Multifunctional cement hydration thermal regulation and control material and preparation method thereof

A technology of cement hydration and heat regulation, which is applied in the field of admixtures in the field of chemical building materials, multi-functional cement hydration heat regulation materials and its preparation, can solve the problems of increasing equipment and site investment, inconvenience of concrete production, etc., and achieves improved convenience. Sexuality, wide applicability, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

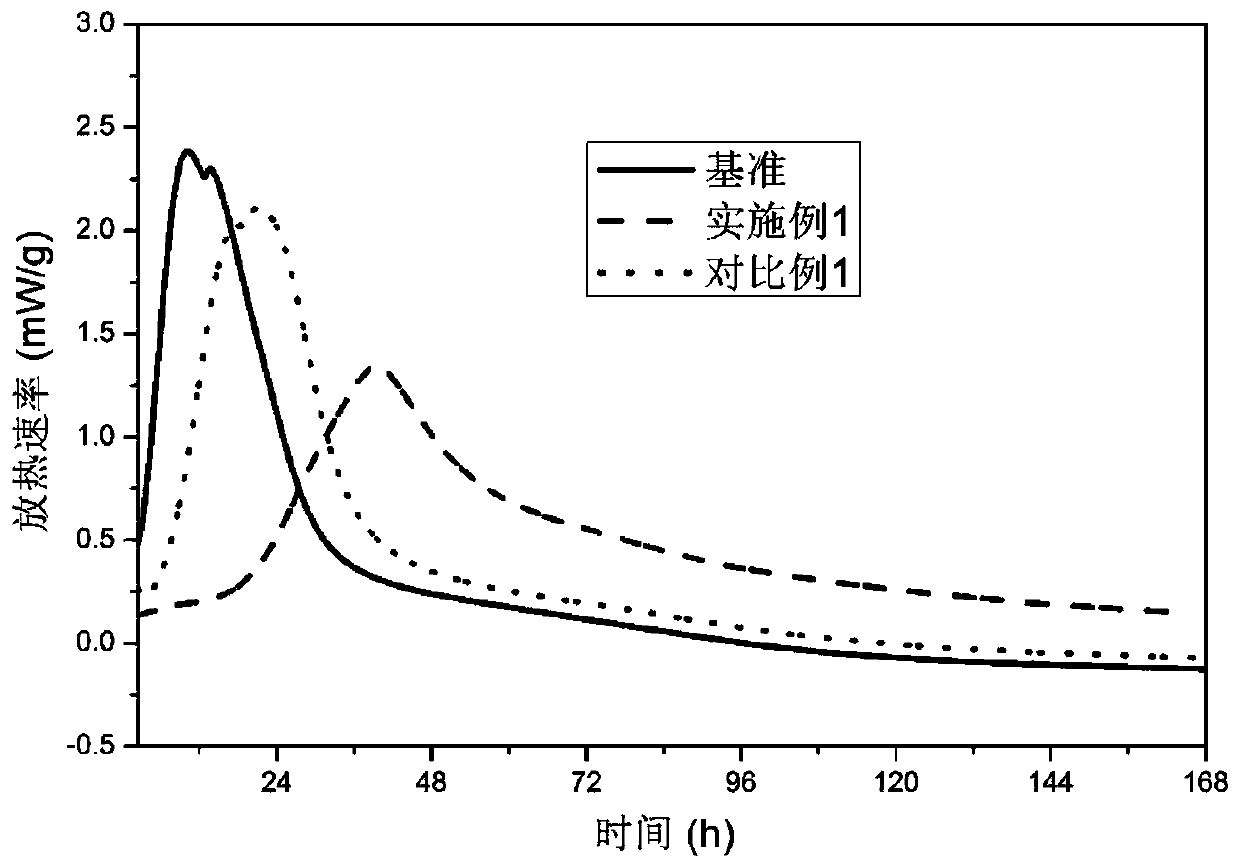

Embodiment 1

[0032] 1) Preparation of monomer B 1 : 0.1mol (11.4g) allyl glycidyl ether and 0.1mol of mannitol are blended, and a ring-opening addition reaction occurs under the action of a basic catalyst at a high temperature to obtain 0.1mol of mannitol-based monomer B 1 . 2) Preparation of multifunctional cement hydration heat control material: 0.1mol of the above monomer B 1 , 0.1mol of methacrylic acid (monomer A 1 , R 1 is methyl) and 0.2mol of polyethylene glycol monoallyl alcohol ether (monomer C 1 , weight average molecular weight about 500, n=10, m=0) and mercaptoethanol accounting for 0.5% of the total mass of the three monomers to make an aqueous solution, vacuumize and replace with nitrogen several times, heat up to 80°C, and add dropwise under stirring The ammonium persulfate aqueous solution was kept warm for 2 hours after the dropwise addition, then cooled to room temperature, and neutralized by adding alkali to a pH value of 7.4 to obtain a multifunctional cement hydra...

