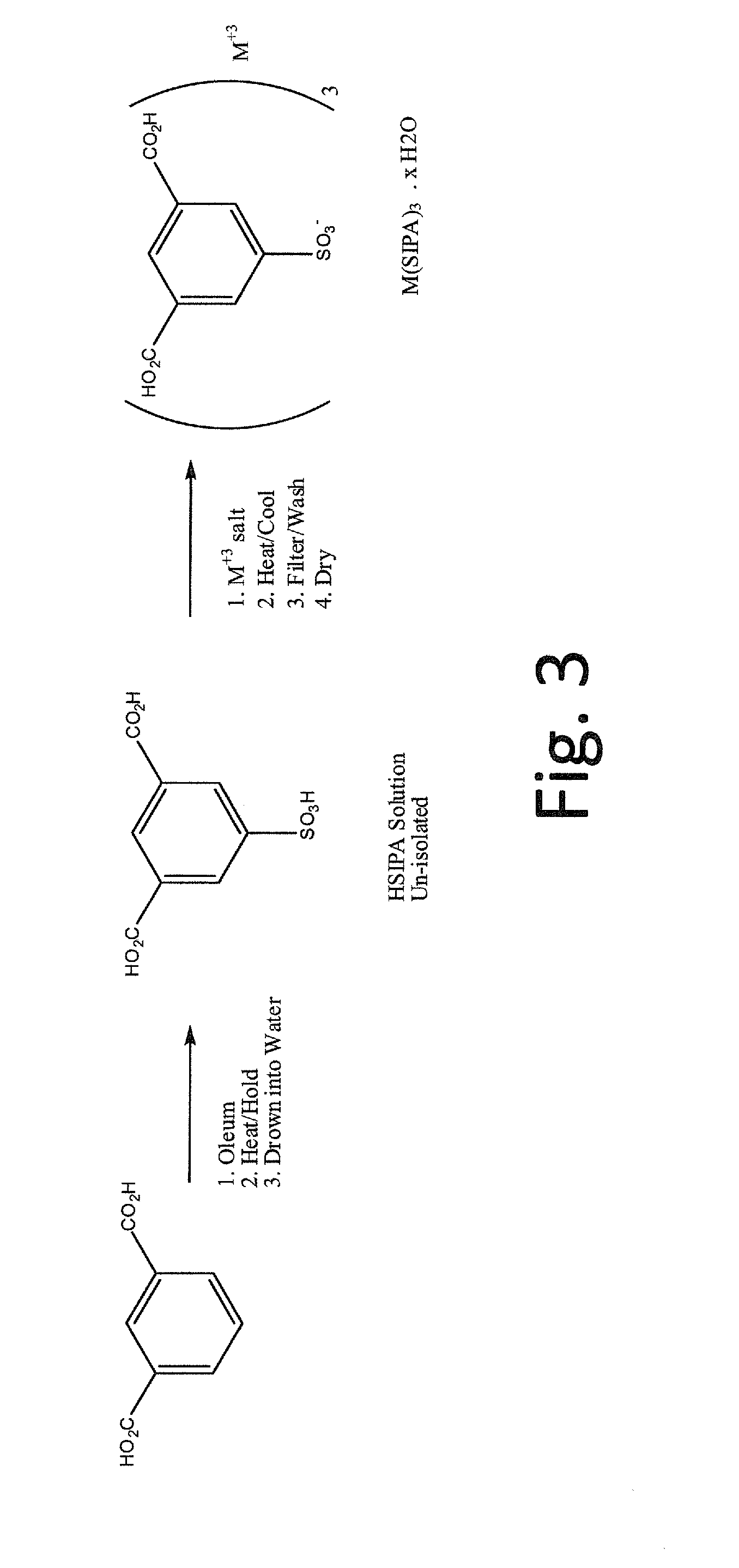

5-sulfoisophthalic acid salts and process for the preparation thereof

This invention relates to methods for the production of sodium, potassium, rubidium, cesium, magnesium, manganese, cobalt, nickel, aluminum, copper (II) and zinc salts of 5-sulfoisophthalic acid. In addition, this disclosure describes new compositions of matter, specifically, the rubidium, manganese, cobalt, nickel, and copper (II) salts of 5-sulfoisophthalic acid. The method utilizes the addition of metals salts to a crude sulfonation solution of 5-sulfoisophthalic acid.

Owner:FUTUREFUEL CHEM

Delustering color master batch based on polytrimethylene terephthalate

InactiveCN104861571AGood low gloss matte modification effectGood glossy matte modified effectPolyethylene terephthalatePolytrimethylene terephthalate

The invention discloses a delustering color master batch based on polytrimethylene terephthalate. The delustering color master batch comprises the following ingredients, by weight, 15%-40% of PTT, 20%-40% of titanium dioxide, 10%-30% of delustering agents, 5%-15% of light stabilizing agents, 5%-10% of fluorescent brighting agents, 8%-15% of 5-sulfoisophthalic acid monosodium salt, 3%-8% of compatilizer and 0.5%-3% of dispersants. The delustering agents are crosslinking butadiene-acrylonitrile polymers or crosslinking styrene-acrylonitrile polymers. The compatilizer is polymethyl methacrylate grafting maleic anhydride. The beneficial effects are that when the delustering color master batch is applied in PTT production, good low-gloss matte modification effects are achieved, the appearance is good, usage is convenient, the cost is low, the processability is good, the preparation technology is simple, and the delustering color master batch is helpful for cleaning production and raising the production efficiency.

Owner:QINGDAO XINZHAN PLASTIC

Articles Having Improved Gas Barrier Properties

The present invention relates to a sulfo-modified copolyester blend composition and polyglycolic acid. The blend of sulfo-modified copolyester and polyglycolic acid can be used to prepare containers with good transparency and high gas barrier properties. The preferred sulfo-modified copolyester composition comprises terephthalic acid, isophthalic acid and 5-sulfoisophthalic acid. A method of preparing a blend of sulfo-modified copolyester and polyglycolic acid is disclosed, as well as master batch processes. The present invention also relates to a method of making a container wherein the sulfo-modified copolyester is blended with the polyglycolic acid at an injection molding machine used to make preforms, which are then blown into bottles.

Owner:TREVIRA HLDG GMBH

5-sulfoisophthalic acid salts and process for the preparation thereof

ActiveUS8809565B2Group 1/11 element organic compoundsSulfonic acids salts preparationRubidiumPotassium

This invention relates to methods for the production of sodium, potassium, rubidium, cesium, magnesium, manganese, cobalt, nickel, aluminum, copper (II) and zinc salts of 5-sulfoisophthalic acid. In addition, this disclosure describes new compositions of matter, specifically, the rubidium, manganese, cobalt, nickel, and copper (II) salts of 5-sulfoisophthalic acid. The method utilizes the addition of metals salts to a crude sulfonation solution of 5-sulfoisophthalic acid.

