Calcium-magnesium composite expansion clinker, preparation method thereof and application of calcium-magnesium composite expansion clinker in low-shrinkage and high-crack-resistance marine mass concrete

A technology of expansive clinker and composite expansive agent, which is applied in the direction of cement production, etc., can solve the problems of difficulty in improving the crack resistance of concrete, rising prices, and complex processes, so as to improve the mechanical properties in the later stage, reduce invalid expansion, and make the preparation process simple and easy line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0105]The performance test results of the low-shrinkage, high-crack-resistant marine mass concrete (C30) prepared by Examples 4 to 6, Reference Example 2, and Comparative Example 4 are shown in Table 5 below:

[0106] table 5

[0107]

[0108] Remarks: In the 28d autogenous volume deformation at 20°C, "-" means the concrete is in a shrinking state, and "+" means that the concrete is in an expanding state.

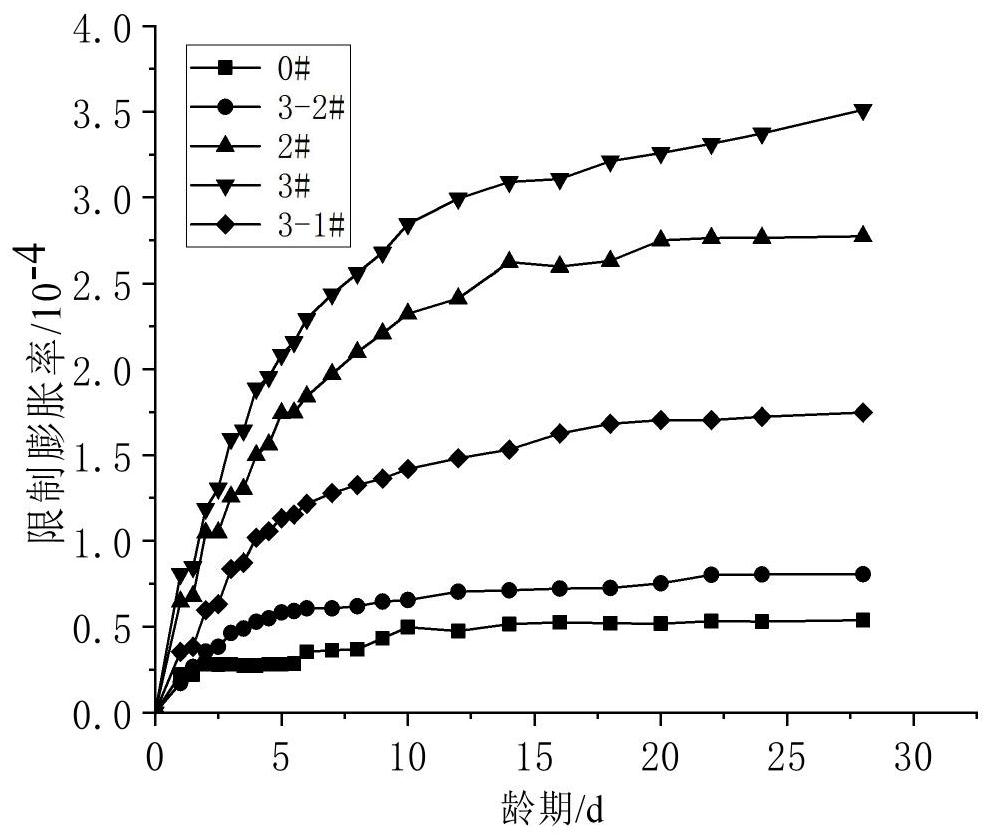

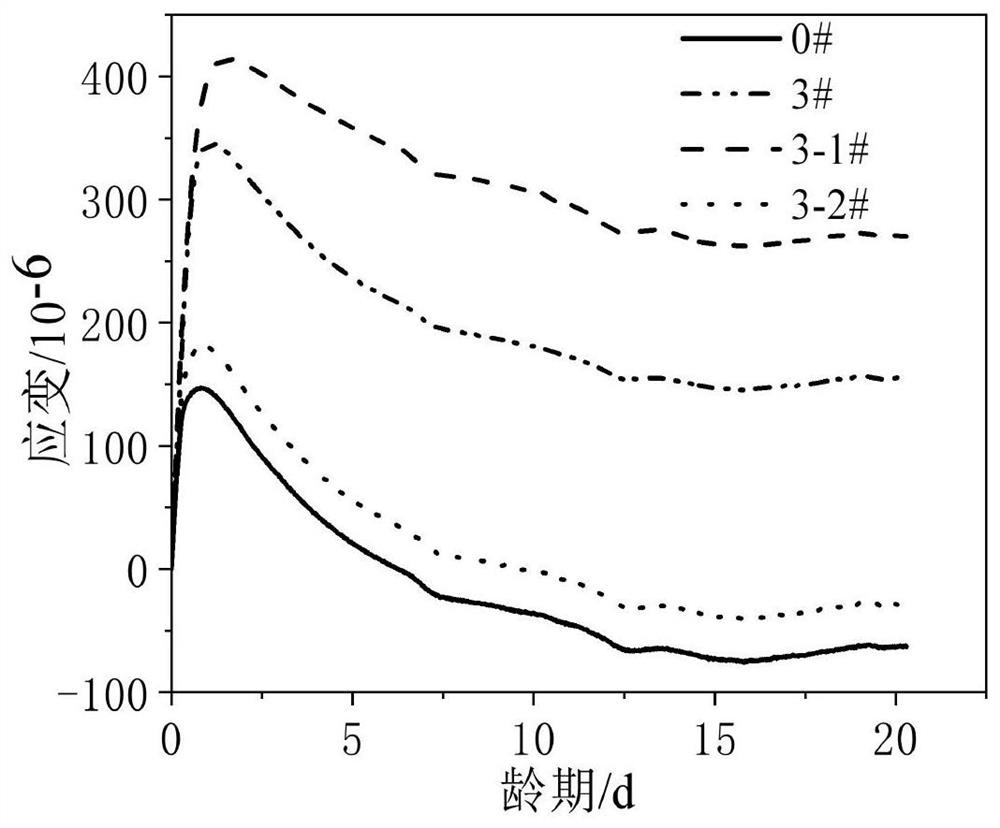

[0109] With the addition of the prepared calcium-magnesium composite expansion agent, compared with the same strength grade, that is, the standard example 2 ordinary marine mass concrete and the concrete obtained by using the commercially available expansion agent (comparative example 4 (6-1#)), The concrete prepared by the invention has good working performance (slump / expansion), volume stability (28d autogenous volume deformation, 60d drying shrinkage deformation) and impermeability and anti-corrosion grades. The marine bulk concrete prepared by the invention has low ...

Embodiment 3