Embodiment 2

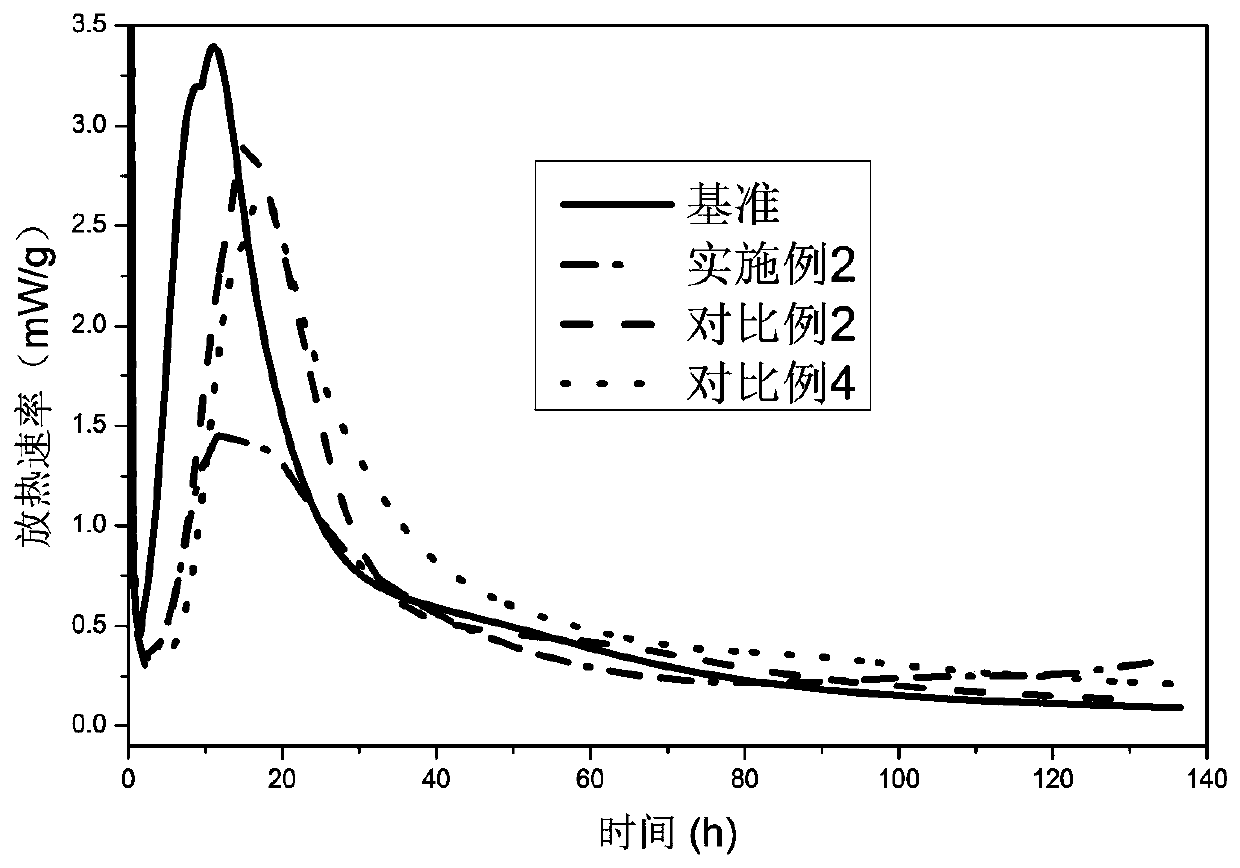

[0034] 1) Preparation of monomer B 2 : Blending 0.1mol (11.4g) allyl glycidyl ether with 0.05mol sorbitol and 0.05mol lactitol, a ring-opening addition reaction occurs under the action of a basic catalyst at high temperature to obtain 0.1mol sugar Alcohol-based monomer B 2 . 2) Preparation of multifunctional cement hydration heat control material: 0.1mol of the above monomer B 2 , 0.2mol of sodium acrylate (monomer A 2 , R 1 Is H), 0.25mol of polypropylene glycol ethylene glycol monoprenol ether (monomer C 2 , weight average molecular weight about 5000, n=86, m=20), mercaptoethanol accounting for 1.0% of the total mass of the three monomers and 0.5% hydrogen peroxide to make an aqueous solution, vacuumize and replace with nitrogen several times, then heat up to 40°C, Add dropwise an aqueous solution of ascorbic acid in an equimolar amount to hydrogen peroxide under stirring, keep warm for 2 hours after the dropwise addition, and then cool to room temperature to obtain a m...