Owner:FUTUREFUEL CHEM

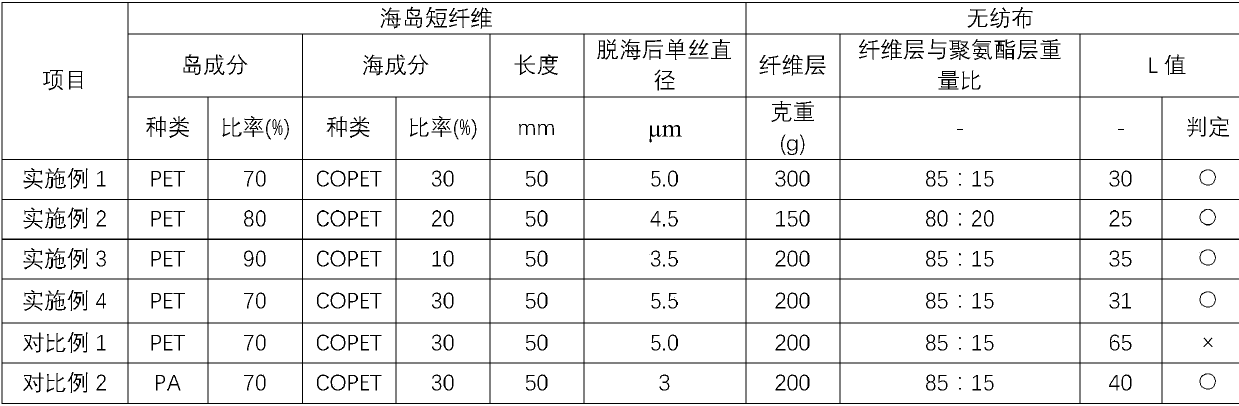

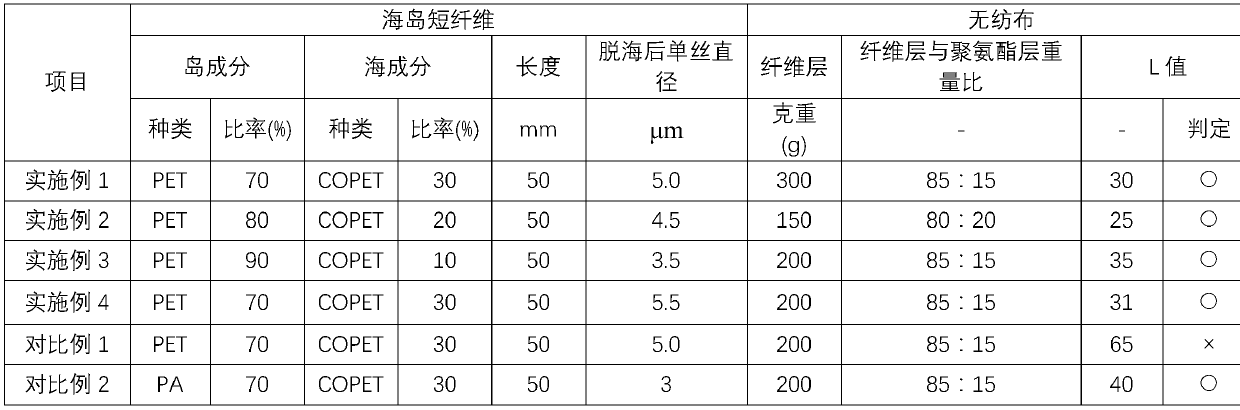

Preparation method of cationic fiber dyeable artificial leather

ActiveCN107841881AExcellent cationic dyeabilityColorfulFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterElastomer

The invention relates to a preparation method of cationic fiber dyeable artificial leather. The preparation method comprises the following steps: (a) transferring a 2-hydroxyethyl methyl terephthalateoligomer into a polyreactor, adding a polycondensation catalyst, 5-sulfoisophthalic acid monosodium salt, polyethylene glycol and a surfactant for reacting to obtain modified polyester; (b) taking the modified polyester as an island component, taking alkali-soluble polyethylene terephthalate as a sea component, and preparing figured island composite staple fibers by using double component spinning equipment; (c) lapping the figured island type island composite staple fibers and forming a non-woven fabric by carrying out cohesion processing through a needling machine; (d) carrying out polymerelastomer padding, alkali treatment, sanding, dyeing and finishing on the non-woven fabric, thus obtaining a finished product. The preparation method of the cationic fiber dyeable artificial leather has the advantages that the initial pressure of melt spinning can be reduced and the rise of the filter pressure is inhibited; the prepared fibers have excellent cationic dyeability and the artificialleather has bright color.

Owner:江苏尚科聚合新材料有限公司

Use of an acetic acid/water solvent mixture for the preparation of low-sulfate 5-sulfoisophthalic acid, mono-lithium salt from 5-ulfoisophthalic acid

There is disclosed a process for making a mono-lithium salt of 5-sulfoisophthalic acid (LiSIPA) having less than 200 ppm sulfate. The process uses a reaction mixture of acetic acid, water, a lithium cation producing compound, and 5-sulfoisophthalic acid. The reaction mixture is heated to reflux, cooled, filtered and washed to obtain a high quality LiSIPA having less than 200 ppm sulfate. Also disclosed is a high quality mono-lithium salt of 5-sulfoisophthalic acid having less than 200 ppm sulfate.

