Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Solve the problem of poor comfort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

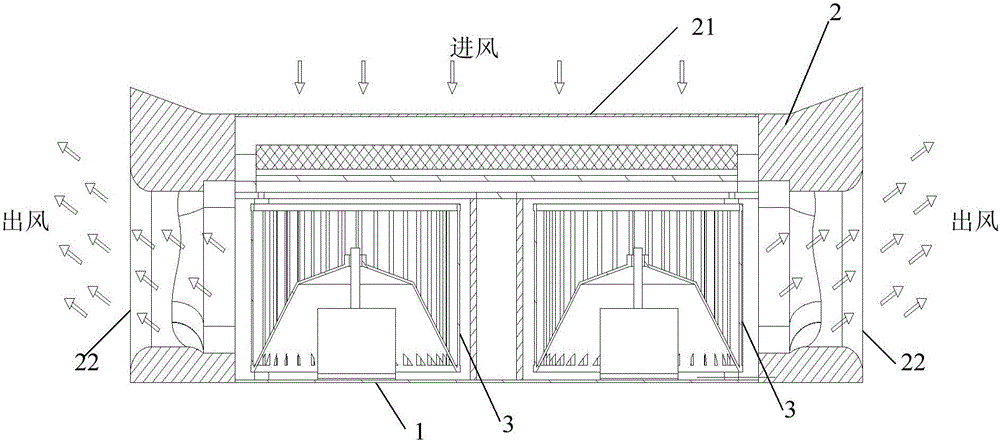

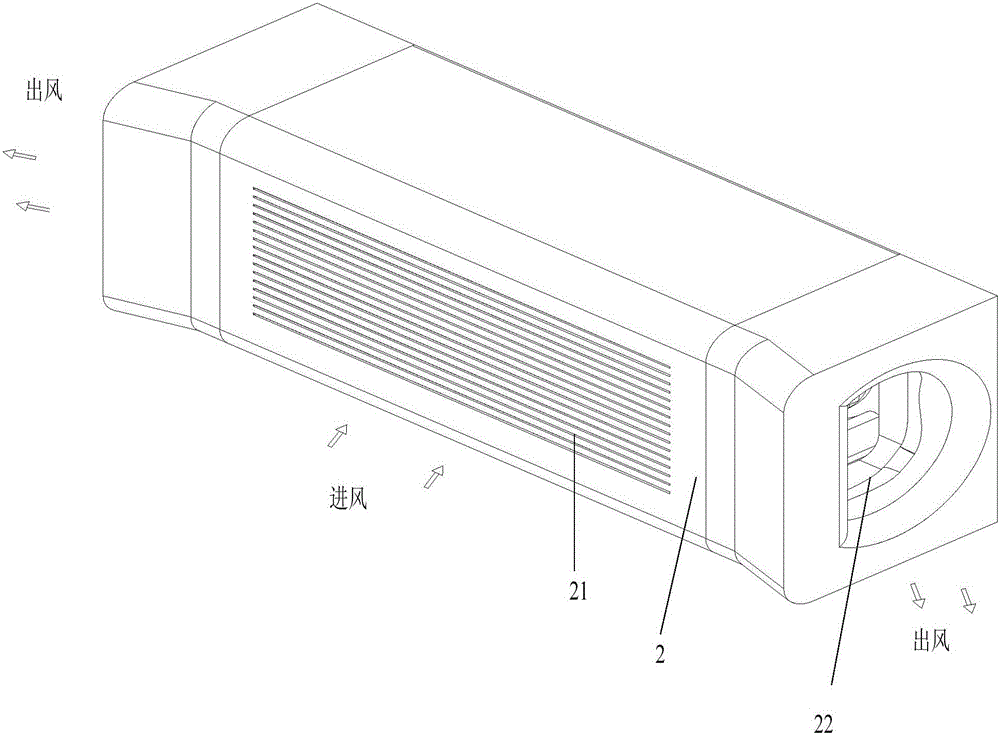

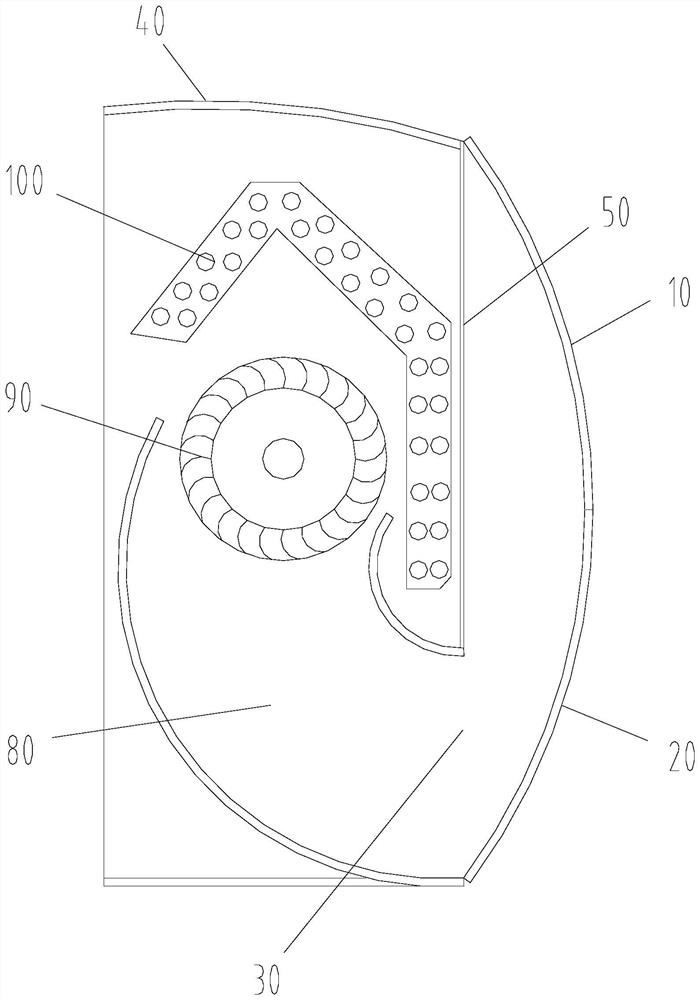

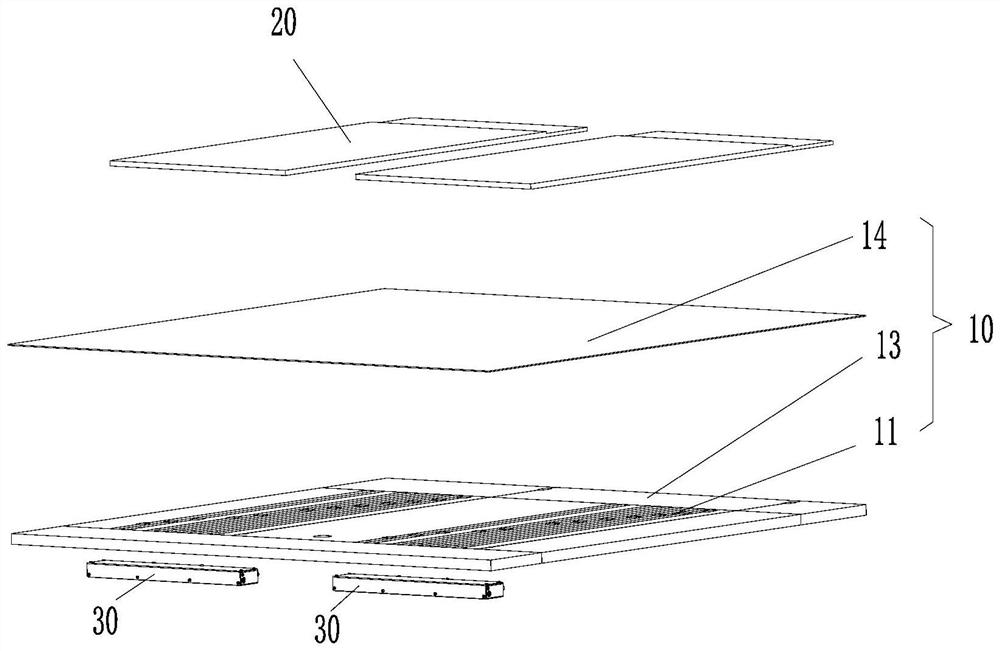

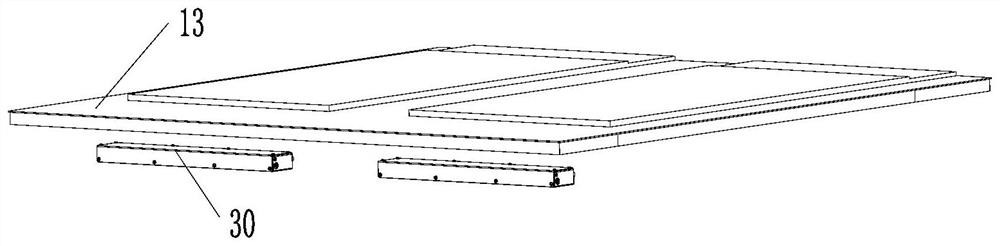

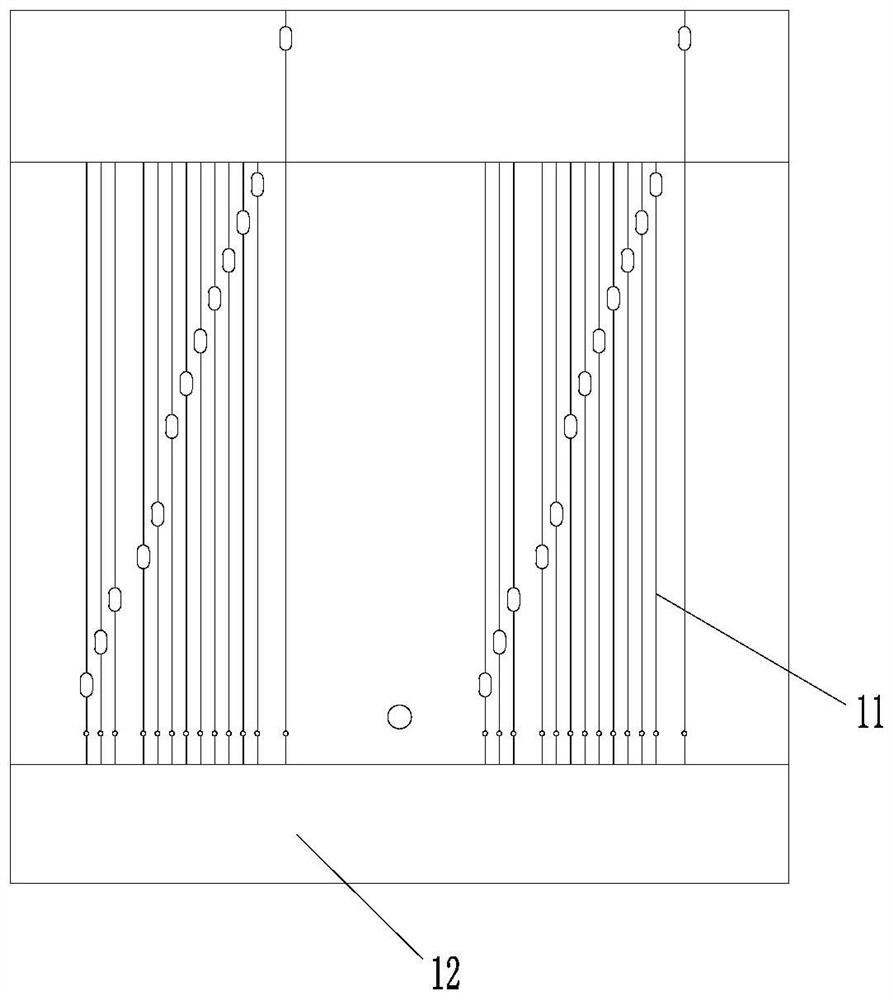

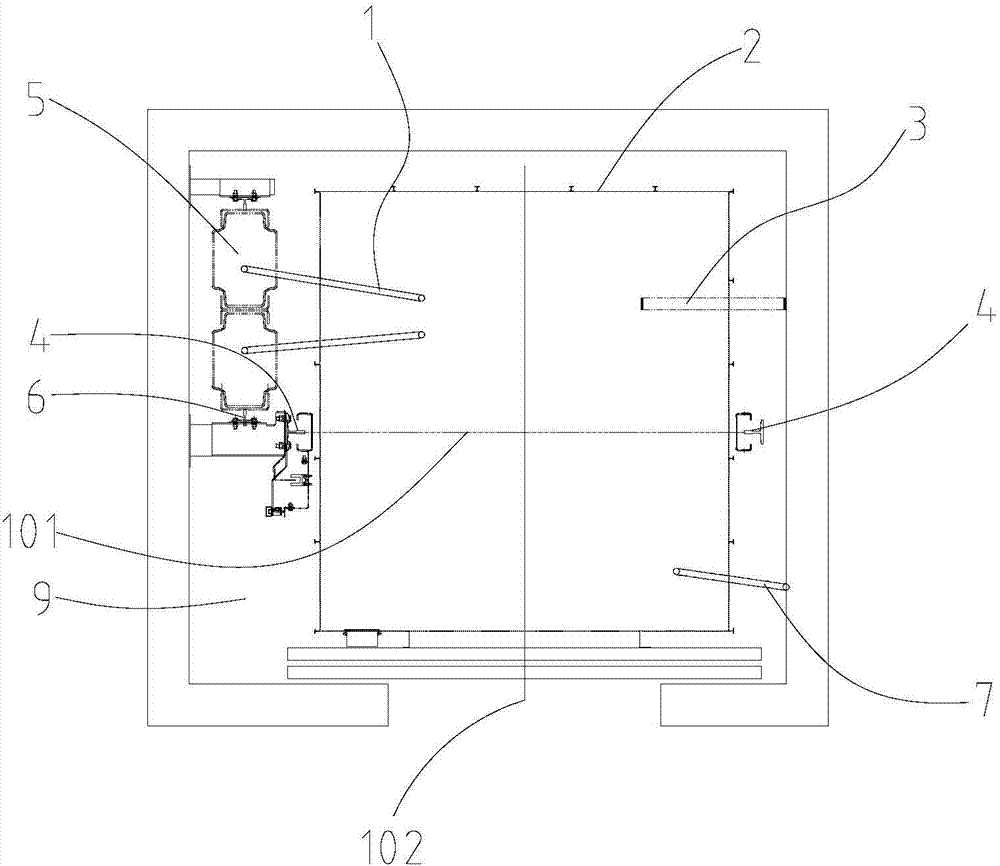

Hanging air conditioner indoor unit

InactiveCN105928070ACycle fastImprove comfortLighting and heating apparatusAir conditioning systemsEngineeringCentrifugal force

The invention provides a hanging air conditioner indoor unit. The hanging air conditioner indoor unit comprises a base and an outer cover, wherein the outer cover covers the base. The hanging air conditioner indoor unit further comprises two centrifugal fans. A first air inlet is formed in the first side surface, right facing the base, of the outer cover. Two first air outlets are oppositely formed in the two second side surfaces of the outer cover in the length direction. The two centrifugal fans are fixedly arranged in a space formed by the outer cover and the base, used for blowing airflow entering from the first air inlet to the first air outlets and in one-to-one correspondence with the first air outlets. According to the hanging air conditioner indoor unit, the two centrifugal fans and the two first air outlets oppositely formed are adopted; when the hanging air conditioner indoor unit is used, the airflow of the first air inlet can be blown to the two first air outlets in the opposite direction and cannot be directly blown to a user, and thus the comfort is improved; and meanwhile, air flow circulation in a room can be faster through bidirectional air blowing, so that the purposes of rapid cooling and heating are achieved.

