Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121results about How to "Moisture permeable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Interior wall adornment leather and preparation method

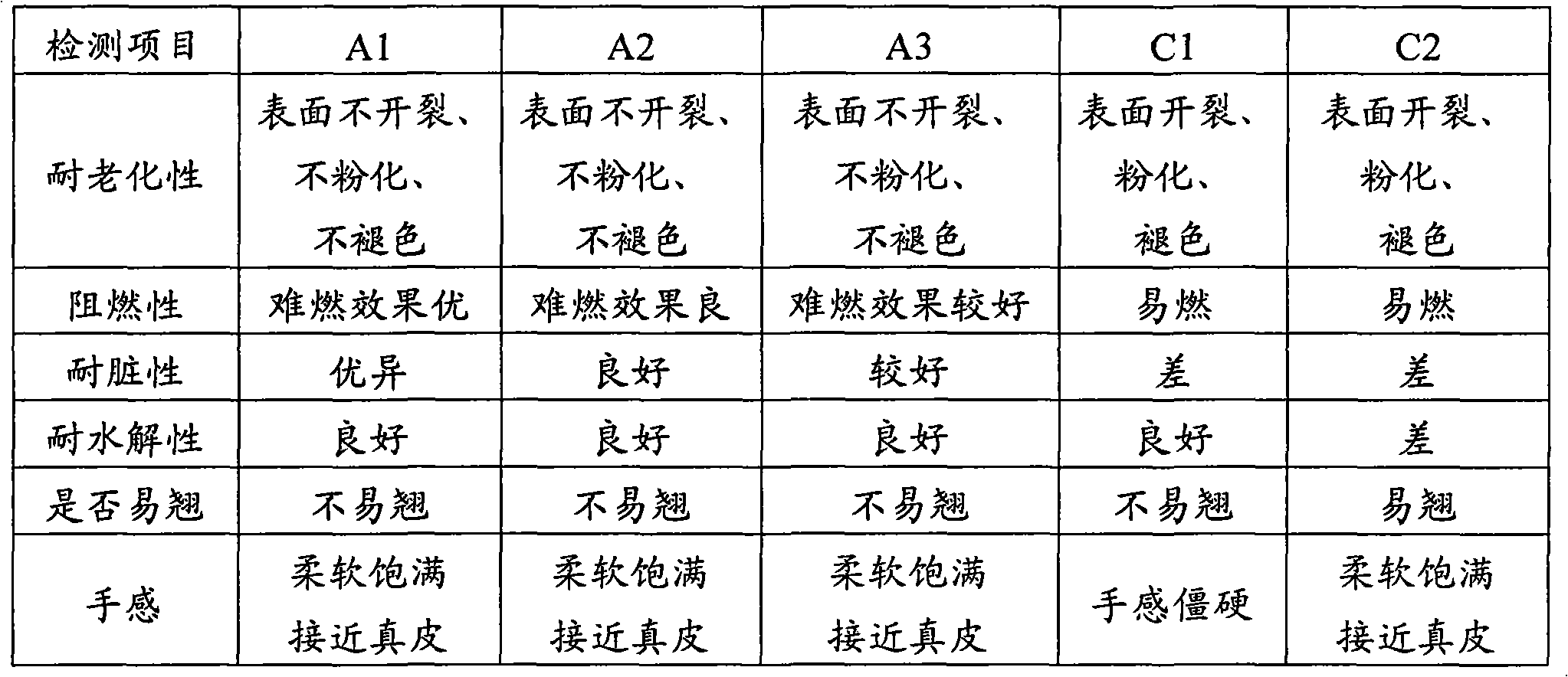

The invention provides interior wall adornment leather and a preparation method. The interior wall adornment leather comprises base fabric, a foaming layer and a surface layer, wherein an adhesive layer is arranged between the base fabric and the foaming layer; the foaming layer contains foamed water-borne polyurethane resin; the surface layer contains inflaming retardant water-borne polyurethane resin; and the adhesive layer contains adhesive water-borne polyurethane resin. The interior wall adornment leather not only has the advantages of traditional wallpaper sound insulation, heat preservation, gorgeousness and easy adornment, but also has the advantages of safety, environment protection, endurance, ageing resistance and fame resistance, which are incomparable with the traditional wallpaper, and can effectively overcome the defects that the traditional wallpaper is easy to raise margins, does not resist dirt and damp, has poor handfeel, and can not be repaired after wrinkling and the like.

Owner:丽水市优耐克水性树脂科技有限公司

Polytetrafluoroethylene multi-layer composite film and its protective material preparation method

InactiveCN101104314ASimple processLow costLaminationLamination apparatusMicroorganismPolymer science

The invention relates to a multi-layer polytetrafluoroethylene composite film and protective material making method thereof. The method is characterized in that a polytetrafluoroethylene base band and a thermoplastic permeable film are drawn longitudinally together under the temperature of 100 to 200 DGE C and then are drawn widthwise together on an expander under the temperature of 50 to 300 DGE C and at last are sintered to stereotype under the temperature of 200 to 400 DGE C, in this way the multi-layer composite film is made. With the method of laminating, the composite film is made into a protective material with machine woven fabric, knitted fabric or non-woven fabric through bonds. The protective material has a steam permitting capability of 3000 to 12000g per square meters per 24 hours, a hydraulic pressure bearing capability of 50 to 220 thousand pa, the filtration efficiency for the microorganism in the air equal to or more than 99 percent, and the filtration efficiency of the polioviruses in liquid equal to or more than 99 percent. The capability of the invention does not impair after washing for a plurality of times. The protective material can be widely used as biochemical protection material, waterproof and permeable material, and windproof and warm keeping material.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Down feather composite fiber modified by polypropylene fiber and preparation method of down feather composite fiber

InactiveCN104195664AThe ratio is scientific and reasonableDelicate feelMonocomponent protein artificial filamentArtifical filament manufactureSucrosePhosphoric acid

The invention discloses a down feather composite fiber modified by polypropylene fiber. The down feather composite fiber modified by polypropylene fiber is prepared from the following raw materials in parts by weight: 18-20 parts of superfine duck down powder, 25-30 parts of puffed goose feather powder, 12-15 parts of polypropylene fiber, 3-5 parts of kaolin, 0.3-0.6 part of calcium saccharate, 1-2 parts of wolfberry fruit, 2-4 parts of fruit of Chinese magnoliavine, 1-3 parts of radix rehmanniae, 3-5 parts of cucumber juice, 0.1-0.3 part of ammonium dihydrogen phosphate, 120-130 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 110-140 parts of 1-ethyl-3-diethyl methyl imidazole phosphoric acid, 2-4 parts of additives and a proper amount of water. According to the down feather composite fiber modified by polypropylene fiber, the components such as the polypropylene fiber, the wolfberry fruit, the fruit of Chinese magnoliavine and the radix rehmanniae are added; the prepared product is soft and smooth in hand feeling, has the characteristics of the down feather, also has the characteristics of being light, soft, warm, breathable, moisture permeable, mildew-proof, mothproof and washable, and is wide in application prospect and further and more competitive in the market.