Owner:FUTUREFUEL CHEM

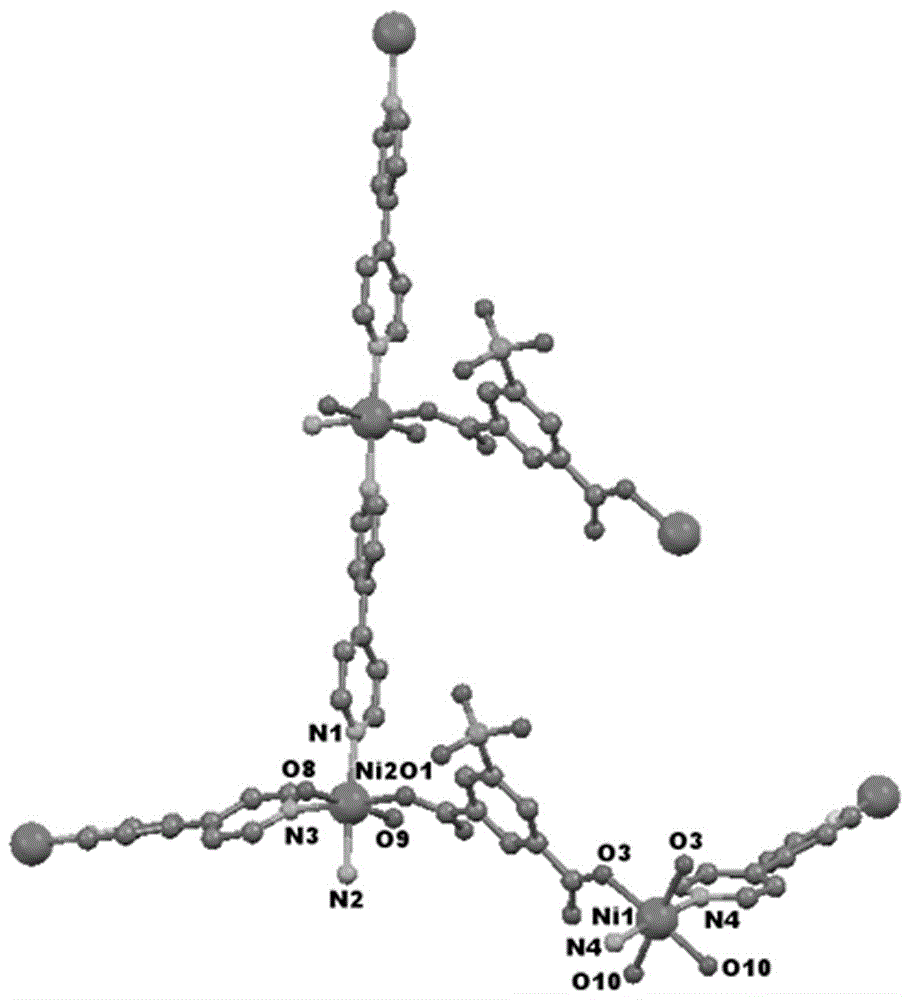

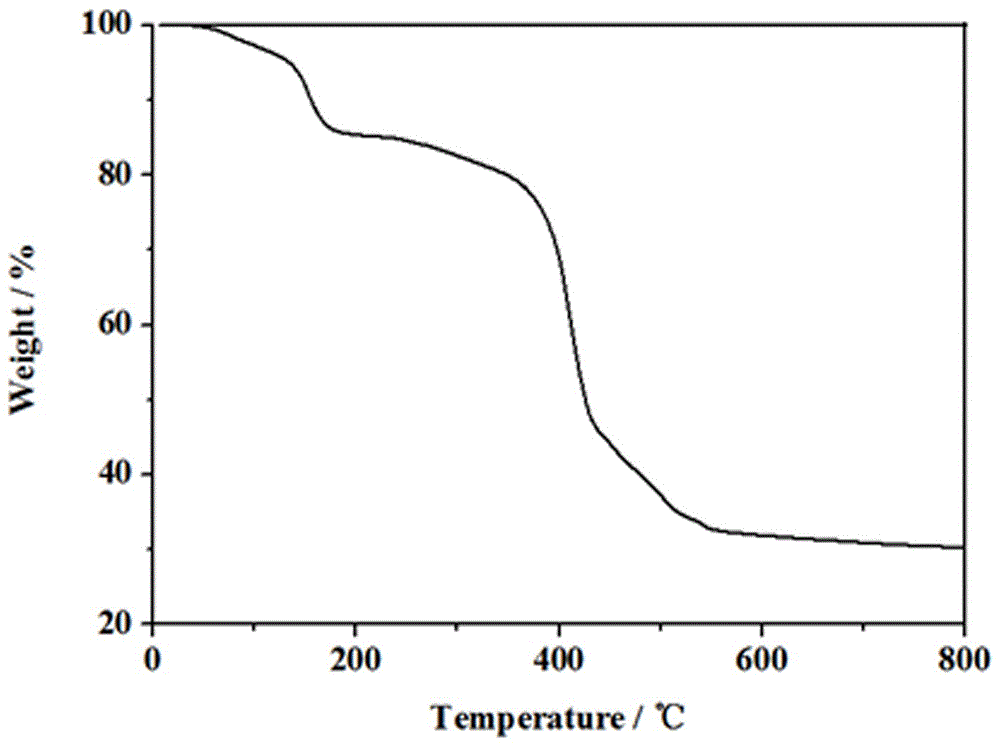

Preparation method of second-order nonlinear optical crystal material

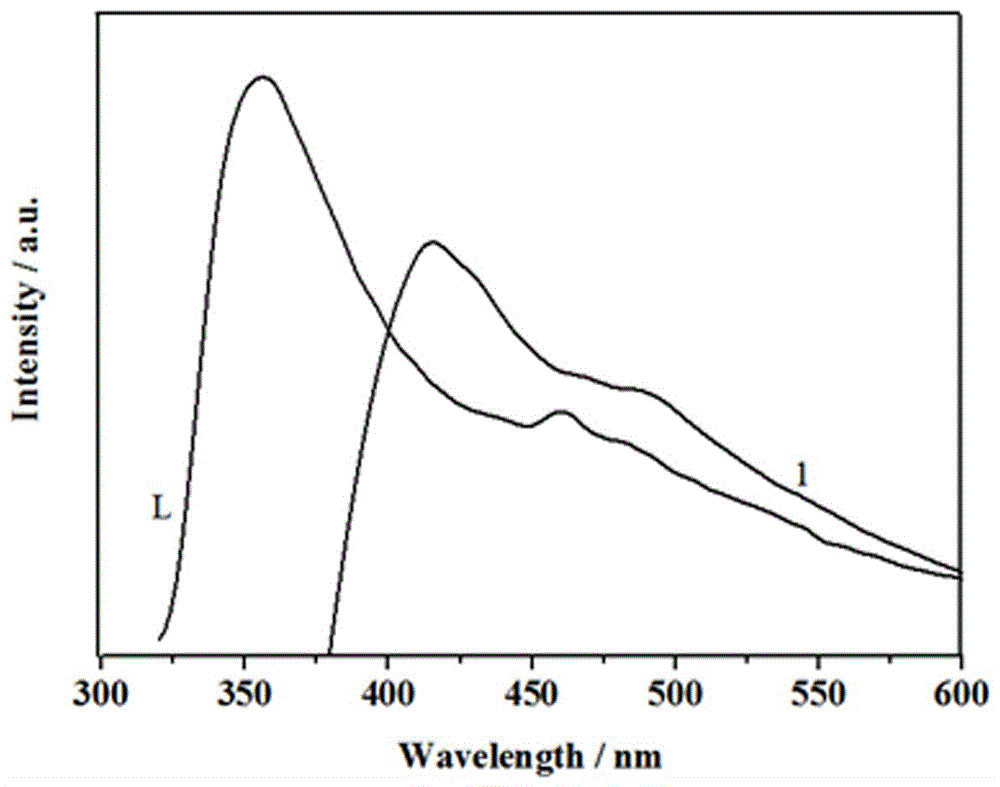

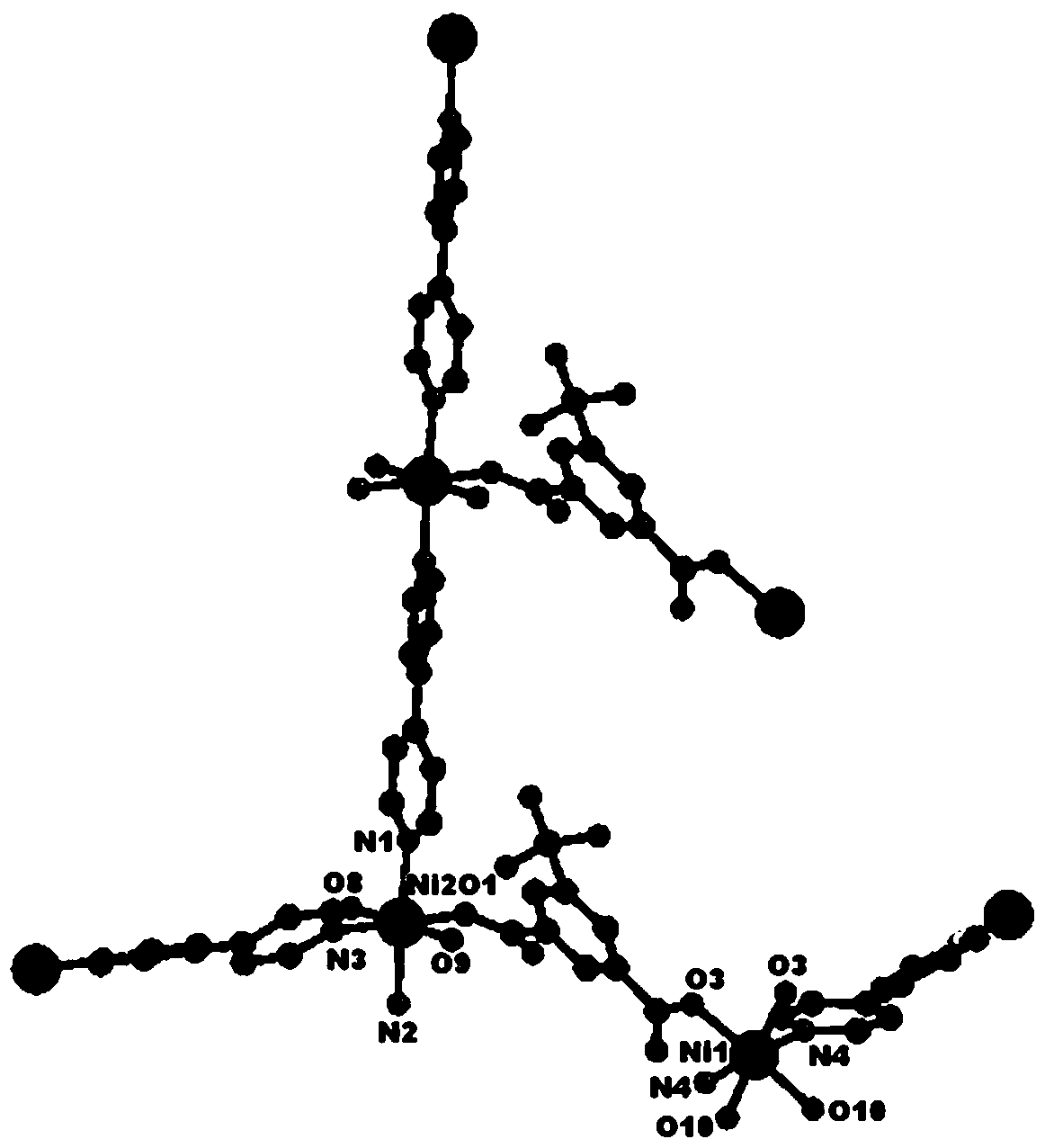