Owner:HISENSE (GUANGDONG) AIR CONDITIONER

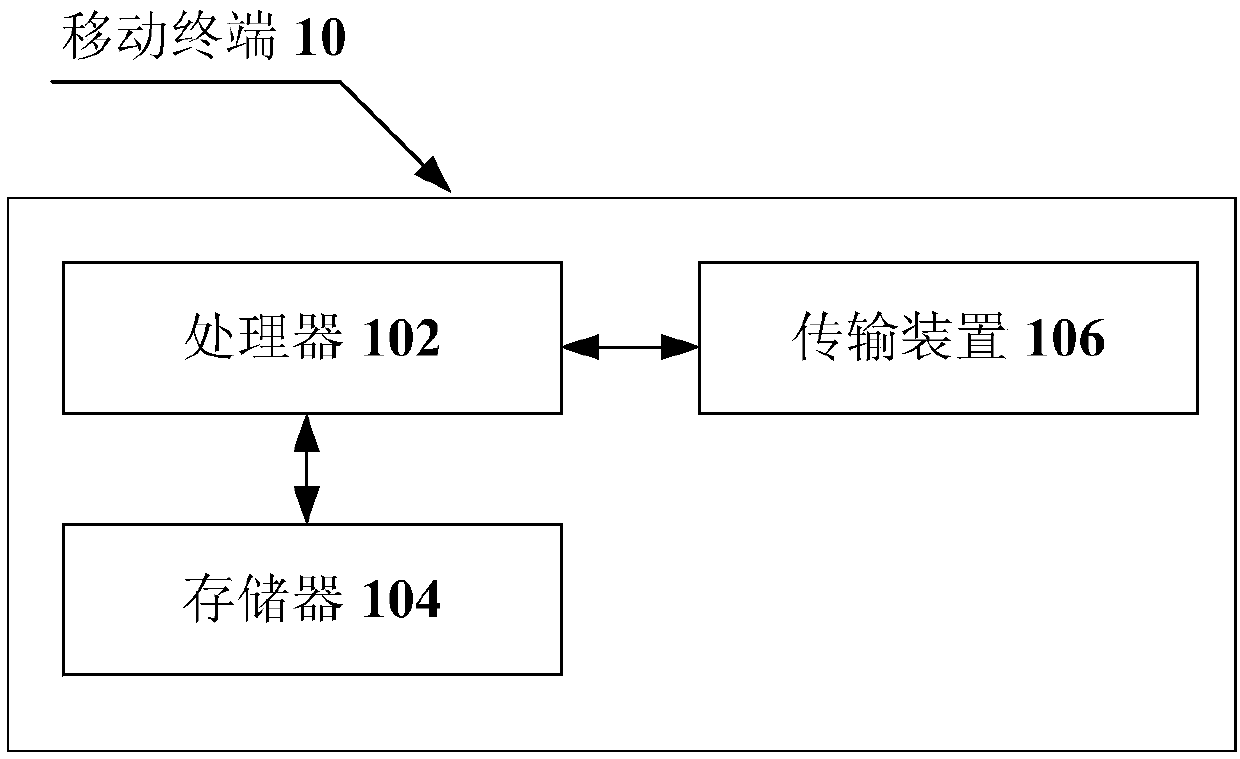

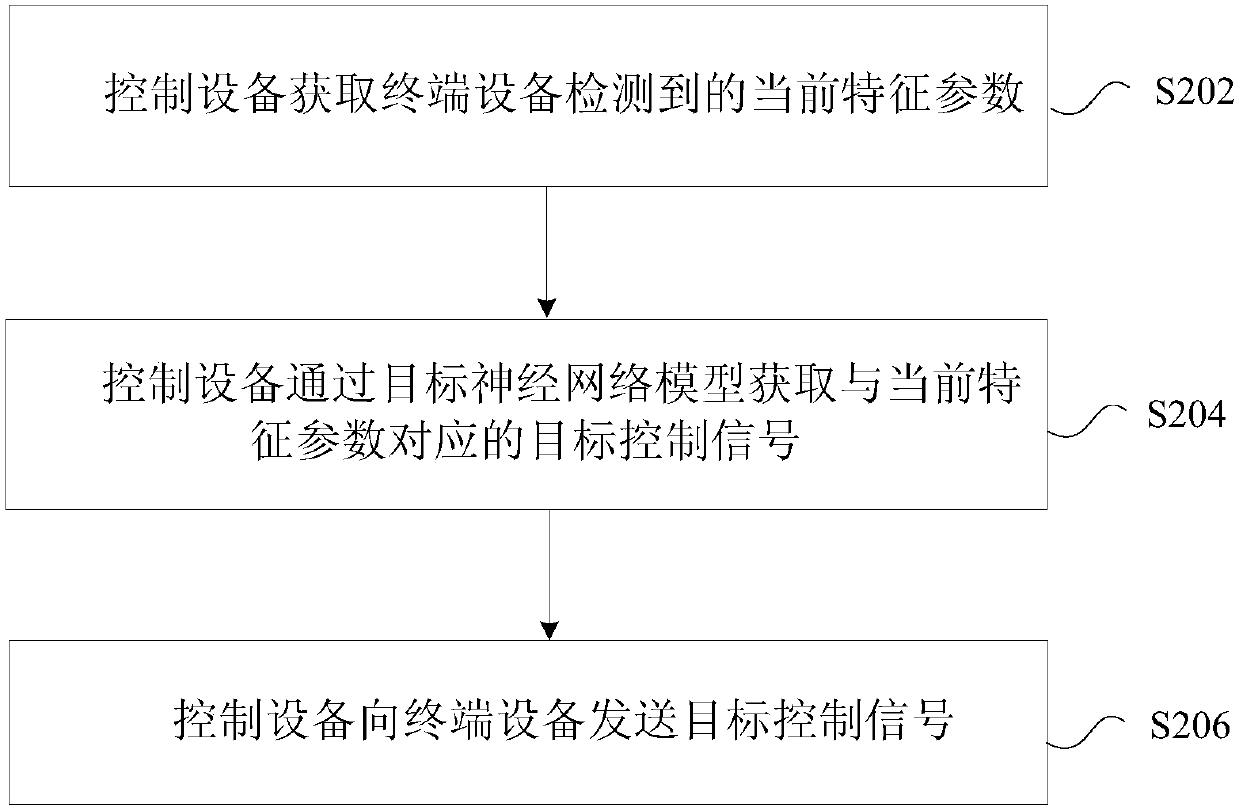

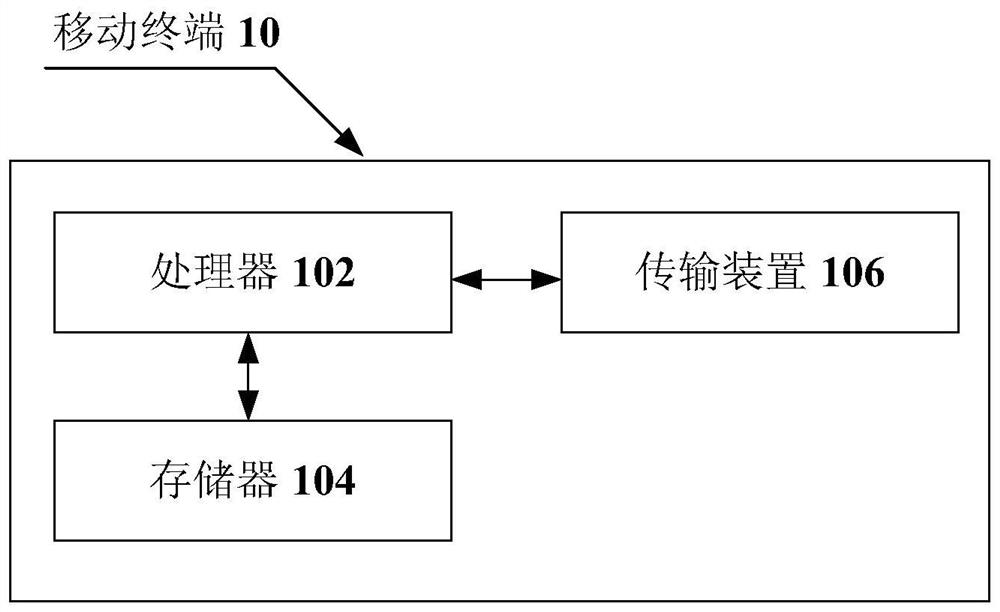

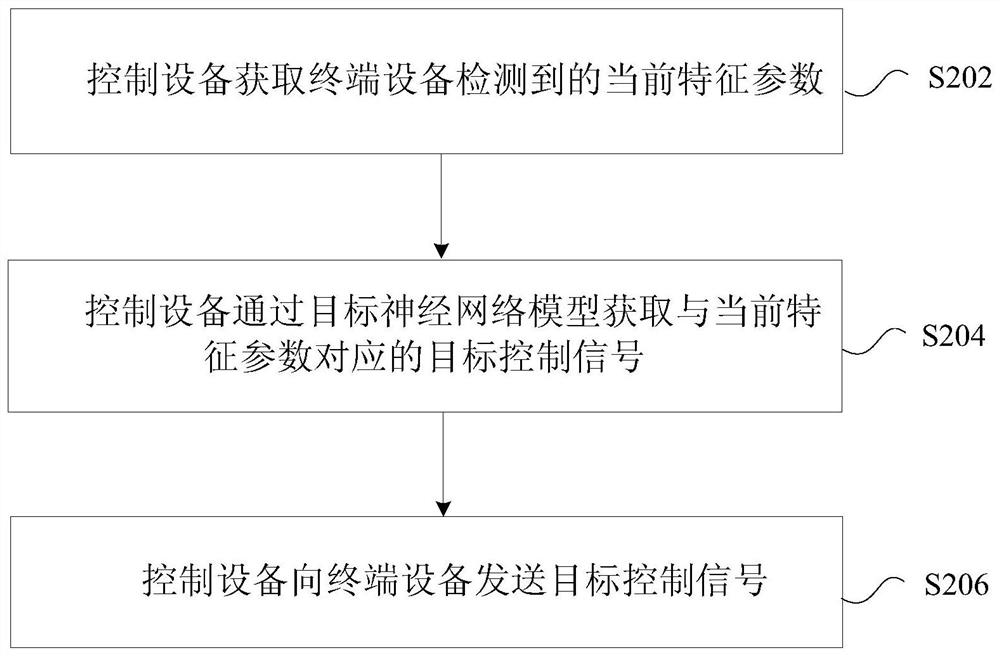

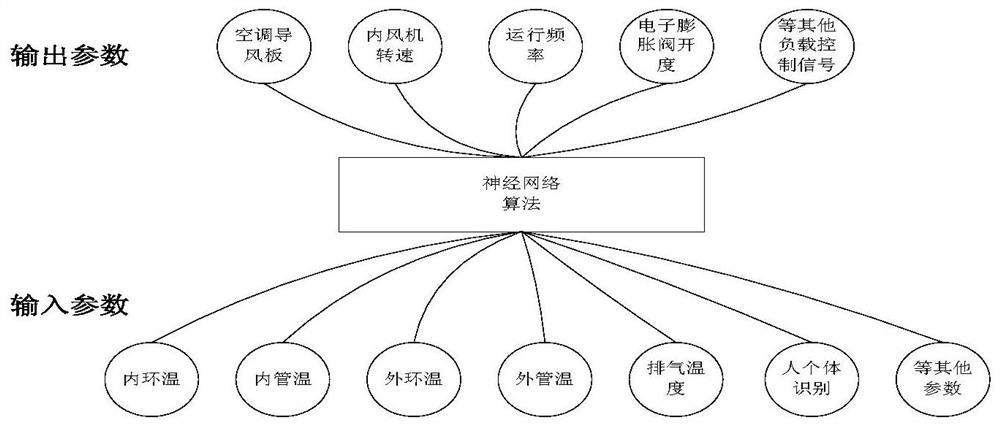

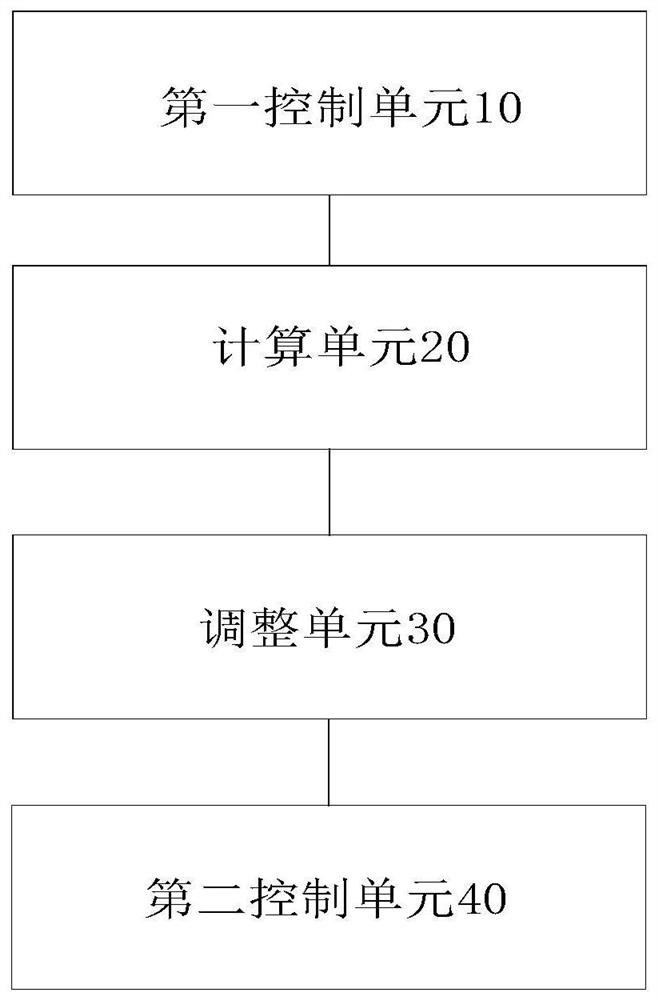

Method and apparatus for controlling terminal device, storage medium, and processor

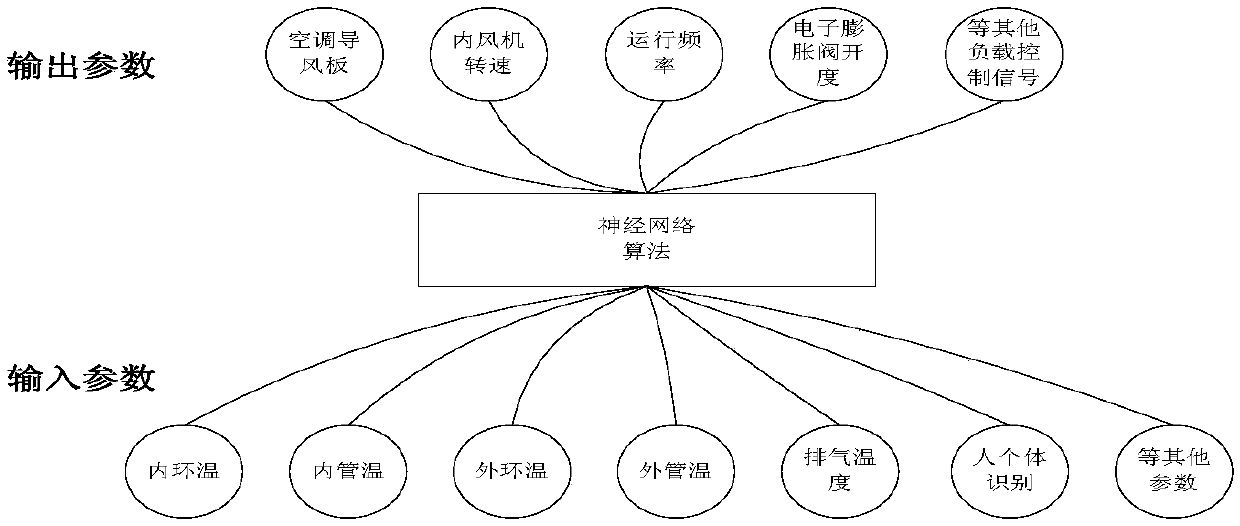

ActiveCN107797459AImprove rationalityImprove comfortComputer controlNeural architecturesTarget controlTerminal equipment

The invention provides a method and apparatus for controlling a terminal device, a storage medium, and a processor. The method comprises: a control device acquires a current feature parameter detectedby a terminal device; the control device acquires a target control signal corresponding to the current feature parameter by a target neural network model; and the control terminal sends the target control signal to the terminal device. Therefore, a problem of poor comfort sensing experience of the user because of poor control reasonability of the terminal device according to the related technology is solved; the reasonability of the terminal device is improved; and the user feels comfortable in a current environment.

Owner:GREE ELECTRIC APPLIANCES INC

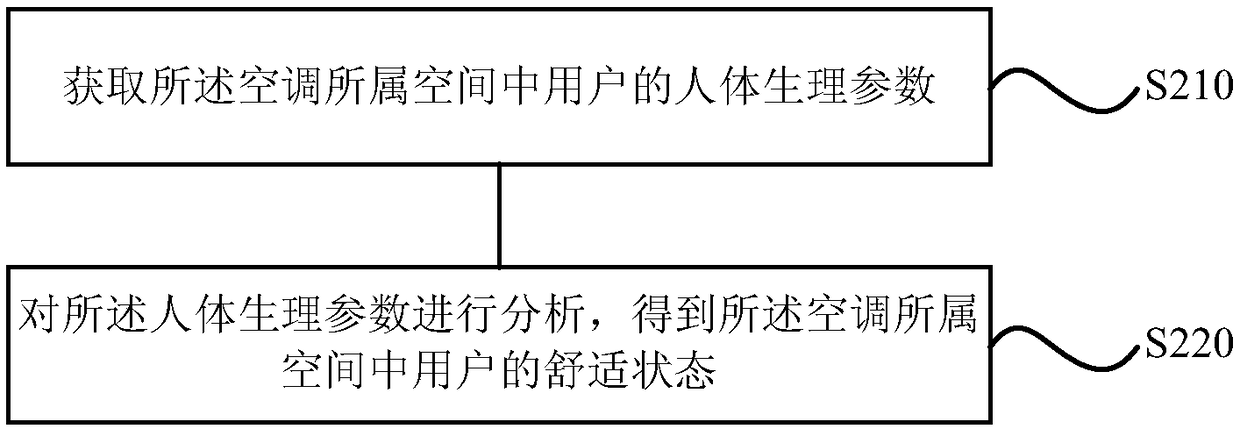

Control method and device of air-conditioner, storage medium and air-conditioner

ActiveCN109442687AImprove thermal comfortEasy to controlMechanical apparatusSpace heating and ventilation safety systemsEngineeringHumidity

The invention discloses a control method and device of an air-conditioner, a storage medium and the air-conditioner. The method includes the steps that the comfort state of a user and human body activity area features in a space where the air-conditioner is located are obtained; operation parameters of the air-conditioner are controlled according to the comfort state and the human body activity area features; and the operation parameters include the rotating speed of an air guiding mechanism of the air-conditioner. By means of the scheme, the problem that the human body comfort is poor in a mode of detecting the environment temperature, humidity and the like to control operation of the air-conditioner can be solved, and the effect of improving human body comfort is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

