Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "With water reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

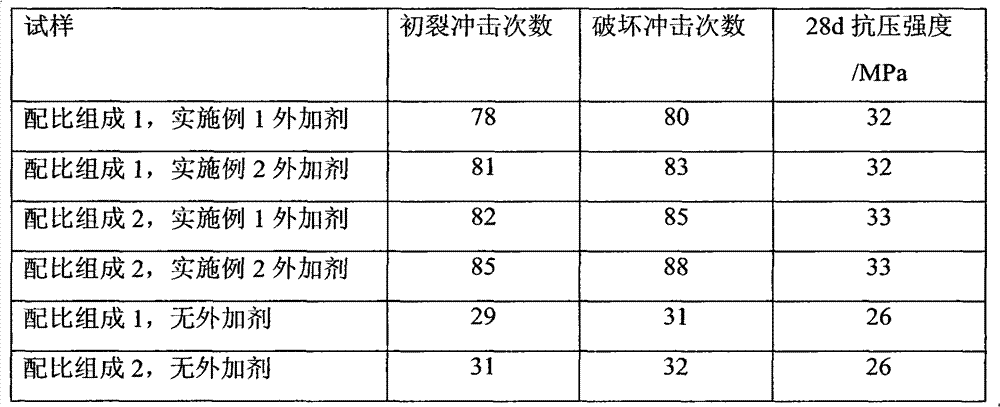

Concrete complex additive

The invention provides a concrete complex additive which comprises the following components by weight percent: 17.5-58.0% of efficient water reducing agent, 0.5-5.5% of organosilicon waterproofing agent, 0.2-2.5% of organosilicon reinforcing agent, 3.5-25% of polyacrylamide, 1.2-2.8% of triethanolamine, 3.2-6.3% of sodium nitrite, 0.3-1.2% of glycol, 0.6-1.3% of glycerol, 2.8-5.5% of sodium gluconate and the balance of water. The impact resistance, crocking resistance, impermeability and waterproofness of the concrete material can be obviously improved by using the complex additive provided by the application in the preparation process of the concrete, thus the concrete complex additives is especially suitable for the requirement on high-performance concrete for construction of airfield runways or highway bridges.

Owner:JIANGSU FENGTAI TOOLS

Preparation method of synthetic type polycarboxylic acid water reducer

The invention discloses a preparation method of a synthetic type polycarboxylic acid water reducer. The synthetic type polycarboxylic acid water reducer has a solid content of 40-50%, and is prepared from the following raw materials in parts by weight: 100 parts of unsaturated polyoxyethylene ether, 7-15 parts of unsaturated acid, 4-10 parts of unsaturated ester, 1-3 parts of an amide derivative, 0.5-2 parts of an oxidant, 0.2-1.2 parts of a chain transfer agent, 0.3-2 parts of a reducing agent, 0.1-1 part of a crosslinking agent, 0.01-0.1 part of ferrous sulfate heptahydrate, 5-10 parts of a commercially available mud-resistant auxiliary agent, 90-130 parts of deionized water and an appropriate amount of liquid caustic soda. The preparation method disclosed by the invention adopts a normal-temperature oxidation-reduction initiating system to synthesize the synthetic type polycarboxylic acid water reducer which not only has functions of water reduction and slump loss resistance, but also has functions of mud resistance and early strength, heating is not needed for reaction, the energy consumption is reduced, and the production cost is greatly reduced.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

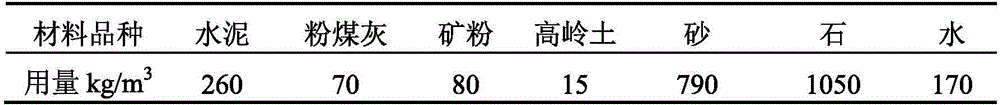

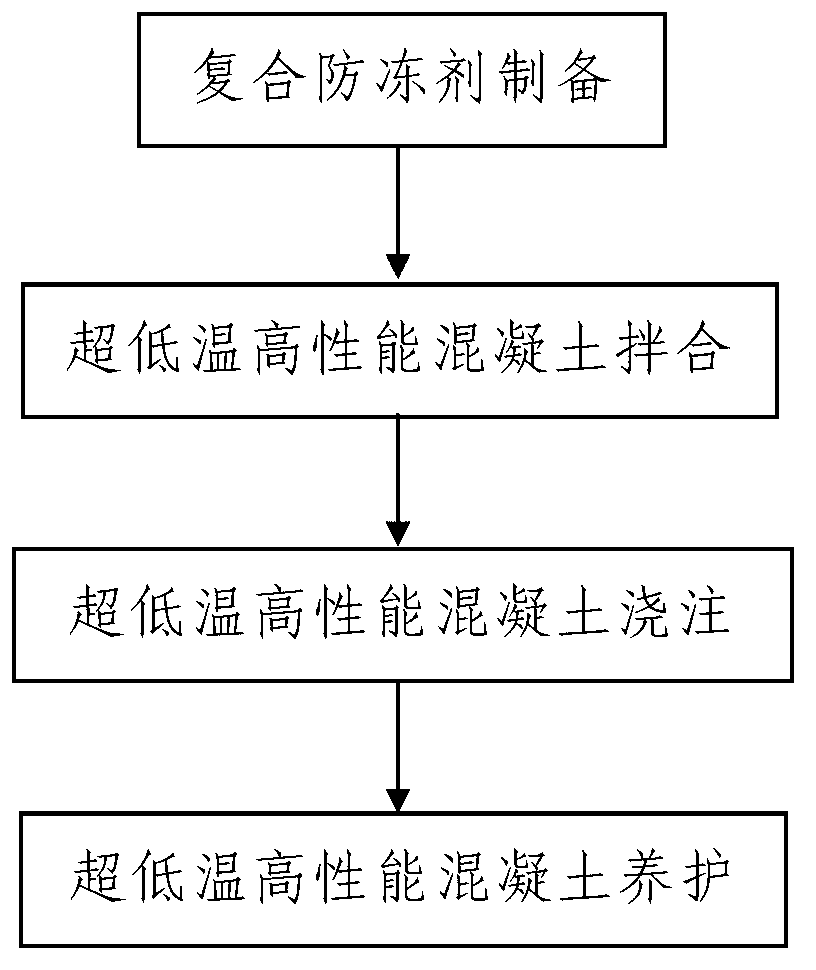

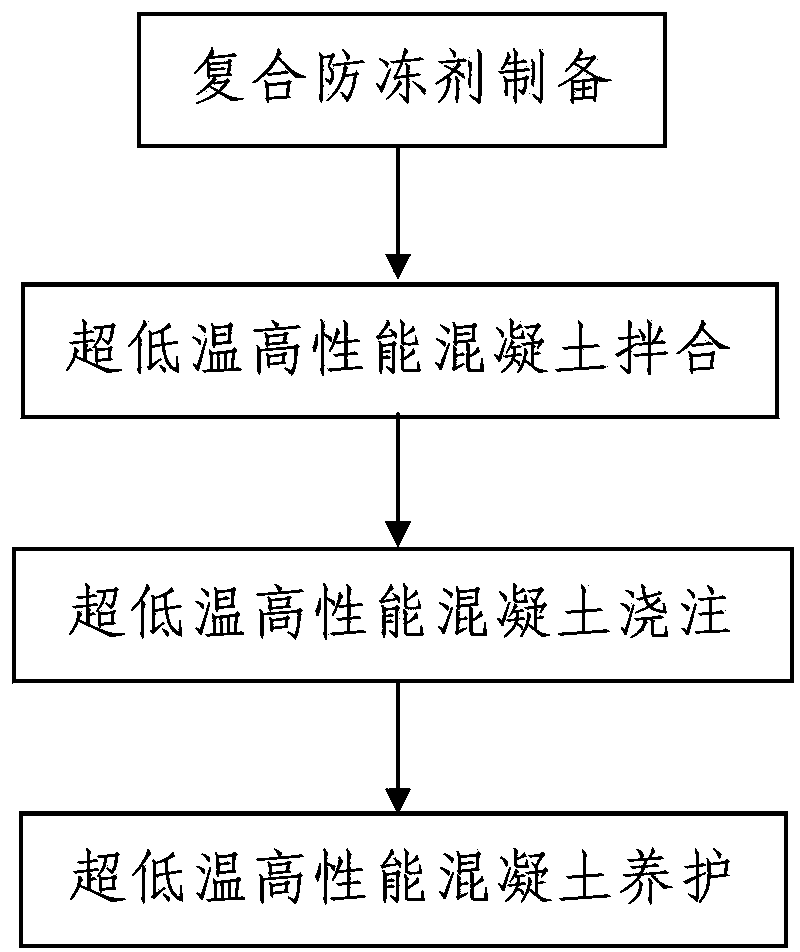

Construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas

ActiveCN102797358AThe process steps are simpleEasy to operateBuilding material handlingCalcium formateSuperplasticizer

The invention discloses a construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas. The construction technique comprises the steps as follows: A, mixing ultralow-temperature high-property concrete: gelled materials, sand, crushed stone, an efficient water reducing agent, compound antifreeze and water are evenly mixed to obtain the ultralow-temperature high-property concrete; the gelled materials are made by evenly mixing cement and mineral admixtures in the weight ratio of (88-78):(12-22); the weight ratio of the compound antifreeze to the mineral admixtures is (3-6):100; the compound antifreeze comprises 30 to 35 wt% of nitrate, 30 to 33 wt% of organic compound, 0.5 to 1wt% of calcium formate, and water as the rest; the nitrate is calcium nitrate or calcium nitrite; and the organic compound is methanol or alcohol; B, pouring the ultralow-temperature high-property concrete; and C, curing the ultralow-temperature high-property concrete. The construction technique has the advantages of reasonable design, simplicity in construction steps, convenience in operation, fast construction progress, low construction cost, and good structural quality of concrete used in construction.