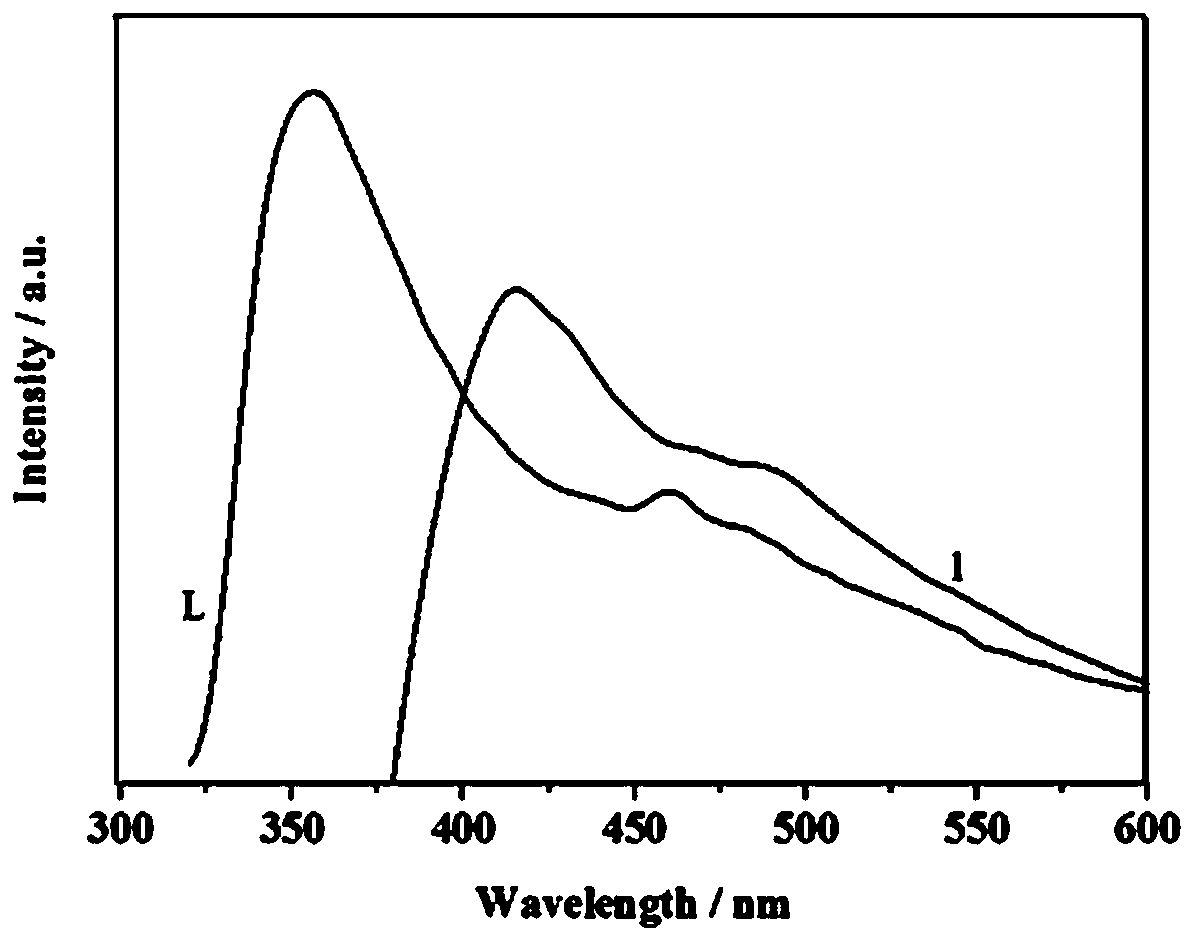

ActiveCN106192011AHas second-order nonlinear optical propertiesFluorescentPolycrystalline material growthFrom normal temperature solutionsNonlinear optical crystalAntiferromagnetic coupling

