Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "With quick drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-component water-based polyurethane high-abrasion-resistance matte varnish and preparation thereof

InactiveCN102533077AReduce glossOvercome the disadvantage of uneven mattingPolyurea/polyurethane coatingsEpoxyAcrylic resin

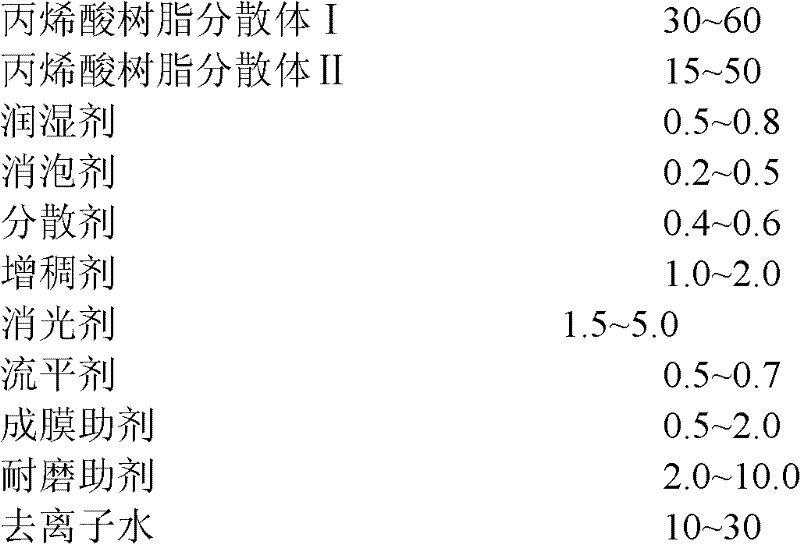

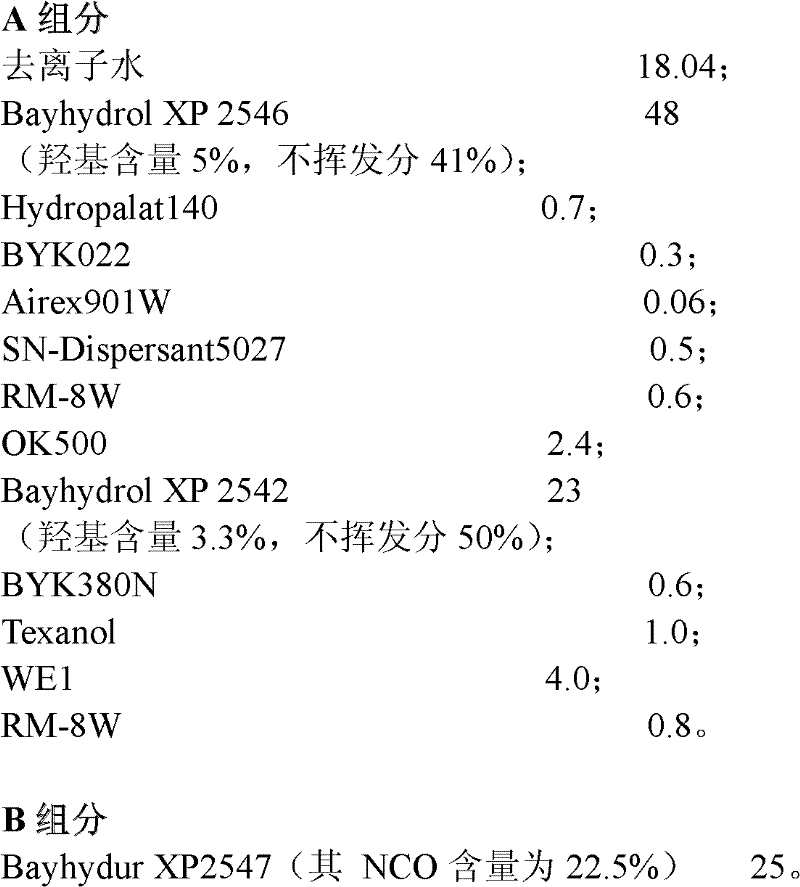

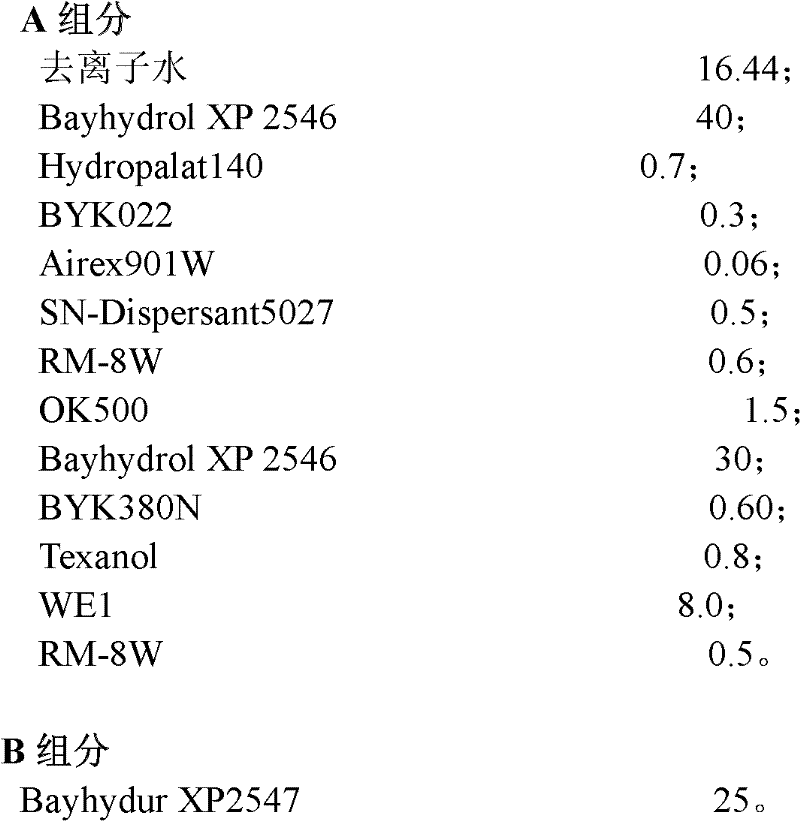

The invention discloses a double-component water-based polyurethane high-abrasion-resistance matte coating and a preparation thereof. The coating comprises two components A and B, wherein the component A is prepared by using an acrylic resin dispersion body as a basic component and adding deionized water, a wetting agent, a defoaming agent, a dispersing agent, a thickening agent, a delustering agent, a leveling agent, a film forming additive and a water resistant additive to the acrylic resin dispersion body to disperse the acrylic resin dispersion body; and the component B is aliphatic polyisocyanate. The invention provides a water-based matte coating with low VOC (Volatile Organic Compounds), low gloss, good adhesion force, wear resistance and corrosion resistance; and the water-based matte coating can be very well combined with a water-based or solvent type epoxy resin floor coating and a polyurethane floor coating. The water-based matte coating disclosed by the invention has the advantages of low delustering agent adding quantity and stability in storage; the gloss of the coating system can be effectively reduced; and the comprehensive performance of the coating system is improved. By using the double-component water-based polyurethane high-abrasion-resistance matte coating disclosed by the invention, the water-based coating system solution with environment friendliness, high performance, stability in storage and low cost can be provided.

Owner:CENT SOUTH UNIV +1

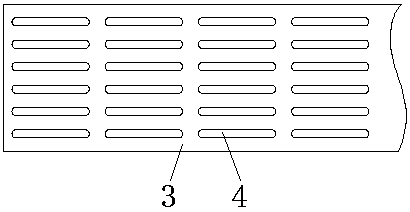

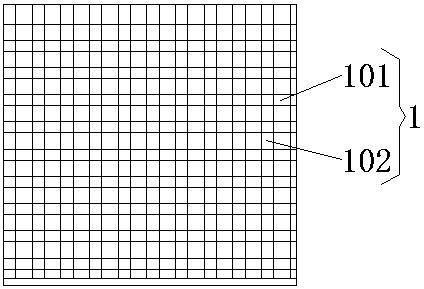

Antibacterial, moisture-absorbent and warming knitted fabric and manufacturing method thereof

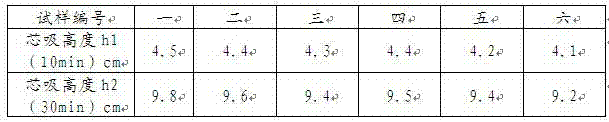

The invention discloses antibacterial, moisture-absorbent and warming knitted fabric and a manufacturing method thereof. The antibacterial, moisture-absorbent and warming knitted fabric has a double-layer structure, wherein an outer layer of the fabric has a mesh structure woven from blended yarns which are blended from cellulosic fibers and nanosilver antibacterial agent-containing profiled polyester fibers; an inner layer of the fabric has a plain structure woven from the nanosilver antibacterial agent-containing profiled polyester fibers; and the inner layer and the outer layer are connected through polyester filaments with grooved sections. The manufacturing method comprises the following steps: for the outer layer of the fabric, manufacturing the mesh structure woven from the blended yarns which are blended from the cellulosic fibers and the nanosilver antibacterial agent-containing profiled polyester fibers; for the inner layer of the fabric, manufacturing the plain structure woven from the nanosilver antibacterial agent-containing profiled polyester fibers; and connecting the inner layer and the outer layer through the polyester filaments with the grooved sections. The antibacterial, moisture-absorbent and warming knitted fabric can meet requirements on moisture absorption for quick drying as well as wearing comfort, can meet an increasingly strong requirement on antibacterial sanitation and has a good warming effect.