Owner:CHINA RAILWAY 20 BUREAU GRP

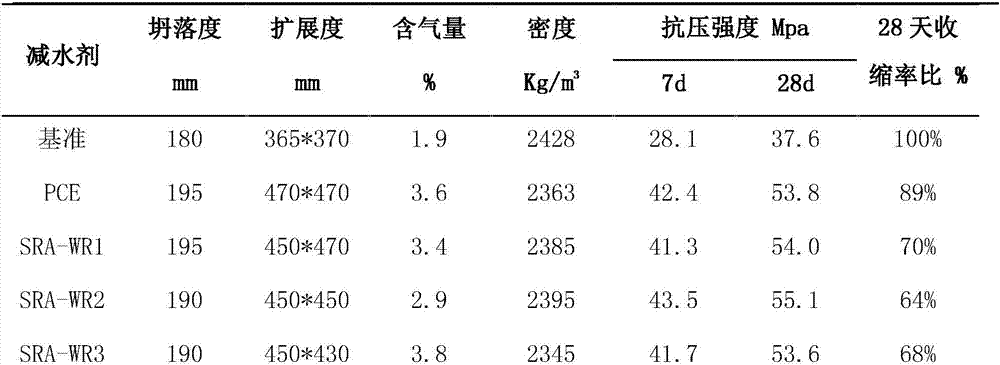

Reducing-type polycarboxylate superplasticizer and preparing method thereof

The invention discloses a reducing-type polycarboxylate superplasticizer and a preparing method thereof. The polycarboxylate superplasticizer is obtained by copolymerizing alkenyl polyether macromonomer, acrylic acid, maleic acid monoalkyl ester and maleic acid polyoxyethylene / polyoxypropylene polydimethylsiloxane ester under the condition of the existence of an initiator and a chain transfer agent and in an aqueous solution with the temperature being 20 DEG C-80 DEG C. The reducing-type polycarboxylate superplasticizer has a good reducing effect under a low admixture dosage; meanwhile, the reducing-type polycarboxylate superplasticizer has a certain water reducing capability and a small influence on the intensity of concrete, and is excellent in performance.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

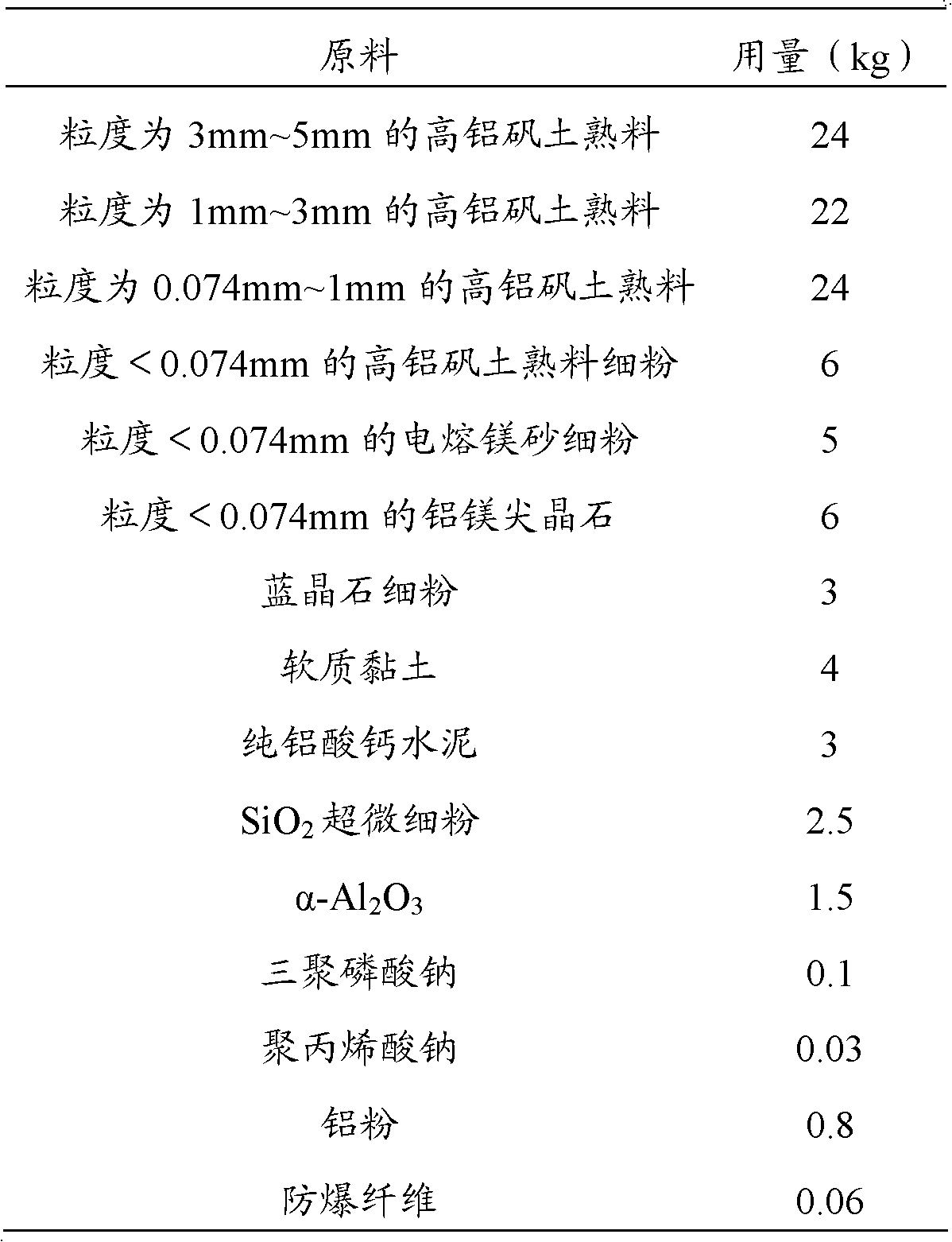

Gunning refractory for heating furnace

The invention provides a gunning refractory for a heating furnace, comprising 45-85 wt% of high alumina bauxite, 5-20 wt% of fused magnesia, 2-10 wt% of aluminum-magnesium spinel, 1-5 wt% of kyanite, 5-35 wt% of binding agent, 0.05-0.5 wt% of sodium tripolyphosphate, 0.01-0.2 wt% of sodium polyacrylate and 0.2-3.0 wt% of aluminum powder. When the heating furnace is repaired by using the gunning refractory provided by the invention, hot-state online repairing can be realized with large speed and high efficiency by using spray-repairing equipment like a gunning machine and a spray gun. Shown bythe experiment, the gunning refractory obtains better adhesion and higher binding strength with the repaired working face after a 20-cm thick collapsed portion on the top of the heating furnace is repaired by using the gunning refractory provided by the invention; and no sparkling or spalling damage appears while the repaired gunning refractory is used for eight months.

Owner:SHANDONG IRON & STEEL CO LTD

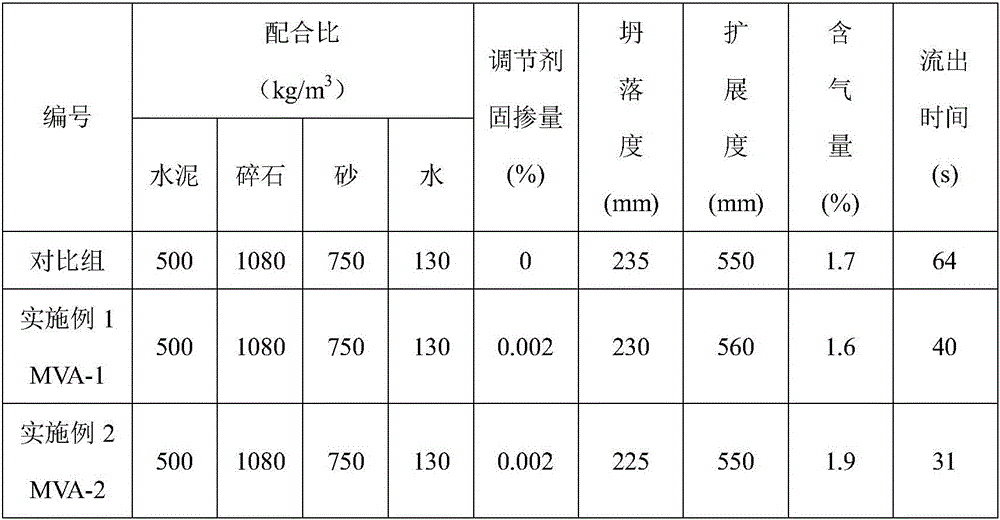

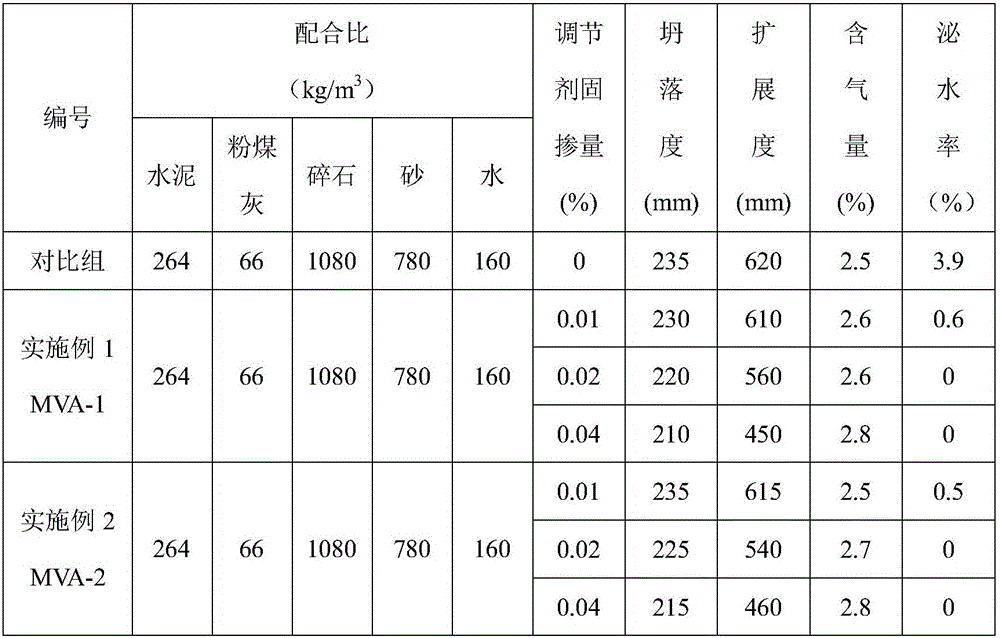

Preparation method for concrete viscosity regulator

The invention discloses a preparation method for a concrete viscosity regulator. The preparation method comprises the following steps: subjecting acrylamide and acrylic acid to copolymerization in an oxidation-reduction system under the condition of 30 DEG C to 35 DEG C, and adding a crosslinking agent polyethylene glycol bisitaconate under the condition of 60 DEG C to 65 DEG C. According to the invention, an acrylamide-acrylic acid copolymer with a high molecular weight is obtained through prepolymerization at a low temperature; the molecular weight of the copolymer is further improved through a reaction by adding the crosslinking agent polyethylene glycol bisitaconate at a high temperature; and the introduction of carboxyl, amide and ester into the molecular structure of the copolymer can guarantee that the copolymer has good hydrophilicity and water-reducing and slump-retaining effects. The concrete viscosity regulator provided by the invention can regulate the workability of a concrete mixture, has viscosity reducing effect at a low mixing amount, has viscosity increasing effect at a high mixing amount, inhibits segregation and bleeding, and has the advantages of good water solubility, convenience in usage, good compatibility with polycarboxylic acid water-reducing agents, etc.

Owner:安徽瑞和新材料有限公司

Concrete early strength agent

The invention discloses a concrete early strength agent, which is composed of the following components in parts by weight: 100 to 120 parts of potassium nitrate, 100 to 150 parts of white vitriol, 50 to 80 parts of sodium sulfide, 80 to 100 parts of potassium nitrate, 20 to 30 parts of gluconic acid, 15 to 20 parts of sodium lignosulfonate, 10 to 30 parts of active carbon, 30 to 50 parts of calcium oxide, 20 to 50 parts of titanium dioxide, 10 to 25 parts of coal cinder, 20 to 25 parts of high-alumina fly ash, and 30 to 35 parts of aluminum oxide. The concrete early strength agent has the characteristics of strong adaptability, low cost, and good early-strength effect, can replace an antifreeze agent in a temperature range of -5 to 5 DEG C, has the functions of promoting early strength, reducing water, preventing freezing, and enhancing the plasticity, does not contain any chlorine ion, does not corrode the steel bar, can be applied to silicate cement, and has a prominent enhancing and modifying effect on slag cement.

