Quick-drying adhesive for casting sand mold

A technology of casting sand and adhesive glue, which is applied in the direction of casting molding equipment, casting molds, and casting mold components, and can solve the problem of repairing sand molds (core strength and drying time need to be improved, bonding strength and curing time are not ideal, castings Easy to produce porosity and other problems, to achieve the effect of short curing time, high bond strength, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

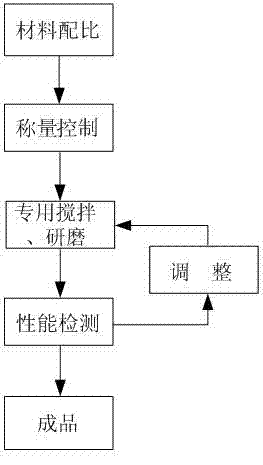

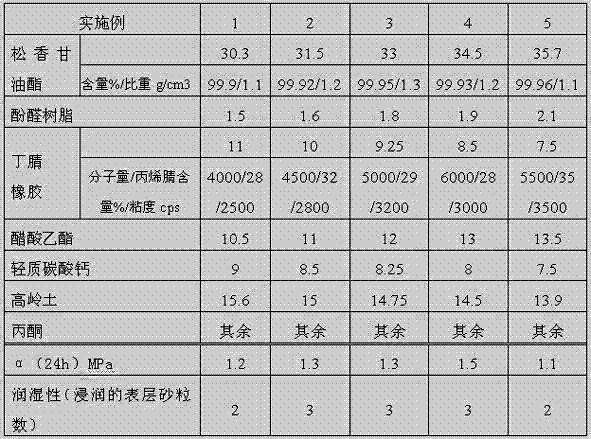

[0016] according to figure 1 The preparation process shown is to prepare sand mold quick-drying adhesive for foundry in proportion, and the weight ratio of its components is:

[0017] Rosin glyceride 30.3%~35.7%, phenolic resin 1.5~2.1%, nitrile rubber 7.5~11%, ethyl acetate 10.5%~13.5%, kaolin 13.9~15.6%, light calcium carbonate 7.5~9%, the rest is acetone.

[0018] Among the rosin glycerides described in C 23 h 36 o 4 Content ≥99.9%, its specific gravity is 1.1~1.3g / cm 3 ;

[0019] Described phenolic resin is a thermoplastic resin;

[0020] The relative molecular mass (ratio of one molecular mass to one carbon atom of 1 / 12) of the described nitrile rubber is 4000~6000, the acrylonitrile content is 28~35%, and the viscosity is 2500~3500cps;

[0021] The purity of the ethyl acetate ≥ 99.5%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com