Owner:ANHUI LION GOOSE PROD

Ice feeling finishing agent and preparation method thereof

The invention belongs to the technical field of printing and dyeing auxiliaries, particularly relates to an ice feeling finishing agent and a preparation method thereof. The ice feeling finishing agent mainly comprises raw silicone oil, an emulgator, a cosolvent, glacial acetic acid and water, wherein the raw silicone oil is prepared by adding 99-99.5% of silicone oil, 0.01-0.9% of a silane coupling agent and 0.01-0.1% of a catalyst into a reaction kettle for reaction. According to the ice feeling finishing agent and the preparation method thereof, provided by the invention, primary amine or / and secondary amine is / are introduced onto the molecular chain of silicone oil, therefore the hydrophilic performance of the overall molecular structure is improved, fabric subjected to finishing of the finishing agent has air-permeating, moisture permeating, moisture-absorbing and sweat releasing functions, at the same time can maintain a certain humidity, and enables people to have a feeling of comfortableness and coldness after wearing the clothes subjected to finishing; besides, the ice feeling finishing agent has excellent stability, thoroughly overcomes the defects that the conventional amino silicon oil is prone to demulsification, floating and roll sticking, can easily produce oil spots, and is not easy to repair.

Owner:珠海华大浩宏新材料有限公司

Ultra-thin breast pad and preparation method thereof

ActiveCN105970489AEliminates the defect of easy hair lossImprove wear resistanceLiquid surface applicatorsLayered productsPhysiologyHot melt

The invention discloses an ultra-thin breast pad and a preparation method thereof and relates to the field of female lactation products. The ultra-thin breast pad is composed of a surface layer hydrophilic non-woven fabric, an intermediate absorbing layer and an impermeable bottom film. The surface layer hydrophilic non-woven fabric is a soft type double-component filament non-woven fabric composed of core layer PP / skin layer PE; and the intermediate absorbing layer is a hot melting non-woven fabric formed by blending core layer PP / skin layer PE and superabsorbent fibers. According to the method for preparing the ultra-thin breast pad, the surface layer hydrophilic non-woven fabric for preparing the ultra-thin breast pad is selected through a PE / PP double-component filament non-woven fabric soft bulkiness processing method, the superabsorbent fibers and the PE / PP double-component fibers are blended, the intermediate absorbing layer is prepared through a plain net hot air reinforcing method, so that the prepared ultra-thin breast pad has the advantages of being not subjected to fiber slip, being ultra-thin and breathable, having moisture breathability and being safe and healthy, and the problems that a breast pad not subjected to fiber slip is poor in comfort, unsafe, high in moisture content and high in material cost are solved.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Moisture permeable bacteriostatic ultraviolet-resistant bamboo fibre fabric and processing technique thereof

InactiveCN101117749ANovel functional designWith slipperyHeating/cooling textile fabricsDyeing processYarnUltraviolet

The present invention discloses a moisture-permeable antibacterial ultraviolet-resistant bamboo fiber fabric, which is made by weaving longitudinal filaments and latitudinal filaments, wherein the longitudinal filaments is made with terylene filaments and rayon cotton-yarn twisted low-twist composite yarns as the raw materials; the latitudinal filaments are made with terylene filaments and bamboo charcoal fiber yarn twisted low-twist composite yarns or terylene filaments and model blended yarn twisted low-twist composite yarns as the raw materials. The present invention also discloses the processing technology of the moisture-permeable antibacterial ultraviolet-resistant bamboo fiber fabric. The present invention overcomes the defects of tradition wear fabrics, including monotonous function design, low fabric grade, poor product comfort degree and low added value, and renders the fabric with functions and advantages of moisture permeability, bacteria resistance, ultraviolet resistance, etc.

Owner:洪桂焕

Water wash cotton for bedding and clothing and production technology thereof

The invention discloses a bedding-clothing water washed cotton and its producing process, and its characteristic: it contains the components in weight percent: cotton and hair fibers 20%-80% and other fibers 80%-20%. It includes the working procedures made in sequence: screening, degreasing, bleaching, high-temperature sterilizing, UV sterilizing, mixing, combing, paving net, and thermal-setting. The beneficial effects: it is a novel heat-preserving material developed by using cotton, hair, and other fibers; it has the functions: heath, moth prevention, moisture transmission, waste wash resistance, good model maintenance, comfort, etc. The product has wide application range, the thin-type low-g weight material can be used to make air-conditioner water-wash bedding for the summer, and fashionable dresses and overskirts, etc; the thick-type high-g weight material can be used to make heat-preserving bedding for the winter, heat-preserving cotton-padded clothes, sleeping bags, cushions, etc.

Owner:王洪云

Multicomponent and multiple boundary layer composite heat insulation material and its producing method

InactiveCN1899814AGood warmth retentionHigh heat retentionHollow filament manufactureLayered productsPolyesterAir trapping

The present invention relates to a kind of multicomponent and multiple boundary layer composite heat insulating material and its production process. The composite heat insulating material is produced through arranging and adhering the following layers: superfine polypropylene non-woven fabric layer as the main air blocking layer, infrared radiation layer, down-like polyester / polypropylene layer as the main air trapping layer, infrared radiation and air blocking layer, and air holding hollow 3D crimping polyester layer. It has the thermal protection quality of 1.03-1.45clo, vapor transfer rate of 6200-8214g / sq m .24h, and air permeability of 2617-3267 ml / sq m .s. The composite heat insulating material has the advantages of being waterproof, poromeric, wind-proof, heat insulating and light.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