Owner:杨南宁

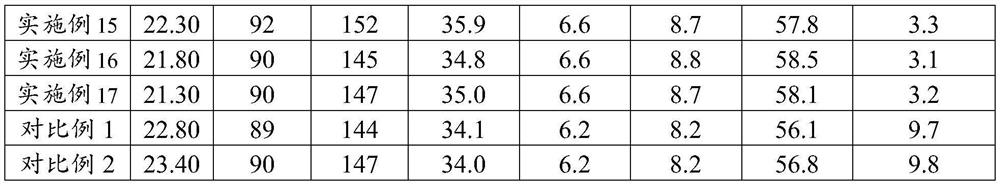

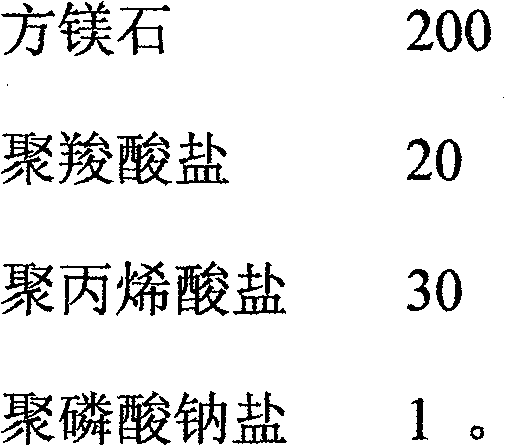

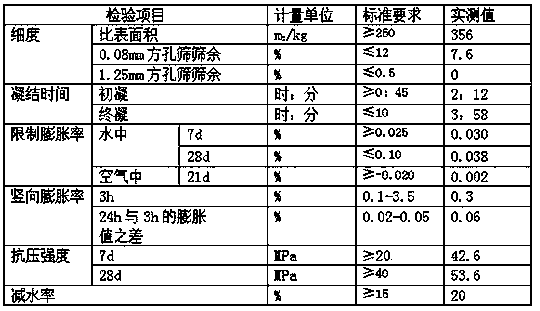

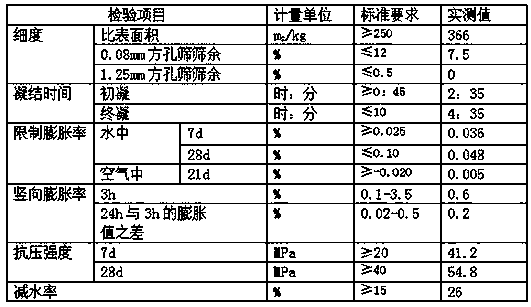

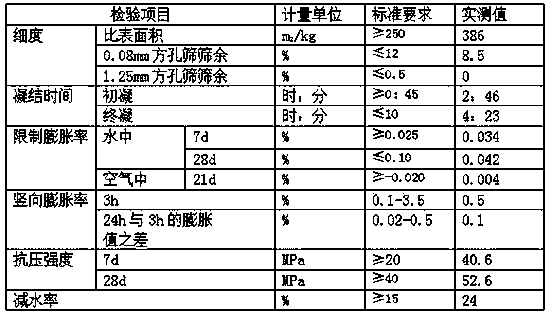

Volume stabilizer for cement-based composite material and preparation method thereof

The invention discloses a volume stabilizer for a cement-based composite material and a preparation method thereof. The volume stabilizer comprises the following components in part by weight: 180 and 220 parts of periclase, 18 to 21 parts of polycarboxylate, 27 to 32 parts of polyacrylate and 0.8 to 1.1 parts of sodium polyphosphate, wherein the periclase is ground into fine powder; the fine powder is sieved by a 85mu m sieve; and residue on the sieve is less than 10 percent. The method comprises the following steps: a, grinding magnesite serving as raw materials into fine power and sieving the fine powder with the 85mu m sieve, wherein residue on the sieve is less than or equal to 10 percent; b, calcining the ground magnesite powder at the temperature of between 900 and 1,250 DEG C, preserving the heat for 30 to 120 minutes, and cooling the calcined magnesite powder to room temperature after the heat preservation is finished to prepare the periclase; c, grinding the periclase into fine powder and sieving the fine powder with a 85mu m sieve, wherein residues on the sieve is less than or equal to 10 percent; and d, mixing the periclase obtained in the step c, the polycarboxylate, the polyacrylate and the sodium polyphosphate in proportion. The volume stabilizer and the preparation method can solve the problem of cracking of cement-based materials caused by contraction.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

High-strength sintering hollow clay brick and preparation method thereof

The invention discloses a high-strength sintering hollow clay brick and belongs to the technical field of hollow bricks. The high-strength sintering hollow clay brick is prepared from the following raw materials in parts by weight: 80-85 parts of clay, 25-28 parts of steel fiber, 17-20 parts of alumina silicate fiber, 12-14 parts of sepiolite powder, 10-14 parts of calcium carbonate, 6-8 parts of zinc oxide, 7-9 parts of polyethylene wax, 13-15 parts of petroleum asphalt, 2-4 parts of lignosulfonate, 6-9 parts of waterproof powder, 3-5 parts of triethanolamine, 1-3 parts of alkylphenol ethoxylates, 8-10 parts of brominated polystyrene, 1-2 parts of anti-freezing agent, 1-2 parts of ultraviolet light absorber, 2-4 parts of antibacterial agent, 5-7 parts of adhesive and a defined amount of water. The invention also discloses a preparation method for the high-strength sintering hollow clay brick. The high-strength sintering hollow clay brick is simply prepared, has excellent strength and fire resistance and is long in service life.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

Recycled aggregate concrete and workability and durability improvement additive

The invention discloses a recycled aggregate concrete constructability and durability improvement additive and belong to the technical field of building materials. The additive comprises lithium silicate, micro-silicon powder, a composite air-entraining agent, a thickened lubricant, a polycarboxylate superplasticizer and a retarder, wherein the ratio of the lithium silicate to a polycarboxylate superplasticizer mixed solution is 0.001:0.08; the ratio of a common air-entraining agent to a nano air-entraining agent is 0.1-5; and according to weight percents of all the additives in the mixed solution, the micro-silicon powder is 0.25-1.5, the composite air-entraining agent is 0.001-0.005, the thickened lubricant is 0.001-0.003, and the retarder is 0.001-0.05. The additive is applied to concrete engineering and can substantially improve concrete constructability, stability and durability. The additive is suitable for a reinforced concrete structure, a concrete structure and other structures. By use of the additive, the viscosity of concrete can be substantially lowered, and the flow velocity, expandability, crack resistance, constructability and working stability of the concrete are improved.

Owner:LIAONING PROVINCIAL COLLEGE OF COMM

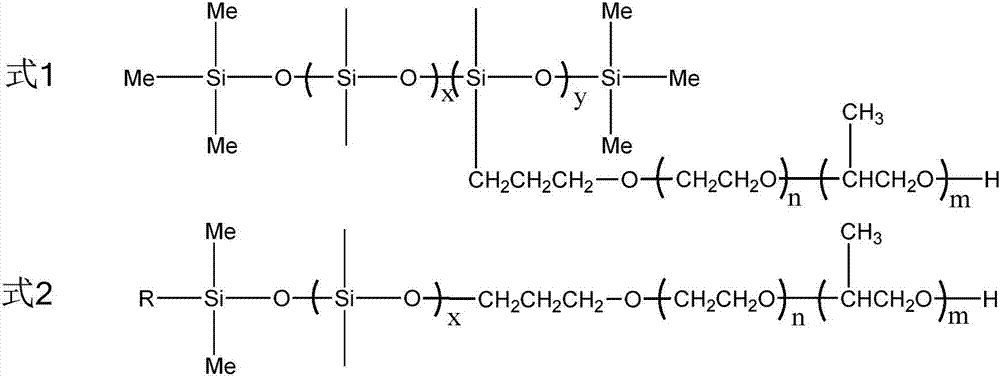

Viscosity-reducing type polycarboxylic acid water reducing agent preparation method

ActiveCN109180876ALightly crosslinkedStructural stretchCross-link2-methacryloyloxyethyl phosphorylcholine

The invention discloses a viscosity-reducing type polycarboxylic acid water reducing agent preparation method, which comprises: (1) preparing an esterification monomer; (2) carrying out a copolymerization reaction; and (3) carrying out a neutralization reaction. According to the present invention, the viscosity-reducing type polycarboxylic acid water reducing agent is prepared by co-polymerizing 2-allyloxyethanol, a blend, VPEG, 2-methacryloyloxyethyl phosphorylcholine and an unsaturated acid, such that the phosphate radical, the carboxylate radical, the quaternary ammonium salt and the estergroup are introduced into the molecular structure of the polymer while the polymer structure is lightly cross-linked, wherein the product obtained by the esterification of the single carboxy in 2-phosphonobutane-1,2,4-tricarboxylicacid prepared by a 2-phosphonobutane-1,2,4-tricarboxylicacid esterification reaction, the product obtained by the esterification of the two carboxy in a small amount of2-phosphonobutane-1,2,4-tricarboxylicacid and the product obtained by the esterification of the three carboxy in a small amount of 2-phosphonobutane-1,2,4-tricarboxylicacid form the blend; and the prepared viscosity-reducing type polycarboxylic acid water reducing agent has advantages of viscosity reducing, water reducing, slump retaining and mud resistance, and can solve the problems of high viscosity, poor workability and rapid loss due to the high mud content in the current concrete raw materials.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