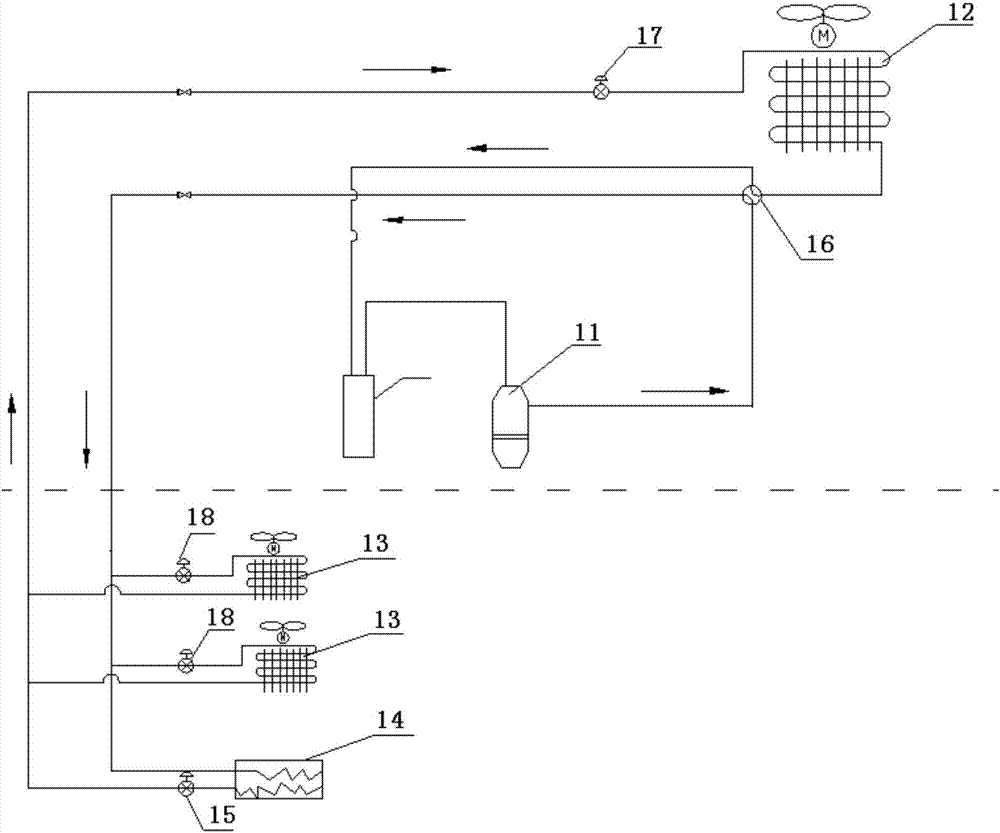

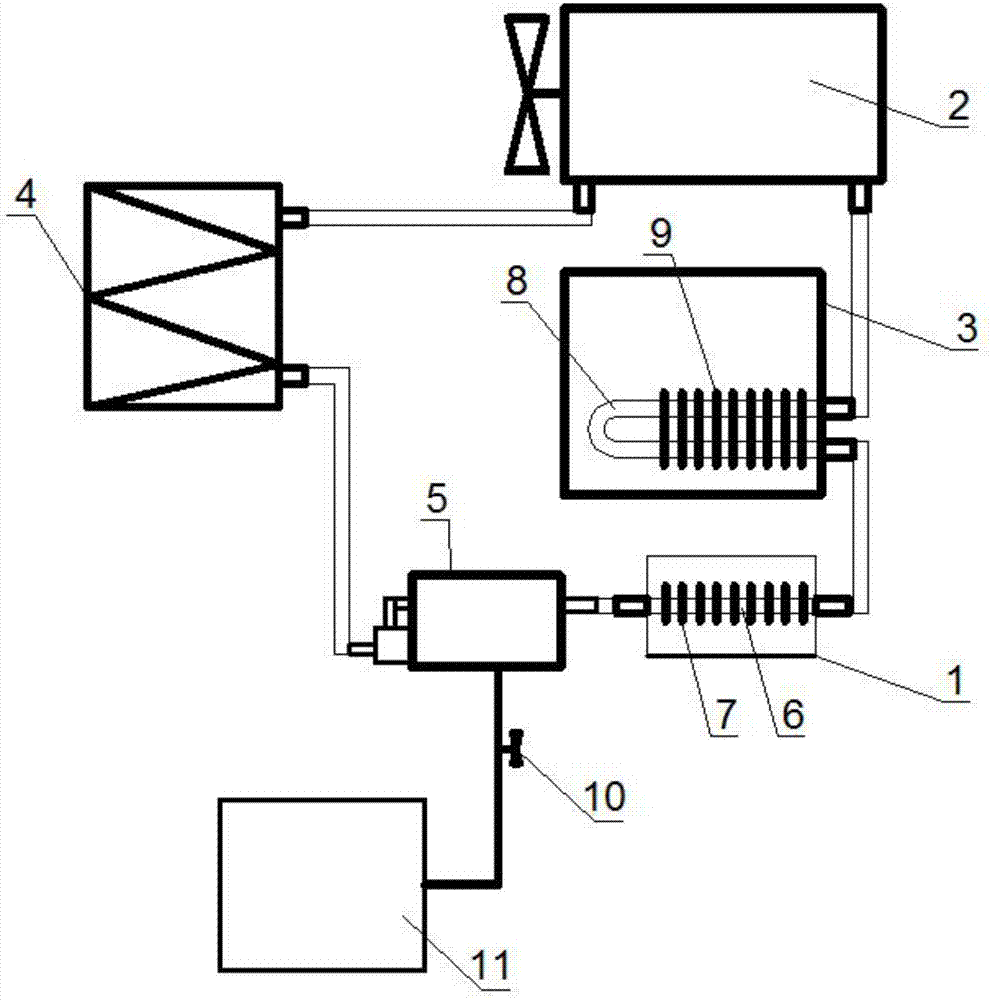

Heat pump system and defrosting control method thereof

PendingCN107044704ASolve the problem of poor comfortMechanical apparatusSpace heating and ventilation safety systemsEngineeringHeat storage material

The invention discloses a heat pump system and a defrosting control method of the heat pump system. The heat pump system comprises a compressor, an outdoor side heat exchanger and indoor side heat exchangers. The compressor, the outdoor side heat exchanger and the indoor side heat exchangers are connected through a pipeline valve system. The heat pump system further comprises a heat storage module. The heat storage module comprises a heat storage material, a heat exchange pipeline capable of exchanging heat with the heat storage material and a valve device for controlling the refrigerant flow in the heat exchange pipeline. The heat exchange pipeline is connected with the pipeline valve system, and the heat exchange pipeline is connected with the indoor side heat exchangers in parallel. In this way, by the adoption of the heat pump system, the problem that in the prior art, when an outdoor side heat exchanger of a heat pump conducts defrosting, it is required to take heat from the inner side of a room, and consequently the comfort of the room is poor is solved.

Owner:GREE ELECTRIC APPLIANCES INC

Anti-wrinkle soft uniform fabric and production process thereof

ActiveCN108950811AImprove uniformityImprove stabilityArtificial thread manufacturing machinesGrip property fibresFiberPolyester resin

The invention relates to a production process of anti-wrinkle soft uniform fabric. Firstly, polyester resin and an auxiliary agent thereof are fused, then extruded and pelletized into polyester chips;secondly, the polyester chips are subjected to a spinning process to form fine-denier polyester staple fibers; thirdly, with blended yarn of conventional polyester staple fibers and carded cotton aswarp yarn and blended yarn of fine-denier polyester staple fibers and combed cotton as weft yarn, the fabric is prepared through a siro spinning and weaving process. The production process has the advantages that according to the anti-wrinkle soft uniform fabric, the fitting surface is soft, comfortable and capable of absorbing moisture and discharging sweat, and the problem of poor comfort of traditional uniform fabric is well solved; the front surface of the fabric is clean, flat, full in granular weave, bright, smooth and soft in luster and smooth and cool in hand feel and has good anti-wrinkle performance, so that daily use and finishing of uniforms are more convenient and simpler; the fabric surface has clear weaves, good stiffness, little hairiness and high strength.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

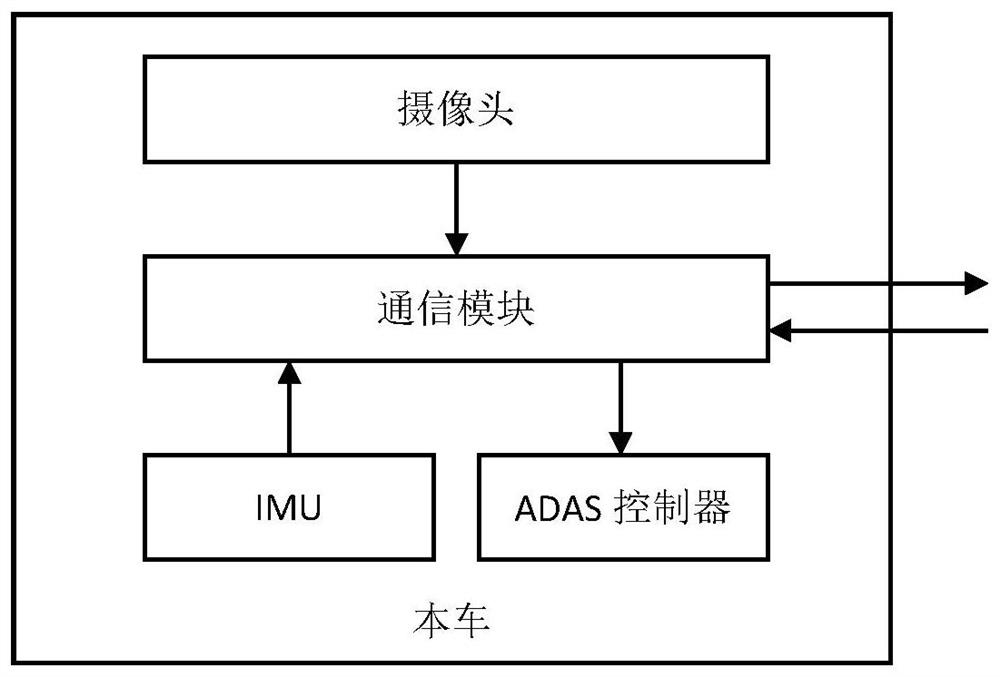

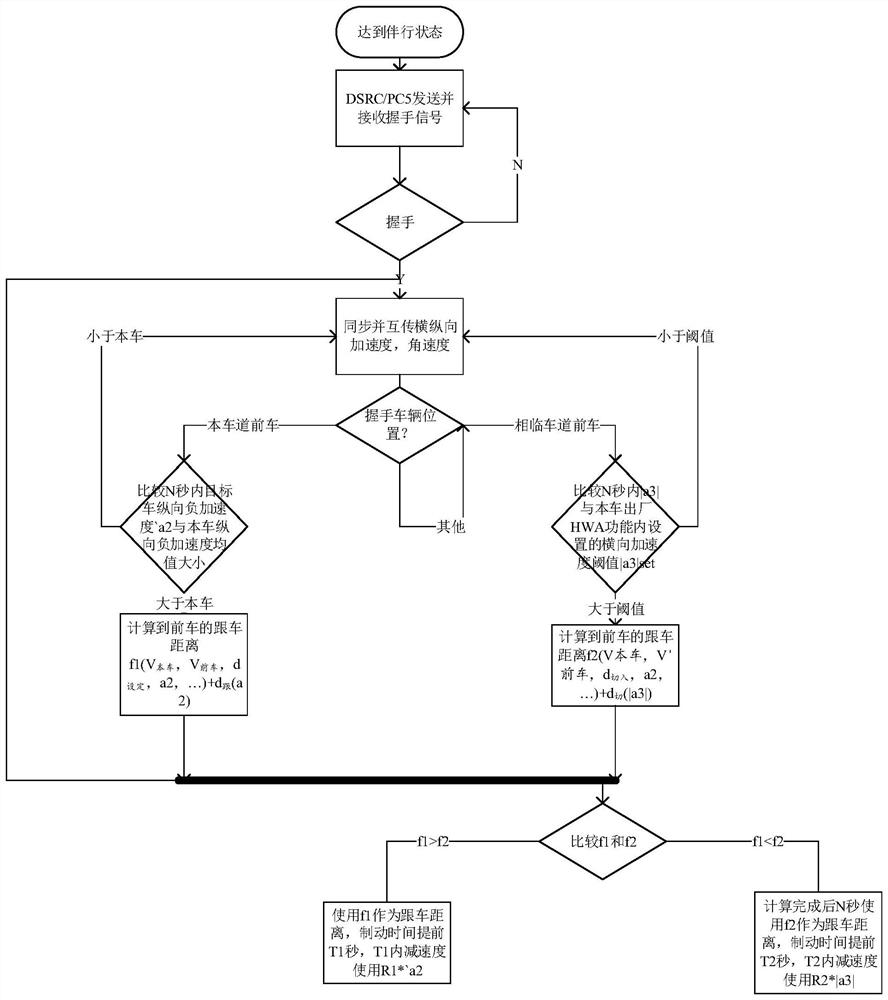

Automatic driving optimization system and method based on V2V

ActiveCN112498351ASolve the problem of poor comfortLane change safetyExternal condition input parametersExternal condition output parametersNetwork conditionsControl theory

The invention discloses an automatic driving optimization system and method based on V2V, and belongs to the field of intelligent driving. The method comprises the steps: enabling a vehicle to carry out V2V data exchange under a condition that the vehicle is accompanied, and building a distribution map of the accompanied vehicle at a periphery through the information of a lane line where the vehicle is located and the license plate number of the vehicle in front of the lane; receiving the transverse acceleration, the longitudinal acceleration and the deflection angular velocity corresponding to the surrounding vehicles one by one for N seconds, and adjusting a following braking time point and the deceleration of the vehicle according to the longitudinal acceleration of the vehicle in frontof the lane and the transverse acceleration of the vehicle in front of the adjacent lane in an accompanying straight running state so that the following of the vehicle in front is more comfortable; under the condition that lane changing is needed during accompanying, enabling the vehicle to adjust a lane changing triggering condition through the longitudinal acceleration habit of the rear vehicleof the adjacent lane so that lane changing of the vehicle is safer; and under the condition of not being limited by network conditions, matching automatic driving of different styles according to different accompanying vehicles, and updating a real-time automatic driving strategy in a personalized mode.