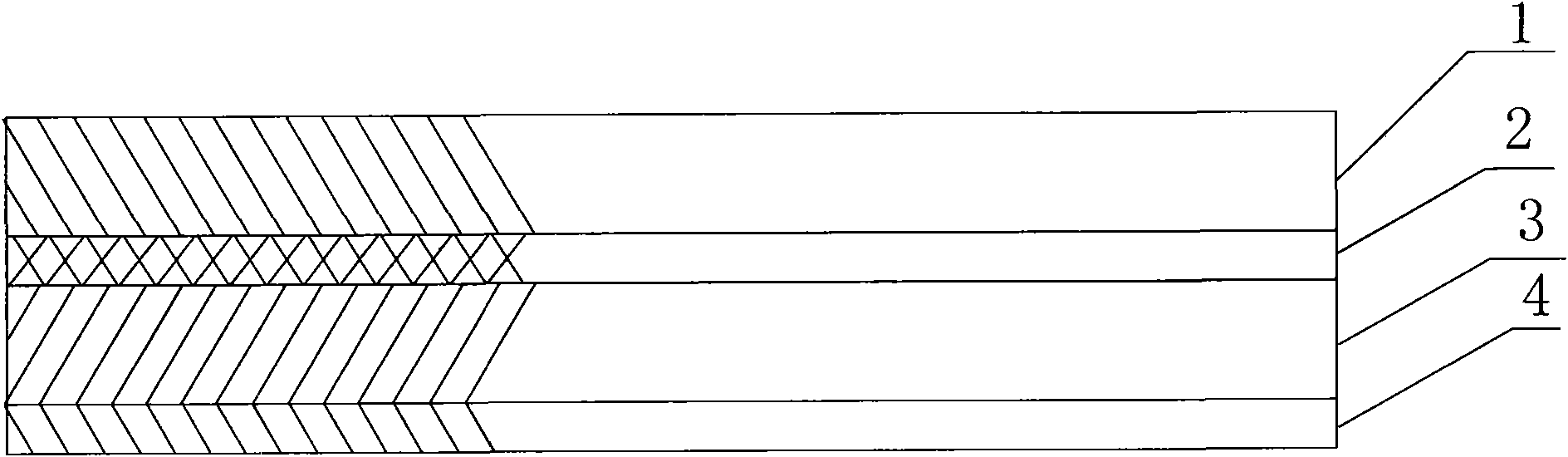

Multifunctional three-layered composite flame-retardant shell fabric and preparation method therefor

InactiveCN105172288AHigh strengthWindproofSynthetic resin layered productsClothingsWoven fabricMoisture permeability

The invention discloses a multifunctional three-layered composite flame-retardant shell fabric and a preparation method therefor. The shell fabric sequentially comprises a woven fabric layer, an E-PTFE film layer and a knitted fabric layer, wherein a glue layer is arranged between the woven fabric layer and the E-PTFE film layer and a glue layer is arranged between the E-PTFE film layer and the knitted fabric layer. The multifunctional three-layered composite flame-retardant shell fabric disclosed by the invention is suitable for offshore oil and gas development, and provides effective protection for the working environment of an offshore oil platform. The shell fabric has the characteristics of permanent flame retardance, high strength, wind protection, salt resistantance, water prevention, oil prevention dirtprevention, static electricity prevention, heat preservation, moisture permeability, safety, light weight and the like.

Owner:CONCORDIA ADVANCED FABRICS SUZHOU

Environment-friendly fabric

InactiveCN101979738AWith sweat absorptionMoisture permeableDyeing processWoven fabricsPolymer scienceCotton fibre

The invention discloses an environment-friendly fabric, which comprises warp yarns and weft yearns in a mass ratio of 40:60, wherein the warp yarns are cotton fibers; the weft yarns are interwoven fibers of tencel, soft bamboo, fibrilia or several other fibers; and the surface of fabric is printed with patterns through an active dye. The environment-friendly fabric has the advantages of no pollution on ambient environment, good dustproof performance and high cleanness, no fading after long washing, and the like.

Owner:JIANGSU LANSIYU HOME TEXTILE

Temperature-regulating blended woven fabric and production method thereof

The invention discloses a temperature-regulating blended woven fabric. The temperature-regulating blended woven fabric comprises warp yarns and weft yarns, and is characterized in that the warp yarns and the weft yarns are blended yarns which are prepared by blending Outlast fibers with cotton fibers and Tencel in the blending dry weight ratio of 15 to 75 percent; the linear density of the blended yarns is 18.4tex; the dry weight ratio of the cotton fibers to the Tencel is 3:2; the blended woven fabric contains 400 to 600 warp yarns per 10cm and 150 to 250 weft yarns per 10cm; the fabric tissue structure of the blended woven fabric is plain, 3 / 2 twill or 5 / 3 satin. The temperature-regulating blended woven fabric has an excellent temperature regulating function, is air-permeable and moisture-permeable, and tastes soft and comfortable, and ecological environmental protection is achieved.

Owner:SUZHOU LIANYOU WEAVING

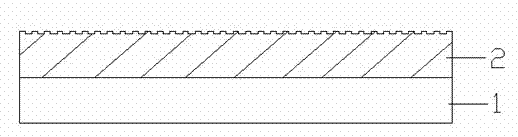

Antibacterial medical fabric

InactiveCN104309201AAnti-blood penetrationWaterproofClothingsProtective garmentEngineeringNatural fiber

The invention relates to an antibacterial medical fabric which comprises a base cloth layer (1) and a fabric layer (2), an antibacterial layer (3) is arranged between the base cloth layer (1) and the fabric layer (2), the antibacterial layer (3) comprises a silver ion antibacterial agent, the silver ion antibacterial agent is bonded between the base cloth layer (1) and the fabric layer (2), the base cloth layer sequentially from top to bottom comprises an isolation layer made of a thermoplastic polyurethane film, a protective layer made of a polypropylene fiber fabric, a protection layer made of a polytetrafluoroethylene film, and a bottom layer comprising weft knitting and warp knitting fabrics of natural fibers, synthetic fibers and regenerated fibers. The antibacterial medical fabric has antibacterial and bactericidal functions so as to achieve the antibacterial effect. The antibacterial medical fabric has anti-blood-permeability, waterproof, moisture-permeable, antibacterial and other a plurality of functions.