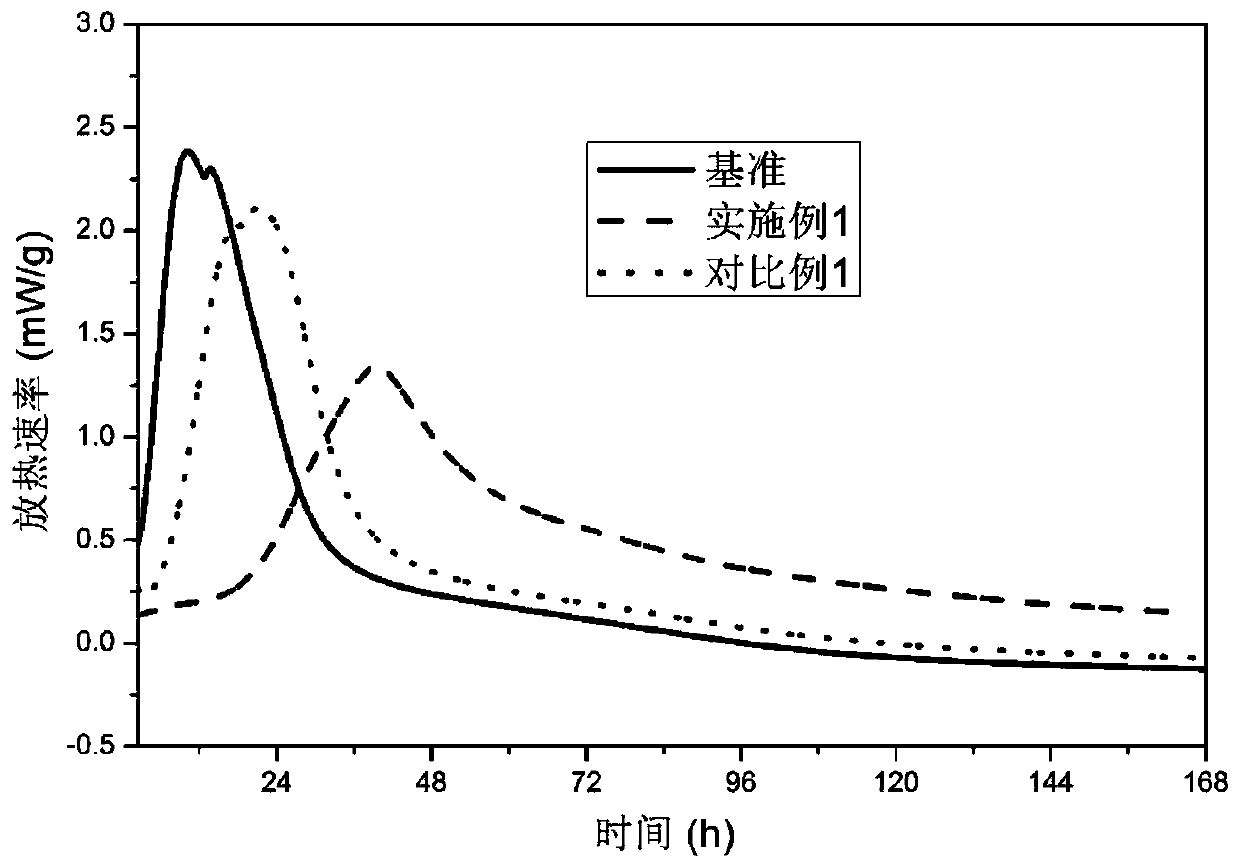

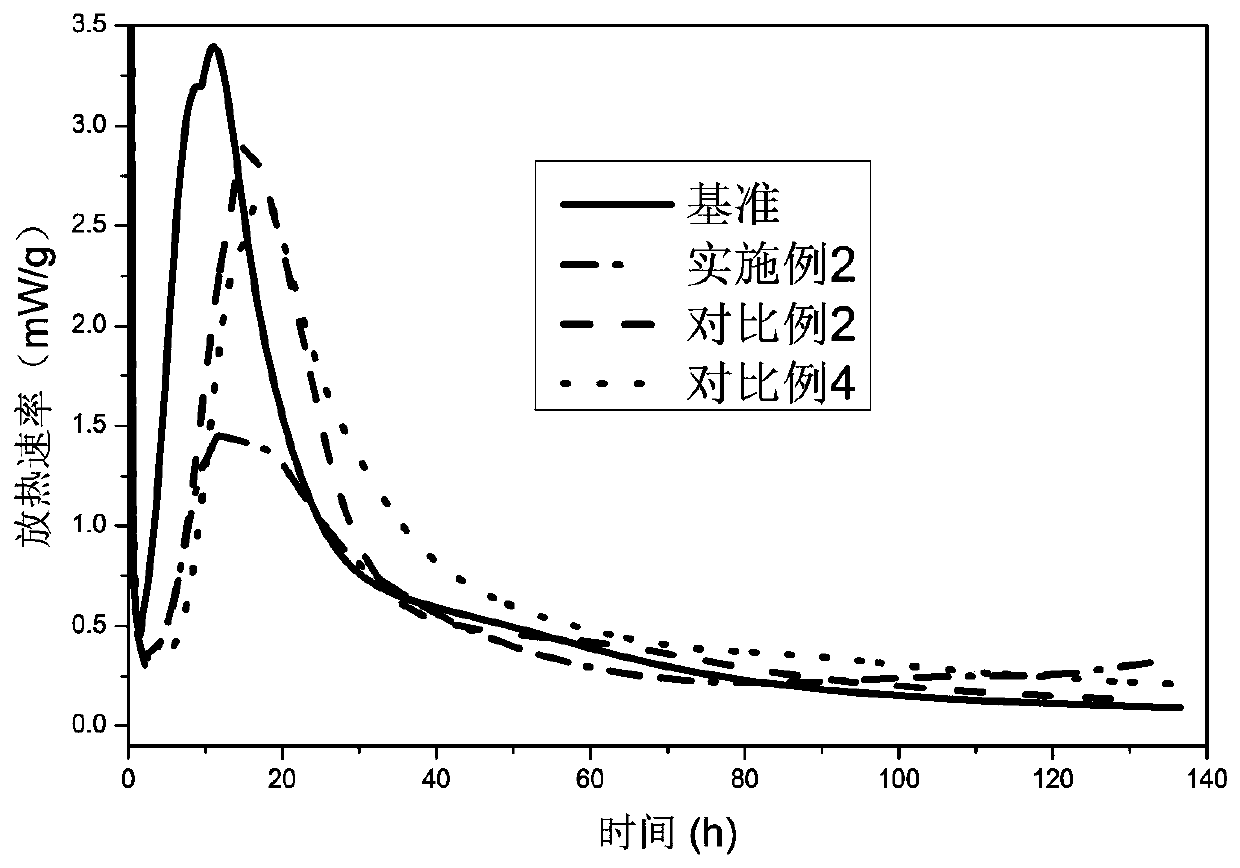

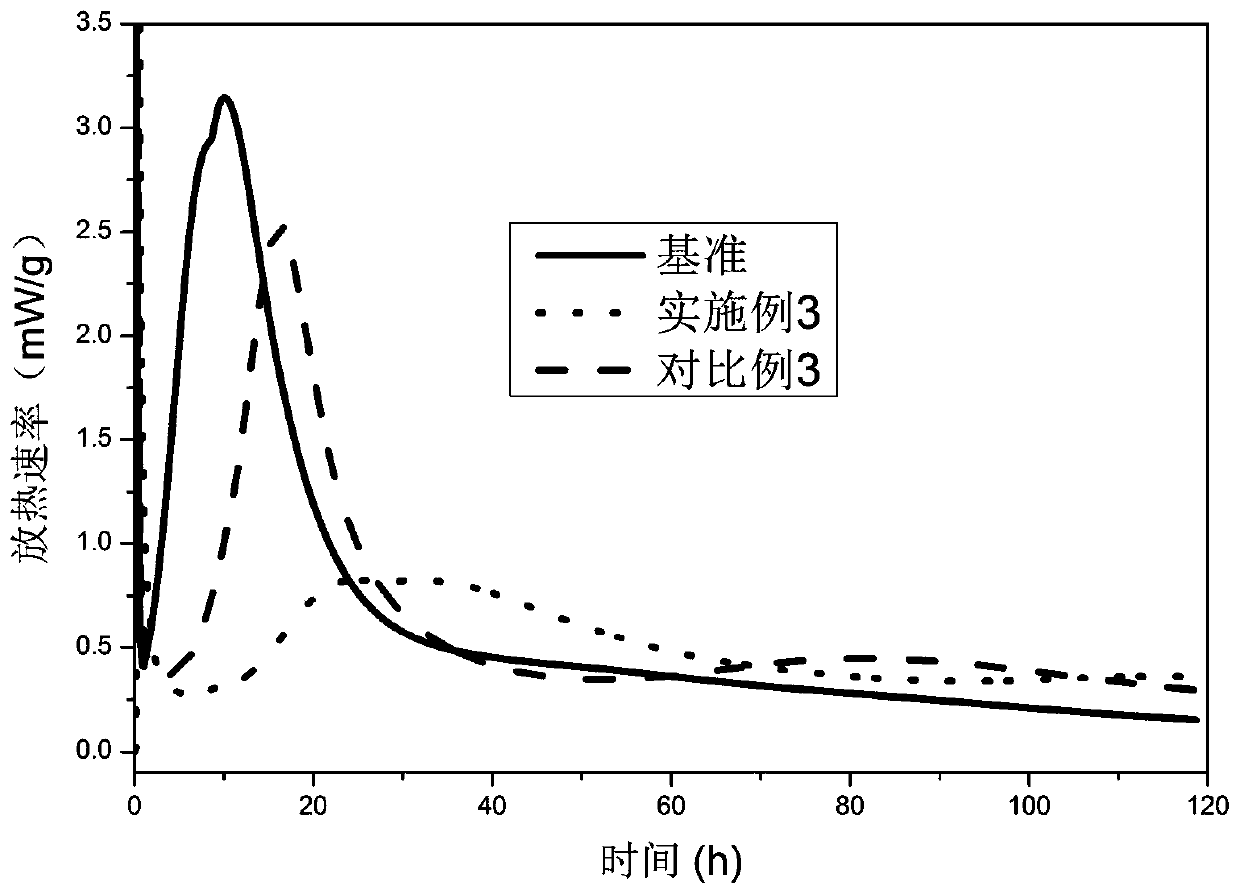

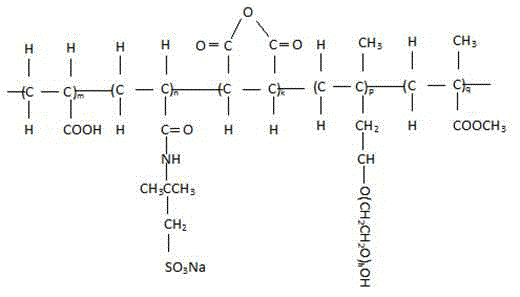

Multifunctional cement hydration thermal regulation and control material and preparation method thereof

The invention discloses a multifunctional cement hydration thermal regulation and control material and a preparation method thereof. The cement hydration thermal regulation and control material is a comb shaped polymer of three side chain structures, wherein the three side chain structures are respectively a carboxyl structure, a sugar alcohol group structure and a polyether structure; a polymer main chain is a carbon chain structure formed by free radical polymerization of double bonds in a double-bond compound monomer. According to the multifunctional cement hydration thermal regulation andcontrol material prepared by the preparation method, the gathering of cement hydration thermal regulation and control performance, water reduction performance and reduction performance can be realizedin the same molecule, the focused regulation and control of performance can be realized through structure regulation, and multi-ingredient compounding is not required during use so as to be more convenient. The regulation and control material disclosed by the invention is nontoxic, has water solubility, can be prepared into proper concentration and is convenient in use.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

High-strength wear-resistant fiber reinforced plastic

InactiveCN107151383ASimple preparation processThe preparation process is environmentally friendly and pollution-freePlastic/resin/waxes insulatorsPolypropyleneSilane coupling

The invention discloses high-strength wear-resistant fiber reinforced plastic. The high-strength wear-resistant fiber reinforced plastic is prepared from, by weight, 15-25 parts of polypropylene, 10-20 parts of epoxy resin, 10-30 parts of nano ceramic particles, 2-8 parts of a silane coupling agent, 5-10 parts of cyclohexanone, 2-6 parts of zirconium oxide and 15-25 parts of a wear-resistant agent. Technical simplicity, environmental friendliness and freeness of pollution in a preparation process are realized, fiber reinforced plastic prepared according to the method is high in wear resistance and has advantages of corrosion resistance and high temperature resistance, and service lives of fiber reinforced plastic cables can be prolonged.