Owner:DONGFENG MOTOR CORP HUBEI

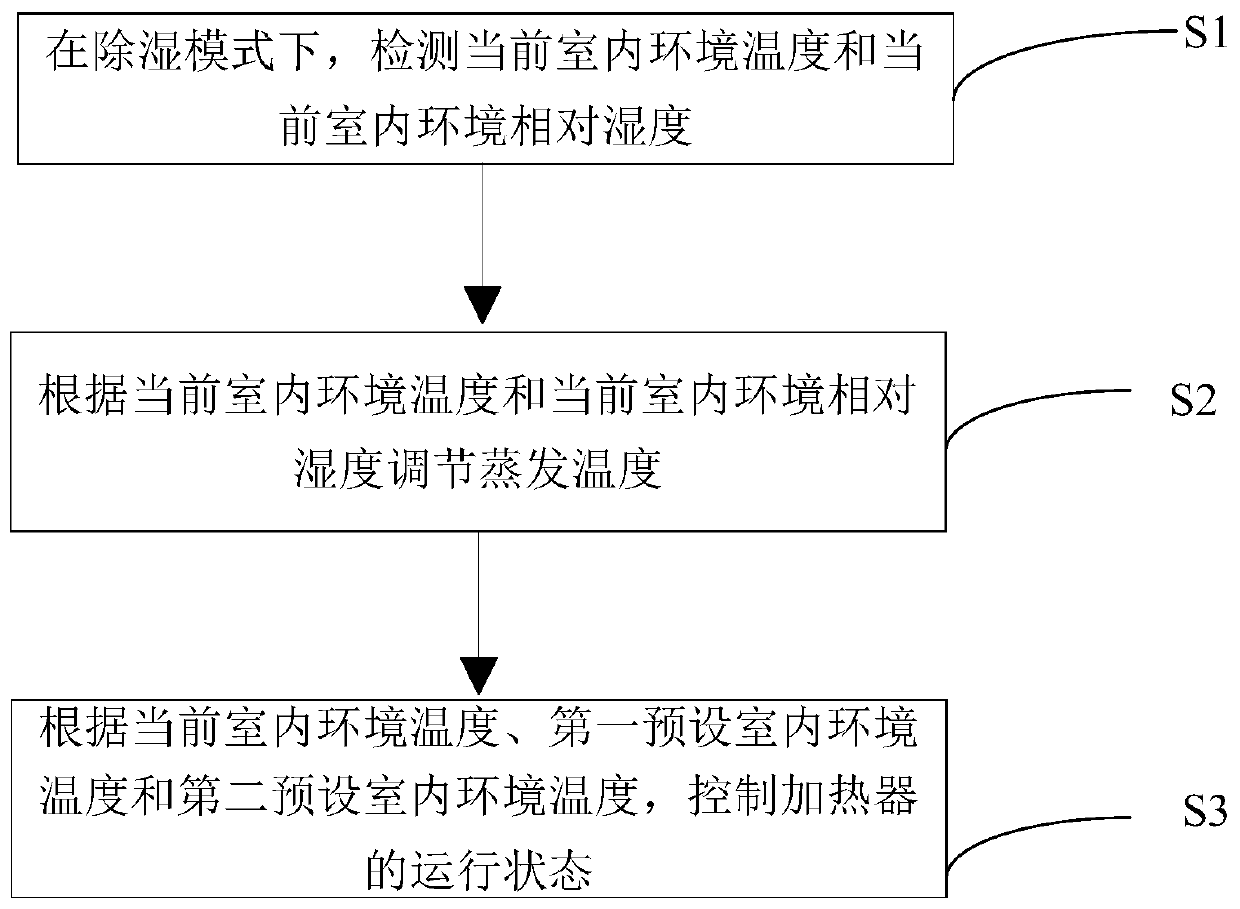

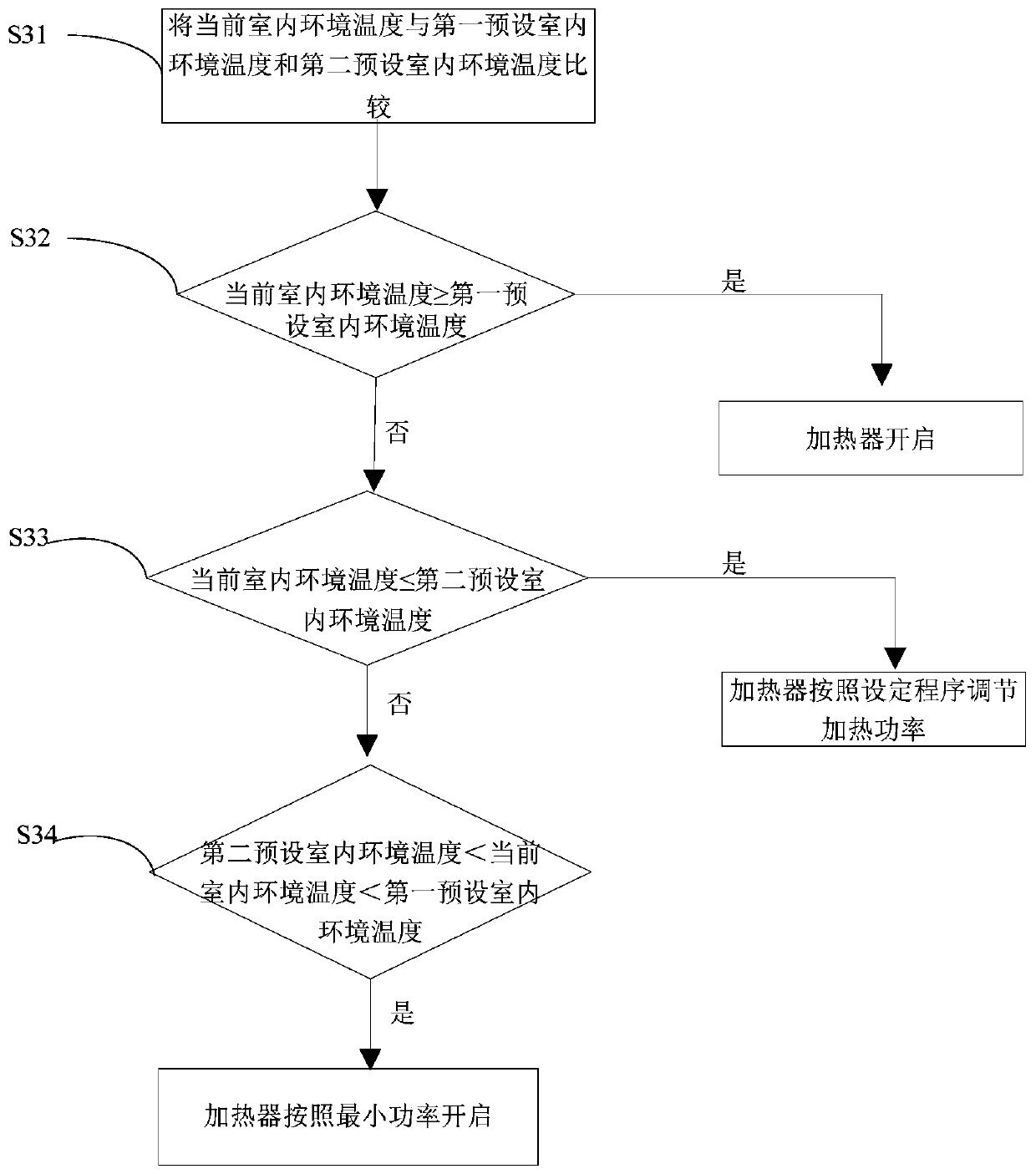

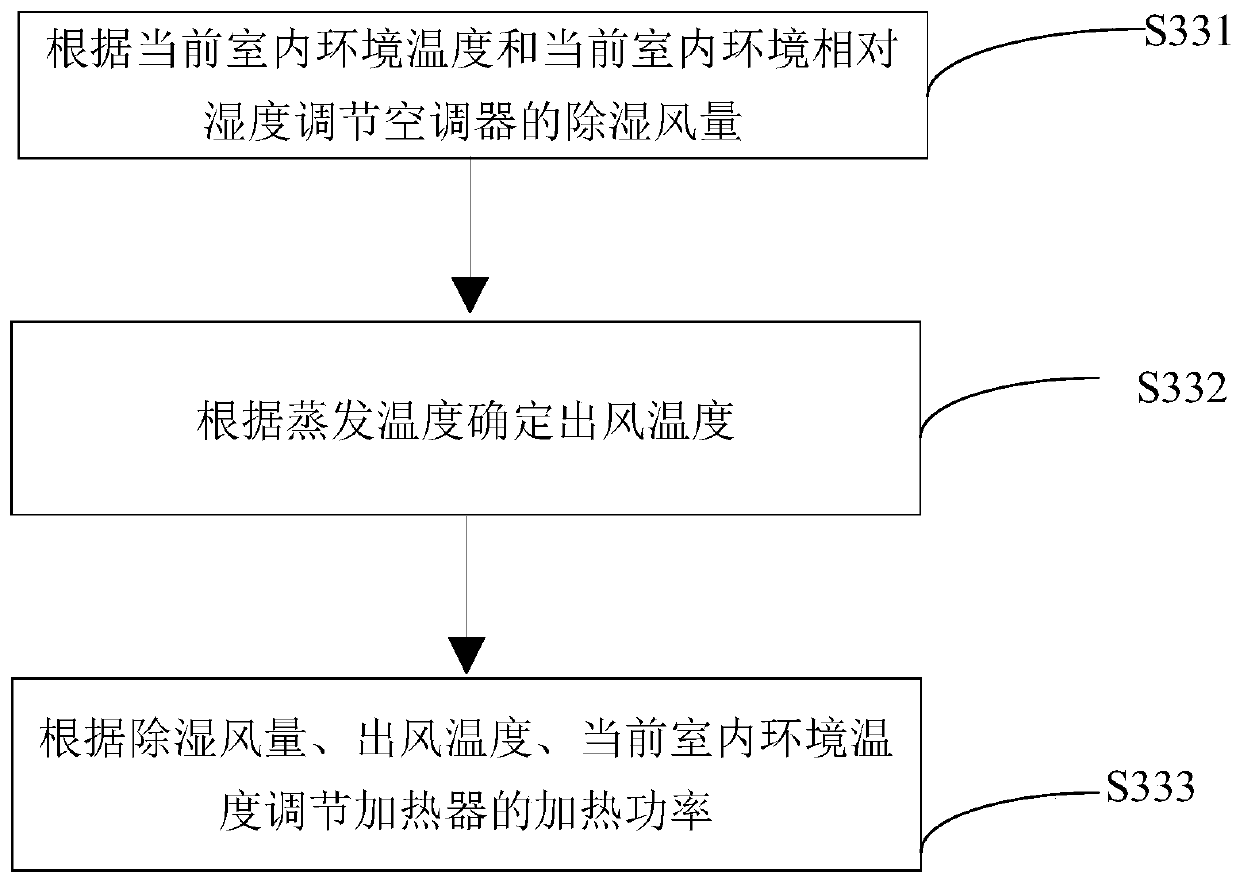

Air conditioner dehumidification control method and air conditioner

ActiveCN110057038AImprove comfortAccurate dehumidificationMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir temperature

The invention provides an air conditioner dehumidification control method and an air conditioner. The air conditioner dehumidification control method includes the steps that in the dehumidification mode, the current indoor environment temperature and the current indoor environment relative humidity are detected; the evaporating temperature is adjusted according to the current indoor environment temperature and the current indoor environment relative humidity; and the operating state of a heater is controlled according to the current indoor environment temperature, a first preset indoor environment temperature and a second preset indoor environment temperature. According to the air conditioner dehumidification control method, accurate dehumidification can be achieved by detecting the current indoor environment temperature and the current indoor environment relative humidity and then adjusting the evaporating temperature according to the current indoor environment temperature and the current indoor environment relative humidity. At the same time, according to the differences between the current indoor environment temperature and the preset indoor environment temperatures, the operating state of the heater is controlled, the effective control of the air outlet temperature can be achieved during precise humidification, and thus the method is beneficial to improving the comfort of the air conditioner dehumidification process.

Owner:NINGBO AUX ELECTRIC +1

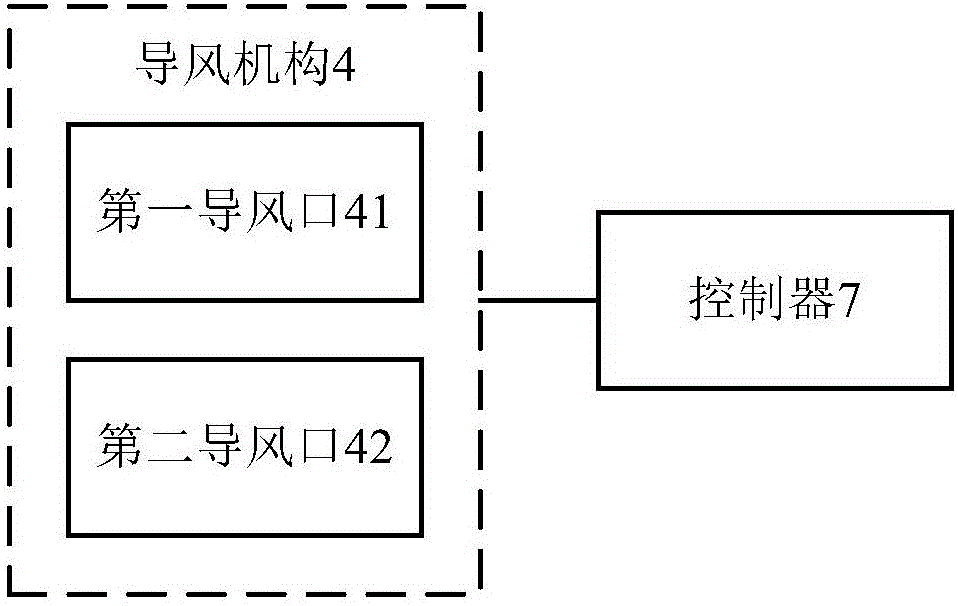

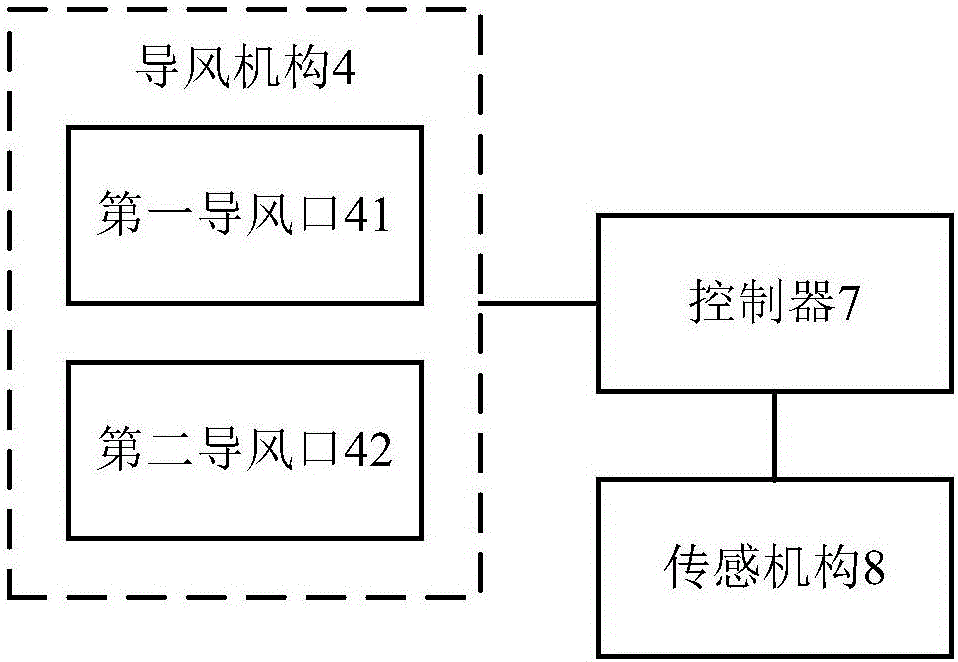

Control device of air conditioner, air conditioner and control method of air conditioner

InactiveCN106765999ASolve the problem of poor comfortImprove comfortMechanical apparatusSpace heating and ventilation safety systemsCold airAir volume

The invention discloses a control device of an air conditioner, the air conditioner and a control method of the air conditioner. The control device of the air conditioner comprises an air guide mechanism and a controller, wherein the air guide mechanism comprises two or more air guide ports with different flow areas; the air guide ports are arranged to be matched with an air outlet of the air conditioner and used for guiding cold air or warm air provided by the air outlet according to the flow areas of the air guide ports; the controller is arranged matched with the an air guide mechanism and used for determining whether the air conditioner guides air according to the set flow area or not, and when the air conditioner does not guide the air according to the set flow area, the current requirement for the size of the flow area of the environment where the air conditioner belongs is determined; and according to the current requirement, the air guide ports are switching-controlled so as to be able to switching-guide the air. According to the control device of the air conditioner, the air conditioner and the control method of the air conditioner, the defects that in the prior art, the air outlet quantity is not prone to controlling, and energy-saving performance and user experience are poor are overcome, and the beneficial effects that the air outlet quantity is easy to control, and the energy-saving performance and user experience are good are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

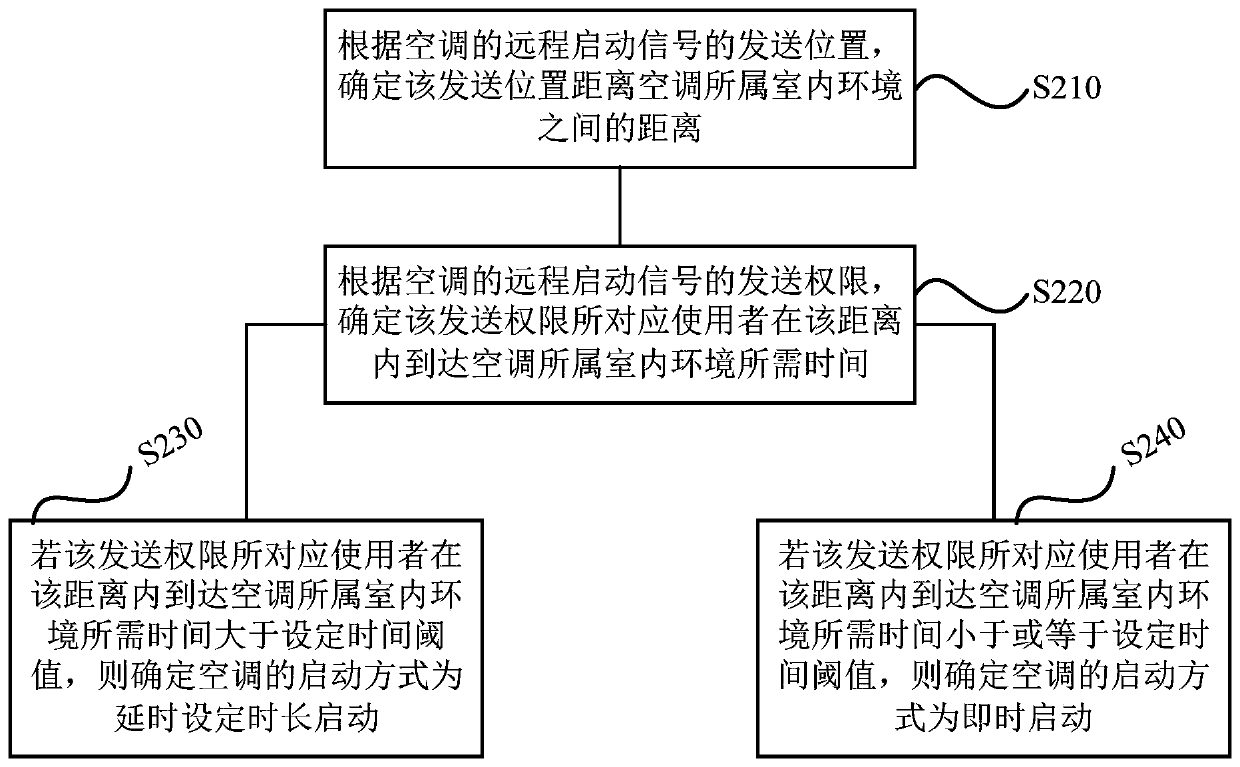

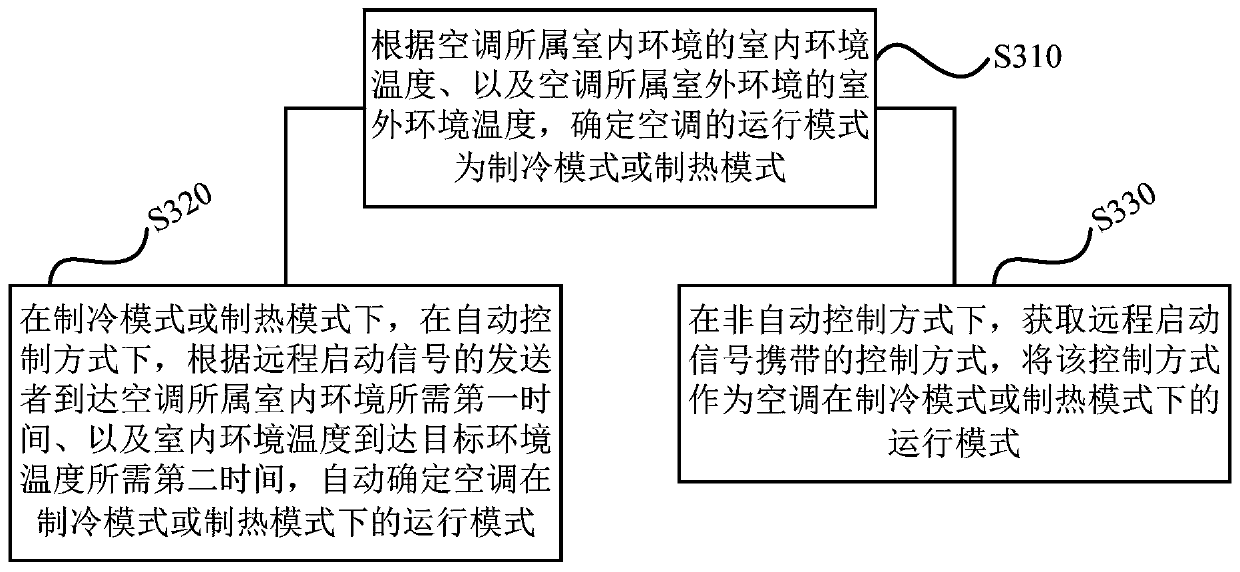

Air conditioner control method and device, storage medium and air conditioner

ActiveCN111070998AOptimized airflow organizationPromote air circulationAir-treating devicesVehicle heating/cooling devicesAutomotive engineeringStart signal

The invention discloses an air conditioner control method and device, a storage medium and an air conditioner. The method comprises the steps of: obtaining the remote starting signal of the air conditioner; determining the starting mode, the operation mode and the operation parameters of the air conditioner according to the remote starting signal of the air conditioner, and adjusting the seat backof a seat in the automobile to be in a set state under the condition that the air conditioner is an automobile air conditioner; controlling the air conditioner to be started according to the determined starting mode; controlling the air conditioner to be turned off or controlling the air conditioner to operate according to the set energy-saving mode under the condition that the air conditioner operates according to the determined operating parameters in the determined operating mode until the indoor environment temperature of the indoor environment to which the air conditioner belongs reachesthe target temperature, and adjusting the seat back of the seat in the automobile to restore the original shape under the condition that the air conditioner is the automobile air conditioner. According to the scheme, the problems that after a user enters the automobile, the air conditioner is started to adjust the temperature in the automobile, and before the temperature reaches the target temperature, the comfort feeling of the human body is poor can be solved, and the effect of improving the comfort feeling of the human body is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Computer desk with lifting function

InactiveCN107319742AEffective liftingImprove practicalityOffice tablesVariable height tablesDeskComputer engineering

The invention discloses a computer table with a lifting function, which includes a workbench, a first support rod and a second support rod are fixedly connected to the top of the workbench from left to right in sequence, and the inner chamber of the first support rod A rotating shaft is arranged transversely at the bottom, and the left side of the rotating shaft penetrates to the outside of the first support rod and is fixedly connected with a connecting rod. The present invention is provided with a table board, a fixed block, a horizontal plate, a second support bar, a first chute, a first slide block, a first slide bar, a connecting rod, a handle, a support plate, a second slide block, and a second chute , the second slide bar, the tooth plate, the rotating shaft and the gear are used together to effectively lift the computer desk, which solves the problem that the existing computer desk is used due to the differences in the user's height, weight and gender. The problem of poor comfort during work reduces labor loss, facilitates the use of users, improves the practicability of the computer desk, and is suitable for popularization and use.