Owner:JIANGYIN YASHUN GARMENT

Waterproof breathable wool spinning western-style clothes composite fabric

InactiveCN105342044AWaterproofMoisture permeableSynthetic resin layered productsCoatingsFiberCompound (substance)

The invention discloses a waterproof breathable wool spinning western-style clothes composite fabric. The waterproof breathable wool spinning western-style clothes composite fabric comprises a coating layer at the uppermost layer, a purified chemical fiber wool-like fabric at the middle layer and a base fabric at the bottommost layer in a combined mode, wherein the base fabric is mixed by dacron, nylon and brocade cotton; the coating layer accounts for 10%-14% of the total weight of the waterproof breathable wool spinning western-style clothes composite fabric; the purified chemical fiber wool-like fabric accounts for 33%-41% of the total weight of the waterproof breathable wool spinning western-style clothes composite fabric; the base fabric accounts for 47%-55% of the waterproof breathable wool spinning western-style clothes composite fabric. The waterproof breathable wool spinning western-style clothes composite fabric provided by the invention has the advantages of waterproofness, moisture permeability, ventilation and durability.

Owner:CHANGSHU TIANCHEN KNITTING

Bamboo fiber and fibrilia fiber blending cloth

InactiveCN105133135AImprove antibacterial propertiesNovel functional designWoven fabricsYarnDying processesApocynum venetum

The invention discloses a bamboo fiber and fibrilia fiber blending cloth formed by raw material according to a weight ratio of bamboo fibers taking up of 90%, hemp fibers of 3%, flax fibers of 25%, ramie fibers of 2%, jute fibers of 1% and apocynum venetum fibers of 2%. The bamboo fiber and fibrilia fiber blending cloth has great product bacteria-resisting performance, protects skin and is characterized by uvioresistant performance, wear resistance, smoothness, a moisture permeability and shrink resistance; natural finishing agent chitosan is employed in the post-processing phase for a product to further enhance cloth bacteria resisting effect; all natural plant dye-fixing agents and coloring agents are employed during the dying process; even dying, simple technology and unfading color can be achieved; no harm is caused to skin; the whole manufacturing process employs natural material during the whole manufacturing process of the blending bamboo fiber cloth, so the cloth is environment-friendly and safe and requires low cost; the cloth functions and design are novel, high-end, possesses great product comfortableness and high additional value.

Owner:JIESHOU SHUANGXIN TEXTILE

Production method of normal-pressure cation dyeable copolyester endless tow, chopped fiber and top wool

ActiveCN102433601BImprove dyeing effectBright colorMonocomponent copolyesters artificial filamentStretch-spinning methodsFiberPolymer science

The invention relates to a production method of normal-pressure cation dyeable copolyester endless tow, chopped fiber and top wool. The normal-pressure cation dyeable copolyester endless tow is obtained by spinning normal-pressure cation dyeable copolyesters. A preparation method of the normal-pressure cation dyeable copolyesters comprises the following steps of: (1) carrying out an esterification reaction on ethylene glycol, terephthalic acid and m-phthalic acid; (2) adding ethylene glycol, mixing, adding an SIPE (5-Sodium Sulfonate Isophthalate Ethyl-ester) solution and carrying out an ester exchange reaction; and (3) adding a mixture obtained in the ester exchange reaction into binary fatty acid, mixing uniformly, and carrying out a condensation polymerization reaction to obtain the normal-pressure cation dyeable copolyesters, wherein the molar ratio of the terephthalic acid to the m-phthalic acid is 50:1-90:1; the ratio of the mole number of the ethylene glycol added in the step (2) to the total mole number of the terephthalic acid and the m-phthalic acid is 0.1:1-0.5:1; and the ratio of the total mole number of the terephthalic acid, the m-phthalic acid and the binary fatty acid to the total mole number of sulfonic acid groups in the SIPE solution is 9:1-28:1.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

Teflon composite film for protective garment

ActiveCN104691069AIncrease elasticityImprove the protective effectSynthetic resin layered productsProtective garmentComposite filmMoisture

The invention discloses a teflon composite film for a protective garment. The teflon composite film comprises a teflon film layer and a PU coating. The PU coating comprises a bottom layer and an upper layer. The upper surface and the lower surface of the teflon film layer are coated with the bottom layer and the upper layer respectively. The teflon film layer comprises, by weight, 85-95 parts of polyflon, 5-8 parts of silicone powder, 2-4 parts of polyether ether ketone and 3.5-6.5 parts of lubricant. The PU coating comprises, by weight, 100 parts of PU resin, 10-15 parts of polyethylene wax, 5-10 parts of nanometer titania and 10-18 parts of N,N- nanometer titania. In this way, according to the teflon composite film for the protective garment, elasticity and protective performance of the film product are improved, the multiple functions of high temperature resisting, abrasion resisting, water resisting, moisture permeating, corrosion preventing and the like are achieved, and the teflon composite film is especially suitable for the protective garment used in a workplace where the working environment is severe.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Moisture permeable anti-ultraviolet rayon facing material and process technique thereof

InactiveCN101109128AOvercome the Monotony of Functional DesignMoisture permeableOther manufacturing equipments/toolsDyeing processPolyesterYarn

The invention discloses an artificial-cotton shell fabric that can penetrate moisture and resist to ultra-violet rays as well as the processing process for the shell fabric, which pertains to the technical field of synthetic-fiber fabric. Wherein, a warp uses low-twist compound yarn of polyester fiber and artificial-cotton yarn; a weft uses low-twist compound yarn of polyester fiber and blended yarn comprising moisture-absorbing and sweat-removing yarn and fine cotton. Wherein, the proportion by weight of polyester to artificial cotton yarn in the warp is 75:133; that of polyester to blended yarn in the weft is 75:166. The invention uses a new process for twisting blended yarn comprising moisture-absorbing and sweat-removing yarn and fine cotton with polyester fiber, so that the product is furnished with such functions as moisture penetrating and resistance to ultra-violet rays, overcomes the shortcomings of traditional synthetic fiber fabric such as singular function, low grade of shell fabric, power comfortableness and low added value, etc.