Owner:SHANGHAI JIALE

Socks and preparing method thereof

The invention relates to a pair of socks and a preparing method thereof, in particular to the socks which can meet the requirement of thermal-wet comfort and have an anti-pilling function, and the preparing method of the socks. Sock heads and sock roots are made of bamboo fiber, cotton, special-shaped cross section polyester fiber, nylon and spandex, sock bodies are made of bamboo fiber, cotton, special-shaped cross section polyester fiber and spandex, wherein the materials are weighed in percentage by mass: the special-shaped cross section polyester fiber is 10-50%, the cotton is 5-60%, the bamboo fiber is 10-50%, and the spandex is 1-5%,the sock bodies comprise sock surfaces and sock soles at the bottoms of the sock surfaces, the diameters of capillary tubes in the materials are gradually reduced along the direction from the sock soles to the sock surfaces, the sock soles are of multi-layer eyed structures and comprise outer layers, middle layers and inner layers, the inner layers are used for being directly contacted with the skin and are blended yarns of special-shaped cross section polyester fiber and spandex, and the middle layers or / and the outer layers are blended yarns of special-shaped cross section polyester fiber, cotton, bamboo fiber and spandex. The socks have excellent thermal-wet comfort and the anti-pilling function.

Owner:HEYE HEALTH TECH CO LTD

Waterborne bi-component bright white finish and application thereof

InactiveCN105505167AGood water resistanceEnergy savingPolyurea/polyurethane coatingsIsocyanateDefoaming Agents

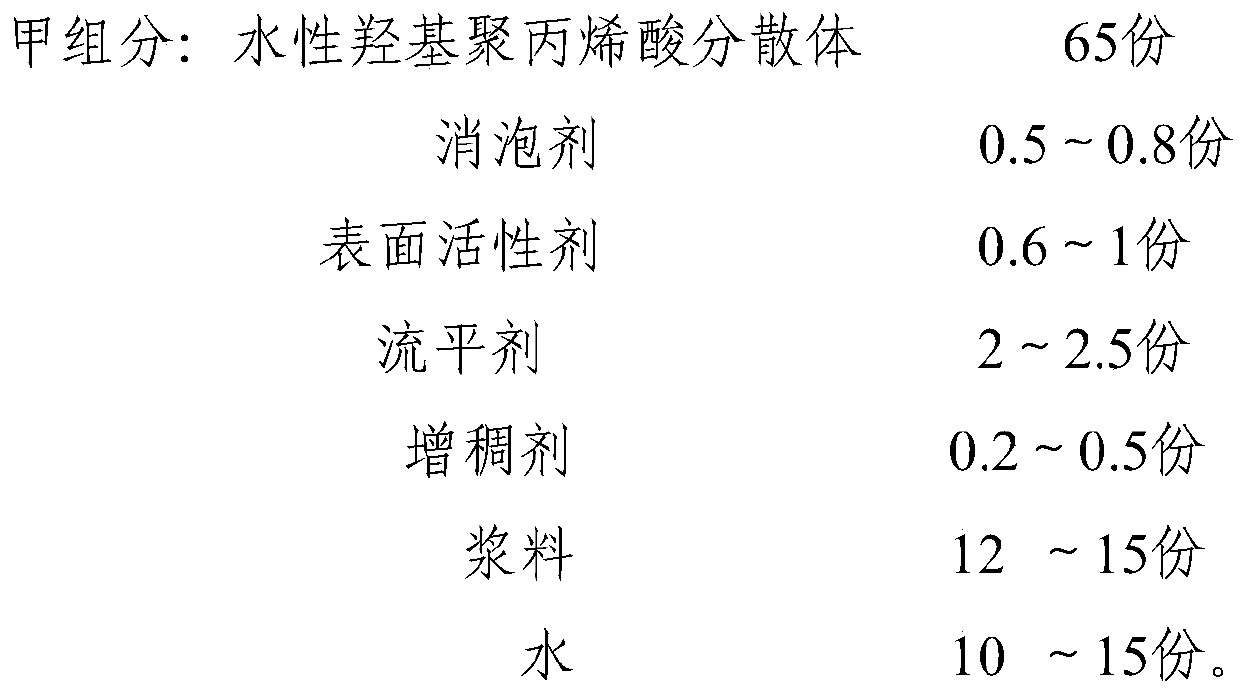

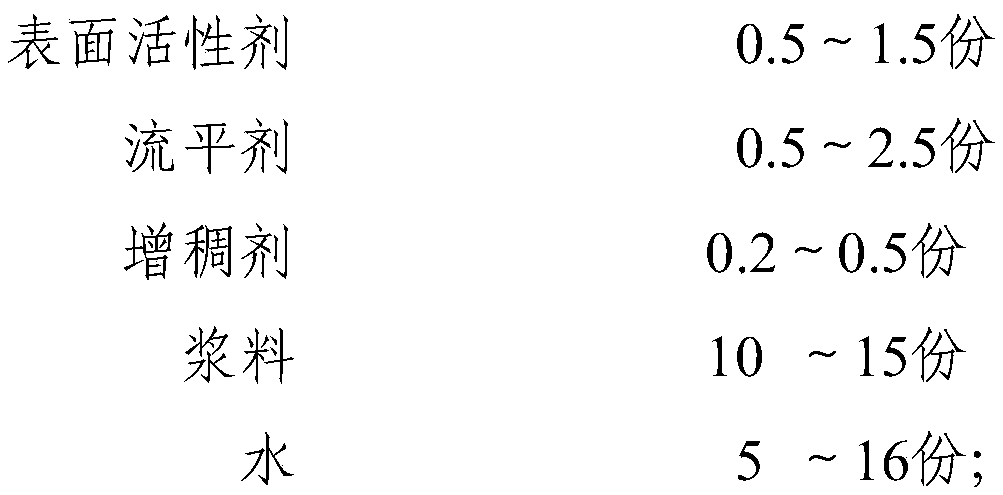

The invention provides waterborne bi-component bright white finish. The waterborne bi-component bright white finish is prepared from, by weight, a component A and a component B. The component A is prepared from, by weight, 60-70 parts of waterborne hydroxyl polyacrylic acid dispersions or waterborne modified acrylic resin, 0.4-1 part of defoaming agent, 0.5-1.5 parts of surface active agent, 0.5-2.5 parts of flattening agent, 0.2-0.5 part of thickening agent, 10-15 parts of sizing agent and 5-16 parts of water. The component b is prepared from, by weight, hydrophilic aliphatic series aliphatic series. The weight ratio of the component A and the component B is 100:(14-25), wherein the preferential weight ratio is 100:(14-20). The waterborne bi-component bright white finish is excellent in materialization, high in fullness, gloss and construction performance, strong in adhesive force and long in constructability time. Most importantly, health of constructors can not be hurt, and the waterborne bi-component bright white finish is a waterborne environment-friendly product.

Owner:BEIJING ZHANCHEN CHEM +5

Low alkali high-strength cement

The invention relates to a low-alkali high-strength cement comprising the following clinker components (by weight parts), C4A3S 20-30 parts, C2S 20-30 parts, C3S 15-30 parts, CaSO4 5-15 parts, C4AF 5-10 parts, C3A 2-5 parts, the cement may also contain CaCO3 5-10 parts or / and SiO2 t-10 parts as additives.

Owner:王红

Quick-drying alkyd resin for double-component polyurethane primer

ActiveCN102311542ALow in Vegetable Oleic AcidShort oilPolyurea/polyurethane coatingsBenzoic acidVegetable oil

The invention discloses a quick-drying alkyd resin for a double-component polyurethane primer for a wooden ware compatible with a polyurethane curing agent. The quick-drying alkyd resin comprises the following raw materials in parts by weight: 8-10 parts of monoacid, 9-11 parts of semidry vegetable oil acid, 0.5-1 part of maleic anhydride, 22-28 parts of phthalic anhydride, 4-6 parts of benzoic acid, 11-15 parts of pentaerythritol, 2-5 parts of trimethylolpropane, 6-9 parts of diglycol, 20-25 parts of dimethyl benzene and 5-8 parts of toluene. The quick-drying alkyd resin for the double-component polyurethane primer for the wooden ware has the characteristics of high drying speed, superior transparency, excellent rubbing property, high cost performance and the like, and also has high intermiscibility with the dimethyl benzene.

Owner:SKSHU PAINT

Organic silicon wrapped fluorescent powder for light emitting coating and preparation method and application thereof

ActiveCN103436249AResistant to hydrolysisReduce loss of luminescent propertiesLuminescent paintsEmulsion paintsWater basedAlcohol

The invention relates to organic silicon wrapped fluorescent powder for a light emitting coating and a preparation method thereof, and further relates to an application of the organic silicon wrapped fluorescent powder in the light emitting coating. The organic silicon wrapped fluorescent powder is prepared by the following method: dissolving ethyl orthosilicate in mixed liquor of water and alcohol; first, adjusting the pH value to 1-2 by nitric acid, and then, adjusting the pH value to 5-7 by alkali to obtain a diluted liquid; adding fluorescent powder into the diluted liquid, and stirring and continuously adjusting the pH value to 7-8 by alkali to prepare the organic silicon wrapped fluorescent powder dispersed in the diluted liquid. The organic silicon wrapped fluorescent powder and the diluted liquid are added into the components of the light emitting coating, and a better embodiment is addition of a water-base resin film-forming material. According to the technical scheme provided by the invention, water-tolerant treatment and organic silicon wrapping are directly carried out in an aqueous phase, so that the fluorescent powder in a water-based medium has hydrolysis resistance and reduces the loss on light emitting property, the dispersibility of the fluorescent powder in the coating is improved to prevent coagulation by further improving the surface electrical property of the fluorescent powder.