Owner:DE RUISEN NANTONG COMPOSITE MATERIAL CO LTD

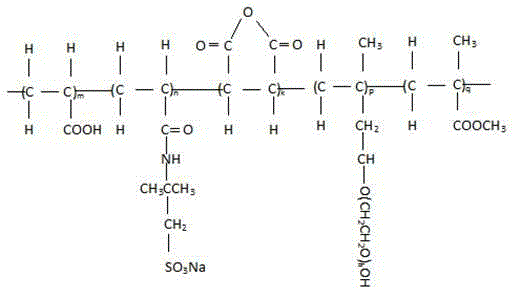

Polycarboxylate superplasticizer masterbatch capable of prolonging coagulating time of concrete and preparation method thereof

The invention relates to a water-reducing agent for concrete and a preparation method thereof, in particular to a polycarboxylate superplasticizer masterbatch capable of prolonging the coagulating time of concrete and a preparation method thereof. The polycarboxylate superplasticizer masterbatch capable of prolonging the coagulating time of concrete is formed by polymerizing isoamyl alcohol polyoxyethylene ether, maleic anhydride, 2-acrylamide-2-methyl sodium propanesulfonate, acrylic acid, methyl methacrylate, an initiator, a chain transfer agent and water. The prepared polycarboxylate superplasticizer masterbatch adopts a comb-type structure of the conventional polycarboxylate superplasticizer, an isoamyl alcohol polyoxyethylene ether macromonomer is used as a side chain, a calcium ion chelating structure which is copolymerized from acrylic acid, maleic anhydride, methyl methacrylate and 2-acrylamide-2-methyl sodium propanesulfonate is used as a main chain, the polycarboxylate superplasticizer masterbatch has water-reducing and coagulation-slowing effects, can obviously prolong the coagulating time of polycarboxylic acid concrete, and is applicable to preparation of a pumping agent for concrete in summer.

Owner:GUIZHOU DR SHI TECH

Anti-crack reinforcing agent for concrete

Owner:湖州华仑助剂科技有限公司

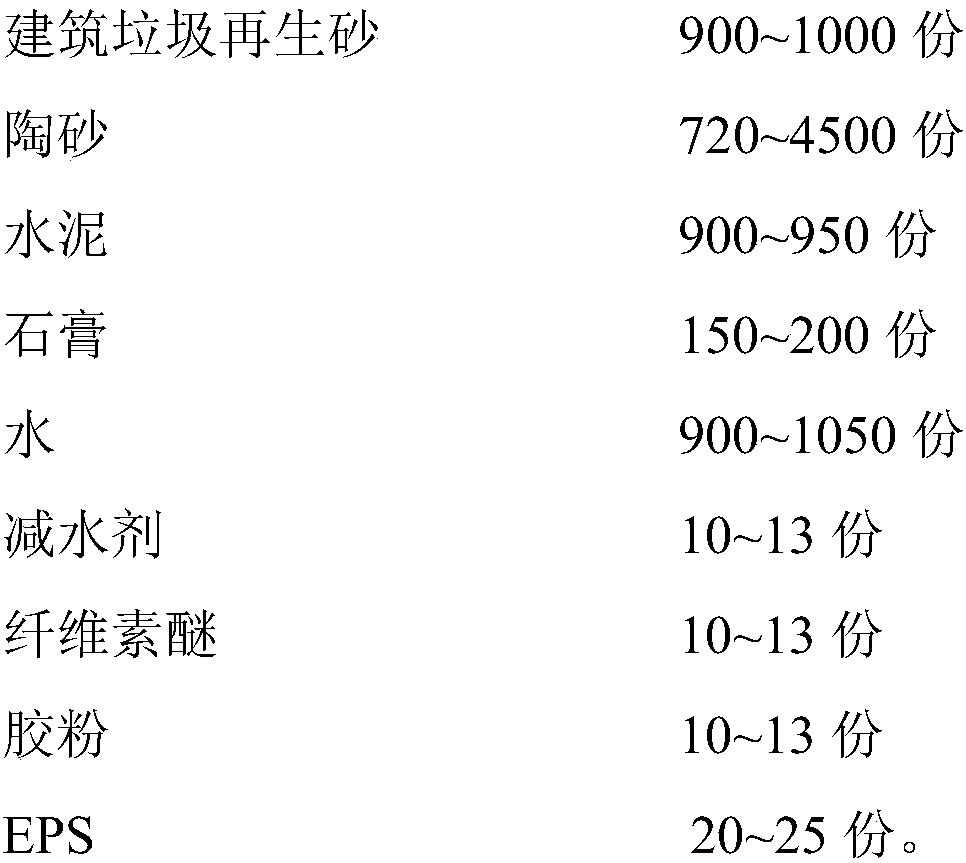

Green mortar produced by building garbage and preparation method thereof

The invention relates to green mortar produced by building garbage and a preparation method thereof. The green mortar is prepared from the following components in parts by weight: 900 to 1000 parts ofregenerated sand of the building garbage, 720 to 4500 parts of ceramic sand, 900 to 950 parts of cement, 150 to 200 parts of gypsum, 900 to 1050 parts of water, 10 to 13 parts of a water reducing agent, 10 to 13 parts of cellulose ether, 10 to 13 parts of rubber powder, and 20 to 25 parts of EPS (expanded polystyrene). The preparation method of the green mortar comprises the following steps of weighing the components of the raw materials according to the proportional ratio by weight, adding into a cement paste mixer, and stirring for 0.5 to 1 min; adding the remaining water into the cement paste mixer, and stirring for 2 to 4 min, so as to obtain the green mortar. Compared with the prior art, the green mortar has the advantage that the regenerated sand of the building garbage can be reasonably utilized, so as to obtain the green mortar which has good thermal insulation property, meets engineering requirements, and has functions such as water reduction, coagulation acceleration, waterretention, water repellence and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

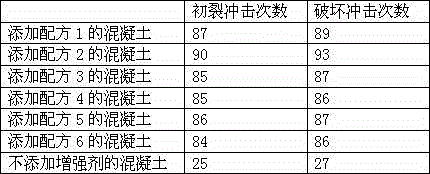

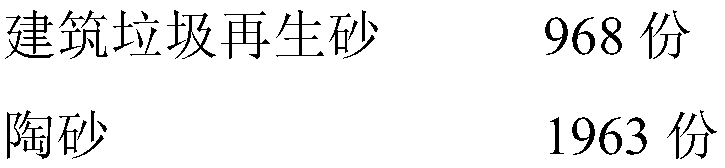

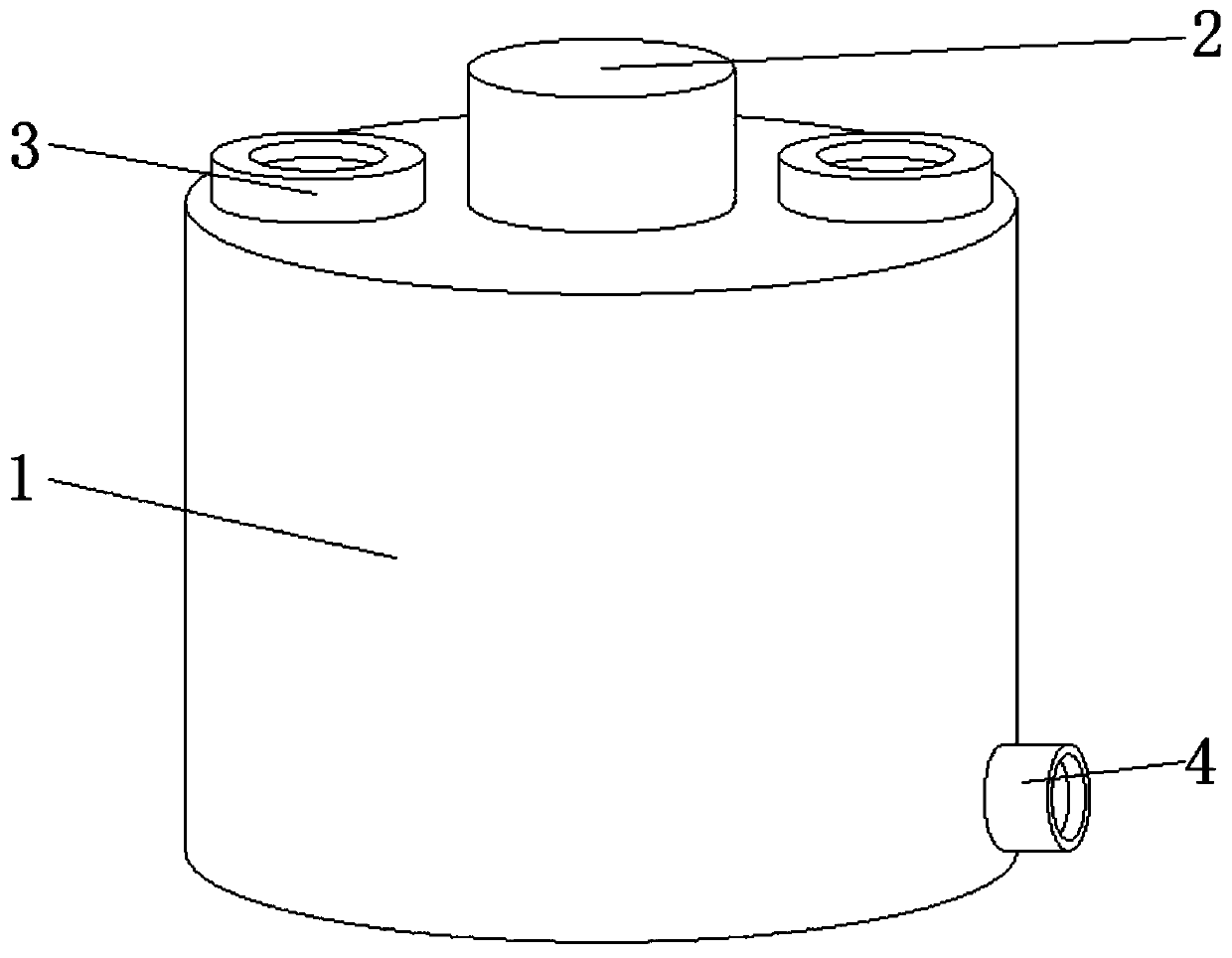

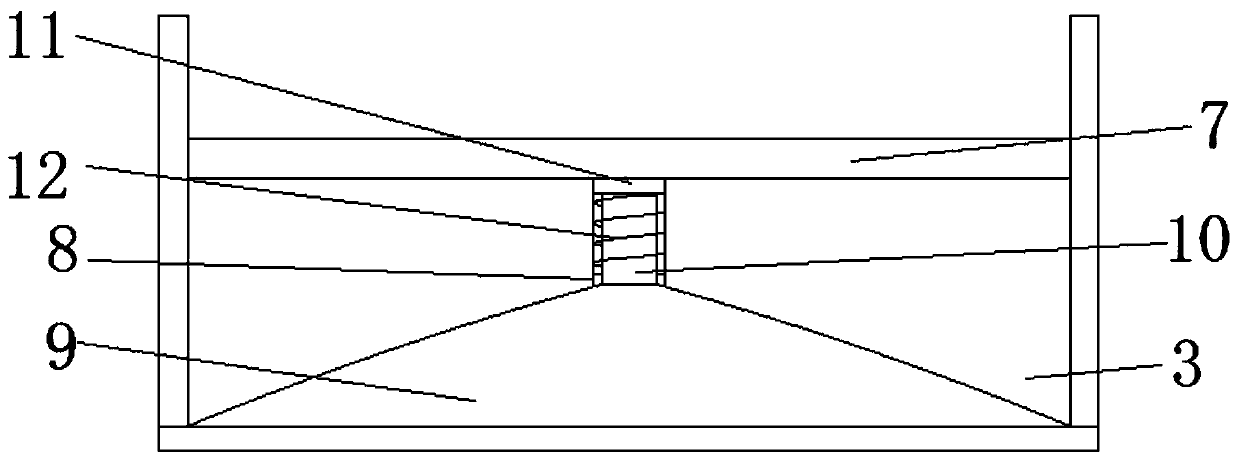

Thermal insulation mortar for thermal insulation prefabricated part of building wall, and preparation method and equipment