Owner:洪桂焕

Ultra-thin outdoor fabric arc prevention garment

InactiveCN104116225AExcellent protection performanceFlame retardant hasProtective garmentSpecial outerwear garmentsUltra fineNH3 compound

The invention relates to an ultra-thin outdoor fabric arc prevention garment. The ultra-thin outdoor fabric arc prevention garment comprises a garment body. Flame-retardant material is added to the coatings of the garment body. The ultra-thin outdoor fabric arc prevention garment is obtained through the steps of room-temperature flame-retardant finishing liquid padding, preliminary drying, ammonia smoking, oxidation washing, drying, preshrinking and finished product obtaining. A base cloth layer is composited on the back face of the garment body and coated with PU glue. PU film is attached to the surface of the PU glue. Ultra-fine-denier fabric, namely, 20-denier fabric, serves as base cloth. By means of the ultra-thin outdoor fabric arc prevention garment, the injuries caused when the skin of the human body makes contact with arc heat energy are reduced to the maximum degree. The ultra-thin outdoor fabric arc prevention garment has the waterproof function, the moisture-permeable function, the warm keeping function, the tear-resistant function, the ultra-thin function and other functions.

Owner:JIANGYIN YINGXIN WEAVING

Waterproof thermal insulation fabric

InactiveCN102285161AIncrease elasticityStrong firmnessSynthetic resin layered productsYarnThermal insulation

The invention relates to a waterproof thermal insulation fabric. The fabric comprises a fabric layer, wherein a waterproof layer is arranged outside the fabric layer; a lining is arranged below the fabric layer; a thermal insulation layer is arranged between the fabric layer and the lining; and the thermal insulation layer is formed by interweaving elastic yarns and fine denier polypropylene yarn meshes. The fabric is characterized by integrating waterproofing, air permeability, moisture absorption, thermal insulation and moisture conductivity, has low cost and is suitable for various clothes.

Owner:余自家

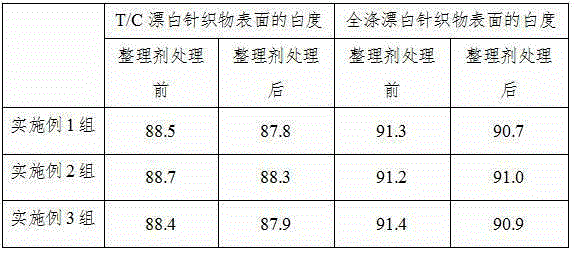

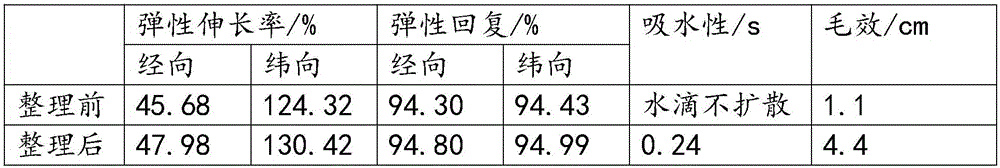

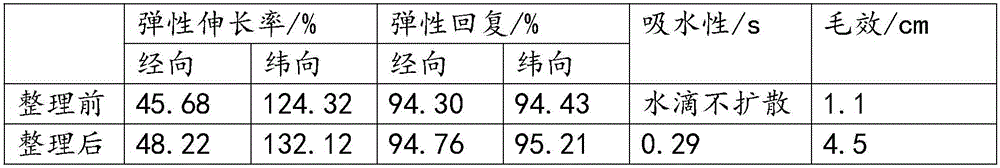

Method for improving moisture-absorption and sweating performance of fatty polyamide fiber/polyurethane fiber fabric

InactiveCN106676899AWith water absorptionMoisture permeableLiquid/gas/vapor removalGrip property fibresOrganic acidEpoxy

The invention provides a method for improving the moisture-absorption and sweating performance of a fatty polyamide fiber / polyurethane fiber fabric. The method comprises the following treatment processes in sequence: step 1, dip padding with a treating agent, step 2, drying, and step 3, baking. The treating agent is made from the following components: isophorone diisocyanate, poly(butyl acrylate), a micromolecule chain extender, organic acid, and epoxy resin. In the step 1, the use amount of the treating agent is 40-70 g / L. In the step 2, the drying temperature is 100-120 DEG C. In the step 3, the baking temperature is 140-200 DEG C, and the baking time is 90-160 s. According to the method, a treating agent is used for finishing a fatty polyamide fiber / polyurethane fiber fabric. The finished fabric can absorb water, is moisture permeable and can be fast dried. The fabric touches soft, fluffy and smooth and is good in draping and washing resistance.

Owner:SHANGHAI JIALE

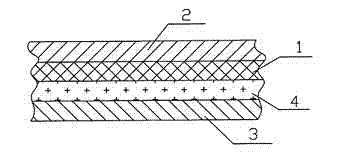

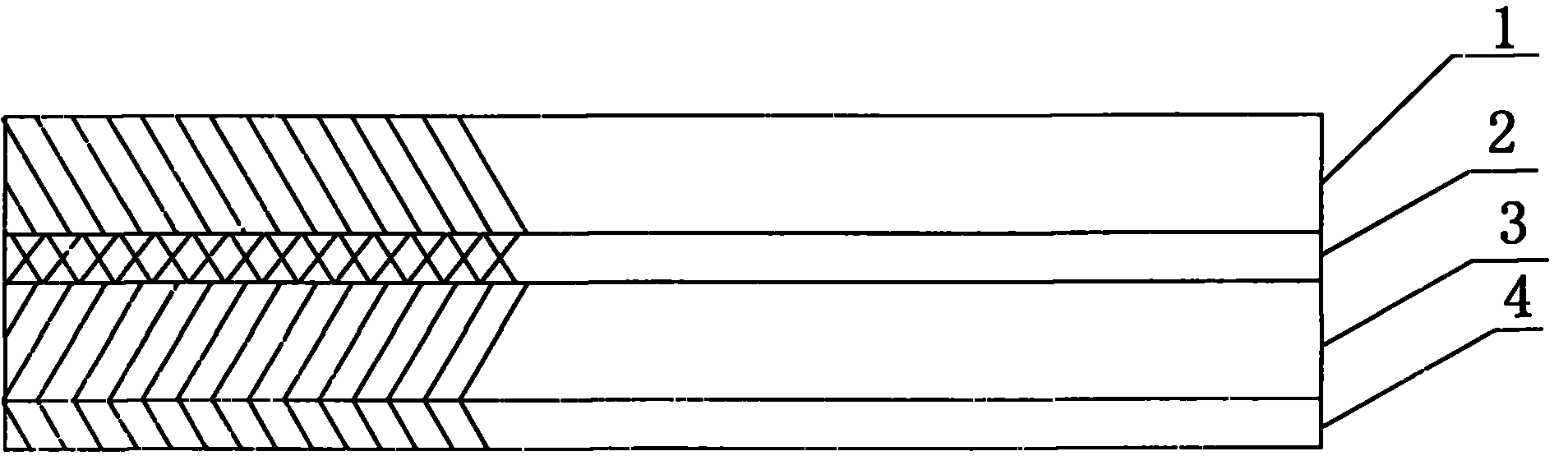

Camouflage multifunctional protecting plus material printed by activated carbon fiber cloth/ polytetrafluoroethylene (PTFE) garment film and chinlon plus materials