Owner:SUZHOU JIAOZI INFORMATION TECH CO LTD

Support ring for internal support of tire

PendingCN110949067ADoes not affect productionEfficiency is not affectedRoad vehicle tyresRoad vehiclesIndustrial engineeringSupport surface

The invention discloses a support ring for inner support of a tire. The support ring is of an annular structure formed by mutually matching and assembling four support units, the top of each support unit is provided with a support surface, the top of each support unit converges towards the bottom, the convergent part is a support part, and one side, far away from the support surface, of the support part is provided with a contact surface. The support ring can play a role in run-flat protection after a tire is broken, so that it is guaranteed that a vehicle is not out of control, necessary tirereplacement is conducted after the vehicle safely runs to a reasonable position, meanwhile, the support ring can meet the run-flat protection requirements of all passenger vehicles, installation is easy and convenient, the adaptive capacity is high, and a traditional tire production process is not affected.

Owner:CHENGDU RUANKE TONGZHENG TECH CO LTD

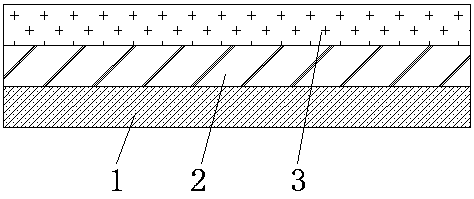

Semi-worsted wool top blended knitting yarn fabric with good antibacterial effect

PendingCN110450472ASolve the problem of poor comfortGuaranteed comfortClothingsWoven fabricsBiochemical engineeringFlax fiber

The invention discloses a semi-worsted wool top blended knitting yarn fabric with a good antibacterial effect. The fabric comprises a bottom layer, the surface of the bottom layer is fixedly connectedwith an antibacterial layer, the surface of the antibacterial layer is fixedly connected with a comfort layer, the surface of the comfort layer is fixedly connected with wool tops, the bottom layer comprises warp yarns and weft yarns, and is formed by interweaving the warp yarns and the weft yarns, the warp yarns are made by blending cotton fibers, flax fibers and bamboo charcoal fibers, the cotton fibers are used as a fiber core, the flax fibers and the bamboo charcoal fibers are spirally bonded to the fiber core, and the weft yarns are made by blending the cotton fibers, the bamboo charcoalfibers and moisture adsorbing and sweat removing fibers. The bottom layer, the antibacterial layer, the comfort layer and the wool tops are cooperatively used, so the problem of poor comfortablenessof traditional knitting yarn fabrics is effectively solved, and the fabric can greatly ensure the comfortableness of human bodies and improve the antibacterial effect, resists the invasion of externalbacteria, and has certain health effects.

Owner:苏州亿迈化纤有限公司

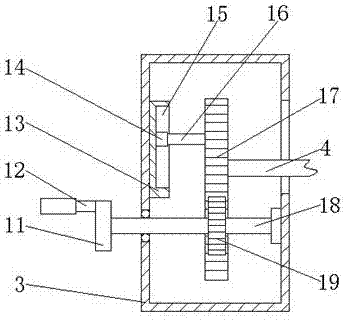

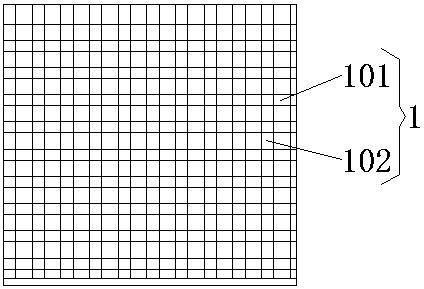

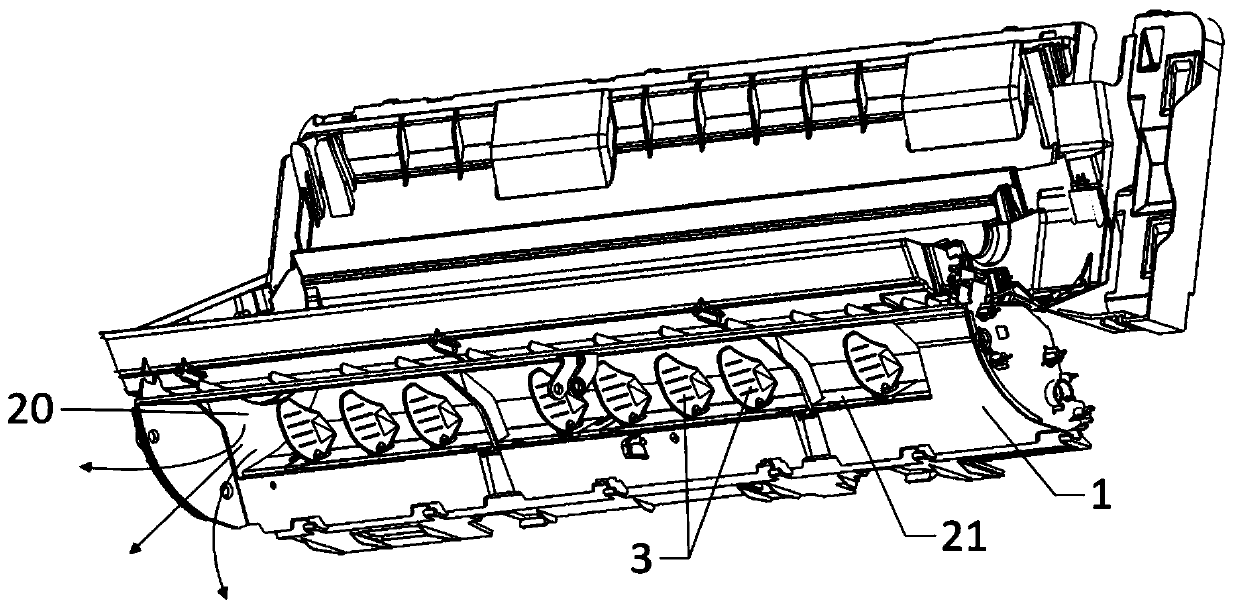

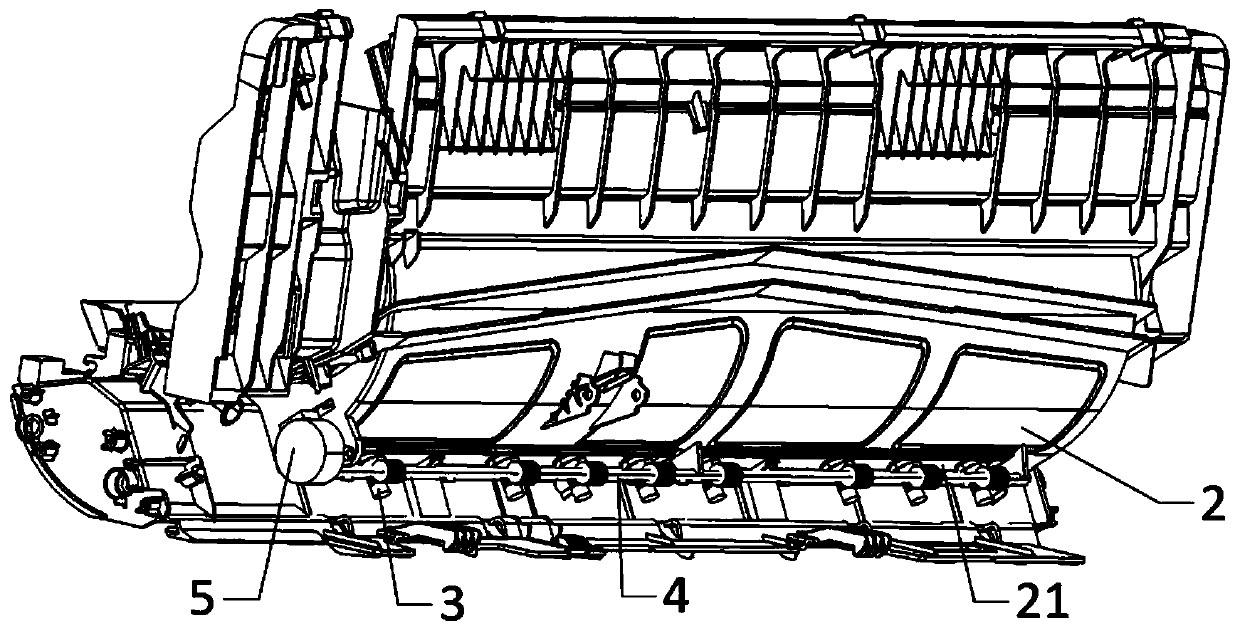

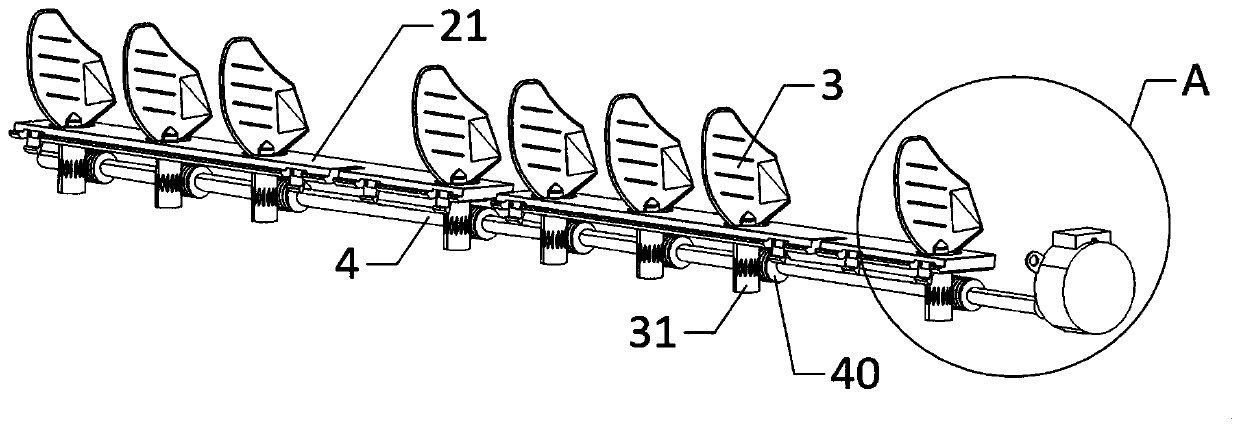

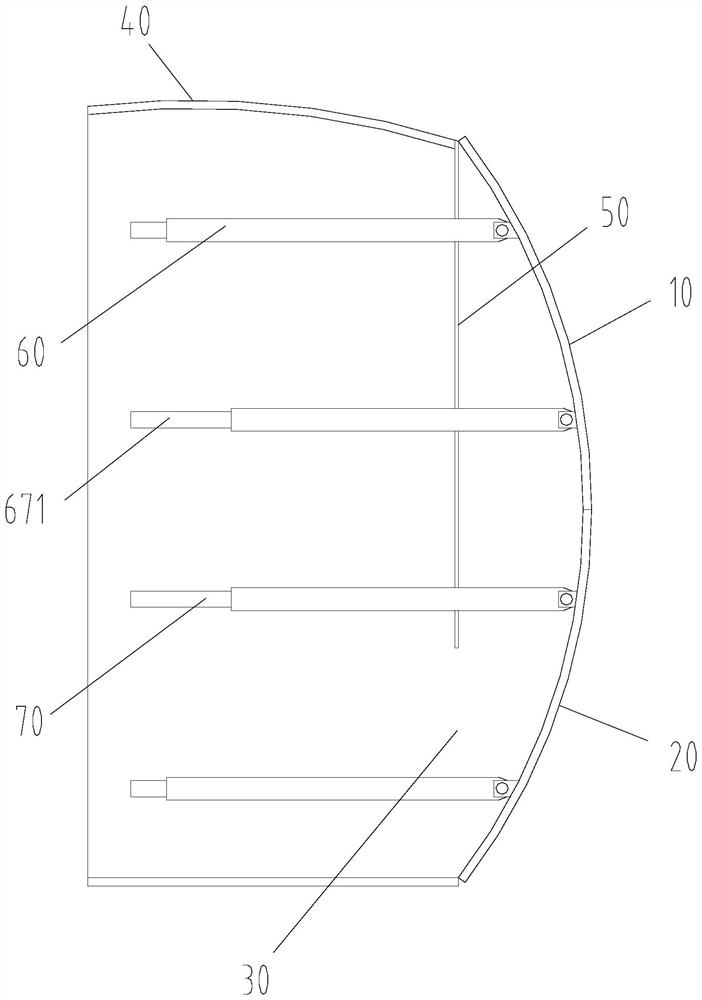

Wind guiding assembly for indoor unit of air conditioner and indoor unit of air conditioner

PendingCN110296470AExpand sweep rangeSimple structureLighting and heating apparatusAir conditioning systemsEngineeringGear tooth

The invention relates to the technical field of air conditioners, solves the problem that an existing swing blade transmission mechanism is complicated in structure and the swinging of swing blades islimited, and provides a wind guiding assembly for an indoor unit of an air conditioner and the indoor unit of the air conditioner. The wind guide assembly comprises a plurality of swing blades, a driving rod and a driving device, wherein the swing blades comprise blade parts and shaft parts; the shaft parts are connected to a fixed structure of the indoor unit in a pivoting manner; worm gear teeth are arranged on the shaft parts; the driving rod comprises a plurality of worm sections capable of being matched with the worm gear teeth; and the driving device is connected with the driving rod, and is used for driving the driving rod to rotate to drive the swing blades to rotate relative to the fixed structure. According to the wind guiding assembly, the swing blades are driven by a worm andgear structure, the limitation of a parallel four-link structure to the swinging angles of the swing blades is broken through, 360-degree rotation of the swing blades is realized, the wind guiding assembly is compact in structure and high in driving efficiency, the flexibility of the swing blades is higher, and the problem of a poor wind supply effect of the air conditioner is effectively solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Sleep-aiding pillow

InactiveCN112169131ADoes not take up spaceImprove comfortPillowsSleep inducing/ending devicesSleep stateStructural engineering

The invention provides a sleep-aiding pillow. The sleep-aiding pillow comprises a sleep-aiding pillow bottom plate and a sleep-aiding pillow body, and also comprises a noise reduction unit and at least one group of retractable light shielding cover units, wherein the noise reduction unit is used for reducing interference of external noise on a user entering a sleep state; the at least one group ofretractable light shielding cover units are arranged at the side, far away from the sleep-aiding pillow bottom plate, of at least one fixed cavity; each light shielding cover unit comprises a first light shielding plate and a second light shielding plate which are provided with cavities; and the second light shielding plate can move back and forth in a cavity of the first light shielding plate along a cavity track of the first light shielding plate through moving parts, so as to change the area of a shading area formed by the light shielding cover units; and the retractable light shielding cover units can be retracted into the cavity of the light shielding plate along the retraction track position of the light shielding cover units, so that the problems that in the prior art, when light shielding is not needed and a light shielding shed is folded, the stacked and accumulated light shielding shed can occupy a large space, the sleeping pillow use space of the user is reduced, and the use comfort of the user is poor are solved.

