Solid acid catalyst for preparation of sodium isophthalate diethylene glycol 5-sulfonate via direct esterification and preparation and application of solid acid catalyst

A technology of diethylene glycol isophthalate and solid acid catalyst is applied in the directions of catalyst activation/preparation, physical/chemical process catalyst, sulfonate preparation, etc., and can solve the problems of inflammability, toxicity, explosion danger and the like, achieve good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

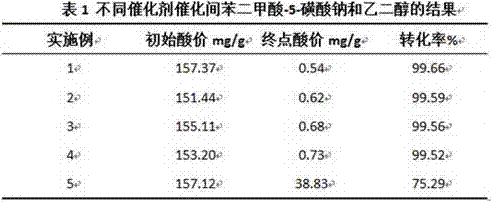

Examples

Embodiment 1

[0030] Dissolve 0.17g of cetyltrimethylammonium bromide in 250.00g of water, add 10.15g of montmorillonite, stir at 70°C for 18h, cool to room temperature, wash and filter, and dry at 80°C for 12h to obtain organically modified montmorillonite Soil (organic soil); preparation of suspension A: add 1.25g of tetrabutyl titanate and 10.00g of organic soil to 50.00g of ethanol, and stir evenly; preparation solution B: mix 0.05g of concentrated hydrochloric acid, 5.25g of water, Mix 50g of ethanol evenly; drop solution B into suspension A at a constant speed, and then stir the mixture at 20°C for 12 hours, then at 70°C for 12 hours; cool the mixed suspension of A and B to room temperature, wash and filter, The filter cake was dried at 110°C for 6h, and calcined at 500°C for 4h to obtain solid acid catalyst a.

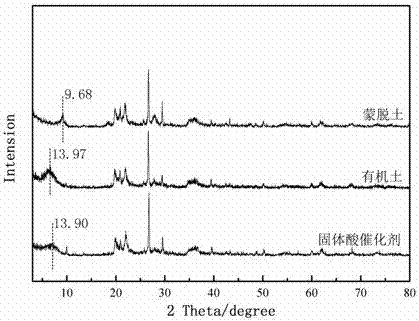

[0031] figure 1 In the preparation process of the obtained solid acid catalyst, the XRD spectrum of montmorillonite, organoclay, and catalyst; after organic modification and...

Embodiment 2

[0034] Dissolve 0.26g of dodecyltrimethylammonium bromide in 500.00g of water, add 13.55g of montmorillonite, stir at 80°C for 10h, cool to room temperature, wash and filter, and dry at 80°C for 12h to obtain organically modified montmorillonite soil (organic soil). Preparation of suspension A: Add 1.66g of tetrabutyl titanate and 10.00g of organic soil to 100.00g of ethanol, and stir evenly; preparation of solution B: Mix 0.12g of concentrated hydrochloric acid, 7.05g of deionized water, and 20.00g of anhydrous Ethanol mixed well. The solution B was dropped into the suspension A at a constant speed, and the mixed solution was stirred at 45°C for 6h and at 20°C for 12h after the dripping was completed. The mixed suspension of A and B was cooled to room temperature, washed and filtered, the filter cake was dried at 80°C for 12h, and calcined at 700°C for 2h to obtain solid acid catalyst b.

[0035] Add 80.25g of isophthalic acid-5-sodium sulfonate, 400.50g of ethylene glycol,...

Embodiment 3

[0037]Dissolve 0.18g of dodecyldimethylbenzyl ammonium chloride in 300.00g of water, add 10.00g of montmorillonite, stir at 50°C for 24h, cool to room temperature, wash and filter, and dry at 80°C for 12h to obtain organically modified Montmorillonite (organic soil). Preparation of suspension A: Add 1.28g of isopropyl titanate and 10.00g of organic soil to 80.00g of ethanol, and stir evenly; preparation of solution B: Mix 0.06g of concentrated hydrochloric acid, 4.08g of deionized water, and 40.00g of anhydrous Ethanol mixed well. Add solution B to suspension A at a constant speed, and then mix the solution at 50°C for 4 hours and at 30°C for 8 hours. The mixed suspension of A and B was cooled to room temperature, washed and filtered, the filter cake was dried at 120°C for 6h, and calcined at 600°C for 3h to obtain solid acid catalyst c.

[0038] Add 80.25g of isophthalic acid-5-sodium sulfonate, 160.09g of ethylene glycol, 0.82g of sodium acetate, and 2.18g of catalyst c in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com