InactiveCN102318918AAntivirusBreathableSynthetic resin layered productsProtective garmentActivated carbonFiber

The invention discloses a camouflage multifunctional protecting plus material printed by activated carbon fiber cloth / polytetrafluoroethylene (PTFE) garment films and chinlon plus materials, which comprises a base cloth layer 1, a middle layer 2, a middle layer 3 and an outer layer 4, wherein the base cloth layer (1) is pasted with the middle layer (2), the outer layer (4) is pasted with the middle layer (3), and the surfaces of the pasted outer layer (4) and the pasted middle layer (3) are coated and pasted with glue water and are compounded with the pasted base cloth layer 1 and the pasted layer 2. Because of the adopted raw materials of activated carbon fiber cloth, PTFE garment films and the like, special functions are realized, and the four-layer compounding is carried out. The plus material disclosed by the invention has the effects and the characteristics of gas defense, ventilation, moisture permeability, heat radiation, comfortable wearing and the like and can be widely applied to departments for military, chemical engineering, medical treatment, environment protection, fire fighting and the like for making special protecting garments.

Owner:SHAOXING SHULILE TEXTILE PROD

Windproof, cold-resistant and color fasting aqueous coating adhesive for textile fabric and preparation method

ActiveCN109610193AImprove bonding fastnessImprove color fastness to rubbingTextiles and paperEpoxyAdhesive

The invention discloses a windproof, cold-resistant and color fasting aqueous coating adhesive for a textile fabric and a preparation method. The preparation method comprises the following steps: carrying out condensation on 100-150 parts of end epoxy silicon oil, 3-9 parts of polyether amine and 15-30 parts of isopropanol, adding 1-2 parts of polyethyl silicate-40, 12-20 parts of isotridecanol polyoxyethylene ether, 1-2 parts of glacial acetic acid and 220-340 parts of softening water for emulsification, and further mixing and thickening with 70-110 parts of a hydroxyl-ended epoxy modified polysiloxane emulsion, 260-440 parts of an anionic polyurethane emulsion, 10-30 parts of an aqueous sealed isocyanate cross-linking agent and 10-20 parts of an associated alkali swelling thickening agent, thereby obtaining a product. A fabric finished with the adhesive is excellent in wind resistance and cold resistance, is soft and smooth in hand feeling and good in rebound resilience, and has airpermeability being 10 mm / s or lower and cold resistance up to minus 30 DEG C; in addition, the friction color fastness of a colored fabric can be improved by 0.5-1.5 degrees.

Owner:LIAONING FIXED STAR FINE CHEM

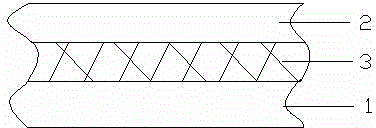

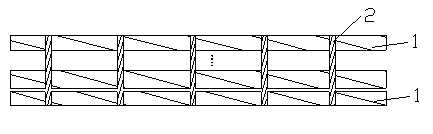

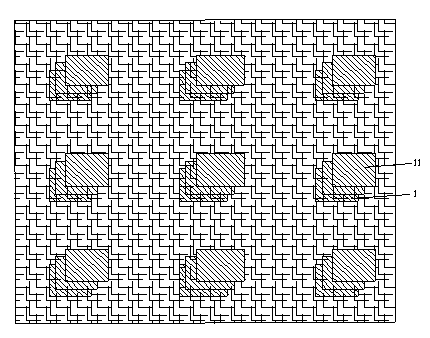

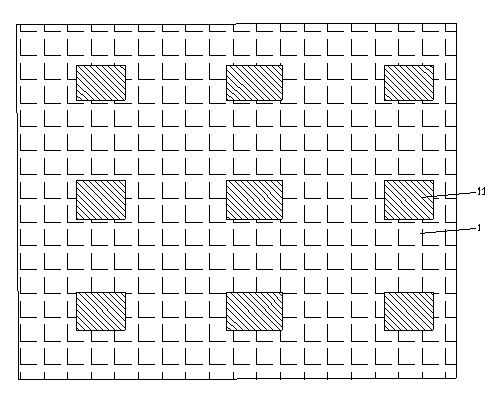

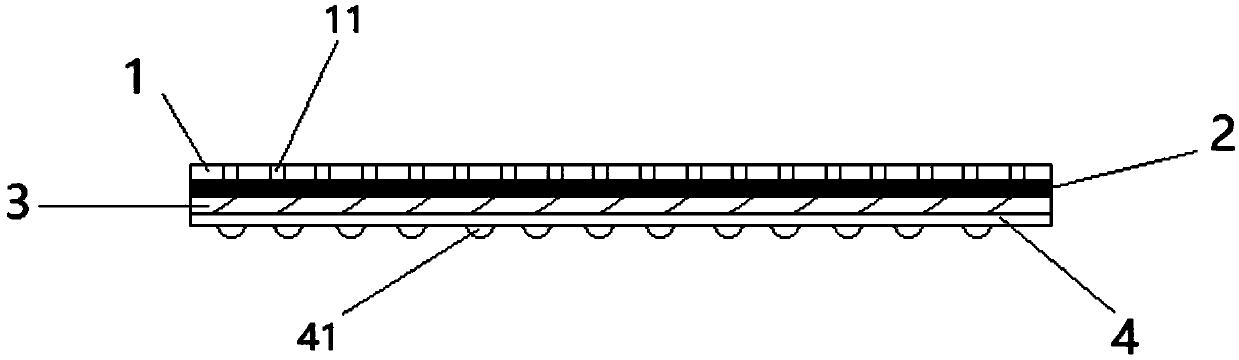

Composite waterproof breathable moisture-permeable mesh-layer fabric

The invention relates to a composite waterproof breathable moisture-permeable mesh-layer fabric and belongs to the field of textile fabrics. The composite waterproof breathable moisture-permeable mesh-layer fabric comprises a plurality of mesh layers (1) which are mesh fabric bodies, a plurality of fabric bodies (11) without meshes are arranged on each mesh layer (1), the fabric bodies (11) without meshes on each two adjacent mesh layers (1) are in sequentially staggered arrangement to form well-arranged pattern layers, the mesh layers (1) are vertically connected through bright yarns (2), and a porous polytetrafluoroethylene film layer (3) is closely composited on the surface of the bottom mesh layer (1). Rich layering is shaped by staggered overlaying and empty-full alternation of the mesh layers, and the bright yarns for connecting the mesh layers add bright colors to the composite waterproof breathable moisture-permeable mesh-layer fabric. A porous polytetrafluoroethylene film has waterproof, breathable and moisture-permeable effects.