The invention relates to a preparation method of a second-order nonlinear optical crystal material. The preparation method comprises the following steps: NiSO4.6H2O, 4,4'-bipyridine and 5-sulfoisophthalic acid monosodium salt are dissolved in water; the materials are stirred for 2 h, packaged in a 25-mL reaction kettle and heated at 120 DEG C for 36 h; the materials are cooled to the room temperature until blue crystals are generated. An MOF (metal-organic framework) compound in the method is different from other second-order nonlinear optical MOF compounds, and is the MOF compound adopting an acentric structure and obtained by synthesizing ligands with a symmetrical structure and metal ions. The second-order nonlinear optical property of the MOF compound is 0.8 times that of urea, and the MOF compound further has phase matching property, fluorescence emission property and magnetic property. The fluorescence emission peak of the compound is at 416 nm, and red shift occurs compared with the ligands. Lone pair electrons are converted into antiferromagnetic coupling at 28 K.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

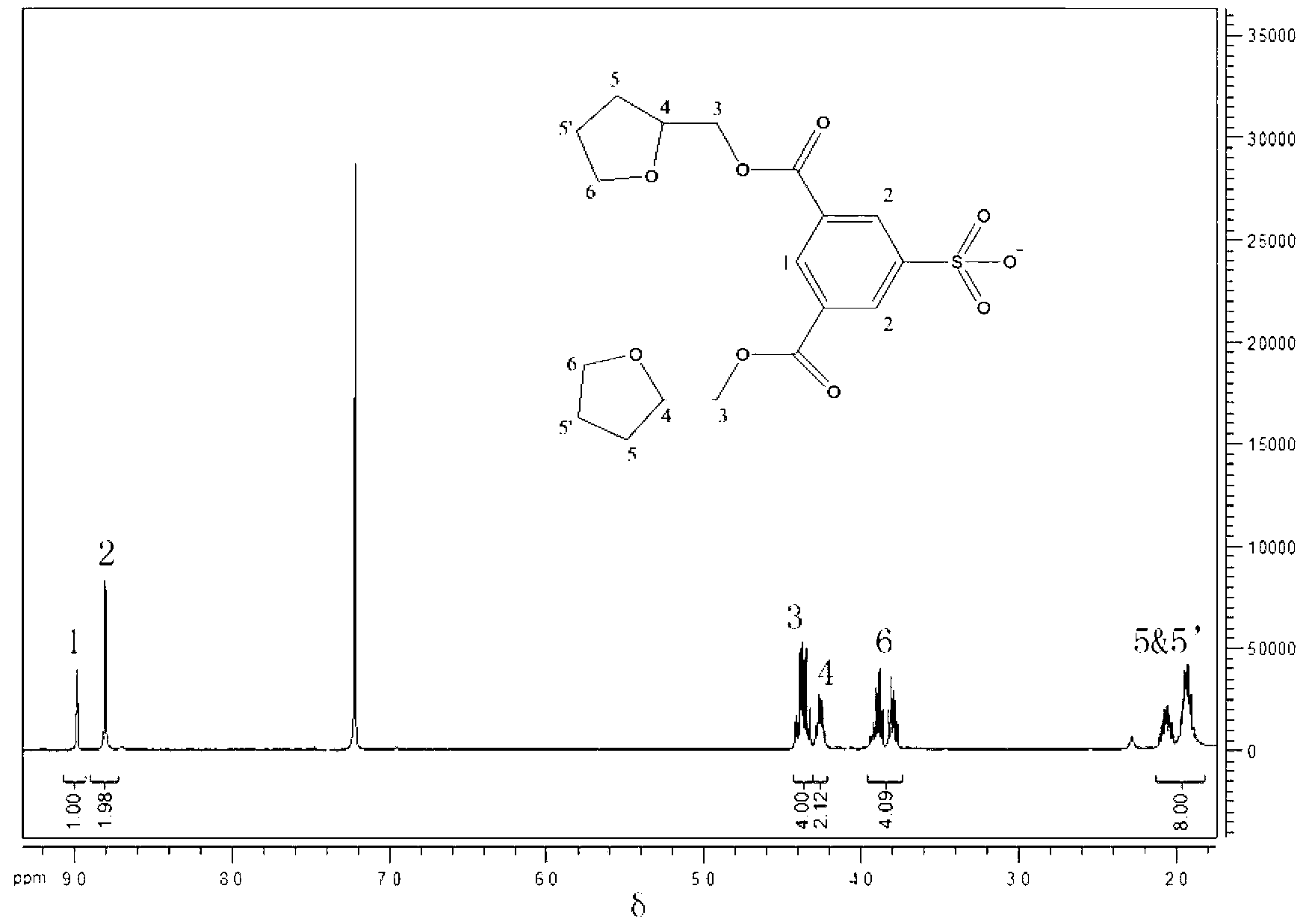

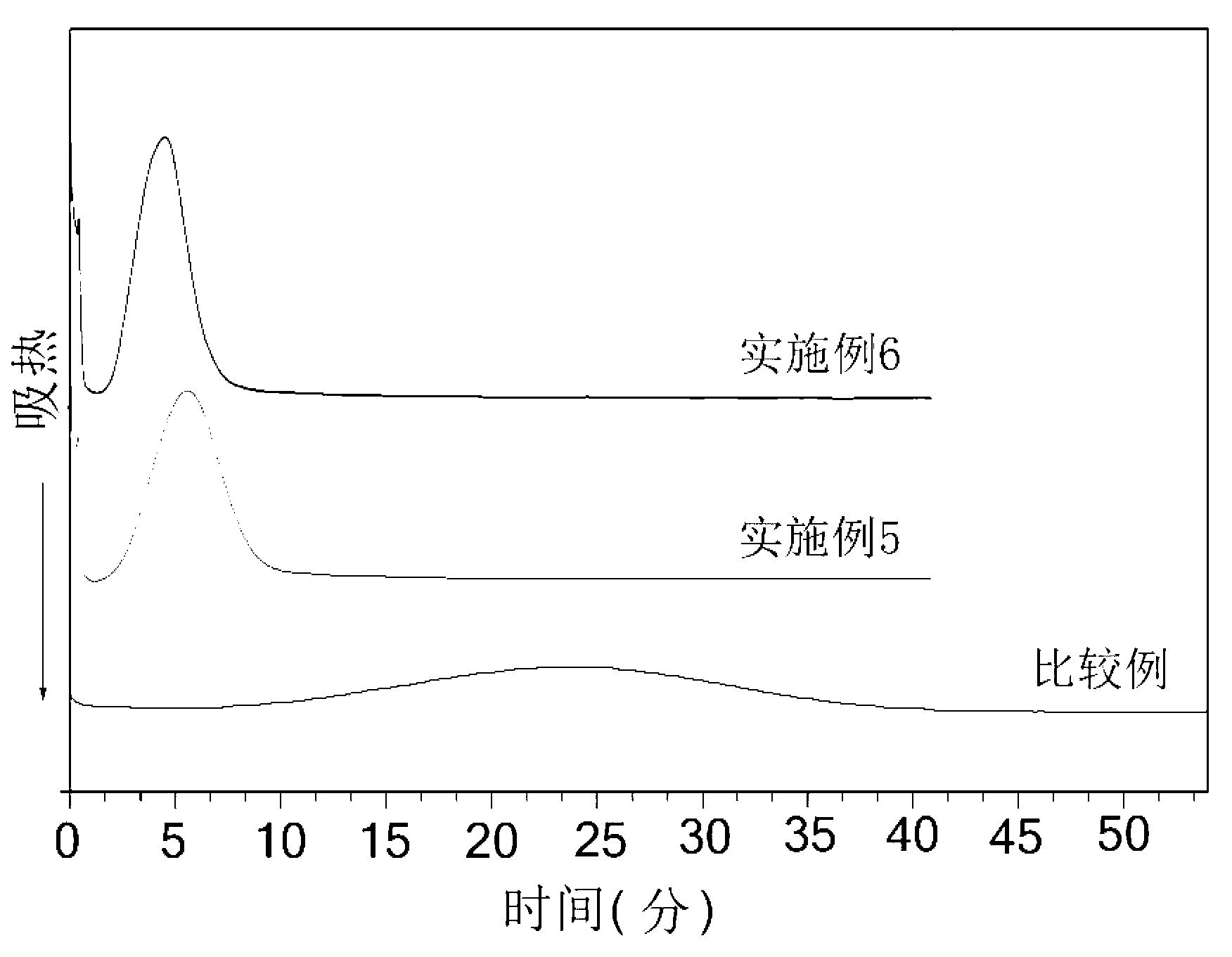