Owner:武汉工大科技园发展有限公司

Polyurethane paint applied to woodworking and application thereof

InactiveCN102504682ANot easy to yellowSolve yellowingPolyurea/polyurethane coatingsOrganic solventKetone solvents

The invention discloses polyurethane paint applied to woodworking and application thereof. The polyurethane paint is used for preventing a paint film of conventional polyurethane paint sprayed on a bleached wooden ware from being yellowed. The polyurethane paint consists of components A, B and C. When the polyurethane paint is in use, the components A, B and C are mixed according to a certain ratio. The component A consists of 30 to 70 percent of hydroxy-containing alkyd resin or acrylic resin, 29 to 45 percent of organic solvent, 1 to 7 percent of zinc stearate and 0 to 18 percent of talcum powder; the component B consists of 20 to 80 percent of isocyanate curing agent and 20 to 80 percent of esters solvent; and the component C is diluent and mainly consists of one or more of an esters solvent, an arene solvent or a ketones solvent. The polyurethane primer is used on a high-end bleached furniture, is used as a primer of the bleached wooden ware and can be used for ensuring the paint film of the conventional polyurethane paint sprayed on a bleached wooden ware not to be yellowed.

Owner:GUANGDONG LANYANG SCI & TECH

Scratch resistant polyurethane woodenware glossy black finish paint

ActiveCN103937402AStrong molecular structureGood flexibilityPolyurea/polyurethane coatingsLacquerAcrylic resin

The invention relates to a preparation method of a scratch resistant polyurethane woodenware glossy black finish paint. The finish paint is composed of a resin paint component A and a curing agent component B; wherein the weight ratio of the component A to the component B is 1:0.5; the resin paint component A is composed of alkyd resin, acrylic resin, aldehyde-ketone resin, carbon black color paste, a chelating leveling agent, an antifoaming agent, an anti-settling agent, and a solvent; and the curing agent component B is composed of a TDI-HDI mixed trimer or a TDI / TMP adduct, a HDI trimer, and a solvent. The prepared finish paint has the advantages of high hardness, low viscosity, and good leveling property. The finish paint can form a membrane at a time, the membrane is thick, and no sag is generated. The paint has high gloss and a transparent crystal appearance like a black jade. The paint membrane is like a crystal, is thick and smooth, gives people a high quality sense, has a decoration effect like a mirror, and creates a fresh, grace, concise, and tranquil space. A refreshing unique feeling is created by the finished paint which is accord with the modern aesthetics, so the finish paint is welcomed by market and customers. The finish paint can be used to decorate and protect the surfaces of woodenware, metal products, and plastic products.

Owner:UNION FOSHAN CHEM +1

Water-based varnish

The invention relates to a material for construction and decoration and in particular relates to water-based varnish. The formula of the water-based varnish is as follows: 15 to 30 parts of water, 10 to 20 parts of acrylic polymers, 12 to 20 parts of titanium dioxide, 3 to 5 parts of barite powders, 5 to 15 parts of ground calcium carbonate, 3 to 5 parts of kaolin, 3 to 5 parts of mica powders, 0.4 to 0.8 parts of wetting and dispersing agents, 0.3 to 0.4 parts of a defoaming agent, 0.3 to 0.6 parts of a leveling agent, 0.5 to 2 parts of a thickener, 0.2 parts of a multifunctional auxiliary agent, 0.8 to 1 part of a film-forming agent, and 0.8 to 2 parts of a disinfectant and anti-mildew agent. The water-based varnish is made from high-quality acrylic polymers, natural mineral powders and multiple auxiliary agents and refined by the advanced production process. The water-based varnish has the characteristics of environmental friendliness, no toxicity, alkali resistance, mildew resistance, primer-coat property, crack resistance, energy saving, flame retardancy, sound insulation, moisture protection, leakage resistance, strong adhesion, high hardness and dry friction resistance.

Owner:深圳市名雕丹迪设计有限公司

Nano self-cleaning external wall paint

The invention discloses a nano self-cleaning external wall paint and a production method thereof, relating to the technical field of chemical industry. The nano self-cleaning external wall paint comprises the following components in percentage by weight: 50-55% of nano silicon resin, 15-18% of titanium white, 13-16% of ultrafine coarse whiting powder, 2-2.5% of C12 alcohol ester, 0.3-1% of sodium polycarboxylate, 0.3-1% of polyether modified siloxane, 0.6-0.8% of 2-(2-hydroxy-3,5-ditert-butyl)-5-benzotriazole chloride, 0.2-0.3% of polyoxyethylene fatty acid ester, 0.5-1% of polyacrylate, 0.1-0.2% of 1,2-benzothiazolinyl-3-one, 0.8-1% of 2-(4-thiazolyl)benzimidazole and the balance of water. The invention can solve the problems of poor pollution resistance, high pollution tendency and dissatisfactory heat insulation effect in the coating.

Owner:DRAGON FISH PAINT

Environment-friendly high-efficiency composite polishing wax and production method thereof

InactiveCN101538447ASafe preparationEasy to manufacturePolishing compositions with abrasivesParaffin waxLanolin

The invention relates to environment-friendly high-efficiency composite polishing wax for polishing metal and non-metal surfaces and a production method thereof. The composite polishing wax comprises the following raw materials by weight ratio: 65 to 75 of stearic acid, 8 to 12 of chromic oxide polishing powder, 10 to 25 of paraffin and 2 to 3.5 of lanolin. The method comprises the following steps: putting the paraffin and the stearic acid in proportional amounts into enamelware and heating to 90 DEG C 120 DEG C to melt the paraffin; adding the chromic oxide polishing powder, stirring uniformly and adding the lanolin under the stirring condition for a chemical modified complex reaction under the condition of 110 DEG C + / - 5 DEG C and the reaction time of 2h + / - 0.5h; and guiding discharge grouting to a precast die after the reaction and guiding the die into a water tank for cooling so as to be solidified into a block product. The product does not contain harmful solvent, is safe and convenient to manufacture, reduces energy consumption and does not pollute the environment, thereby being suitable for various polishing modes.

Owner:吴壮城

Special high temperature-resistant coating on outer wall of tobacco-curing furnace and preparation method thereof

InactiveCN102153947AMeet the needs of useHigh temperature resistance hasCoatingsMicrosphereTemperature resistance

The invention discloses a special high temperature-resistant coating on an outer wall of a tobacco-curing furnace, which consists of the following components according to parts by weight: 30-40 parts of organic silicon resin, 5-10 parts of aluminium paste, 8-12 parts of titanium white, 30-40 parts of mixed stuffing, 0.5-1.5 parts of organic bentonite, 2-4 parts of PM, 1-3 parts of PMA (Propylene Glycol Monomethyl Acetate), and 4-6 parts of absolute ethyl alcohol, wherein the mixed stuffing consists of the following components according to parts by weight: 35-45 parts of low-melting point glass powder, 10-20 parts of hollow ceramic microspheres, 10-20 parts of zinc phosphate, 5-15 parts of aluminum tripolyphosphate and 18-22 parts of talcum powder. The special high temperature-resistant coating on the outer wall of the tobacco-curing furnace mainly has the advantages that a viscosity number reaches 85s, the percentage of solid reaches 65%, surface dry only needs 16 minutes, hard dry only needs 6 hours, the thermal endurance is strong, and the coating is not stripped for 6h at 500 DEG C. The coating has the advantages of high temperature resistance, rust prevention, quick drying, heat insulation, environmental protection and the like, can satisfy the use requirements on the outer wall of the tobacco-curing furnace, and is especially applicable for the tobacco-curing furnace.

Owner:无锡市南雅化工有限公司

Preparation method of scratch and yellowing resistant polyurethane woodenware glossy white finish paint

ActiveCN103937400AStrong molecular structureGood flexibilityPolyurea/polyurethane coatingsKetoneSolvent

The invention relates to a preparation method of a scratch and yellowing resistant polyurethane woodenware glossy white finish paint. The finish paint is composed of a resin paint component A and a curing agent component B, wherein the weight ratio of the component A to the component B is 1:0.5; the resin paint component A is composed of alkyd resin, acrylic acid resin, aldehyde-ketone resin, titanium dioxide, a dispersant, a yellowing resistant agent, a chelating leveling agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B is composed of a TDI-HDI mixed trimer or a TDI / TMP adduct, a HDI trimer, and a solvent. The finish paint has the advantages of high paint membrane gloss, beautiful and refreshing appearance like a white jade, crystal-liked, transparent, thick and high quality paint membrane, and smooth and mirror-liked decoration effect; can create a refreshing, grace, concise and tranquil space, brings people a relaxed and happy feeling, is accord with the modern aesthetics, is welcomed by the market and customers, and is widely used to protect and decorate surfaces of woodenware, metal products, and plastic products.