InactiveCN110950678ALow manufacturing costLow cost of preparationClimate change adaptationHeat proofingSilica fumeThermal insulation

The invention discloses thermal insulation mortar for a thermal insulation prefabricated part of a building wall. The thermal insulation mortar is prepared from the following components in parts by weight: 350 parts of Portland cement, 7 parts of polyphenyl granules, 100 parts of ash calcium powder, 520 parts of quartz sand, 20 parts of silica fume, 15 parts of modified seaweed, 15 parts of a concrete admixture and the balance of water. The invention also discloses a preparation method of the thermal insulation mortar, which comprises the following steps: S1, well mixing and stirring Portlandcement, ash calcium powder, quartz sand, silica fume and water; S2, adding polyphenyl granules into a mixture obtained in the S1 and stirring well; and S3, adding modified seaweed into a mixture obtained in the S2 and stirring well to obtain the thermal insulation mortar for a thermal insulation prefabricated part of a building wall. The invention further discloses preparation equipment of the thermal insulation mortar, which can prevent the mortar from splashing out through a feeding tank in the stirring process. The mortar provided by the invention has the advantages of good heat insulationand heat preservation performance, low preparation cost, high viscosity, strong polyphenyl particle wrapping performance, good crack resistance and short hard drying period.

Owner:清远肆柒柒新材料科技有限公司

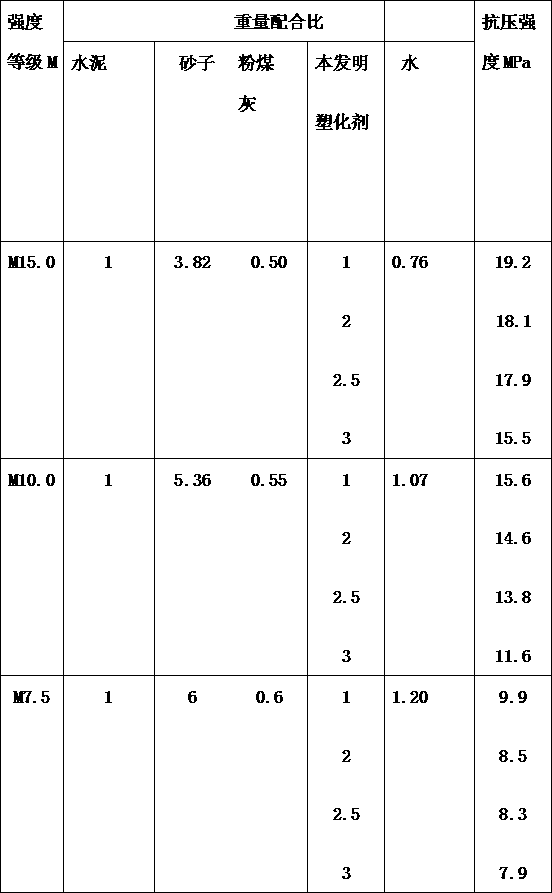

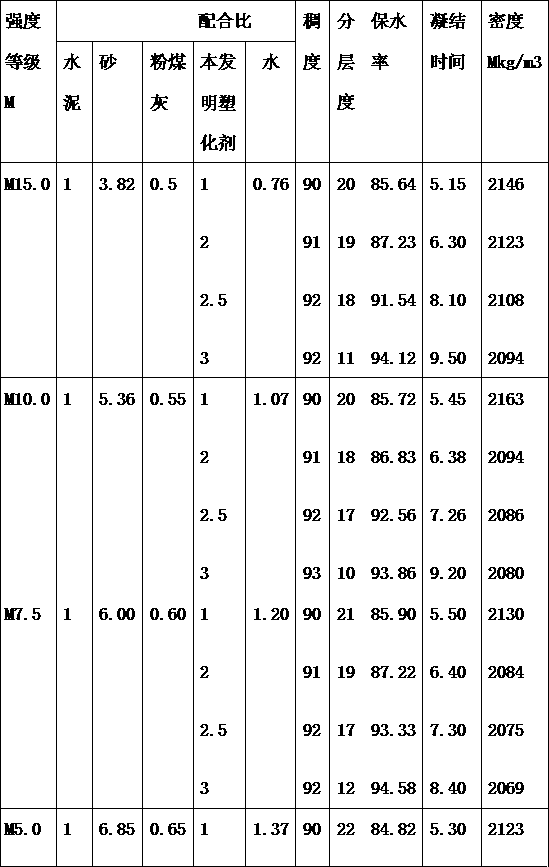

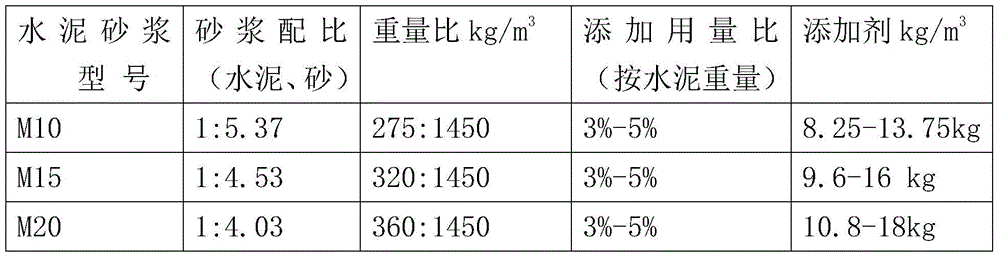

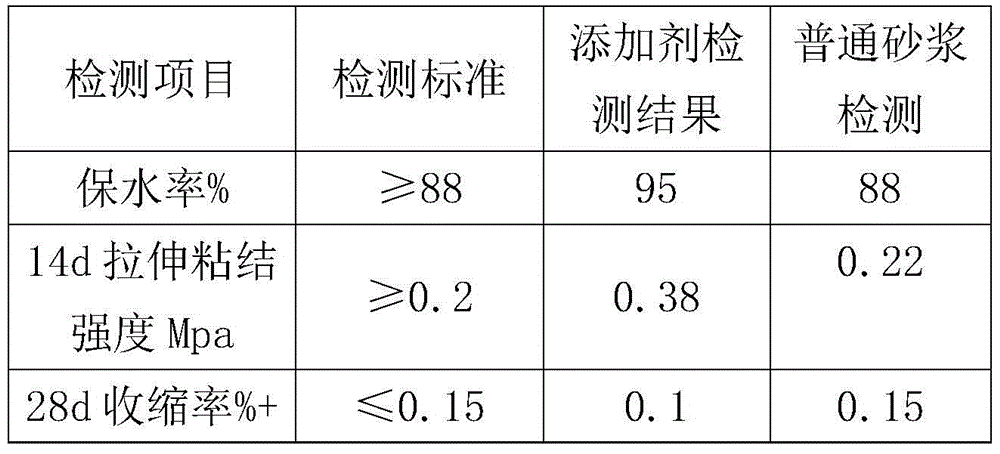

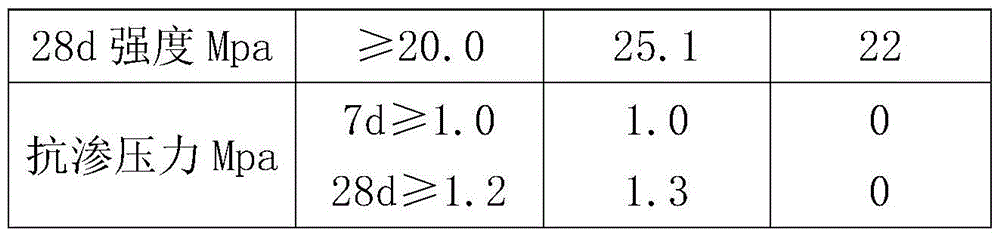

Masonry, plastering mortar plasticizer and preparation method

InactiveCN103121806AThe formula is scientific and reasonableUnique effectPolyvinyl alcoholPlasticizer

The invention provides masonry, a plastering mortar plasticizer and a preparation method. The plastering mortar plasticizer comprises the components in the weight ratio of rosin to sodium hydroxide to polyvinyl alcohol to water of (8-12):1:(8-12):(80-120). The formula of the plastering mortar plasticizer is scientific and reasonable, the preparation method is simple, and cost is low. By adopting the plastering mortar plasticizer provided by the invention, numerous small bubbles can be produced in mortar, volume of cement can be increased, a friction force among sand grains is reduced, performance of cement mortar can be improved, peaceability and water-retaining property of mortar are enhanced; meanwhile, construction and plastering effects of the mortar are improved; ash fallen to ground is also reduced; cement is saved, no lime paste is used, and the environment is protected; besides, the effects of diffusing the cement, emulsifying and foaming can be achieved; common problems of flaking and cracking are solved; and good effect also can be achieved when the plastering mortar plasticizer provided by the invention is used for bottoming of bottom surface of aerated concrete and common concrete or is used on the surface layer of the aerated concrete and the common concrete. Detection is carried out on building mortar added with the plastering mortar plasticizer provided by the invention according to the Chinese National Standard, and results show that the plastering mortar plasticizer provided by the invention is completely in conformity with the Chinese National Standard.

Owner:CHANGCHUN INST OF TECH

Mortar additive, mortar additive preparation method and method for preparing mortar with mortar additive

The invention provides a mortar additive, a mortar additive preparation method and a method for preparing mortar with the mortar additive.The mortar additive is composed of organic silicon type water repellents, redispersible latex powder, hydroxypropyl methyl cellulose ether, polycarboxylic type water reducer, modified starch ether, polypropylene fibers and fillers according to a weight ratio of 0.8-1.2:0.8-1.2:0.6-0.8:0.3-0.58:0.1-0.13:0.3-0.58:0.1-0.3.Compared with a common additive, the mortar additive has the advantages that reaction is quicker and more complete, strength increase is quicker and higher, abrasion resistance, durability, cracking resistance and seepage proofing performances of concrete can be evidently improved, functions of water reduction, early strengthening and air entrainment are realized, and the mortar additive is higher in adaptability to various concretes and extensive in application prospect.