Owner:袁丽

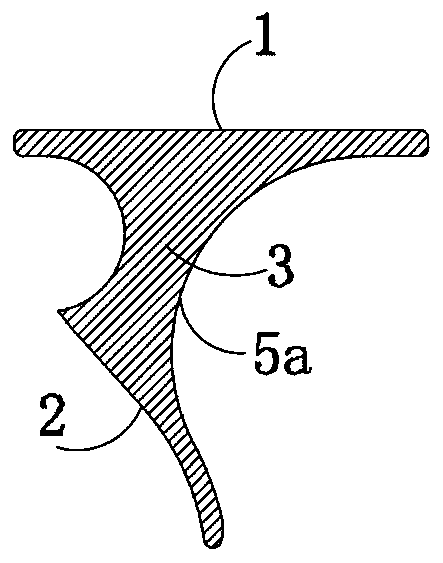

Air deflector assembly and air conditioner with same

InactiveCN113865069AExtended angle rangeExpand the range of air supplyDucting arrangementsHeating and ventilation casings/coversMechanical engineeringPhysics

The invention provides an air deflector assembly and an air conditioner with the same. The air deflector assembly is suitable for the air conditioner, the air conditioner further comprises a shell and a front panel, the front panel is a straight panel, an air outlet is formed between the lower side of the front panel and the side, close to a supporting base plane, of the shell, and the air deflector assembly comprises a first air deflector and a second air deflector; the first air deflector is movably arranged on the outer side of the front panel, and the first air deflector is provided with a plurality of first positions; at least part of the second air deflector is movably arranged on the outer side of the air outlet, and the second air deflector is provided with a plurality of second positions; and one of a plurality of first positions of the first air deflector is matched with one of a plurality of second positions of the second air deflector, so that the air outlet is opened or closed jointly or a plurality of air guide channels used for guiding airflow flowing out of the air outlet are formed, and the problem that in the prior art, the air supply range and the air supply angle of an indoor unit of an air conditioner are limited is solved.

Owner:GREE ELECTRIC APPLIANCES INC

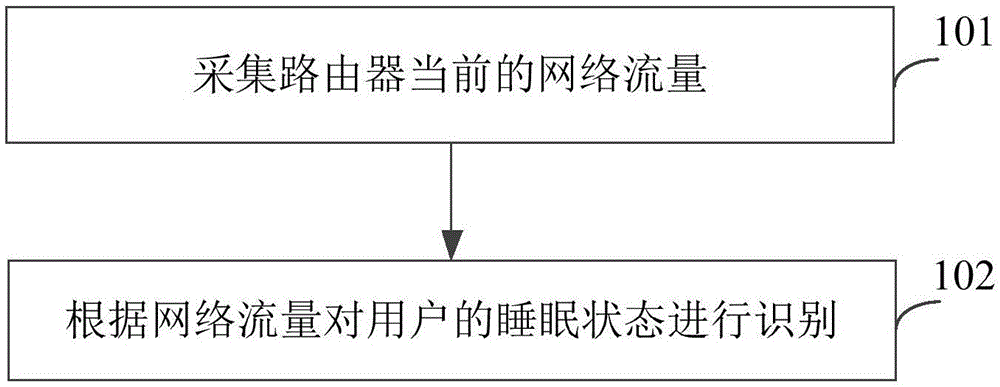

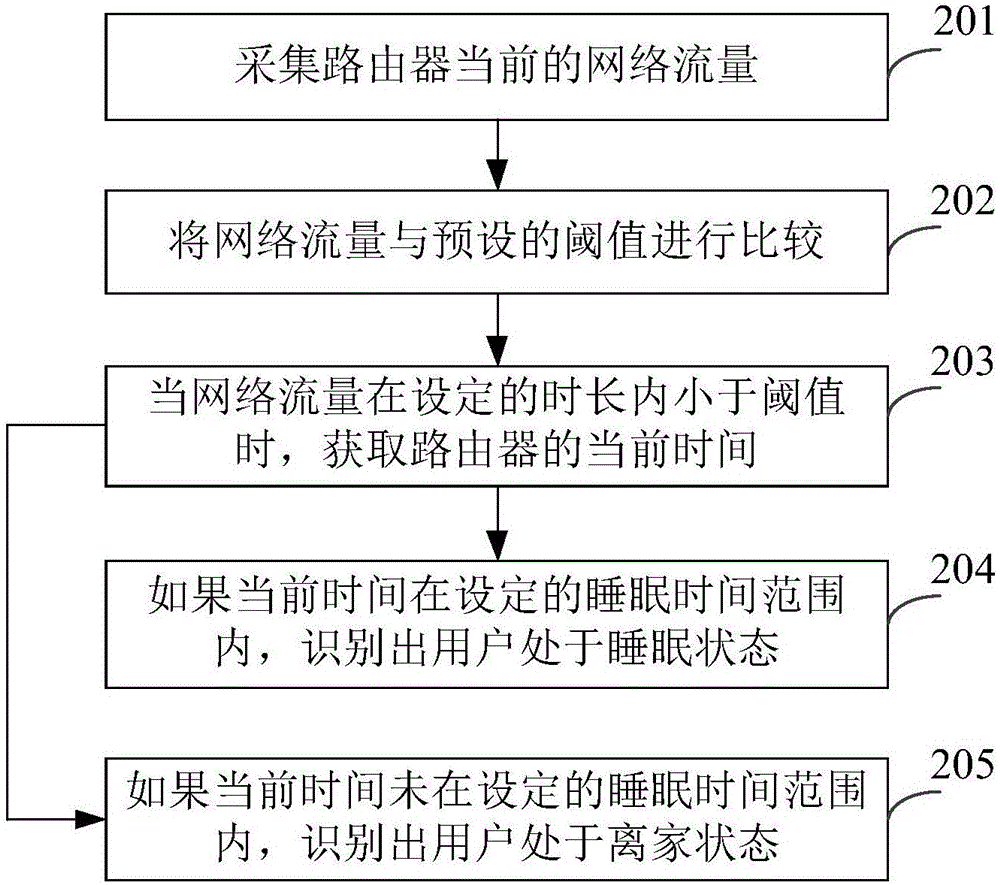

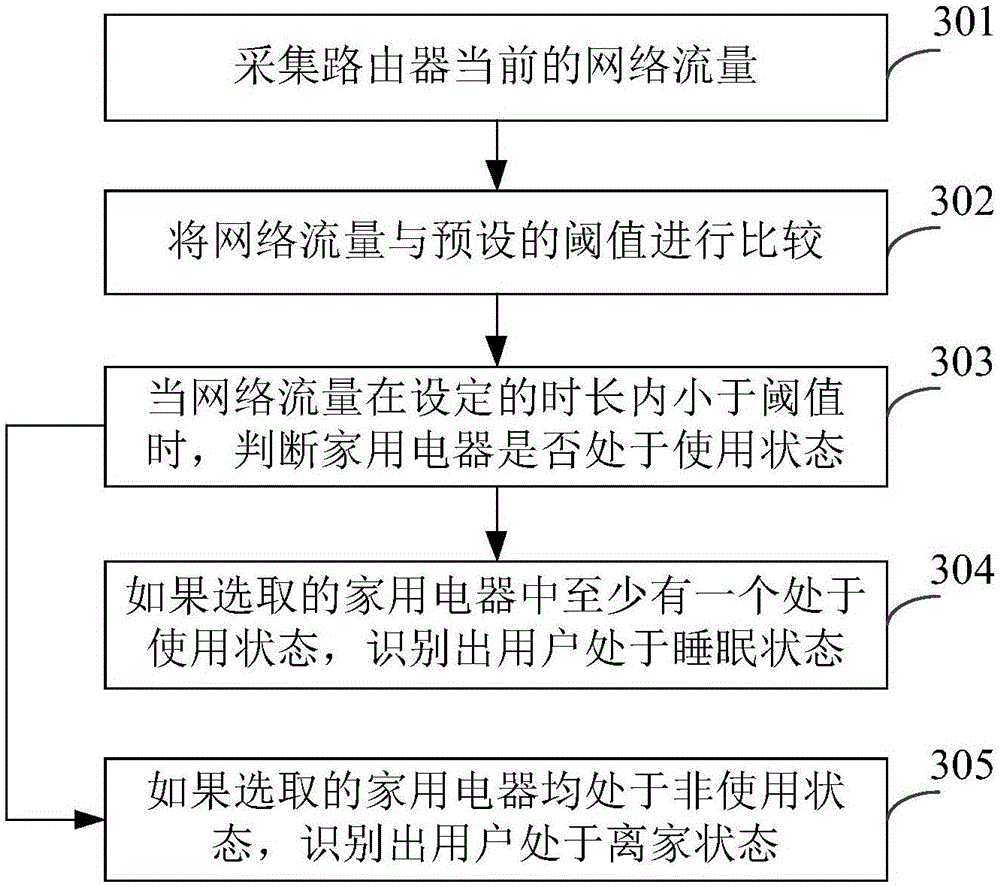

Sleeping state recognition method and device, router and internet of things server

InactiveCN106725311ASolve the problem of poor comfortDiagnostic recording/measuringSensorsTraffic volumeTraffic capacity

The invention provides a sleeping state recognition method and device, a router and an internet of things server. The method comprises the steps of collecting a current network flow of a router, and then recognizing the user sleeping state on the basis of the network flow of the router, so that the purpose of recognizing the user sleeping state without depending on intelligent wearable equipment any more is achieved, a user does not need to wear the intelligent wearable equipment in the sleeping process, and therefore the problem that in the prior art, the user comfort level is poor when the user sleeping state is recognized through the intelligent wearable equipment is solved.

Owner:MIDEA GRP CO LTD +1

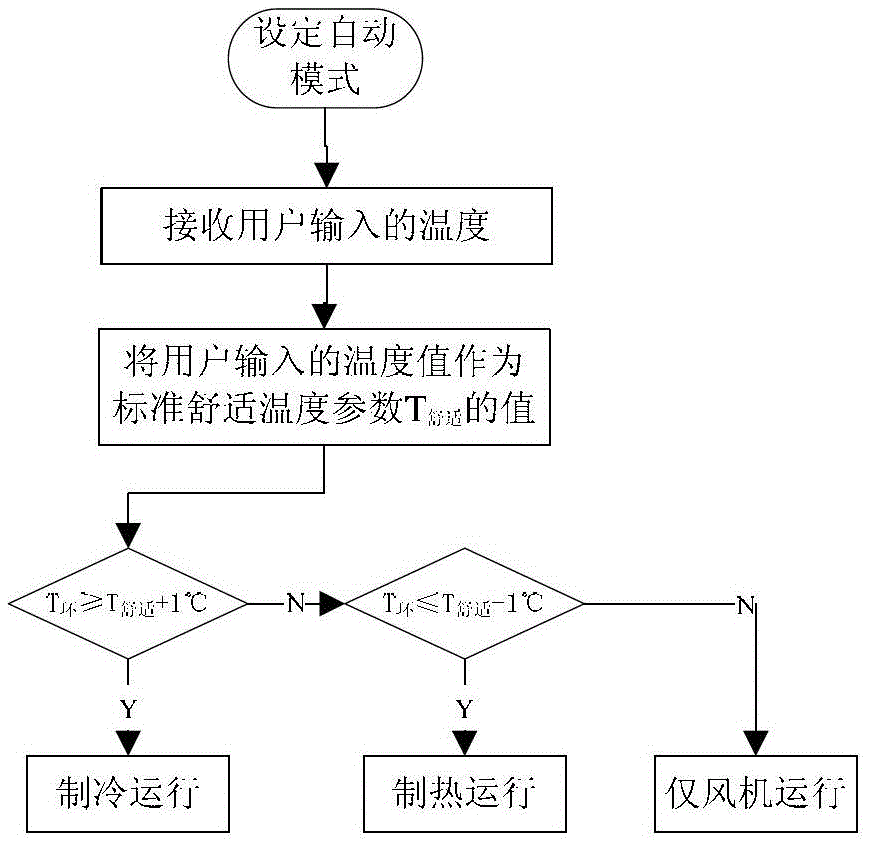

Air conditioner control method and control device

ActiveCN103591667BSolve the problem of poor comfortImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusComputer engineeringControl algorithm

The invention discloses a control method and a control device of an air conditioner. The control method includes: when the air conditioner is running in the automatic mode, receiving the temperature value input by the user; determining that the value of the standard temperature parameter in the control algorithm of the automatic mode is equal to the temperature value input by the user; and controlling the operation of the air conditioner according to the control algorithm. Through the present invention, the standard temperature of the air conditioner in the automatic mode can be set by the user, thereby meeting the individual needs of the user and improving the comfort of the air conditioner in the automatic mode.

Owner:GREE ELECTRIC APPLIANCES INC

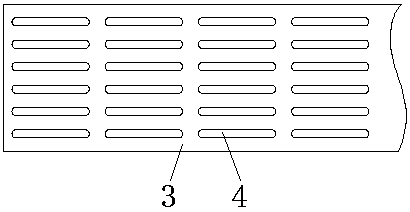

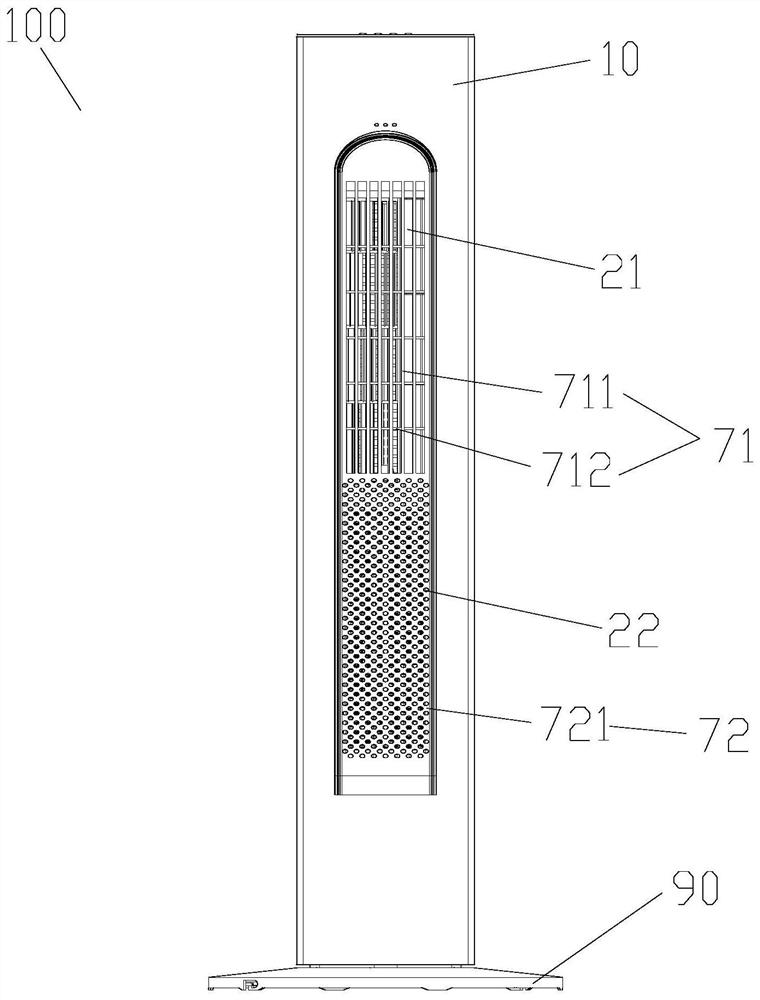

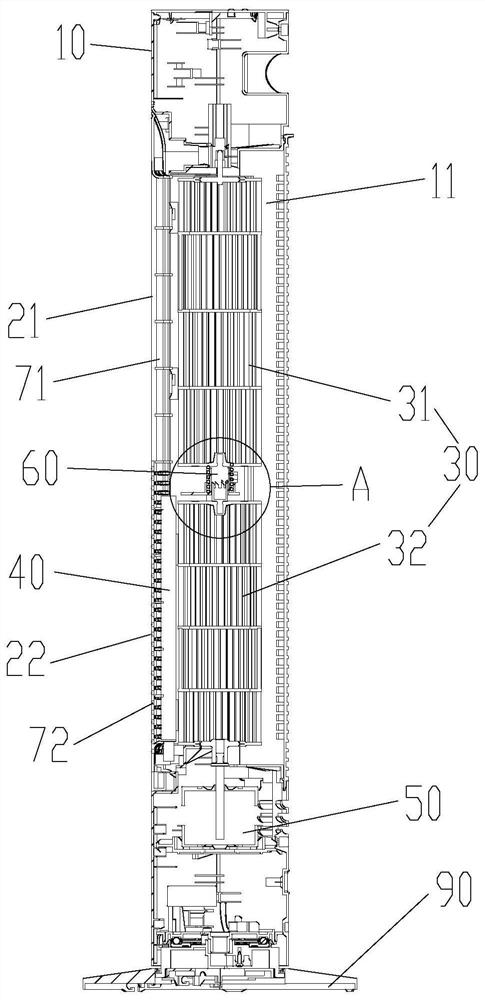

Air outlet device and tower fan

PendingCN111622972ASolve the problem of poor comfortEnhance the sense of windPump componentsAir heatersThermodynamicsGas passing

The invention provides an air outlet device and a tower fan. The air outlet device comprises a shell, a wind wheel assembly and a heating component. The shell is provided with a containing cavity andfurther provided with an air inlet, a first air outlet and a second air outlet which communicate with the containing cavity. The wind wheel assembly and the heating component are both arranged in thecontaining cavity. The wind wheel assembly comprises a first wind wheel and a second wind wheel, and the first wind wheel is located on one side of the first air outlet so that airflow in the containing cavity can flow out of the first air outlet under the action of the first wind wheel. The second wind wheel is located on one side of the second air outlet so that airflow in the containing cavitycan flow out of the second air outlet under the action of the second wind wheel. The heating component is located between the second air outlet and the air inlet so that the heating component can be used for heating at least part of gas passing through the second air outlet. The synchronous rotation state and the independent rotation state are achieved between the first wind wheel and the second wind wheel. By usage of the device, the problem that a cooling and heating type tower fan in the prior art is poor in comfort can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

Machine shell assembly and air conditioner

PendingCN112747448AImprove comfortSolve the problem of poor comfortDucting arrangementsSpace heating and ventilation safety systemsCold airEngineering

The invention provides a machine shell assembly and an air conditioner. The machine shell assembly comprises a machine body, a first air guide plate and a second air guide plate, a first air outlet opening is formed in the machine body, and the first air guide plate and the second air guide plate are both arranged at the position of the first air outlet opening. The first air guide plate and the second air guide plate are arranged vertically in a spaced mode so that a circulating air duct can be formed between the first air guide plate and the second air guide plate. When the first air outlet opening is used for blowing out cold air, the circulating air duct is arranged obliquely upwards. When the first air outlet opening is used for blowing out hot air, the circulating air duct is arranged obliquely downwards, and therefore the hot air which is blown out can fall onto the ground in time, the comfort of the air conditioner is improved, and the problem that the comfort of an air conditioner in the prior art is poor is solved.