Ditetrahydrofurfuryl isophthalate-5-sulfonic acid and salt, preparation method and application thereof, and polylactic resin

ActiveCN103224478AIncrease the rate of crystallizationHigh crystallinityOrganic chemistryChemical recyclingSulfonateCrystallinity

The invention provides ditetrahydrofurfuryl isophthalate-5-sulfonic acid, ditetrahydrofurfuryl isophthalate-5-sulfonate, a preparation method and an application thereof, and polylactic resin. According to the invention, isophthalic acid is adopted as a raw material, and a sulfonation reaction is carried out, such that 5-sulfoisophthalic acid is synthesized; an acylation reaction is carried out, and an alcoholysis reaction is carried out with tetrahydrofurfuryl alcohol, such that ditetrahydrofurfuryl isophthalate-5-sulfonic acid is obtained. The obtained ditetrahydrofurfuryl isophthalate-5-sulfonic acid is subjected to a reaction with one of metal, metal oxide, metal hydroxide, and metal salt, such that ditetrahydrofurfuryl isophthalate-5-sulfonate is obtained. The obtained ditetrahydrofurfuryl isophthalate-5-sulfonic acid or salt thereof can be used in a nucleating agent of polylactic resin. Experiment results show that polylactic resin crystallization rate and crystallinity are substantially improved.