Embodiment 3

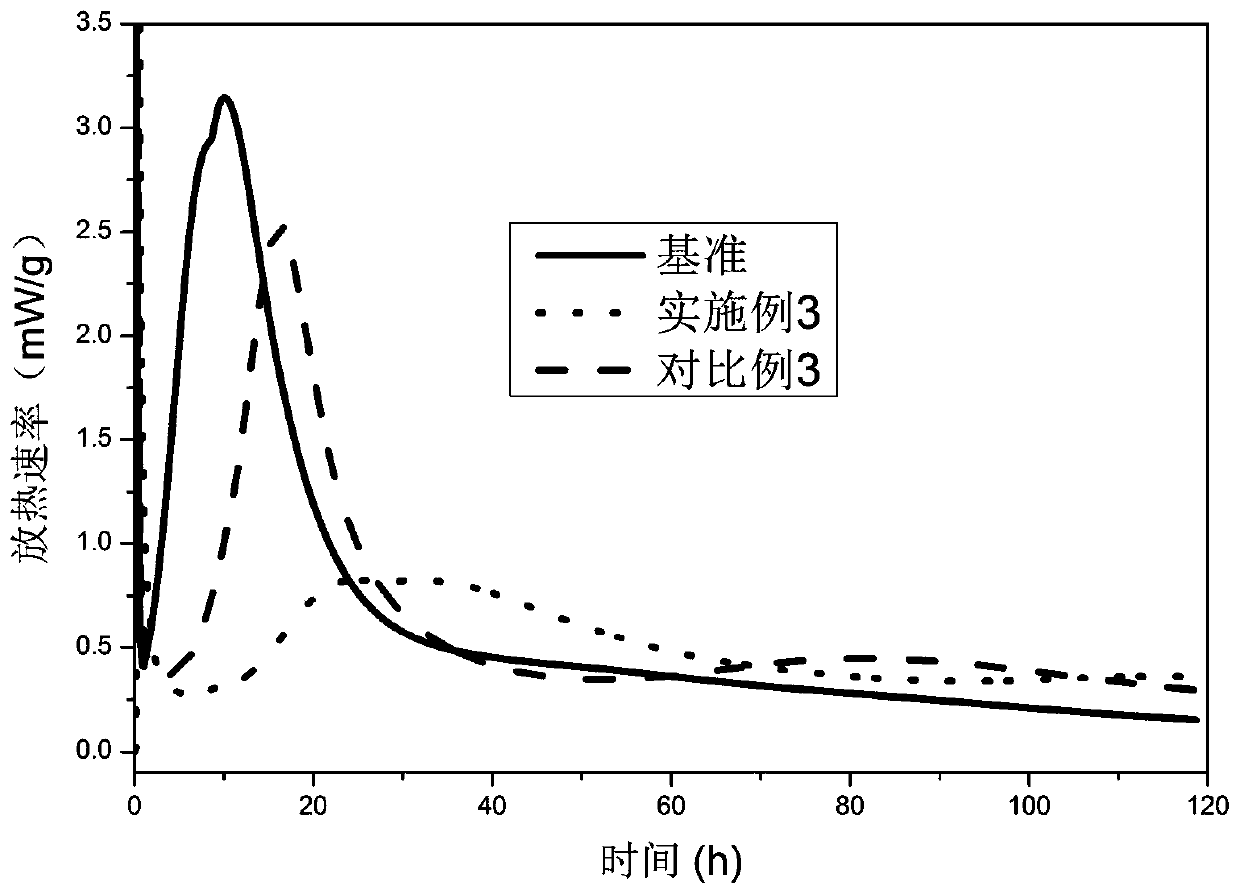

[0036]1) Preparation of monomer B 3 : 0.1mol (11.4g) allyl glycidyl ether, 0.02mol mannitol, 0.02mol xylitol and 0.06mol maltitol are blended, and a ring-opening addition reaction occurs under the action of a basic catalyst at a high temperature to obtain 0.1mol sugar alcohol-based monomer B 3 . 2) Preparation of multifunctional cement hydration heat control material: 0.1mol of the above monomer B 3 , 0.05mol of acrylic acid and 0.01mol of potassium methacrylate (monomer A 3 , R 1 is methyl), 0.05mol of polypropylene glycol monoisobutenol ether (monomer C 3 , weight average molecular weight about 1000, n=0, m=16) and 0.2% mercaptoacetic acid accounting for the total mass of the three monomers to prepare an aqueous solution, vacuumize and replace with nitrogen several times, heat up to 80°C, and add dropwise over The sodium sulfate aqueous solution was kept warm for 2 hours after the dropwise addition, and then cooled to room temperature, and neutralized by adding alkali t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com