[0148] The experimental results of Example 3 and Comparative Example 2 show the important role of alumina in the system of this invention, and the free calcium oxide produced by the decomposition of alumina and dolomite is fully reacted to generate monocalcium dialuminate (CA). 2 ), directional melting and wrapping on the surface of the free calcium oxide of the calcareous expansion component produced by the decomposition of dolomite to form monocalcium dialuminate melt-wrapped minerals, which can better reduce the ineffective expansion of the calcareous expansion component in the plastic stage and improve the calcium The expansion performance of the mass expansion component improves the later mechanical properties of the cement-based material mixed with the expansion agent; the solid-phase reaction between alumina and free barium oxide particles forms an inclusion of barium aluminate wrapped around the barium oxide, which improves the expansion of the expansion agent. efficacy...

Embodiment 7

[0149] The experimental results of Example 7 and Comparative Example 6 show that in the presence of anhydrite, the barium hydroxide and anhydrite crystals formed by the hydration of barium oxide and barium aluminate act to block the internal pores of the concrete and improve the performance of the concrete. Corrosion resistance of ; Ba in surface concrete 2+ Compatible with SO in seawater 4 2- The ions combine to form an insoluble barium sulfate crystal protective layer, which effectively improves the resistance to sulfate corrosion; and the barium sulfate (barite) formed in the concrete system has certain radiation protection properties.

[0150]The radiation-proof calcium-magnesium composite expansion agent for concrete provided by the invention and the preparation method thereof, compared with the resource origin limitation of magnesite, the raw material of the magnesia expansion component of the existing calcium-magnesium composite expansion agent, the invention makes ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com