Owner:GREE ELECTRIC APPLIANCES INC

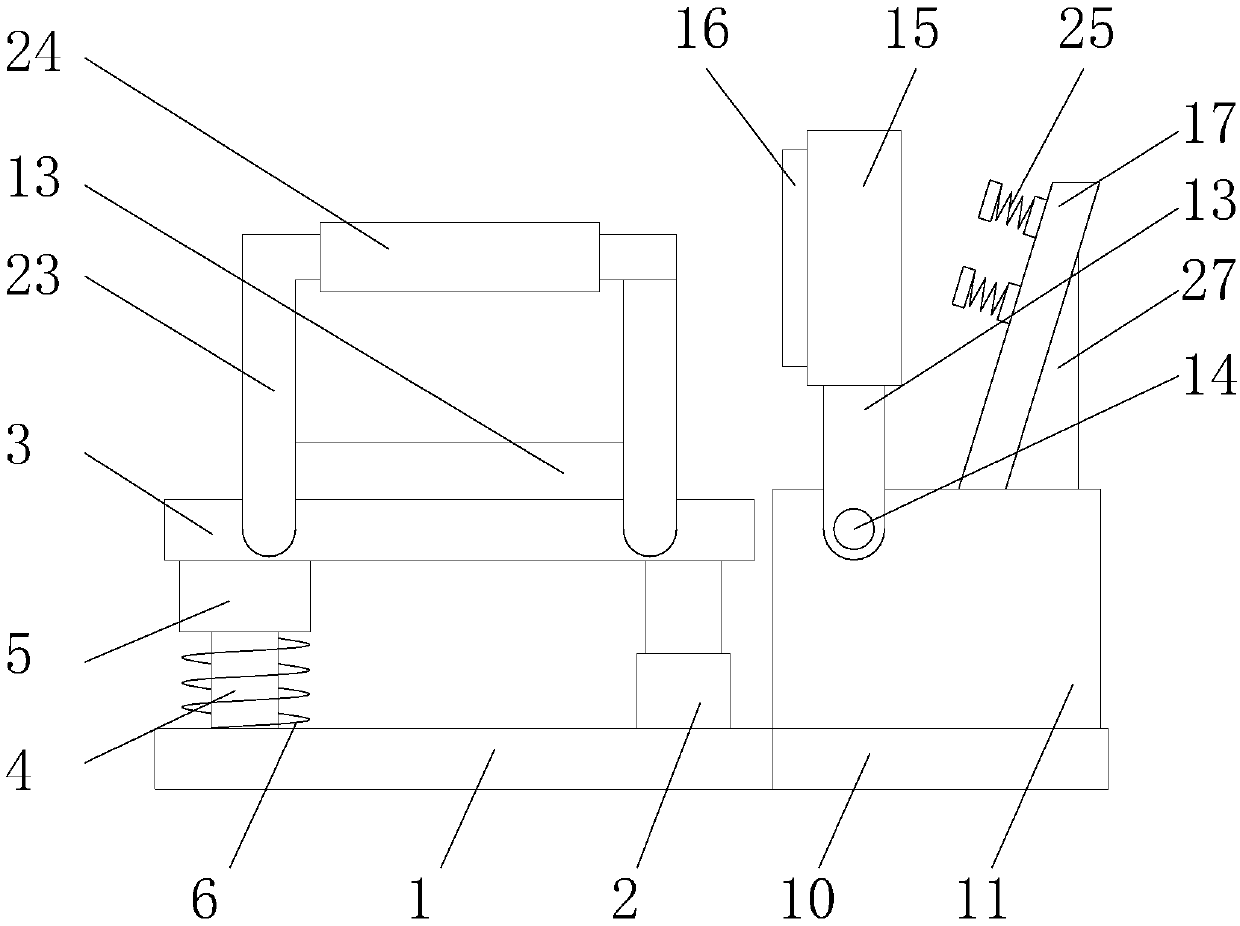

Gynecological nursing tray

InactiveCN107928927ASolve the problem of poor comfortAccurate dressing changeOperating tablesNursing bedsEngineeringPatient care

The invention discloses a tray for gynecological care, comprising a support base, two telescopic rods are arranged symmetrically on the rear side of the top of the support base, the tops of the two telescopic rods are fixedly connected by the tray body, and the front side of the top of the support base is In addition, two fixed columns are arranged symmetrically corresponding to the position of the telescopic rod, and a circular sleeve is fixedly connected to the position corresponding to the fixed column at the bottom of the tray body. The present invention solves common gynecological problems by arranging a fixed column, a circular sleeve, a first buffer spring, a slot, a second buffer spring, a soft seat cushion, a first rotating plate, a second rotating plate, a backrest and a soft cushion. The patient with the nursing tray has poor comfort when using it, and avoids the problem of difficulty in disinfection due to uncomfortable sitting posture and movement. The nursing doctor can accurately change the dressing on the patient's genitals without serious problems such as bacterial infection. And nursing doctors have brought great convenience.

Owner:成都千里之行科技有限公司

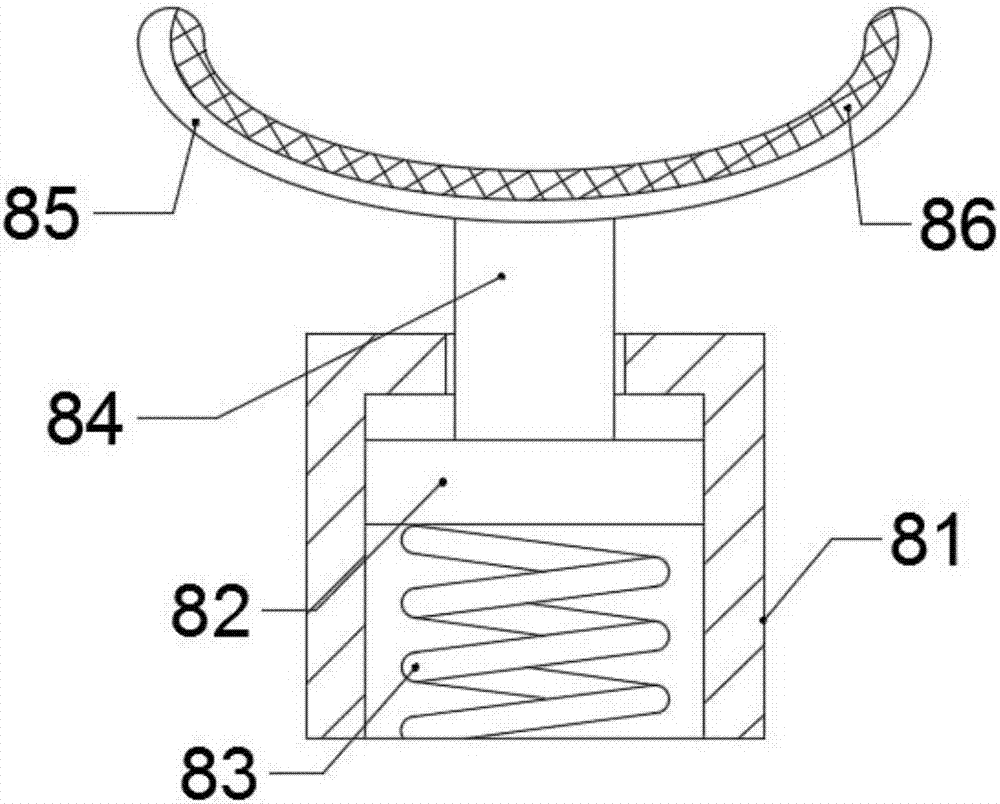

Cushion and bed

PendingCN114010002ASolve the problem of poor comfortFeel goodFluid mattressesBedsClassical mechanicsCushion

The invention relates to the technical field of beds, and provides a cushion and a bed. The cushion comprises: a support layer assembly in which a pipeline channel is embedded; an air bag assembly located on the supporting layer assembly; and a pipeline assembly which is at least partially arranged in the pipeline channel in a penetrating mode and communicates with the air bag assembly. According to the technical scheme, the problem that in the prior art, due to fixation of the air pipe, the comfort of the cushion is poor is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

Low-temperature preheating system for engineering machine

InactiveCN107339186ASolve the cold start problemEffective warm-upMachines/enginesThermal treatment of fuelGasoline fuelFuel tank

Disclosed is a low-temperature preheating system for an engineering machine. The bottoms of an engine oil tank and a diesel oil fuel tank are provided with a first heating pipeline and a second heating pipeline respectively, and the first heating pipeline and the second heating pipeline are each provided with a plurality of dissipating fins. An oil inlet of a fuel heater is connected with the bottom of a gasoline fuel tank, a water inlet of the fuel heater is connected with a water outlet of a warm air system through a pipeline, a water inlet of the warm air system is connected with a third water outlet on an engine assembly through a pipeline, a third water inlet on the engine assembly is connected with a second water outlet of a second heating pipeline through a pipeline, a second water inlet of the second heating pipeline is connected with a first water outlet of a first heating pipeline through a pipeline, and a second water outlet of the first heating pipeline is connected with a water outlet of the fuel heater through a pipeline. A riser tube is low in cost, iron corrosion in the casting process can be avoided, and impact formed at the bottom of a foundry furnace caused by backflow of molten metal can be effectively lowered. The system can solve the cold-boot problem, and can improve the comfort level of a driver.

Owner:XUZHOU DONGLI FORGING MACHINERY

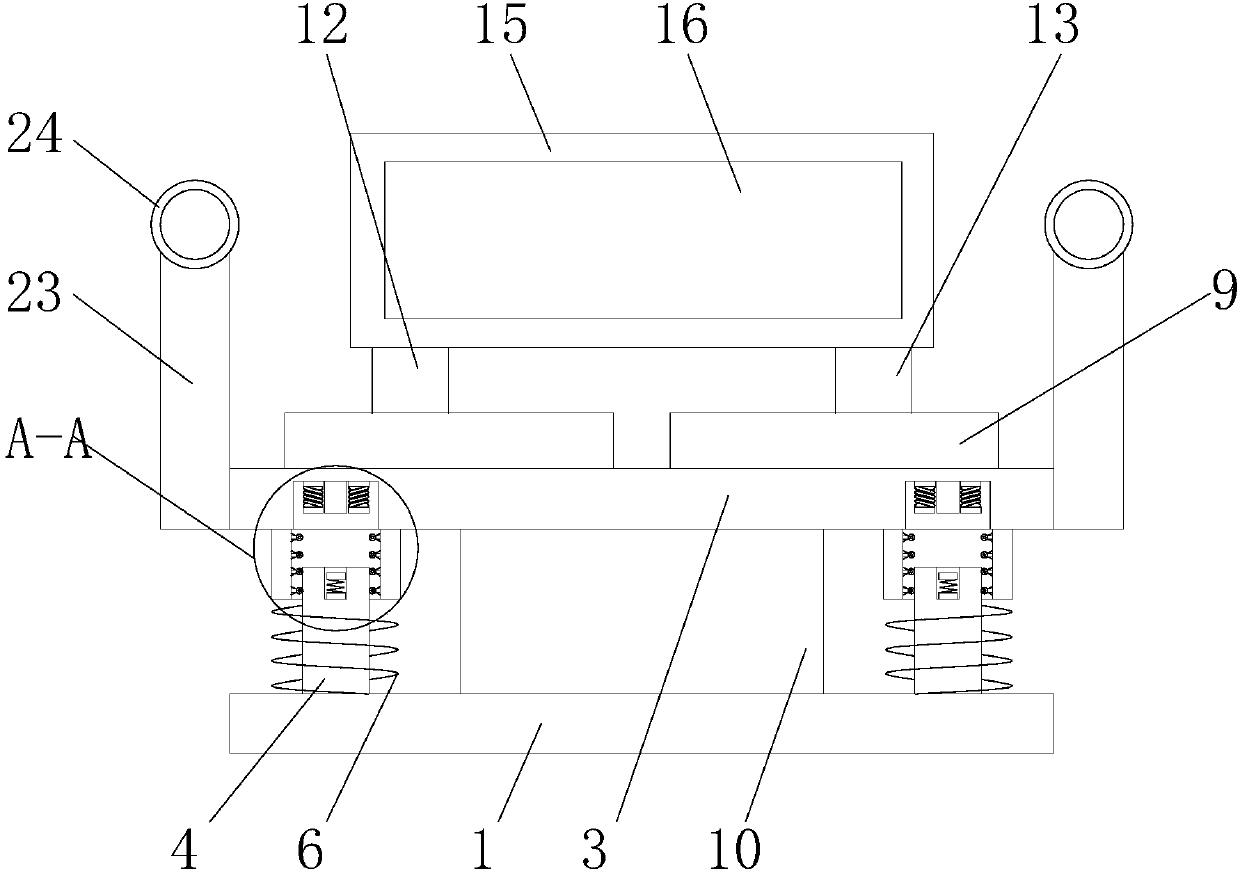

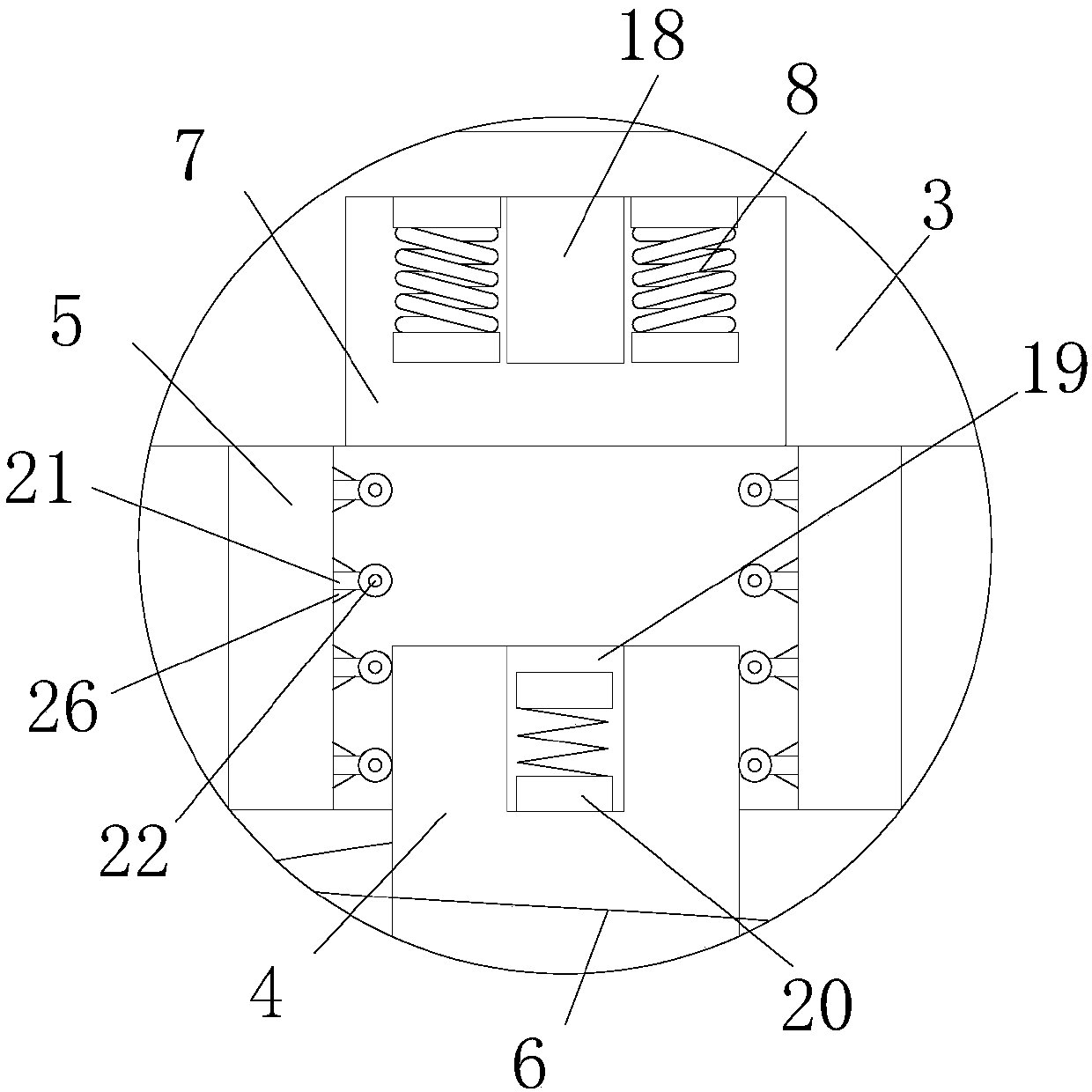

Elevator

PendingCN106956995ANo skewSolve the problem of poor comfortBuilding liftsMine liftsDynamic balanceControl theory

The invention discloses an elevator. The elevator comprises a dynamic compensating device, a steel wire rope compensating device, a traveling cable, a counterweight which is movably installed on a counterweight guide rail inside a hoistway, and a lift car assembly which is movably installed on a lift car guide rail inside the hoistway. The lift car assembly comprises a lift car and a car frame. The steel wire rope compensating device and the travelling cable are installed at one side of the plane where the lift car guide rail is located, and the dynamic compensating device is installed at the other side of the plane where the lift car guide rail is located. The dynamic compensating device comprises a first end and a second end in the length direction of the dynamic compensating device. The first end is fixedly connected to the lift car assembly, and the second end is fixedly connected into the hoistway. According to the elevator, in the operating process of the lift car, dynamic equilibrium of the two sides of the plane where the guide rail is located can be kept, deflection can be avoided, and the comfort feeling of the elevator cannot be deteriorated after long-term operation.

