Concrete complex additive

A technology for compounding admixtures and concrete compositions, applied in the field of concrete admixtures, can solve a single problem, and achieve the effects of improving strength and friction resistance, excellent waterproof performance, and enhancing impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

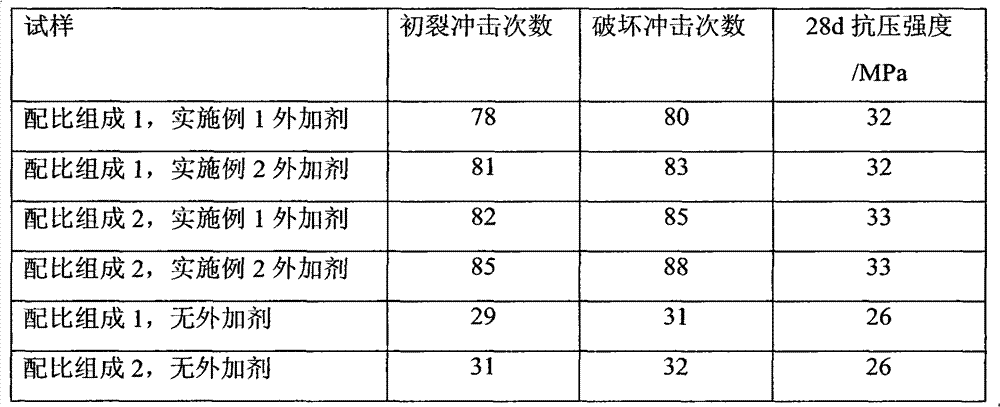

Examples

Embodiment 1

[0022] Preparation of admixture 1 of the present invention

[0023] Methacrylic acid / methyl acrylate copolymer: 22.5wt%, Amide: 28.5wt%, Octyltriethoxysilane: 0.75wt%, Polymethyltriethoxysilane: 0.25wt%, Silicone reinforcement (e.g. C 12 h 25 N(EO) 7 (PO) 5 H): 1.2wt%, polyacrylamide: 7.5wt%, triethanolamine: 1.2wt%, sodium nitrite: 3.2wt%, ethylene glycol: 0.5wt%, glycerol: 0.8wt%, sodium gluconate: 3.2 wt% and balance water.

Embodiment 2

[0025] Preparation of admixture 2 of the present invention

[0026] Methacrylic acid / methyl acrylate copolymer: 26.5wt%, Amide: 18.5wt%, Octyltriethoxysilane: 0.6wt%, Polymethyltriethoxysilane: 0.2wt%, Silicone reinforcement (e.g. C 12 h 25 N(EO) 7 (PO) 5 H): 1.8wt%, polyacrylamide: 12.5wt%, triethanolamine: 1.5wt%, sodium nitrite: 3.5wt%, ethylene glycol: 0.75wt%, glycerol: 0.8wt%, sodium gluconate: 3.8 wt% and balance water.

Embodiment 3

[0028] Concrete is prepared by using cement, water, fine aggregate, coarse aggregate and the compound admixture of the present application.

[0029] First, the essential components of the concrete composition of the present invention will be described.

[0030] Relative to the mass of cement, the amount of the above-mentioned composite admixture is preferably not less than 0.05wt%, but not more than 2.2wt%. When the added amount is less than 0.25wt%, satisfactory performance cannot be obtained, and when a high amount of more than 2.2wt% is used, the obtained effect will be basically saturated, and economic disadvantages may be borne. More preferably, the added amount is not more than 1.5wt%, not less than 0.15wt%. The above-mentioned admixtures can be mixed in the above-mentioned additive amount, and the addition in this form will produce various beneficial effects, such as reducing the unit moisture content, increasing strength and improving durability, frost resistance, imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com