Owner:UNION FOSHAN CHEM +1

Water-based varnish

The invention relates to a material for construction and decoration and in particular relates to water-based varnish. The formula of the water-based varnish is as follows: 15 to 30 parts of water, 10 to 20 parts of acrylic polymers, 12 to 20 parts of titanium dioxide, 3 to 5 parts of barite powders, 5 to 15 parts of ground calcium carbonate, 3 to 5 parts of kaolin, 3 to 5 parts of mica powders, 0.4 to 0.8 parts of wetting and dispersing agents, 0.3 to 0.4 parts of a defoaming agent, 0.3 to 0.6 parts of a leveling agent, 0.5 to 2 parts of a thickener, 0.2 parts of a multifunctional auxiliary agent, 0.8 to 1 part of a film-forming agent, and 0.8 to 2 parts of a disinfectant and anti-mildew agent. The water-based varnish is made from high-quality acrylic polymers, natural mineral powders and multiple auxiliary agents and refined by the advanced production process. The water-based varnish has the characteristics of environmental friendliness, no toxicity, alkali resistance, mildew resistance, primer-coat property, crack resistance, energy saving, flame retardancy, sound insulation, moisture protection, leakage resistance, strong adhesion, high hardness and dry friction resistance.

Owner:深圳市名雕丹迪设计有限公司

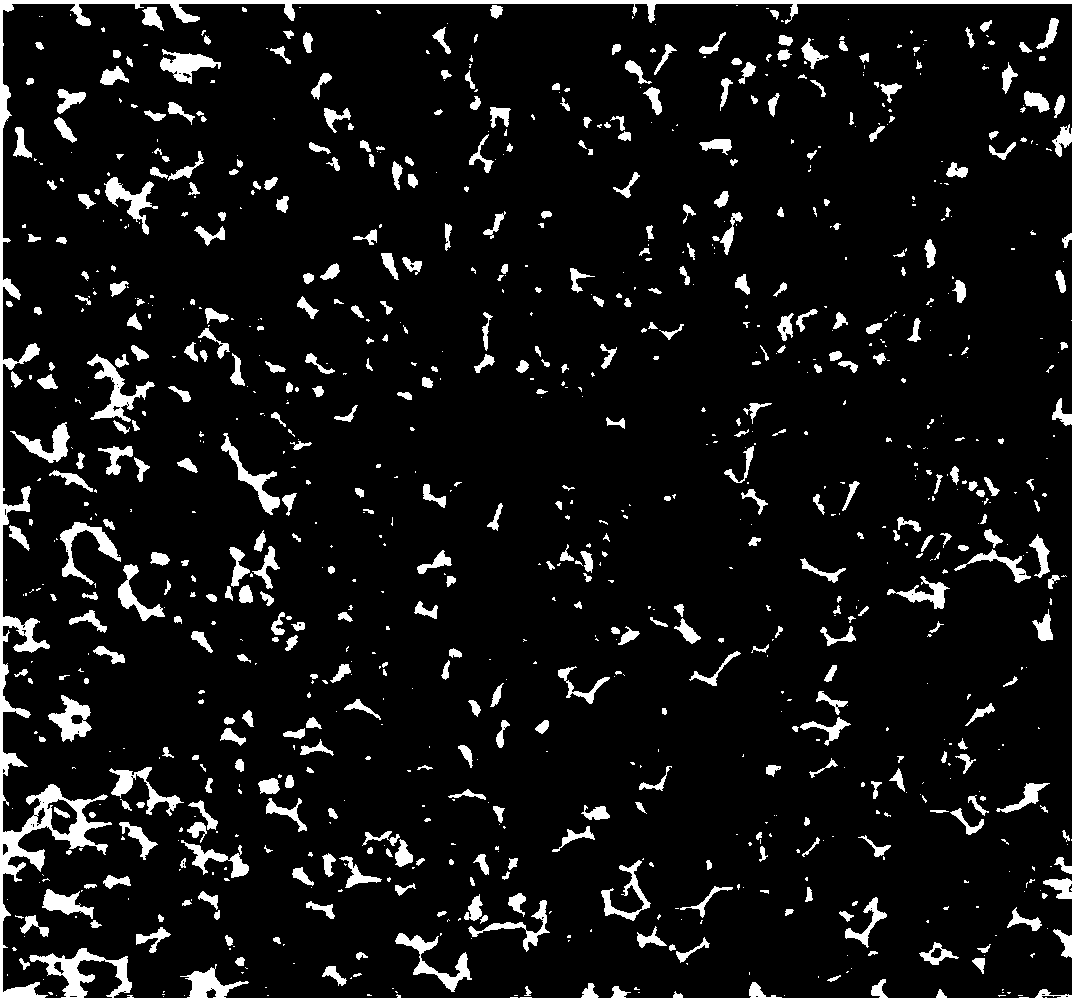

Slowly-rebounded sponge and preparation method thereof

The invention discloses a slowly-rebounded sponge. The slowly-rebounded sponge comprises the following raw materials: 20-70 parts of a slowly-rebounded polyether polyol, 20-70 parts of flexile polyether polyol foam, 0.1-0.5 part of a pore opening agent, 1-4 parts of a foaming agent, 25-48 parts of isocyanate, 0.1-0.6 part of a catalyst and 0.2-1 part of a stabilizer; and a net-shaped sponge is obtained through a reaction of the above raw materials, then blasting film-removing treatment is performed, and therefore the hydrophobic slowly-rebounded sponge with a net-shaped structure and a pore diameter of 1-5mm is obtained. According to the invention, the slowly-rebounded sponge has excellent performance of springback, loosening and softness, hydrophobicity, quick drying, air permeability andthe like, and can be washed with water, so that bacteria are not bred, and accordingly health is not affected.