Owner:广东金能建筑节能材料科技有限公司

Concrete admixture

The invention relates to the field of building concrete and in particular relates to a concrete admixture. With the adoption of the technical scheme of the invention, the concrete admixture consists of the following components in percentage by weight: 20-30 percent of triethanolamine, 3-5 percent of tartaric acid, 12-25 percent of ferric trichloride, 8-12 percent of sodium chloride, 22-25 percent of cane sugar, 5-10 percent of surfactant and 20-35 percent of sodium dodecyl sulfate. On the basis of the scheme, the concrete admixture consists of the following components in percentage by weight: 22 percent of triethanolamine, 4 percent of tartaric acid, 13 percent of ferric trichloride, 8 percent of sodium chloride, 22 percent of cane sugar, 7 percent of surfactant and 24 percent of sodium dodecyl sulfate.

Owner:QINGDAO YONGTONG ELEVATOR ENG

Construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas

ActiveCN102797358BThe process steps are simpleEasy to operateBuilding material handlingCalcium formateSuperplasticizer

Owner:CHINA RAILWAY 20 BUREAU GRP CORP LTD

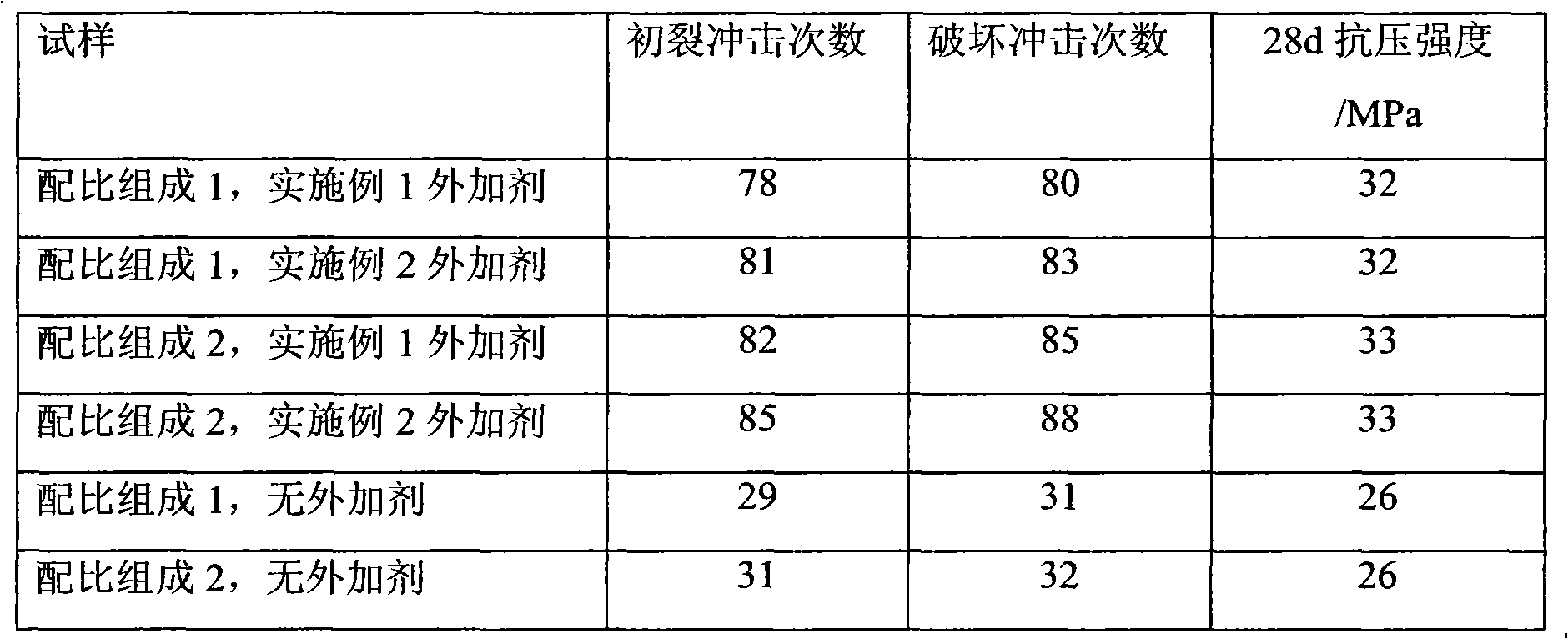

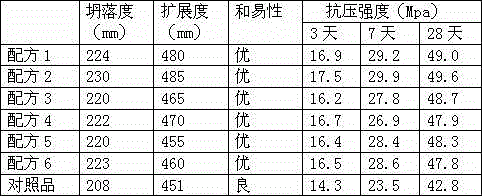

Concrete complex additive

The invention provides a concrete complex additive which comprises the following components by weight percent: 17.5-58.0% of efficient water reducing agent, 0.5-5.5% of organosilicon waterproofing agent, 0.2-2.5% of organosilicon reinforcing agent, 3.5-25% of polyacrylamide, 1.2-2.8% of triethanolamine, 3.2-6.3% of sodium nitrite, 0.3-1.2% of glycol, 0.6-1.3% of glycerol, 2.8-5.5% of sodium gluconate and the balance of water. The impact resistance, crocking resistance, impermeability and waterproofness of the concrete material can be obviously improved by using the complex additive provided by the application in the preparation process of the concrete, thus the concrete complex additives is especially suitable for the requirement on high-performance concrete for construction of airfield runways or highway bridges.

Owner:JIANGSU FENGTAI TOOLS

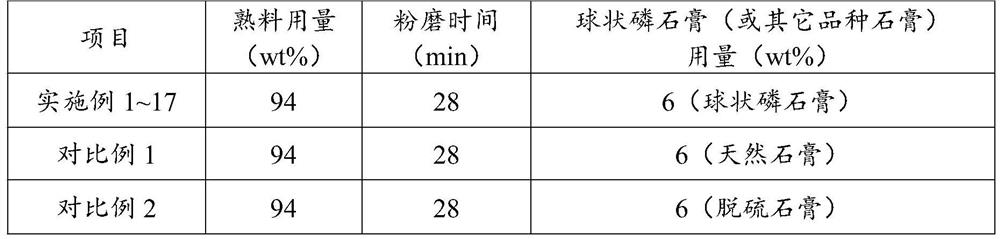

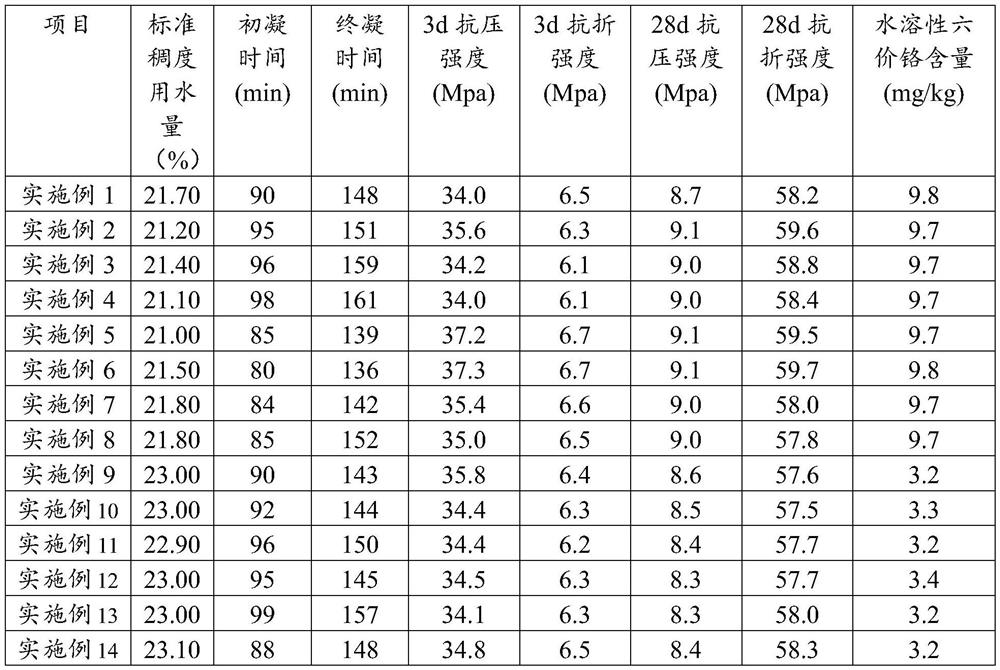

Spherical phosphogypsum as well as preparation method and application thereof

The invention relates to the technical field of comprehensive utilization of solid wastes, and provides spherical phosphogypsum as well as a preparation method and application thereof. The spherical ardealite provided by the invention is prepared from the following raw materials: ardealite powder, cement and a modifier, wherein the modifier comprises alkaline lignin and / or ferrous sulfate. The spherical ardealite provided by the invention is high in physical strength, is not easy to break, and has a good retarding effect, when the modifier comprises lignin, the spherical ardealite can also improve the cement strength and reduce mixing water, and when the modifier comprises ferrous sulfate, the spherical ardealite can also reduce the content of water-soluble hexavalent chromium in cement. The spherical ardealite provided by the invention has a large amount of ardealite powder, is conducive to promoting the balance of production and elimination of ardealite, and fundamentally solves the ecological environmental protection problem caused by ardealite. Furthermore, the alkaline lignin is from the papermaking black liquid, the ferrous sulfate is from the titanium dioxide waste residues, and resource utilization of the papermaking black liquid and the titanium dioxide waste residues can be achieved.

Owner:HUBEI XINYANGFENG NEW BUILDING MATERIAL TECH CO LTD

Volume stabilizer for cement-based composite material and preparation method thereof

The invention discloses a volume stabilizer for a cement-based composite material and a preparation method thereof. The volume stabilizer comprises the following components in part by weight: 180 and 220 parts of periclase, 18 to 21 parts of polycarboxylate, 27 to 32 parts of polyacrylate and 0.8 to 1.1 parts of sodium polyphosphate, wherein the periclase is ground into fine powder; the fine powder is sieved by a 85mu m sieve; and residue on the sieve is less than 10 percent. The method comprises the following steps: a, grinding magnesite serving as raw materials into fine power and sieving the fine powder with the 85mu m sieve, wherein residue on the sieve is less than or equal to 10 percent; b, calcining the ground magnesite powder at the temperature of between 900 and 1,250 DEG C, preserving the heat for 30 to 120 minutes, and cooling the calcined magnesite powder to room temperature after the heat preservation is finished to prepare the periclase; c, grinding the periclase into fine powder and sieving the fine powder with a 85mu m sieve, wherein residues on the sieve is less than or equal to 10 percent; and d, mixing the periclase obtained in the step c, the polycarboxylate, the polyacrylate and the sodium polyphosphate in proportion. The volume stabilizer and the preparation method can solve the problem of cracking of cement-based materials caused by contraction.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

Grouting expanding agent and production method thereof

The invention discloses a grouting expanding agent which comprises the following raw materials in parts by weight: 60-90 parts of an expansion master batch, 10-40 parts of activated mineral admixture,0.5-2.5 parts of a plastic expanding agent and 2-8 parts of a polycarboxylate water reduction agent, wherein the expansion master batch comprises the following raw materials in parts by weight: 35-55parts of gypsum residues, 20-40 parts of silicate clinker and 10-40 parts of lime factory wastes. The product has dual effects of plastic expansion and hardening period expansion, shrinkage of concrete is sufficiently compensated, and the grouting expanding agent is a concrete additive with a low admixture amount and composite functions of expansion, water reduction, cracking resistance and the like.