Owner:SJEC CORP

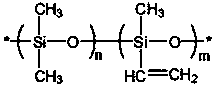

Surface treatment process for hydrophilic-group silica gel

InactiveCN109353036AGood chemical resistanceImprove antifouling performanceGeneration processIlluminance

The invention discloses a surface treatment process for hydrophilic-group silica gel. The surface treatment process for the hydrophilic-group silica gel comprises the following steps: (1) a pluralityof silica gel parts are placed in an emptying jig at intervals; (2) a hydrophilic-group machine is started, and hot gas is discharged; (3) a plurality of hydrophilic-group lamp pipes are turned on from a cold state, and illuminance and a temperature in a tunnel furnace start to rise; and (4) a conveying belt conveys the emptying jig into the tunnel furnace, the hydrophilic-group lamp pipes irradiate the outer surfaces of the plurality of silica gel parts on the emptying jig, high-energy photons irradiated from the hydrophilic-group lamp pipes break oxygen atoms in air, and the reaction equation is that O2 is decomposed into O and O; and meanwhile, the high-energy photons break the structural formula of methyl vinyl silicone rubber in the silica gel parts to obtain CH3, the broken oxygen atoms are reacted with the methyl vinyl silicone rubber to generate hydrophilic groups CHO-, OH- and COH-. The surfaces of the silica gel parts treated through the surface treatment process for the hydrophilic-group silica gel are smooth, and better hand feeling during touch is achieved; and meanwhile, the fitting degree and the antifouling property of the surfaces of the silica gel parts are greatly improved, and in the generation process for the hydrophilic groups, pollution is completely avoided, and higher environment friendliness is achieved.

Owner:DONGGUAN TAIYANG RUBBER PLASTIC INDAL

Control method, device, storage medium and processor of terminal equipment

ActiveCN107797459BImprove rationalityImprove comfortComputer controlNeural architecturesComputer hardwareTarget control

The present invention provides a terminal device control method, device, storage medium and processor, wherein the method includes: the control device obtains the current characteristic parameters detected by the terminal device; the control device obtains the current characteristic parameters through the target neural network model A corresponding target control signal; the control device sends the target control signal to the terminal device. The above technical solution solves the problem in the related art that poor control of terminal equipment leads to poor comfort for users, improves the rationality of terminal equipment, and makes users more comfortable in the current environment.

Owner:GREE ELECTRIC APPLIANCES INC

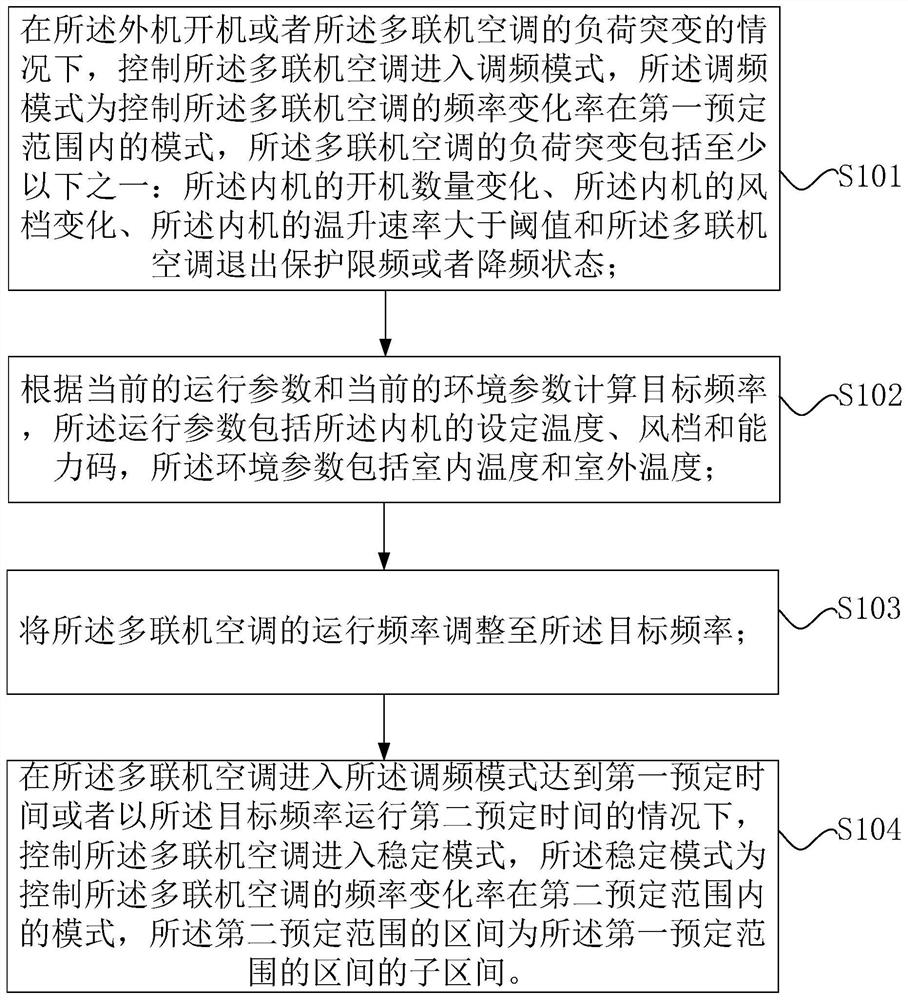

Frequency control method and device for multi-split air conditioner and air conditioning system

ActiveCN113958997ASolve the problem of poor comfortImprove reliabilityMechanical apparatusSpace heating and ventilation safety systemsControl engineeringAir conditioning

The invention provides a frequency control method and device for a multi-split air conditioner and an air conditioning system. The method comprises the steps that under the condition that an outdoor unit is started or the load of the multi-split air conditioner changes suddenly, the multi-split air conditioner is controlled to enter a frequency modulation mode, and the frequency modulation mode is a mode for controlling the frequency change rate of the multi-split air conditioner to be in a first preset range; a target frequency is calculated according to a current operation parameter and a current environment parameter; the operation frequency of the multi-split air conditioner is adjusted to a target frequency; and under the condition that the frequency modulation mode of the multi-split air conditioner reaches a first preset time or the multi-split air conditioner operates at the target frequency for a second preset time, the multi-split air conditioner is controlled to enter a stable mode, the stable mode is a mode for controlling the frequency change rate of the multi-split air conditioner to be in a second preset range, and the interval of the second preset range is a subinterval of the interval of the first preset range. The problem that in the prior art, when the load of the multi-split air conditioner changes suddenly, the frequency cannot be adjusted in time, and consequently comfort is poor is solved.

Owner:GREE ELECTRIC APPLIANCES INC

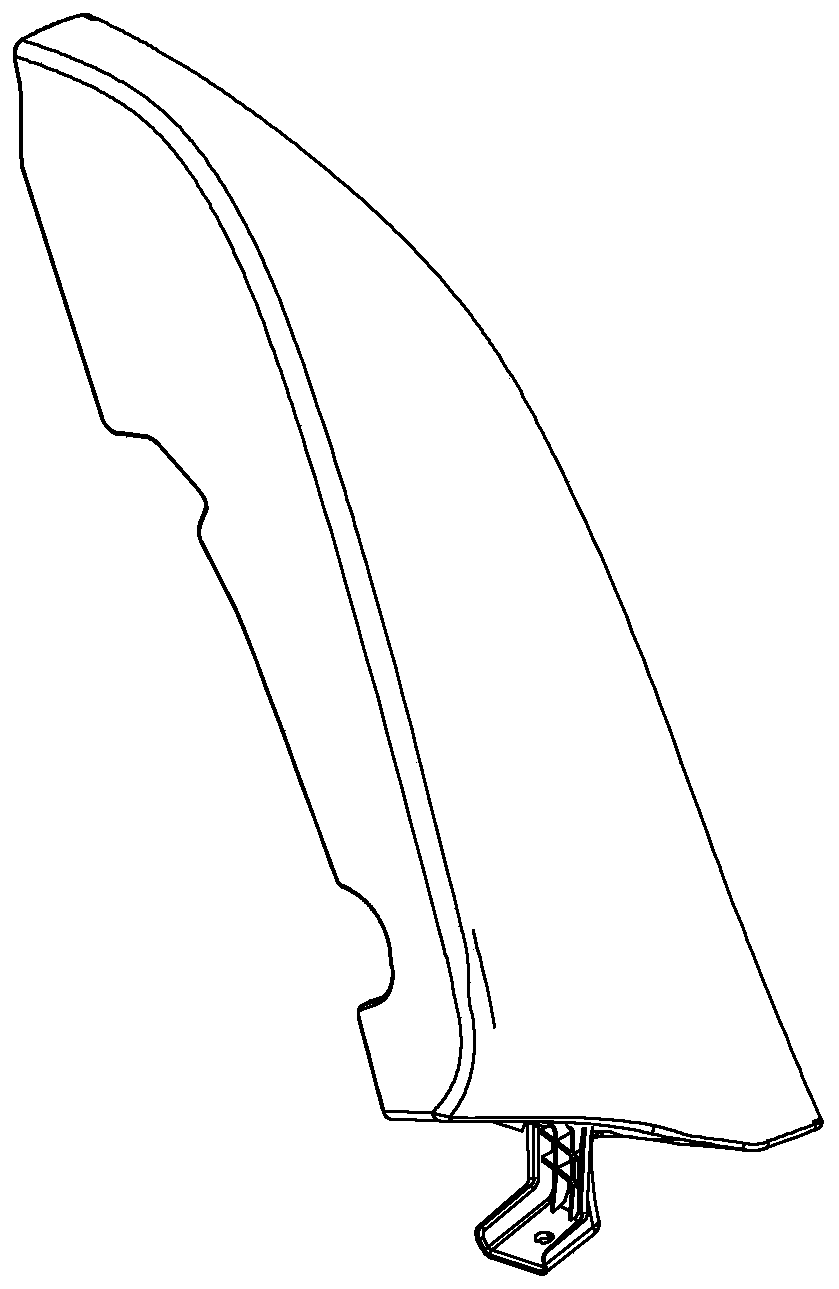

Comfortable and easy-to-disassemble automobile rear seat flank

The invention discloses a comfortable and easy-to-disassemble automobile rear seat flank. The automobile rear seat flank comprises a plastic flank framework. The upper end of the flank framework is provided with a flank fixing buckle to form an upper fixing point, the upper fixing point can be directly buckled into a hole in a vehicle body, the lower end of the flank framework is provided with a lower fixing point, and the lower fixing point is connected with the vehicle body through bolts, so that the seat flank and the vehicle body are convenient to disassemble and assemble. The seat flank also comprises flank foam and flank skin, and the flank foam is buckled on the flank framework. The flank skin positioned on the outermost side covers the flank foam and is hung on the flank framework.According to the seat flank, a foaming and skin covering technology is adopted, so that the comfort degree of the flank and the visual effect of the appearance of the flank are improved. Moreover, the flank and the vehicle body are detachably connected with each other, and not only is the strength of a mounting structure is ensured, but also the requirement of a whole vehicle factory for disassembling and assembling flank assemblies several times is met.

Owner:GAC COMPONENT CO LTD

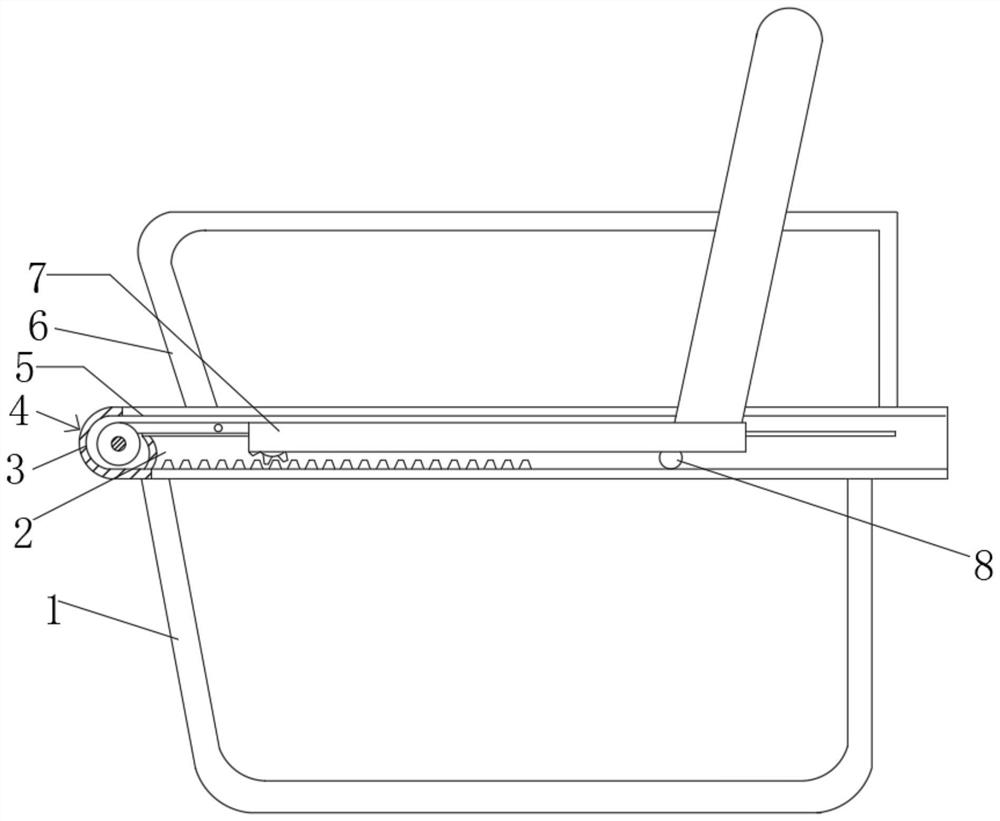

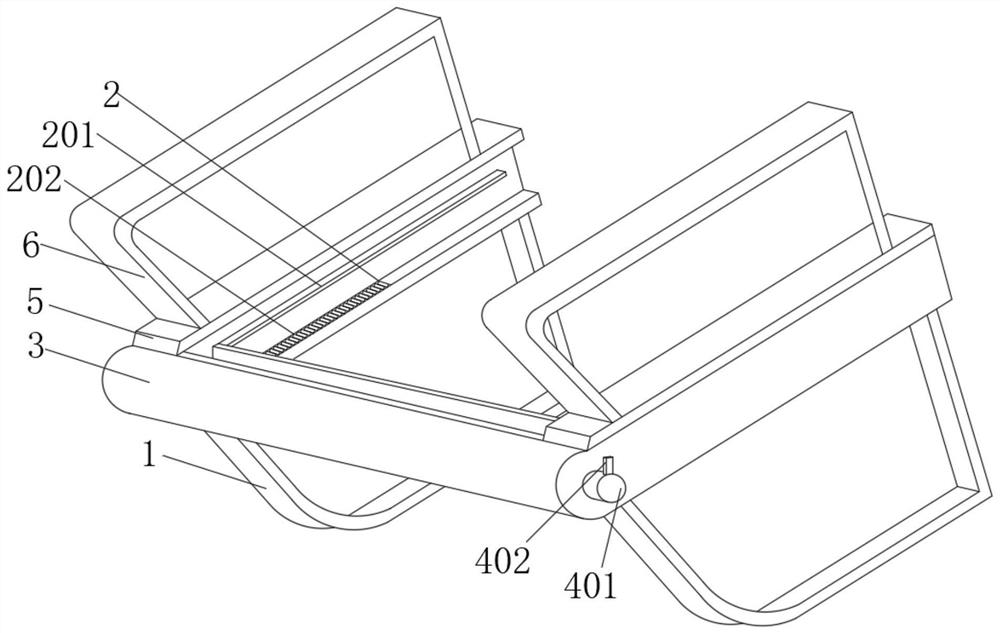

Office chair convenient to adjust

The invention relates to the technical field of office chairs, and discloses a convenient-to-adjust office chair which comprises chair legs; a transverse bearing plate is fixedly mounted at the tops of the chair legs, a storage box is fixedly connected to one end of the transverse bearing plate, and a rotating wheel structure is rotatably connected to an inner cavity of the storage box; armrests are fixedly installed at the top of the transverse bearing plate, a sliding groove is formed in the side face of the transverse bearing plate, a gear rack is fixedly installed at the bottom of an innercavity of the sliding groove, a sliding plate is fixedly connected to the side face of the inner cavity of the sliding groove, and a cushion structure is slidably connected into the sliding groove. The office chair disclosed by the invention solves the problems that a common office chair cannot incline a backrest to enable a user to lie on the backrest to have a rest due to the limitation of an office place; the common office chair cannot enable the user to have a comfortable rest environment during noon break, and the common office chair is poor in comfort.

Owner:海宁华瀚电子科技有限公司

Getting-up assisting device for nursing

InactiveCN113893103ASolve the problem of poor comfortImprove comfortNursing bedsHuman bodyNursing care

The invention discloses a getting-up assisting device for nursing and relates to the technical field of nursing instruments. The getting-up assisting device is mainly used for solving the problem that an existing getting-up assisting device for nursing is poor in comfort. The getting-up assisting device comprises a bed body assembly, a driving mechanism, an air bag part and an inflation assembly, wherein a movable bed body is arranged on the bed body assembly, the air bag part is located on the movable bed body, and the inflation assembly comprises a sealing part filled with gas and a compression piece located in the sealing part; and a conveying piece is connected between the sealing part and the air bag part. An eccentric part in the driving mechanism can be used for applying pressure to a pressure bearing piece through eccentric rotating motion, thus, the movable bed body is driven to rotate at a certain angle, the movable bed body doing the rotating motion drives the compression piece to move in the sealing part through a first linkage piece, the moving compression piece compresses the air in the sealing part to the air bag part through the conveying piece, the air entering the air bag part drives the air bag part to expand so as to achieve the purpose of supporting a human body, and the getting-up assisting device has the characteristic of being good in comfort.

Owner:XUCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com