Owner:孙建良

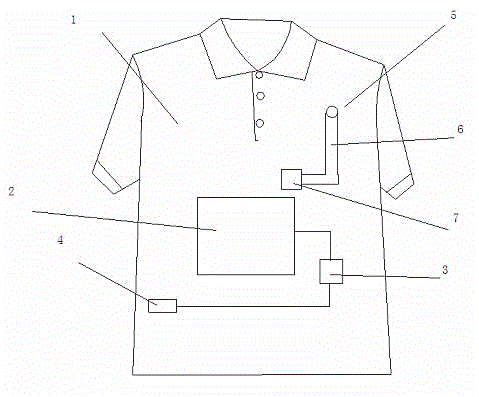

Heat preservation and deodorization clothes with charging function

InactiveCN105433453AComfortable to useWaterproofBatteries circuit arrangementsElectric powerLithiumBiochemical engineering

The invention relates to heat preservation and deodorization clothes with a charging function. The clothes comprise a clothes body (1), multiple solar cell panels (2) are arranged on the back face of the clothes body (1) and connected with one lithium cell (3), and a terminal of the lithium cell (3) is connected with a USB interface (4); a plastic gear (5), a support (6) and a mobile phone bracket (7) are arranged on the front of the clothes body (1). The clothes body is made of shell fabric, the shell fabric is manufactured by compounding base cloth, a polytetrafluoroethylene film and a bamboo charcoal negative ion PU film, and the theolytetrafluoroethylene film and the bamboo charcoal negative ion PU film are sequentially pasted on one side surface of the base cloth. The clothes can charge electronic products at the side of a user at any time and has the waterproof, moisture permeable, heat preserving, deodorizing, and antibacterial functions.

Owner:沈卫军

Improved coating material for fabric coating finishing

InactiveCN105401432AAnti-agingImprove wrinkle resistanceLight resistant fibresMicrosphereAntioxidant

An improved coating material for fabric coating finishing is prepared from, by weight, 25-35 parts of a silicone acrylic emulsion, 12-16 parts of an adhesive, 2-5 parts of a phosphite antioxidant, 1.5-2.6 parts of nanometer calcium carbonate, 4-7 parts of aqueous latex, 0.3-0.6 parts of a dispersant, 15-35 parts of deionized water, 12-20 parts of butanetriol, 2-4.2 parts of an antiseptic, 6-12 parts of NTB emission powder, 5-8 parts of a fire retardant, 3-6 parts of nitrile butadiene rubber, 20-30 parts of PVC resin, 12-26 parts of hollow ceramic microspheres and 10-14 parts of EVA. The improved coating material for fabric coating finishing has the advantages of good ageing and crease resistance, realization of shading, radiation prevention and moisture permeation functions of fabrics, convenient construction and no pollution.

Owner:王丽萍

Method for preparing antibacterial health care socks by blending cotton and bamboos

InactiveCN110820154AGood antibacterial effectMoisture permeableWeft knittingBiochemical treatment with enzymes/microorganismsYarnCotton fibre

The invention discloses a method for preparing antibacterial health care socks by blending cotton and bamboos. According to the method, cotton fibers and bamboo fibers serve as raw materials and are pretreated, the pretreated bamboo fibers and the pretreated cotton fibers are prepared into yarns, slivering, combing, braiding and dyeing are sequentially implemented to obtain antibacterial sock fabrics, the antibacterial sock fabrics are conveyed into a hosiery machine according to a sock knitting process and subsequently treated to obtain finished antibacterial health care socks prepared by blending the cotton and the bamboos. The antibacterial health care socks prepared by the method are resistant to abrasion, soft, comfortable and suitable for long-time wearing and cannot easily accumulate dust or breed bacteria.