Owner:周志坚

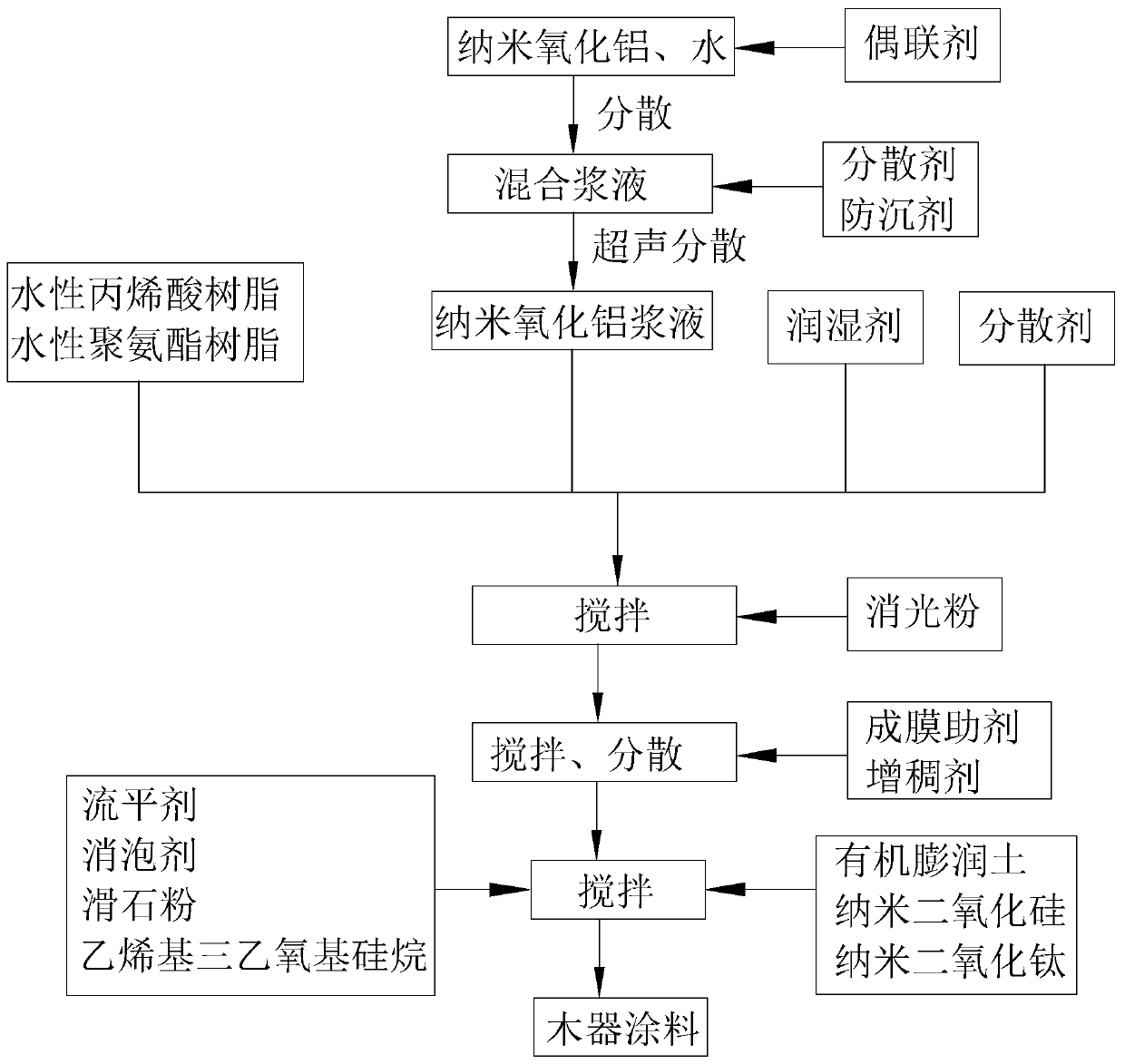

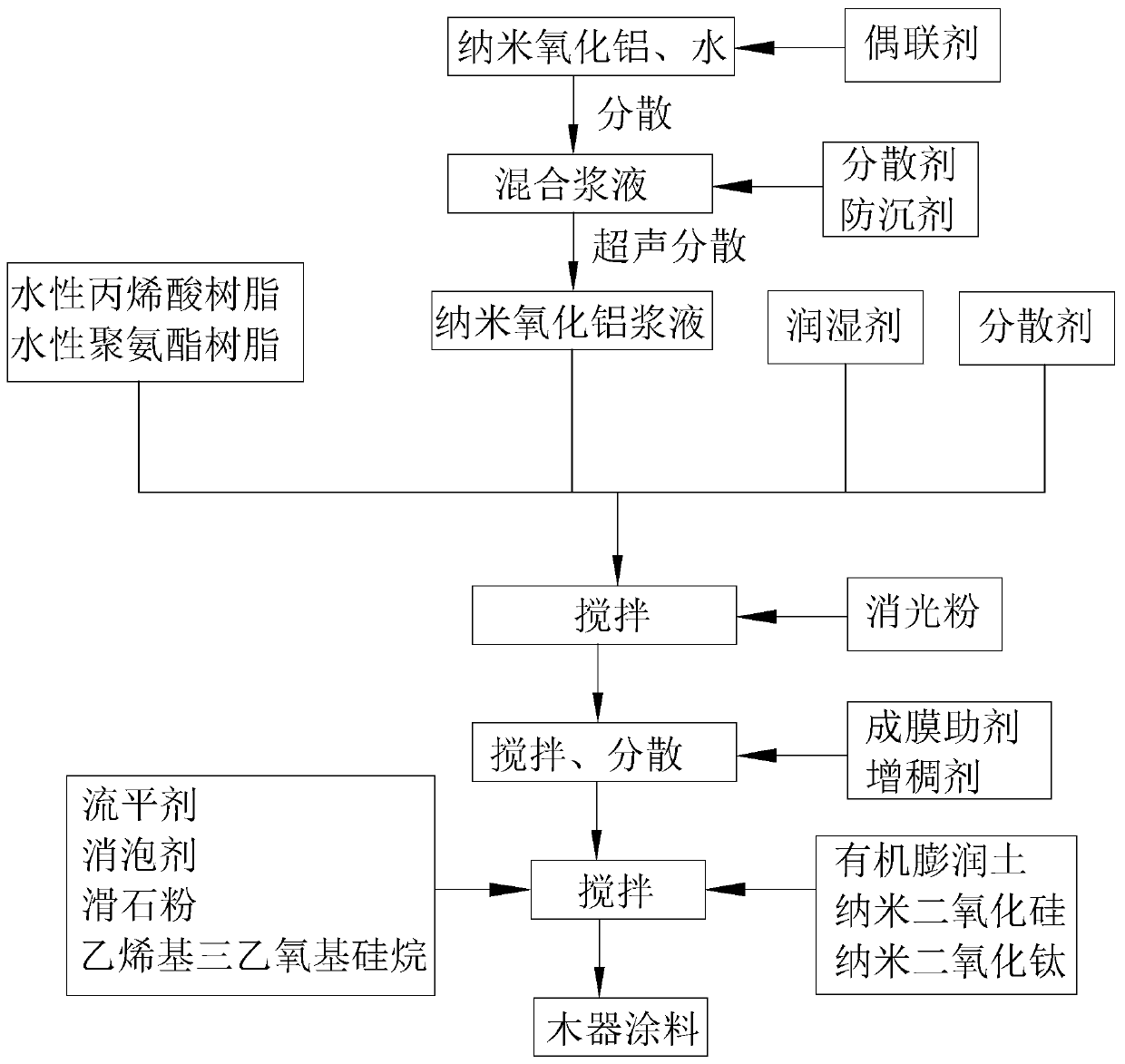

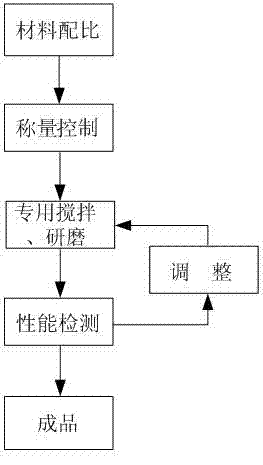

Water-based single-component wood coating and preparation method thereof

InactiveCN111171691AStrong volume effectStrong quantum size effectPolyurea/polyurethane coatingsPolymer scienceNano al2o3

The invention relates to a water-based single-component wood coating and a preparation method thereof. The water-based single-component wood coating comprises, by weight, 30-40 parts of waterborne polyurethane resin, 35-40 parts of waterborne polyurethane resin, 4-6 parts of organic montmorillonite,10-15 parts of a nano-alumina slurry, 3-5 parts of nano silicon dioxide, 1-3 parts of nano titaniumdioxide, 0.5-1 parts of a wetting agent, 0.1-0.5 part of an antifoaming agent, 6-8 parts of a coalescing agent, 0.3-0.5 part of a leveling agent, 1-2 parts of a thickener, 0.2-0.3 part of a dispersingagent, 0.4-0.8 part of talcum powder, 0.1-0.3 part of vinyltriethoxysilane and 3-5 parts of an extinction powder. The hardness of a coating film is improved, so that the wood coating is suitable forhigh-grade wood furnitures.

Owner:成都迪泰化工有限公司

Low-cost silicasol-type interior wall coating

The invention discloses a low-cost silicasol-type interior wall coating. The low-cost silicasol-type interior wall coating consists of the following components in percentage by weight: 6 to 8 percent of styrene-acrylic emulsion, 10 to 14 percent of silicasol, 2 to 6 percent of bentonite, 35 to 45 percent of titanium dioxide and wollastonite powder, 6 to 8 percent of hydroxyethyl cellulose, 6 to 8 percent of dispersing agent, 3 to 5 percent of defoaming agent, 0.05 to 0.1 percent of multi-functional aid, 3 to 8 percent of Texanol lipidol, 0.15 to 0.25 percent of antiseptic and antimildew agent, 1 to 2 percent of thickening agent and 15 to 25 percent of water. The coating provided by the invention has the hardness of inorganic coatings and certain flexibility, keeps the quick dryness and easy painting performance of organic coatings, displays the advantages of inorganic coatings and organic coatings and contributes to the performance improvement of coatings as well as cost reduction.

Owner:顾欣锋

Preparation method for environmental-protection and odorless anti-scratch polyurethane wood matt black top coat

InactiveCN104710928AAnti-scratch hasHigh hardnessPolyurea/polyurethane coatingsPigment pastesKetoneSolvent

The present invention relates to a preparation method for an environmental-protection and odorless anti-scratch polyurethane wood matt black top coat, which comprises double components A and B according to a weight ratio of 1:0.5, wherein the component A comprises a odorless anti-scratch alkyd resin, matting powder, a dispersant, a carbon black color paste, a modified leveling agent, a defoamer, an anti-sedimentation agent and a solvent, and the component B comprises TDI, a HDI trimer or a benzene-free curing agent adopting the adduct as the main component. According to the present invention, the prepared matt black top coat of the present invention does not contain aromatic hydrocarbons, aldehydes, ketones and heavy metals, and the odorless effects is achieved after the paint film is dried for 48 h; the matt black top coat has characteristics of no precipitate during storage, high solid while low viscosity, good leveling property, thick film formed in one time, no sagging, soft handfeeling, plump, delicate, solemn, rigid, soft, and full mirror-like decorative effect, and elegant and comfortable feeling, is adapted to the modern aesthetics, is popular in markets and customers, and is widely applied on the surface of wood ware, metal, plastics and other products so as to provide the protection decoration effect.

