Masonry, plastering mortar plasticizer and preparation method

A plastering mortar and plasticizer technology, applied in the field of construction, can solve the problems of high cost and environmental pollution, and achieve the effects of low cost, high bonding strength and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

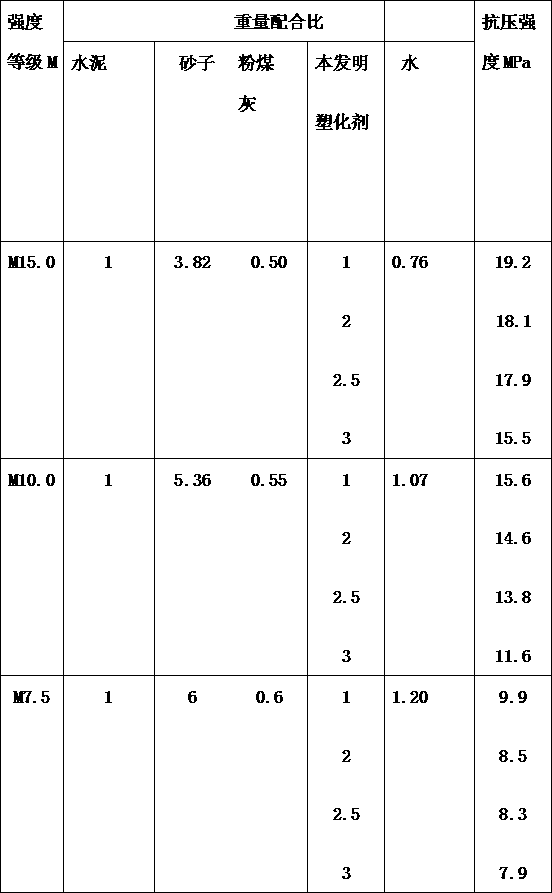

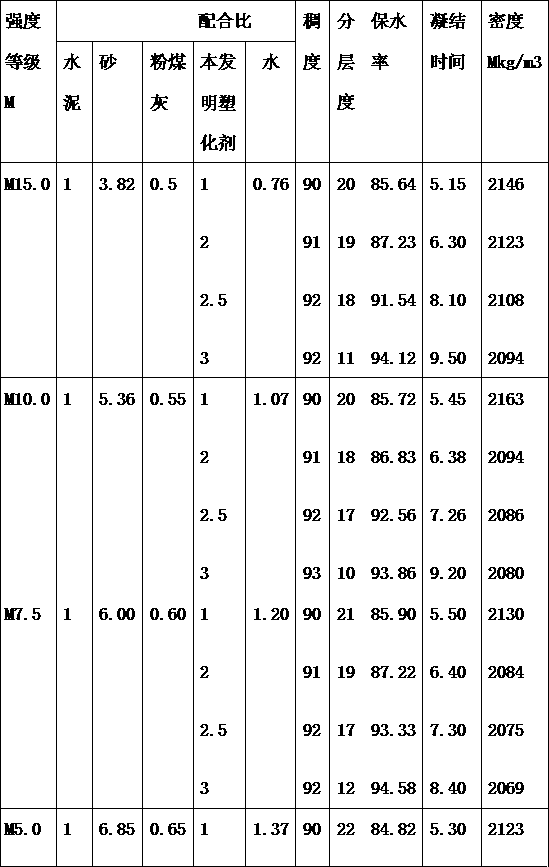

Examples

Embodiment 1

[0011] Example 1 A plasticizer for masonry and plastering mortar. The composition and weight ratio of the plasticizer are rosin: sodium hydroxide: polyvinyl alcohol: water = 10:1: 10:90; said rosin is a first-grade product for industrial use; sodium hydroxide is an industrial grade.

[0012] A kind of masonry provided by the invention, the preparation method of plastering mortar plasticizer is as follows:

[0013] According to the weight ratio of rosin: sodium hydroxide: water is 10:1:10, add water and sodium hydroxide into the water bath and heat to 60°C, then add rosin powder with a particle size of 1mm evenly; according to polyvinyl alcohol: The weight ratio of water is 10:80, add polyvinyl alcohol and water, until the rosin is completely dissolved and become a light yellow thick body, continue to boil for 2 hours, and condense into a dark brown paste.

[0014] Usage: (1) According to the weight ratio of plasticizer and water of 1:10, dilute the plasticizer for masonr...

Embodiment 2

[0015] Example 2 A plasticizer for masonry and plastering mortar. The composition and weight ratio of the plasticizer are rosin: sodium hydroxide: polyvinyl alcohol: water = 8:1: 12:80; said rosin is a first-grade product for industrial use; sodium hydroxide is an industrial grade.

[0016] A kind of masonry provided by the invention, the preparation method of plastering mortar plasticizer is as follows: press rosin: sodium hydroxide: the weight ratio of water is 8:1: 10, water, sodium hydroxide are added in the water-bath pot and heated to 60°C, then add rosin powder with a particle size of 1mm evenly; according to the weight ratio of polyvinyl alcohol:water of 12:70, add polyvinyl alcohol and water, until the rosin is completely dissolved and becomes a light yellow thick body, continue to boil for 2 Hours, condensed into a dark brown paste. The rest are the same as in Example 1

Embodiment 3

[0017] Example 3 A plasticizer for masonry and plastering mortar. The composition and weight ratio of the plasticizer are rosin: sodium hydroxide: polyvinyl alcohol: water = 12:1: 8:120; said rosin is a first-grade product for industrial use; sodium hydroxide is an industrial grade.

[0018] A kind of masonry provided by the invention, the preparation method of plastering mortar plasticizer is as follows: press rosin: sodium hydroxide: the weight ratio of water is 12:1: 15, water, sodium hydroxide are added in the water bath pot and are heated to 60°C, then add rosin powder with a particle size of 1mm evenly; according to the weight ratio of polyvinyl alcohol:water of 8:105, add polyvinyl alcohol and water, until the rosin is completely dissolved and becomes a light yellow thick body, continue to boil for 2 Hours, condensed into a dark brown paste. The rest are the same as in Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com