Owner:湖南尚珂伊针纺有限公司

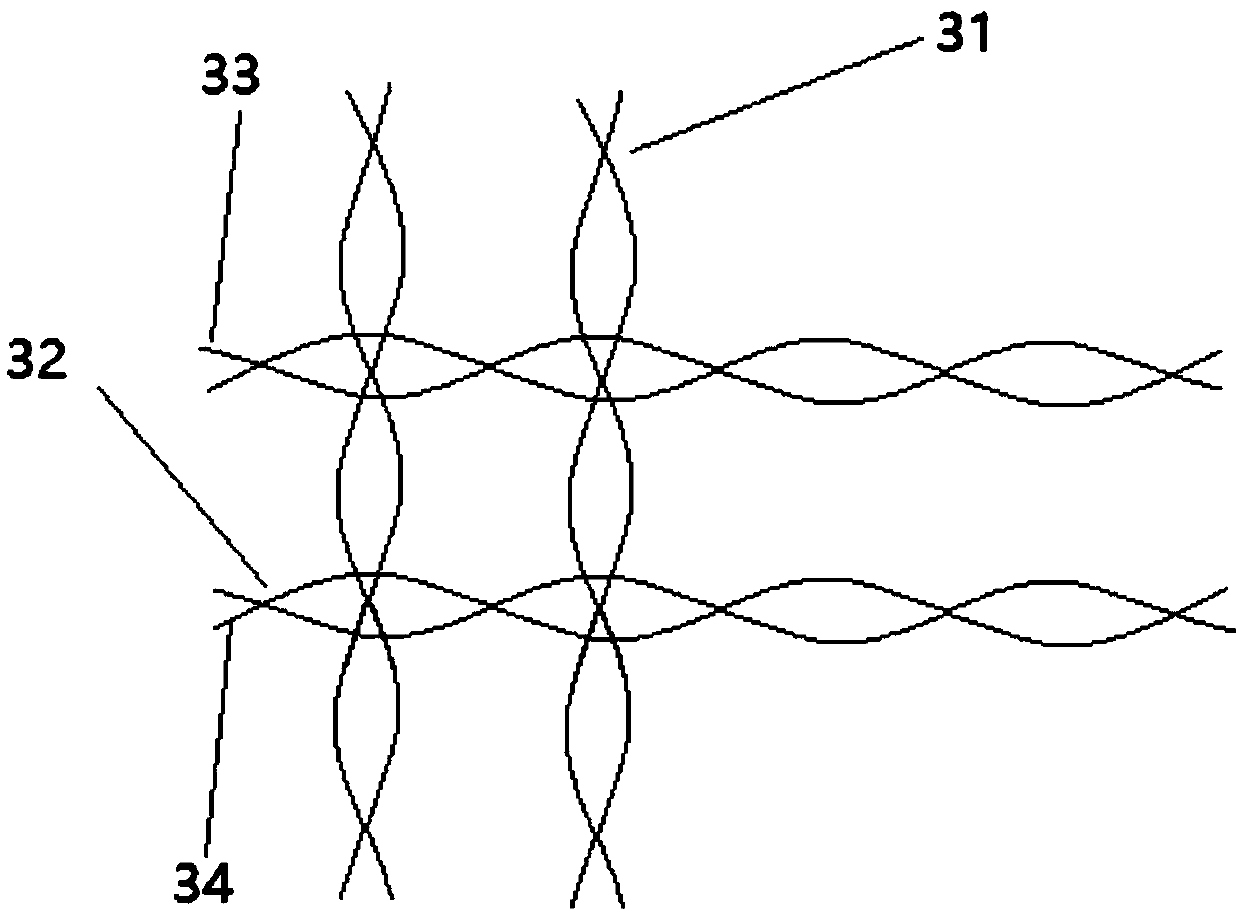

Warm-keeping and antibacterial garment fabric

InactiveCN107901544AImprove insulation performanceWith far-infrared radiationSynthetic resin layered productsClothingsFiberPolyester

The invention relates to a warm-keeping and antibacterial garment fabric. The warm-keeping and antibacterial garment fabric comprises a transparent micro-pore polyurethane thin layer (1), a warm-keeping layer (2), an antibacterial fabric layer (3) and a lining layer (4), which are compounded in sequence from outside to inside, wherein the warm-keeping layer (2) is formed by taking yarns formed byintertwining polyester fibers (21) and cotton fibers (34) as warp and weft yarns and interweaving; far infrared ceramic powder particles (22) are arranged on the yarns of the polyester fibers (21). Compared with the prior art, the warm-keeping and antibacterial garment fabric has a good antibacterial and warm-keeping effect; meanwhile, the warm-keeping and antibacterial garment fabric has a good ventilation effect, high wearing comfort and the like.

Owner:劲霸男装(上海)有限公司

Moisture permeable bacteriostatic ultraviolet-resistant bamboo fibre fabric and processing technique thereof

InactiveCN101117749BNovel functional designWith slipperyHeating/cooling textile fabricsDyeing processYarnFiber

The present invention discloses a moisture-permeable antibacterial ultraviolet-resistant bamboo fiber fabric, which is made by weaving longitudinal filaments and latitudinal filaments, wherein the longitudinal filaments is made with terylene filaments and rayon cotton-yarn twisted low-twist composite yarns as the raw materials; the latitudinal filaments are made with terylene filaments and bamboocharcoal fiber yarn twisted low-twist composite yarns or terylene filaments and model blended yarn twisted low-twist composite yarns as the raw materials. The present invention also discloses the processing technology of the moisture-permeable antibacterial ultraviolet-resistant bamboo fiber fabric. The present invention overcomes the defects of tradition wear fabrics, including monotonous function design, low fabric grade, poor product comfort degree and low added value, and renders the fabric with functions and advantages of moisture permeability, bacteria resistance, ultraviolet resistance, etc.

Owner:洪桂焕

Method for preparing moisture-absorbing and quick-drying textiles

PendingCN111607973AInhibit the growth of fungiSignificant antibacterial and deodorizing functionsWeft knittingYarnThin membraneCotton fibre

The invention relates to a method for preparing moisture-absorbing and quick-drying textiles, and belongs to the technical field of textile materials. The method for preparing the moisture-absorbing and quick-drying textiles comprises the steps that cotton fiber doped graphene fibers are used as raw materials to obtain a fabric substrate, polytetrafluoroethylene is used as a main body, graphene oxide and nano silica are combined to prepare a microporous thin-film, and the microporous thin-film with the prepared fabric substrate are compounded to prepare the moisture-absorbing and quick-dryingtextiles. The prepared microporous thin-film uses a layer of a thin film with a micropore diameter between the maximum diameter of a water molecule and an air molecule and the minimum diameter of a water droplet molecule, and then the thin film and an outer-layer fabric are compounded, so the fabric has the effect of waterproof, breathable and quick-drying performance. According to the fabric withthe principle, the microporous thin film plays a role of water sprinkling and plays a role of breathability; and the microporous thin film can quickly transfer moisture to the surface of the clothes,and sweat is evaporated through air circulation so as to achieve the purpose of quick drying.

Owner:杜卫强

Heat insulating and deodorizing discoloring fabric

InactiveCN104260527AMeet needsAchieve color changing effectSynthetic resin layered productsClothingsYounger peoplePolytetrafluoroethylene

The invention relates to a heat insulating and deodorizing discoloring fabric. The fabric comprises a fabric body (1) and is characterized in that the surface of the fabric body (1) is coated with a layer of discoloring coating (2); the discoloring coating (2) is made from thermosensitive compounds; the fabric body is prepared by compositing three materials: a base fabric, a polytetrafluoroethylene film and a bamboo charcoal anionic PU (polyurethane) film; the polytetrafluoroethylene film and the bamboo charcoal anionic PU film are stuck to the surface of one side of the base fabric in sequence. The discoloring fabric is in different colors at different temperatures, thus achieving the discoloring effect and meeting the requirements of some young people seeking to be different. The discoloring fabric has multiple functions, such as water resistance, moisture permeation, heat insulation, deodorization, bacterium resistance, and the like.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com