Owner:吉林锦玉自动化设备科技有限公司

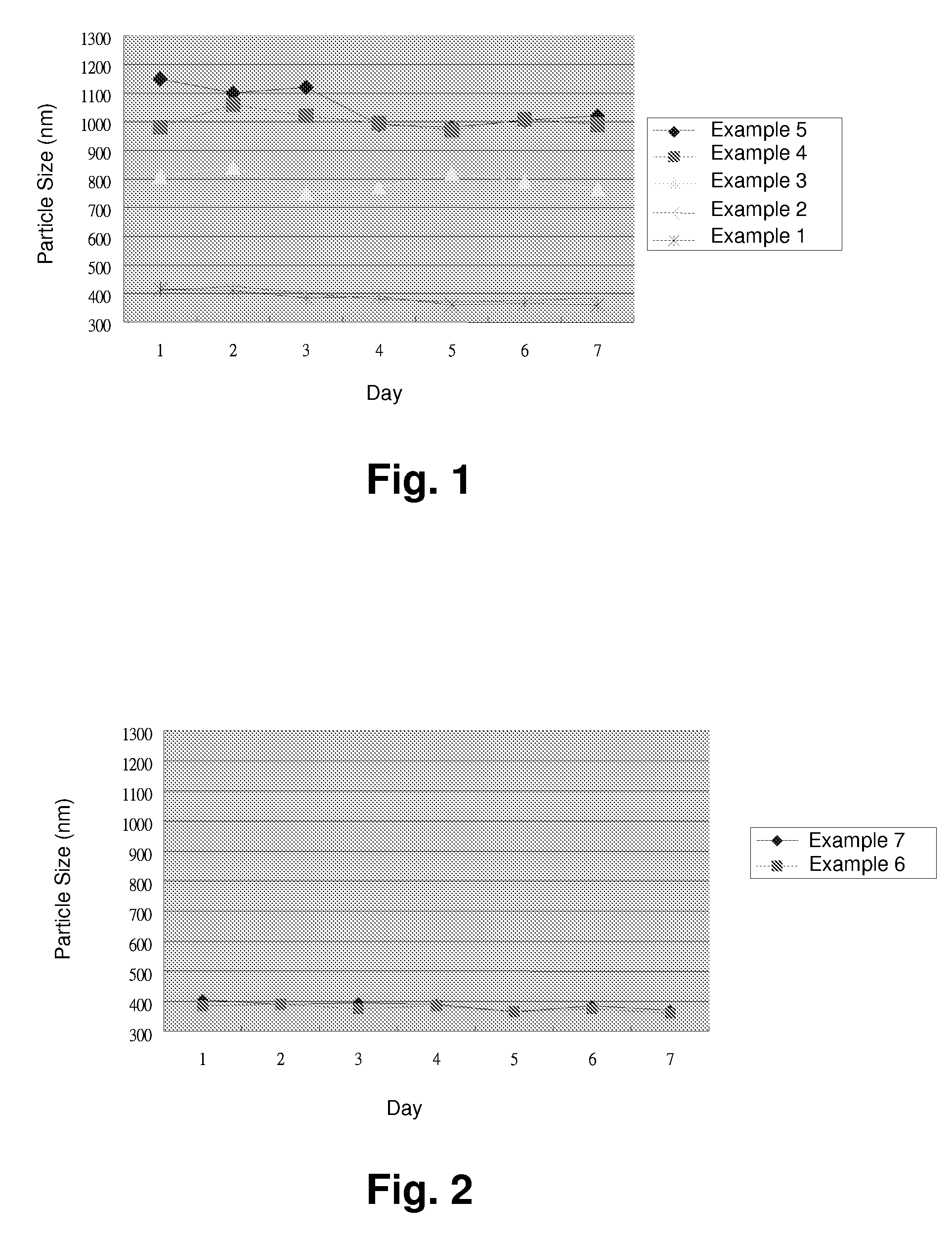

Sulfopolyesters having improved clarity in water-dispersible formulations and products made therefrom

A sulfopolyester comprising repeat residue units from the reaction product dimethyl-5-sodiosulfoisophthalate, isophthalic acid, 1,4-cyclohexanedimethanol and diethylene glycol, has at least one property selected from: a) an acidity of greater than 0.030 measured as milliequivalents H+ / gram of sulfopolyester; b) a titanium concentration, measured as metal, of less than about 27 ppm, based on the amount of sulfopolyester; or c) an acidity of greater than 0.010 measured as milliequivalents H+ / gram of sulfopolyester, a pH of less than 6.0 and a concentration of a base compound of less than 0.0335 moles / kg of sulfopolyester.A method for making the water-dispersible or water-dissipative sulfopolyester of the present invention is disclosed.Aqueous dispersion having from 0.001 to about 35 weight % of the sulfopolyester of the present invention is also disclosed.The sulfopolyester is useful in making hair spray formulations suitable for pump or aerosol spray applicators.

Owner:EASTMAN CHEM CO

Metal salts of a dialkyl ester of 5-sulfoisophthalic acid and method of preparing same

ActiveUS9193677B2Group 1/11 element organic compoundsOrganic compound preparationMedicinal chemistryMetal salts

The claimed invention meets these and other objects by providing a method of preparing a metal salt of a dialkyl ester of 5-sulfoisophthalic acid. Broadly speaking, the method provides for the contacting of a dialkyl ester of 5-sulfoisophthalic acid with a metal cation in a buffered reaction mixture to form the metal salt of the dialkyl ester. The reaction mixture is buffered, at least in part, by the acetate of the metal cation. The method according to invention also encompasses various methods of preparing the dialkyl ester of 5-sulfoisophthalic acid.

Owner:FUTUREFUEL CHEM

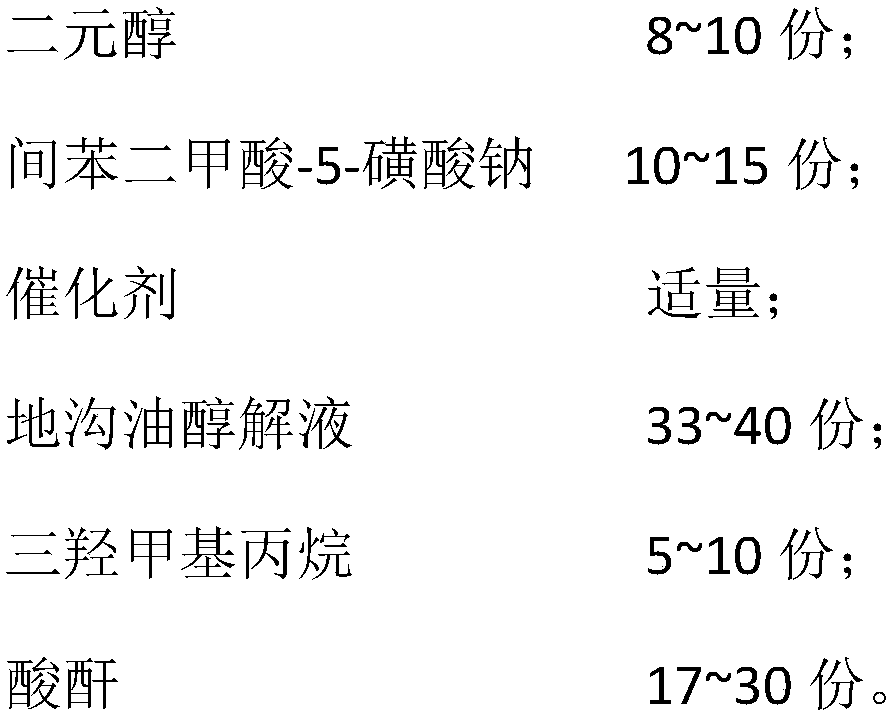

Method for preparing nearly-zero VOC (volatile organic compound) alkyd resin from gutter oil and alkyd resin

The invention discloses a method for preparing nearly-zero VOC (volatile organic compound) alkyd resin from gutter oil and alkyd resin. The method comprises the following steps: S1, evenly mixing 8-10parts by mass of dihydric alcohol, 10-15 parts by mass of 5-sulfoisophthalic acid monosodium salt and an appropriate quantity of a catalyst; S2, heating the mixture in step S1, then adding 33-40 parts by mass of a gutter oil alcoholysis solution, 5-10 parts by mass of trimethylolpropane and 15-30 parts by mass of anhydride, performing heating for reaction for a period of time, and cooling a product for later use when the viscosity of the product reaches a predetermined value. 100% solid alkyd resin can be obtained, the use of volatile organic solvents is avoided, nearly-zero VOC alkyd resin is obtained, and environment friendliness is excellent. Alkyd resin is prepared from the gutter oil, the production cost of alkyd resin is reduced, and the gutter oil is recycled.

Owner:绍兴长木新材料科技有限公司

Use of an acetic acid wash to prepare low-sulfate 5-sulfoisophthalic acid, mono-lithium salt

There is disclosed a process for making a mono-lithium salt of 5-sulfoisophthalic acid (LiSIPA) having less than 500 ppm sulfate. The process uses a reaction mixture of water, a lithium cation producing compound, and 5-sulfoisophthalic acid. The reaction mixture is heated to reflux, cooled, filtered and washed with acetic acid to obtain a high quality LiSIPA having less than 500 ppm sulfate. Also disclosed is a high quality, non-purified reaction product containing a mono-lithium salt of 5-sulfoisophthalic acid and having less than 500 ppm sulfate.

