Waterborne acrylic acid modified epoxy ester resin as well as preparation method and application thereof

An epoxy ester resin, water-based acrylic technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of loss of anti-corrosion performance and decline of epoxy active groups, and achieve high weather resistance, low VOC emissions, and high anti-corrosion properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

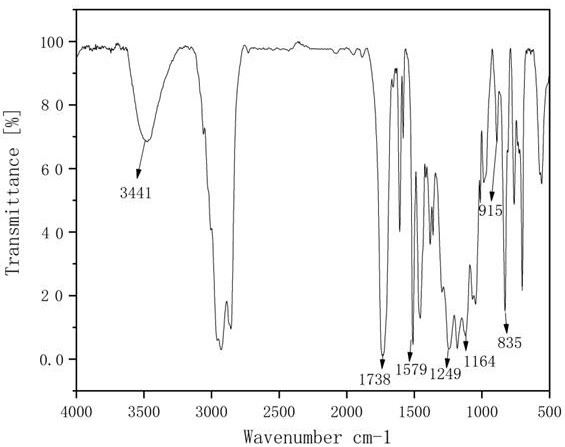

Image

Examples

Embodiment 1

[0047]A waterborne acrylic modified epoxy ester resin, comprising the following components in mass percentage: epoxy ester resin 42%, epoxy phosphate ester 4%, styrene 5%, methyl methacrylate 8%, butyl acrylate 1 %, acrylic acid 3%, benzoyl peroxide 0.5%, tert-butyl hydroperoxide 0.07%, ethylene glycol monobutyl ether 1.5%, dimethylethanolamine 5%, deionized water 29%.

[0048] The epoxy ester resin is prepared from the following raw materials in mass percentage: 35% linoleic acid, 1.3% crotonic acid, 27% E20 epoxy resin, 0.013% zinc oxide, 4% xylene, ethylene glycol Monobutyl ether 30%.

[0049] The epoxy phosphate is prepared according to the following mass percentages of raw materials: 60% of E20 epoxy resin, 1% of phosphoric acid, and 38% of ethylene glycol monobutyl ether.

[0050] A kind of preparation method of waterborne acrylic acid modified epoxy resin, comprises the following steps:

[0051] A. Add epoxy ester resin and epoxy phosphate into the reaction kettle, ra...

Embodiment 2

[0073] A water-based acrylic modified epoxy ester resin, comprising the following components in mass percentage: epoxy ester resin 38%, epoxy phosphate ester 6%, styrene 6%, methyl methacrylate 9%, butyl acrylate 2 %, acrylic acid 4%, benzoyl peroxide 0.7%, tert-butyl hydroperoxide 0.09%, ethylene glycol monobutyl ether 1.7%, dimethylethanolamine 6%, deionized water 31%.

[0074] The epoxy ester resin is prepared from the following raw materials in mass percentage: 33% linoleic acid, 1.5% crotonic acid, 29% E20 epoxy resin, 0.015% zinc oxide, 5% xylene, ethylene glycol Monobutyl ether 33%.

[0075] The epoxy phosphate is prepared from the following raw materials in mass percentage: E20 epoxy resin 58%, phosphoric acid 2%, ethylene glycol monobutyl ether 40%.

[0076] A kind of preparation method of waterborne acrylic acid modified epoxy resin, comprises the following steps:

[0077] A. Add epoxy ester resin and epoxy phosphate into the reaction kettle, raise the temperature ...

Embodiment 3

[0098]A water-based acrylic modified epoxy ester resin, comprising the following components in mass percentage: epoxy ester resin 41%, epoxy phosphate ester 5%, styrene 5.11%, methyl methacrylate 8.4%, butyl acrylate 1.2% %, acrylic acid 3.1%, benzoyl peroxide 0.6%, tert-butyl hydroperoxide 0.08%, ethylene glycol monobutyl ether 1.6%, dimethylethanolamine 5.6%, deionized water 30%.

[0099] The epoxy ester resin is prepared according to the following mass percentage raw materials: 34% linoleic acid, 1.4% crotonic acid, 28% E20 epoxy resin, 0.014% zinc oxide, 4.5% xylene, ethylene glycol Monobutyl ether 32%.

[0100] The epoxy phosphate is prepared from the following raw materials in mass percentage: 59% of E20 epoxy resin, 1.5% of phosphoric acid, and 39% of ethylene glycol monobutyl ether.

[0101] A kind of preparation method of waterborne acrylic acid modified epoxy resin, comprises the following steps:

[0102] A. Add epoxy ester resin and epoxy phosphate into the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com