Owner:UNION FOSHAN CHEM +1

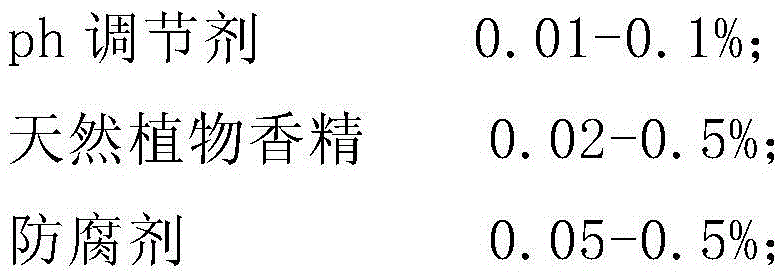

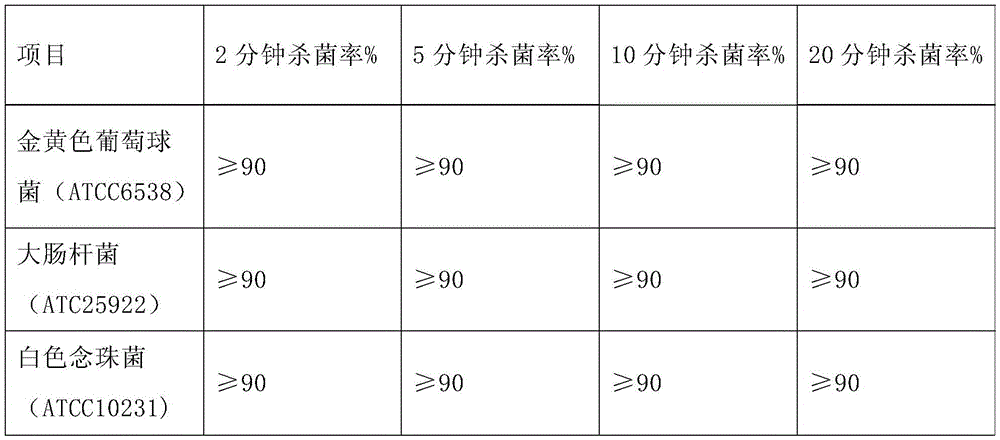

Lens cleaning towel

InactiveCN105419979AEasy maintenanceAntistatic hasDetergent materialsOrganic non-surface-active detergent compositionsAntistatic agentPreservative

The invention discloses a lens cleaning towel which comprises a base material and a cleaning agent immersed into the base material. The cleaning agent is prepared from a ph adjusting agent, a natural plant essence, preservative, anti-fog silicone oil, an antistatic agent, an assisting agent, isopropanol and deionized water. The lens cleaning towel has the advantages of resisting static electricity, preventing and killing bacteria, preventing fog, being dried rapidly, being free of mark, producing no damage to a lens, having the natural plant fragrance and the like. The service life of the lens can be effectively prolonged, and the effect of well maintaining the lens is achieved.

Owner:SHANGHAI YINJING MEDICAL SUPPLIES

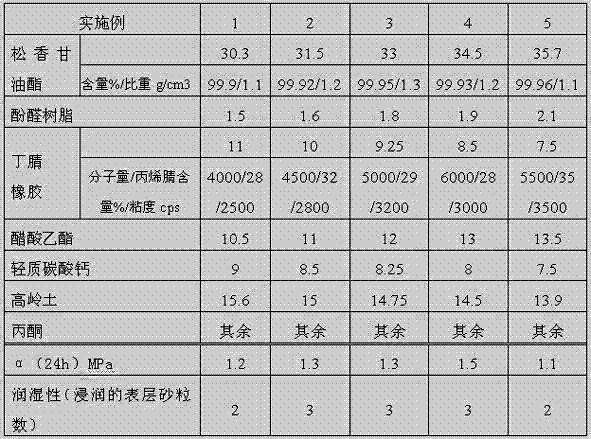

Quick-drying adhesive for casting sand mold

InactiveCN102391826AWith quick dryingShort curing timeNon-macromolecular adhesive additivesFoundry mouldsAdhesiveAcrylonitrile

The invention discloses a quick-drying adhesive for a casting sand mold, which is characterized in that the quick-drying adhesive comprises the following components by weight percent: 30.3%-35.7% of rosin glycerides, 1.5-2.1% of phenolic resin, 7.5-11% of butadiene-acrylonitrile rubber, 10.5%-13.5% of ethyl acetate, 13.9-15.6% of kaolin, 7.5-9% of light calcium carbonate and the balance of acetone. Through a large number of tests and summarization, a bonding system with short curing time and high final strength under normal temperature is developed, the auxiliary curing process step is not required, the displacement can be prevented within 15 minutes after bonding the sand mold during the use, and the bonding strength at 24 hours can be improved to above 1MPa. The quick-drying adhesive is coated on the breakage and the section of the sand mold, thereby being capable of effectively providing the bonding strength which is not lower than that of the sand mold when the sand mold is intact within a short period of time, reducing the number of damages of the sand mold during the casting production process, avoiding the repeated labor and the waste of energy and material, and improving the production efficiency.

Owner:鑫工艺(上海)材料科技有限公司

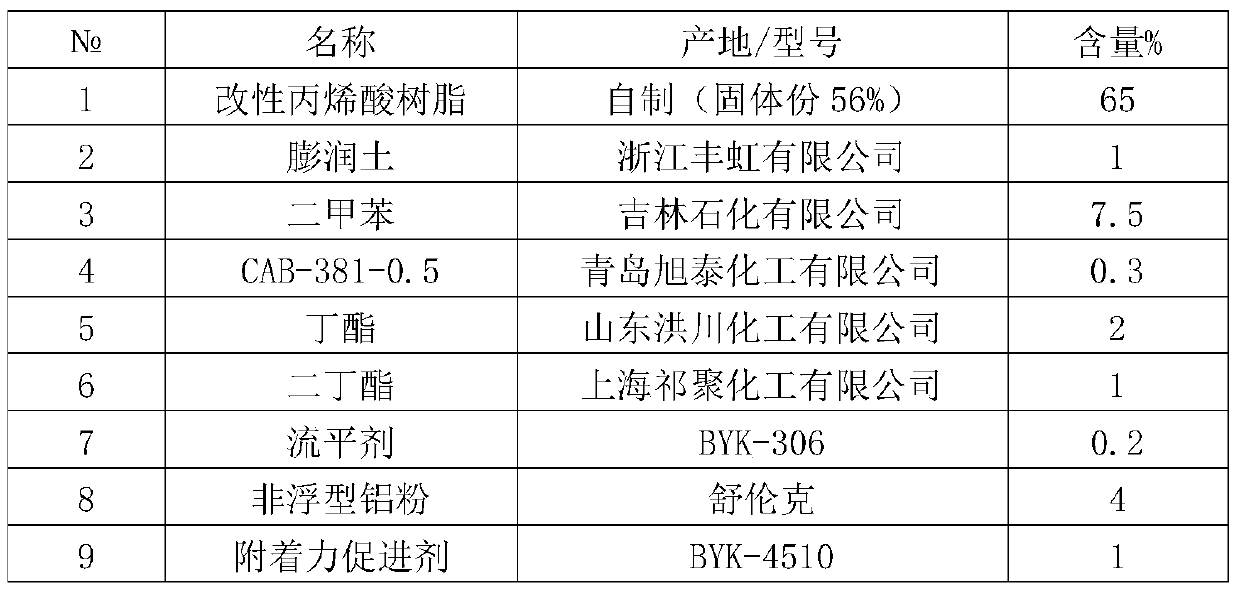

Paint special for surface of special non-ferrous metal and preparation method of paint

InactiveCN109897498AOvercome adhesionSlightly poorer corrosion resistanceAnti-corrosive paintsCelluloseMethacrylate

The invention belongs to the field of paint and particularly relates to paint special for the surface of special non-ferrous metal and a preparation method of the paint. The paint special for the surface of special non-ferrous metal comprises, by weight percentage, 65-68% of modified acrylic resin, 0.8-1.2% of bentonite, 7-11% of xylene, 0.1-0.3% of cellulose, 1-2% of butyl ester, 1-3% of dibutylester, 0.2-0.4% of leveling agent, 3-5% of non-floating type aluminum powder, 1-3% of adhesion promoter and 16-18% of toluene, wherein the modified acrylic resin is prepared by mixing butyl acetate, butyl acrylate, epoxy resin, methacrylic acid, styrene, methyl methacrylate, isopropyl methacrylate, toluene and benzoyl peroxide (BPO). The prepared paint special for the surface of special non-ferrous metal has the advantages that the paint is quick in drying and has super-high adhesion on the surface of the special non-ferrous metal, the paint film of the paint does not become sticky when meeting with heat, and the paint conforms to the national lead-free and environment-friendly regulations.

Owner:辽宁苏博特船牌制漆有限公司

Ink capable of being used for disc printing and preparation method thereof

The invention discloses ink capable of being used for disc printing and a preparation method thereof. The ink comprises the following components in parts by mass: 0.5-8 parts of water-soluble dyes, 2-15 parts of water-based resin, 5-30 parts of an organic solvent, 0.1-0.5 part of a preservative, 0.2-3 parts of surfactants, 0.1-1 part of a pH regulator, 0.05-0.5 part of a levelling agent and 40-80 parts of water, wherein the water-based resin is at least one of water-based acrylic resin and water-based styrene-acrylic resin or styrene-acrylic emulsion; the levelling agent is one of BYK345, BYK347, BYK348, BYK349, Hydropalat<(R)>140 and EFKA-3580. The ink has the beneficial effects that through adding the water-based acrylic resin and the water-based styrene-acrylic resin or styrene-acrylic emulsion to the ink, the scuff resistance of patterns obtained after jet printing, the gradation property and the waterproofness can be effectively improved; the ink can be endowed with better levelling property and diffusion of the ink can be reduced by adding the levelling agent, so that the edges of patterns and characters obtained after printing are clear and sharp.