Owner:广西云燕特种水泥建材有限公司

Compounding method and application of novel anti-freeze composite additive

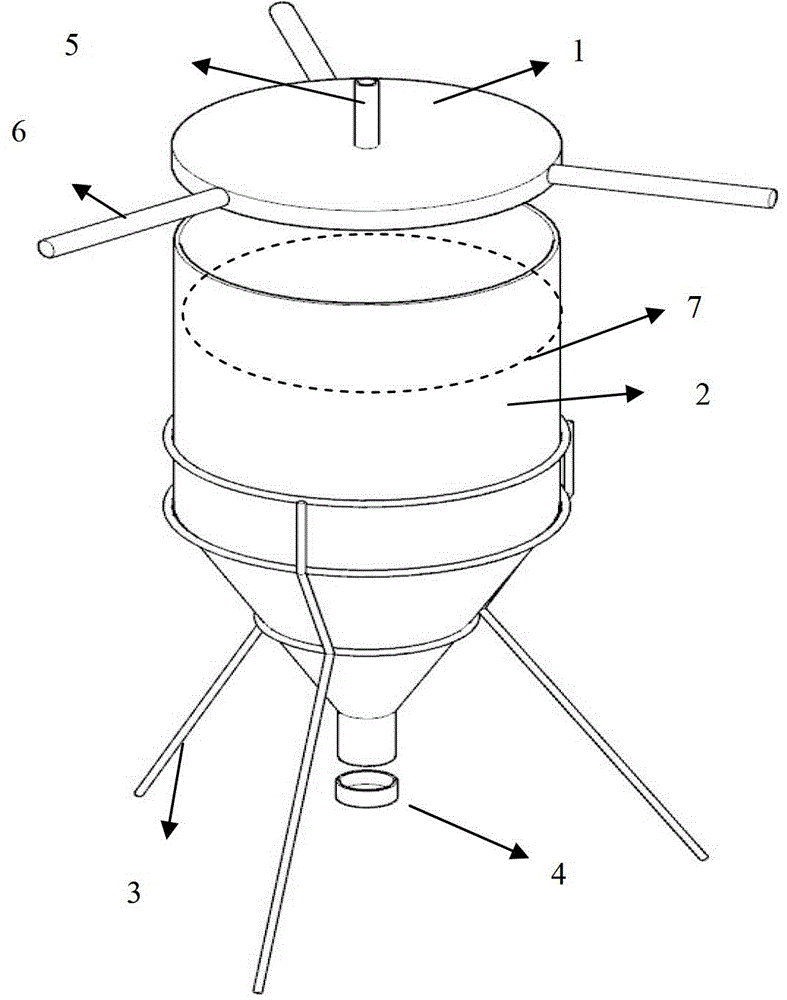

The invention provides a compounding method and an application of a novel anti-freeze composite additive. The additive comprises 6-12wt% of hydroxysuccinimide, 28-34wt% of dimethyl formamide, 5wt% of triethanolamine, 6wt% of a naphthalene water reducer, 8wt% of a sodium alkyl sulfate air entraining agent and 41wt% of water. The novel anti-freeze composite additive is added to cement according to a weight ratio of the additive to used cement of 5.0:100 at an environment temperature of -12DEG C, and the novel anti-freeze composite additive is added to cement according to a weight ratio of the additive to the used cement of 8.0:100 at an environment temperature of -12-20DEG C. The novel anti-freeze composite additive can effectively promote setting of concrete under low temperature or minus temperature conditions, obviously improves the workability and the durability of the concrete, has the effects of early strength, water reduction, air entraining and freeze prevention, and is mainly used in concrete for casting of industrial civil buildings, roads and bridges.

Owner:LANGFANG RONGSHENG CONCRETE

Fireproof thermal insulation sheet and preparation method thereof

ActiveCN111662063AStable and controllable qualityLow water absorptionHeat proofingCeramicwareEpoxyMetallic aluminum

The invention provides a fireproof thermal insulation sheet and a preparation method thereof. The fireproof thermal insulation sheet comprises 40-55 parts of an active reaction material, 2-6 parts ofa gas forming time regulator, 45-60 parts of sand, 1-5 parts of ultrafine aggregate, 0.3-1 part of a gas forming agent and 0.5-5 parts of a modifier, wherein the gas-forming time regulator is preparedby grinding one of triethanolamine, diethanol amine, pentaerythritol, glycerol and xylitol and building gypsum according to a mass ratio of (1-5): 50; the modifier is cyanamide modified epoxy resin;the gas generating agent is metal aluminum powder, octadecenoic acid and triterpenoid saponin, the particle size of the metal aluminum powder is 10-60 [mu] m for continuous grading, and the ratio of D50 greater than or equal to 10 [mu] m and less than 30 [mu] m to D50 greater than or equal to 30 [mu] m and less than or equal to 60 [mu] m is (1-3): (1-2). The fireproof thermal insulation sheet is good in quality, the heat conductivity coefficient is not larger than 0.10 W / m.K, and the cutting loss rate is not larger than 5% when the thickness is 50-75 mm.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

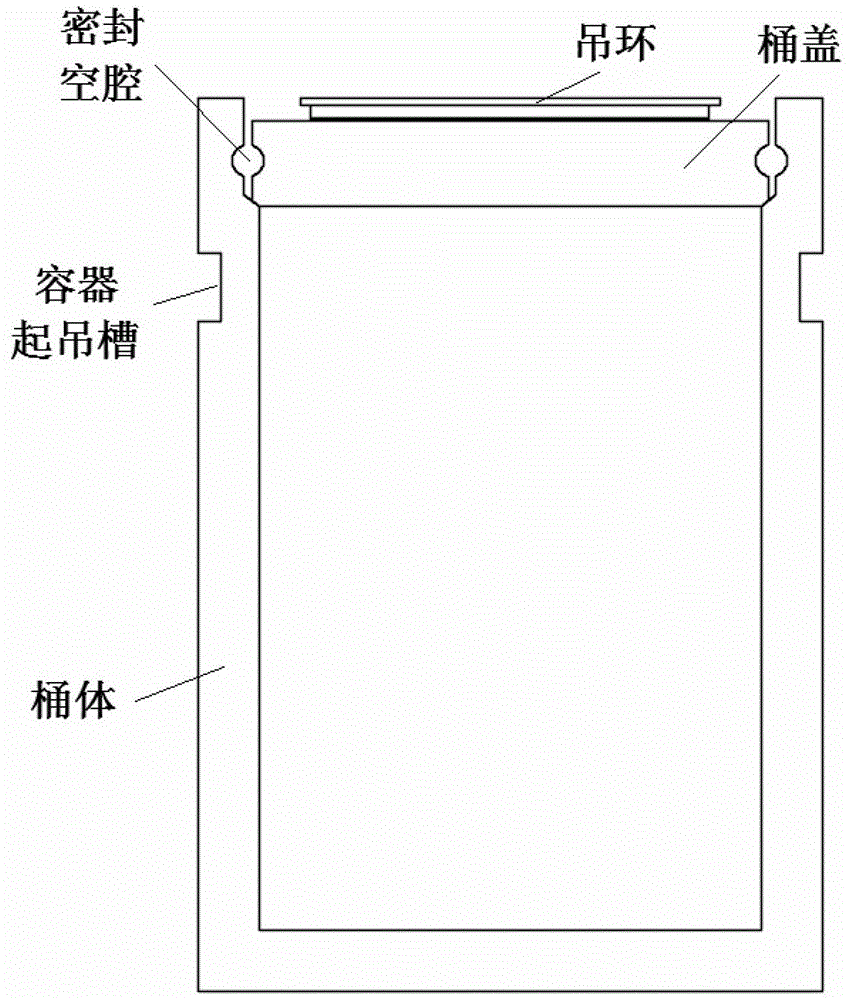

High-integrity container sealing material and its preparation method and application

ActiveCN103193439BHigh bonding strengthSmall shrinkageRadioactive decontaminationTO-18High integrity

The invention discloses a sealing material for a container with high integrity and a preparation method as well as an application thereof. The sealing material comprises 78.4 to 117.6 parts of cement, 2.96 to 18.4 parts of polymer emulsion, 80 to 120 parts of sand, 6.85 to 21.35 parts of water, 0.24 to 1.2 parts of water reducing agent, 1.6 to 19.2 parts of swelling agent and 0.44 to 2.76 parts of curing agent. The sealing material is high in denseness strength, high in fluidity, free of shrinkage, high in irradiation resistance and high in durability. The sealing material is grouted into a sealing cavity between a barrel cover and a barrel body of the container with the high integrity by using an air pressure grouting method. After the sealing material is hardened, the barrel cover and the barrel body of the container with the high integrity can be combined to form the whole structure, so that nuclear waste materials in the container cannot leak within 300 years. The sealing material can be applied to the fields of nuclear waste treatment and building structure restoration.

Owner:CHINA BUILDING MATERIALS ACAD

Concrete admixture suitable for fine aggregate as tunnel hole slag and preparation method of concrete admixture

ActiveCN114426407AConvenience to workImprove mechanical propertiesSolid waste managementVitamin CSlag

The invention provides a concrete admixture with tunnel slag as fine aggregate and a preparation method of the concrete admixture. Comprising the following components: 3.5%-5.0% of polyethylene glycol, 6.1%-9.2% of methacrylic acid, 5.5%-7.4% of acrylic acid, 0.6%-1.1% of ammonium persulfate, 0.5%-0.9% of vitamin C, 0.2%-0.4% of sodium hydroxide, 0.4%-0.8% of sodium sulfate, 0.5%-0.8% of hydrogen peroxide, 3.5%-6.0% of allyl alcohol, 7.0%-11.4% of polyoxyethylene ether, 2%-4% of mercaptoacetic acid, 1.5%-3.0% of hydroquinone, 2.4%-4.2% of phenothiazine, 0.8%-1.5% of styrene and the balance of deionized water. The invention also relates to a preparation method of the admixture. The problems that concrete with the fine aggregate being the tunnel hole slag is prone to segregation and collapse, poor in appearance quality and the like are solved, meanwhile, the performance of the concrete is effectively improved, recycling of solid waste such as the tunnel hole slag is promoted, and the concrete is simple and practical and has important practical significance and engineering application value.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD +2

anti-crack mortar

The invention discloses anti-cracking mortar, and relates to the technical field of building materials. The anti-cracking mortar is prepared from the following components of cement, fly ash, vermiculite powder, yellow sand, opal, perlite, cellulose ether, furfuryl alcohol activated clay, wood fiber and water. The anti-cracking mortar has the advantages that by determining the contents of the components, each component is ensured to reach the optimum synergistic effect; especially under the synergistic action of the furfuryl alcohol activated clay, the multiple properties of water seepage prevention, shock resistance, abrasion resistance, water reduction, freezing resistance, cracking resistance and the like are simultaneously realized.

Owner:咸阳恒鼎商用混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com