Owner:FUTUREFUEL CHEM

Water-based polyester resin for amino baking coating and synthesis device of water-based polyester resin

The invention discloses water-based polyester resin for an amino baking coating. The water-based polyester resin is prepared from the following raw materials in parts by weight: neopentyl glycol, diethylene glycol, trimethylolpropane, glycidyl tertiary carbonate, 1,4-cyclohexane dicarboxylic acid, phthalic anhydride, hexahydrophthalic anhydride, isophthalic acid, 5-sulfoisophthalic acid monosodiumsalt, 1,4-butanediol-2-sodium sulfonate, xylene, a catalyst, a neutralizer, a cosolvent, a solvent and deionized water. The invention further discloses a synthesis device for the water-based polyester resin for the amino baking coating. The monomer of the water-based polyester resin for the amino baking coating prepared by the preparation method has good performance, and performance of the aminobaking coating prepared from the water-based polyester resin provided by the invention is superior to performance of amino baking coatings prepared from common water-based polyester resin in the market. According to the synthesis method for the water-based polyester resin for the amino baking coating, heating rods and a spiral heating pipe can be simultaneously used for heating from inside and outside, heating efficiency is improved, and production efficiency of the whole water-based polyester resin is improved.

Owner:吕悦

Sulfonated aliphatic-aromatic copolyesters and shaped articles produced therefrom

Sulfonated aliphatic-aromatic copolyesters are provided. The copolyester is produced from a mixture of aromatic dicarboxylic acids, aliphatic dicarboxylic acids, ethylene glycol, other diols, and components containing alkali metal or alkaline earth metal sulfo groups such as metal 5-sulfo Phthalic acid derivatives. The copolyesters have lower sulfonation than known sulfonated polyesters and provide advantageous thermal properties for some end uses. The sulfonated aliphatic-aromatic copolyesters are useful for forming coatings or films on various substrates, and for packaging. Some compositions comprising the sulfonated aliphatic-aromatic copolyesters are biodegradable, as are some sulfonated aromatic-aromatic copolyesters.

Owner:EI DU PONT DE NEMOURS & CO

A kind of preparation method of second-order nonlinear optical crystal material

ActiveCN106192011BHas second-order nonlinear optical propertiesImprove thermal stabilityPolycrystalline material growthFrom normal temperature solutionsNonlinear optical crystalAntiferromagnetic coupling

The invention relates to a preparation method of a second-order nonlinear optical crystal material. The preparation method comprises the following steps: NiSO4.6H2O, 4,4'-bipyridine and 5-sulfoisophthalic acid monosodium salt are dissolved in water; the materials are stirred for 2 h, packaged in a 25-mL reaction kettle and heated at 120 DEG C for 36 h; the materials are cooled to the room temperature until blue crystals are generated. An MOF (metal-organic framework) compound in the method is different from other second-order nonlinear optical MOF compounds, and is the MOF compound adopting an acentric structure and obtained by synthesizing ligands with a symmetrical structure and metal ions. The second-order nonlinear optical property of the MOF compound is 0.8 times that of urea, and the MOF compound further has phase matching property, fluorescence emission property and magnetic property. The fluorescence emission peak of the compound is at 416 nm, and red shift occurs compared with the ligands. Lone pair electrons are converted into antiferromagnetic coupling at 28 K.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Water-soluble polyester suitable for polyester filament-fabric soft coating and preparation method of water-soluble polyester

InactiveCN109422869AUse interface cleanProduction environment and environmental protectionTextiles and paperSynthetic monomerRaw material

The invention discloses a water-soluble polyester suitable for polyester filament-fabric soft coating. The water-soluble polyester is characterized by consisting of the following raw materials in percentage by mass: 40-45% of aliphatic binary acid, 10% of aromatic binary acid, 15% of 5-sulfoisophthalic acid monosodium salt; 5% of tri-functional binary acid and 25% of dihydric alcohol. Compared with the prior art, the water-soluble polyester has the advantages that the water-soluble polyester has extremely high adhesive force with dacron, the water resistance can meet use requirements, synthetic monomers are wide, and the hand feeling is easy to control. The water-soluble polyester provided by the invention can be used for replacing solvent-based polyurethane filament-fabric soft coatings which is used in a large scale at present. According to statistics, China is the biggest spinning power in the world, and the required amount of polyester filament-fabric soft coating glue is one hundred thousand tons to one hundred and fifty thousand tons. Therefore, popularization of the water-soluble polyester provided by the invention has a very considerable economic benefit and profound environmental protection significance.

Owner:SICHUAN HANZHOU CHEM TECH

Use of copolymerizable sulfonate salts to promote char formation in polyesters and copolyesters

comonomers have been shown to improve flammability characteristics of polyesters and copolyesters. Incorporation of sulfonate containing monomers such as 5-sodiosulfoisophthalic acid significantly decreases the heat release capacity of copolyesters. These comonomers also increase the formation of char as measured by thermogravimetric analysis. The decrease in the heat release capacity and increase in char formation indicates that these compositions may have reduced flammability and thus are useful for producing products have reduced flammability. In particular, it has also been demonstrated that incorporation of as little as 0.1 mole % 5-sodiosulfoisophthalic acid to a polyester or copolyester significantly increases the char formation independent of composition.

Owner:EASTMAN CHEM CO

Partially ester-exchanged SIPM and process therewith

A process for producing a partially ester-exchanged SIPM such as an alkali metal bis(2-hydroxyethyl) 5-sulfoisophthalate produced from an alkali metal dimethyl 5-sulfoisophthalate in an alcohol is disclosed. The partially ester-exchanged SIPM in an alcohol can be used to copolymerize with oligomer of terephthalic acid or dimethyl terephthalate and an alcohol. Also disclosed is a process for controlling the color of a dyeable polyester using a phosphorous compound.

Owner:INVISTA TECHNOLOG IES S A R L

A kind of preparation method of cationic fiber dyeable artificial leather

ActiveCN107841881BExcellent cationic dyeabilityColorfulFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterElastomer

The invention relates to a preparation method of cationic fiber dyeable artificial leather. The preparation method comprises the following steps: (a) transferring a 2-hydroxyethyl methyl terephthalateoligomer into a polyreactor, adding a polycondensation catalyst, 5-sulfoisophthalic acid monosodium salt, polyethylene glycol and a surfactant for reacting to obtain modified polyester; (b) taking the modified polyester as an island component, taking alkali-soluble polyethylene terephthalate as a sea component, and preparing figured island composite staple fibers by using double component spinning equipment; (c) lapping the figured island type island composite staple fibers and forming a non-woven fabric by carrying out cohesion processing through a needling machine; (d) carrying out polymerelastomer padding, alkali treatment, sanding, dyeing and finishing on the non-woven fabric, thus obtaining a finished product. The preparation method of the cationic fiber dyeable artificial leather has the advantages that the initial pressure of melt spinning can be reduced and the rise of the filter pressure is inhibited; the prepared fibers have excellent cationic dyeability and the artificialleather has bright color.

Owner:江苏尚科聚合新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com