Owner:深圳市墨库图文技术有限公司

Manufacturing process of nanometer mineral energy down jacket

InactiveCN105962510APossesses nano mineral energyAntibacterialGarment special featuresOvergarmentsFiberOxygen

The invention relates to a down jacket, in particular to a manufacturing process of a nanometer mineral energy down jacket. The method includes the specific steps of selecting at least 20 kinds of available natural mineral elements to prepare a nanometer mineral energy modification agent, directly adding the nanometer mineral energy modification agent to the polymerization end of a polymer monomer, synthesizing the modification agent and the polymer monomer to form liquid copolymer, conducting high-temperature reaction on the liquid copolymer to form solid, granulating the solid, conducting silk forming through drawing, fusing silk into fiber to obtain nanometer mineral energy fiber, weaving the fiber into cloth, selecting ordinary down feathers to be processed through the nanometer technology to obtain nanometer down filler, and wrapping the nanometer down filler by the cloth to be sewn into a jacket body. By means of the manufacturing process, the nanometer mineral energy down jacket can be recyclable, bacteria resisting and odor removing can be achieved and anion oxygen activating and odor removing can be achieved through photocatalyst, and the jacket has nanometer mineral energy and has the advantages of resisting bacteria, preventing moisture, preventing odor, being easy to wash, quick to dry and easy to take care of and the like.

Owner:宁波浚源国际贸易有限公司

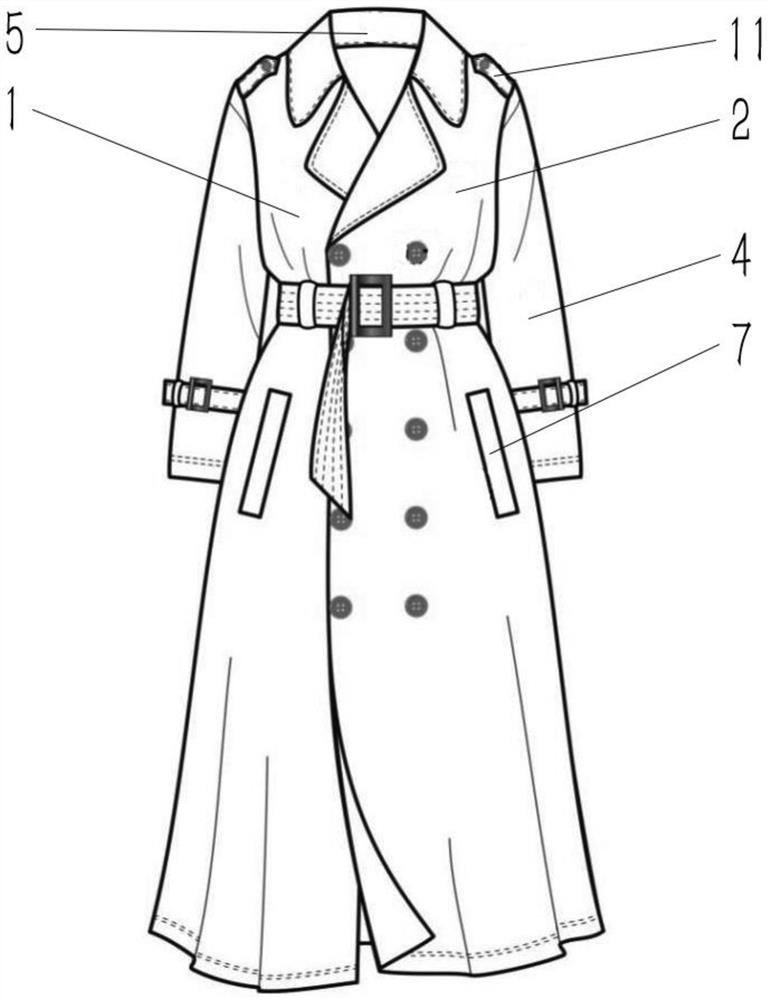

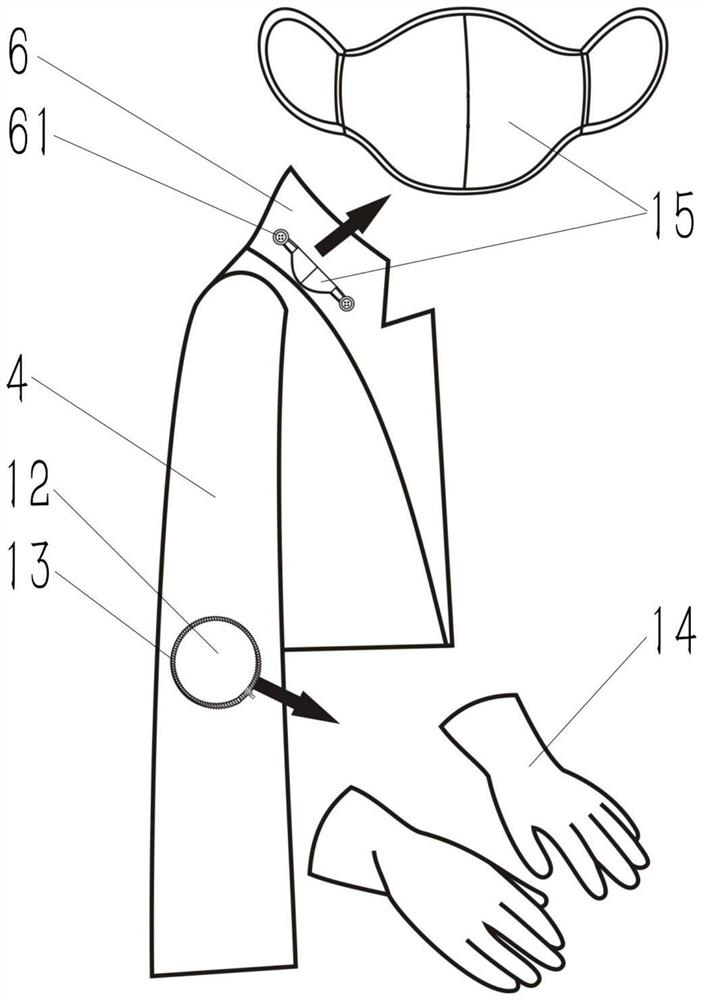

Female wind coat suit and preparation method thereof

PendingCN112155260AWith wear resistanceHygroscopicOvergarmentsProtective garmentAnimal scienceMedicine

The invention discloses a female wind coat suit which comprises a wind coat body and a mask, and two buckles are arranged on the outer side of a lapel of the wind coat body; two hanging lugs of the mask are hooked on the two buckles respectively, and the lapel cannot deform due to the elasticity of the hanging lugs; when the lapel is turned down, the mask is shielded by the lapel and hidden between the wind coat body and the lapel. The mask is fixed between the lapel and the front piece, and meanwhile, the gloves are placed in the cavities between the cover pieces and the sleeves, so that themask and the gloves are prevented from being polluted by the external environment, and the problem that the mask and the gloves are inconvenient to carry is also solved; as the mask and the gloves canbe independently placed and are not in contact with articles in common positions such as pockets, the problem that the used mask and gloves pollute other articles is solved.

Owner:QINGDAO XUEDA GRP

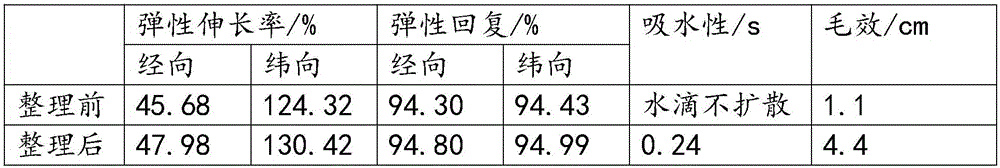

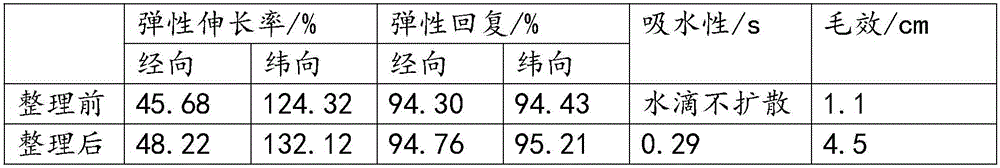

Method for improving moisture-absorption and sweating performance of fatty polyamide fiber/polyurethane fiber fabric

InactiveCN106676899AWith water absorptionMoisture permeableLiquid/gas/vapor removalGrip property fibresOrganic acidEpoxy

The invention provides a method for improving the moisture-absorption and sweating performance of a fatty polyamide fiber / polyurethane fiber fabric. The method comprises the following treatment processes in sequence: step 1, dip padding with a treating agent, step 2, drying, and step 3, baking. The treating agent is made from the following components: isophorone diisocyanate, poly(butyl acrylate), a micromolecule chain extender, organic acid, and epoxy resin. In the step 1, the use amount of the treating agent is 40-70 g / L. In the step 2, the drying temperature is 100-120 DEG C. In the step 3, the baking temperature is 140-200 DEG C, and the baking time is 90-160 s. According to the method, a treating agent is used for finishing a fatty polyamide fiber / polyurethane fiber fabric. The finished fabric can absorb water, is moisture permeable and can be fast dried. The fabric touches soft, fluffy and smooth and is good in draping and washing resistance.

Owner:SHANGHAI JIALE

Preparation technology of polymer blend fibers

InactiveCN108699732AGood touchWith sweat absorptionConjugated cellulose/protein artificial filamentsMelt spinning methodsYarnState of art

The invention relates to the technical field of textile, in particular to the preparation technology of polymer blend fibers. The technology comprises steps of wrapping the surfaces of the natural fibers with silicon resin coatings so as to allow the natural fibers to be capable of bearing high temperature of melt spinning; and allowing the natural fibers wrapped with the resin coatings and chemical fibers under the high-temperature molten condition to be subjected to melt spinning to prepare the polymer fibers. According to the invention, by wrapping the natural fibers with silicon resin coatings, the defect that natural fibers in the prior art fail to bear the high temperature of melt spinning technology is overcome; compared with the traditional natural fiber blending technology, the spinning efficiency and yarn intensity are greatly improved; the prepared polymer fibers touch well like natural fibers and have advantages of absorbing sweat absorption, quickly getting dry and being light like chemical fibers.

Owner:FUJIAN HUACAI NEW MATERIALS CO LTD

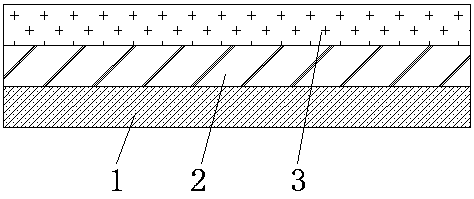

Semi-worsted wool top blended knitting yarn fabric with good antibacterial effect

PendingCN110450472ASolve the problem of poor comfortGuaranteed comfortClothingsWoven fabricsBiochemical engineeringFlax fiber

The invention discloses a semi-worsted wool top blended knitting yarn fabric with a good antibacterial effect. The fabric comprises a bottom layer, the surface of the bottom layer is fixedly connectedwith an antibacterial layer, the surface of the antibacterial layer is fixedly connected with a comfort layer, the surface of the comfort layer is fixedly connected with wool tops, the bottom layer comprises warp yarns and weft yarns, and is formed by interweaving the warp yarns and the weft yarns, the warp yarns are made by blending cotton fibers, flax fibers and bamboo charcoal fibers, the cotton fibers are used as a fiber core, the flax fibers and the bamboo charcoal fibers are spirally bonded to the fiber core, and the weft yarns are made by blending the cotton fibers, the bamboo charcoalfibers and moisture adsorbing and sweat removing fibers. The bottom layer, the antibacterial layer, the comfort layer and the wool tops are cooperatively used, so the problem of poor comfortablenessof traditional knitting yarn fabrics is effectively solved, and the fabric can greatly ensure the comfortableness of human bodies and improve the antibacterial effect, resists the invasion of externalbacteria, and has certain health effects.

Owner:苏州亿迈化纤有限公司

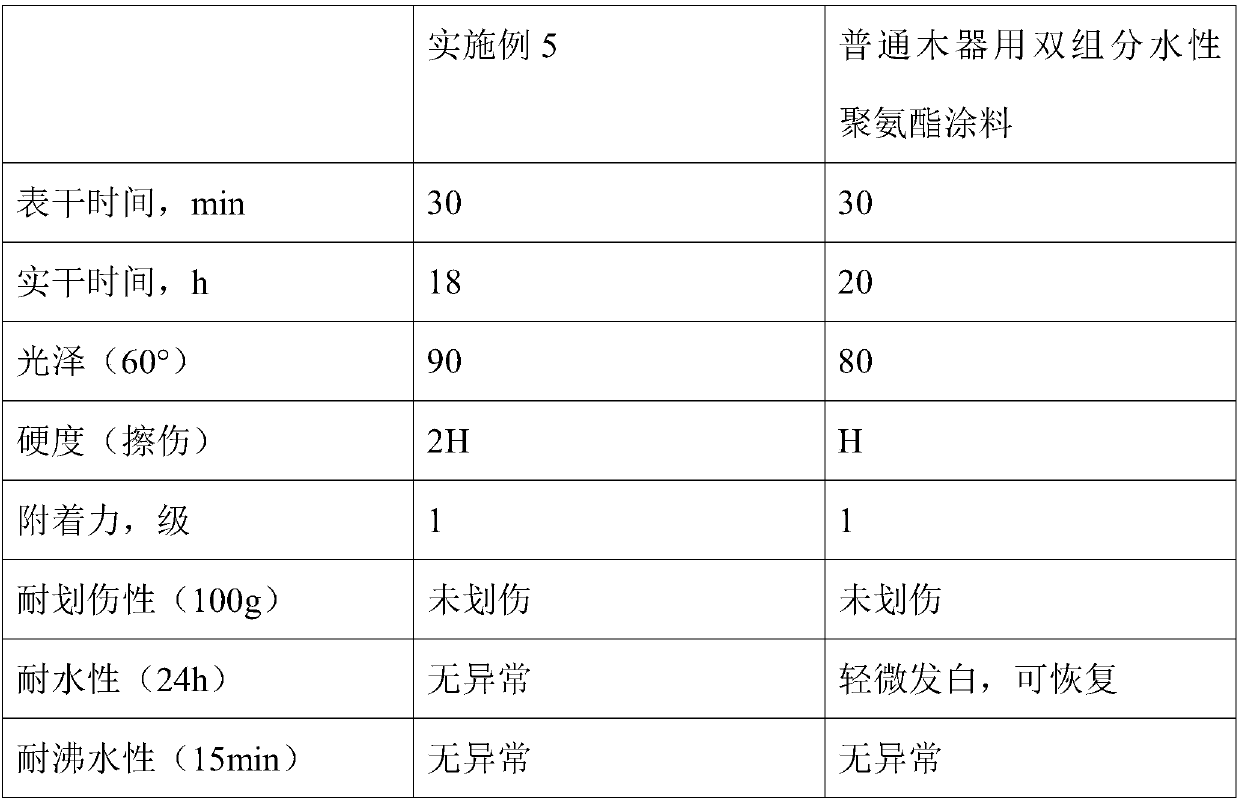

Double-component water-based polyurethane coating for woodware

InactiveCN109609018AScratch resistantAnti-adhesionPolyurea/polyurethane coatingsWater basedMicrosphere

The invention discloses a double-component water-based polyurethane coating for woodware. The coating comprises a component a and a component b, and the weight ratio of the component a to the component b is (7-9):(1-3); raw materials of the component a comprise a waterborne polyurethane dispersion, water-based alkyd resin, a low-hydroxyl-value acrylic emulsion, degraded polyethylene glycol microspheres, white carbon black, zinc phosphate, epoxidized soybean oil, disproportionated rosin, a wetting agent, a defoaming agent, a flatting agent, a thickening agent and deionized water; and raw materials of the component b comprise water-based isocyanate and water. The degraded polyethylene glycol microspheres are prepared by the following process: degrading polyethylene glycol 6000 by irradiation, carrying out exhausting and degassing, carrying out crushing, adding oxidized polyethlene wax, carrying out stirring, then adding aluminum nitrate, boric acid and water, uniformly carrying out stirring, dropwise adding ammonia water under a stirring state until the pH value of the system is 8.1-8.5, carrying out stirring to obtain a white emulsion suspension, carrying out a hydrothermal reaction, and carrying out cooling to obtain the degradable polyethylene glycol microspheres.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

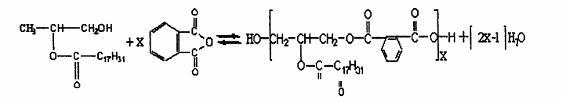

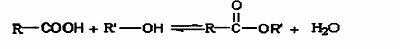

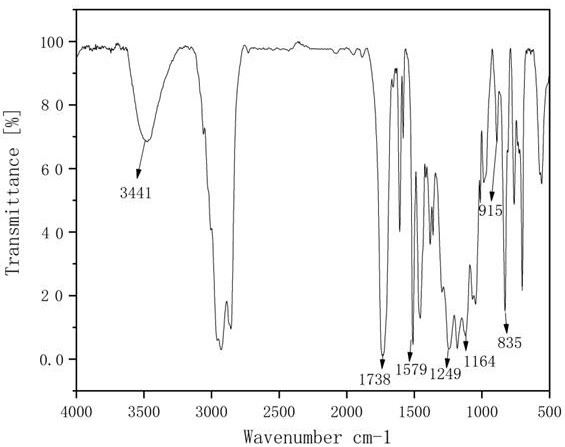

Waterborne acrylic acid modified epoxy ester resin as well as preparation method and application thereof

PendingCN112979889AAvoid lostImprove weather resistanceAnti-corrosive paintsEthyleneglycol monobutyl etherEther

The invention discloses waterborne acrylic modified epoxy ester resin as well as a preparation method and application thereof, belongs to the field of chemical engineering, and solves the problem that the corrosion resistance of existing hydrophilic resin is reduced. The resin comprises epoxy ester resin, epoxy phosphate, styrene, methyl methacrylate, butyl acrylate, acrylic acid, benzoyl peroxide, tert-butyl hydroperoxide, ethylene glycol monobutyl ether, dimethylethanolamine and deionized water. The preparation method comprises the following steps: heating the epoxy ester resin and the epoxy phosphate; dropwise adding a mixed solution of the styrene, methyl methacrylate, butyl acrylate, acrylic acid and benzoyl peroxide; adding the tert-butyl hydroperoxide; cooling and vacuumizing; adding the dimethylethanolamine for a neutralization reaction, and adding the deionized water for emulsification and dispersion. The waterborne acrylic modified epoxy ester resin is applied to water-based industrial anticorrosive paint. The water-based anticorrosive paint prepared from the waterborne acrylic modified epoxy ester resin has the characteristics of quick drying and high weather resistance of acrylic resin, and also has the characteristics of high adhesive force, high corrosion resistance and the like of epoxy resin.

Owner:西北永新涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com