Quick-drying alkyd resin for double-component polyurethane primer

A two-component polyurethane and alkyd resin technology, applied in the resin field, can solve problems such as poor hardness and poor sandability, and achieve the effects of sufficient crosslinking, good sandability, and uniform production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

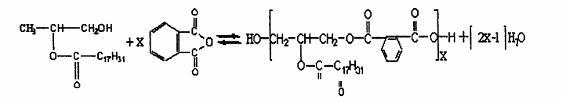

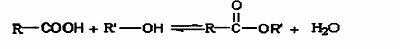

Method used

Image

Examples

Embodiment 1

[0039] The quick-drying alkyd resin for two-component polyurethane primer of the present invention, its raw material and mass proportioning are:

[0040] Raw material ratio%

[0041] monoacid 8

[0042] Semi-dry vegetable oleic acid 9

[0043] Maleic anhydride 0.5

[0044] Phthalic anhydride 28

[0045] Benzoic acid 4

[0046] Pentaerythritol 12.45

[0047] Trimethylolpropane 2

[0048] Diethylene glycol 6

[0049] Antioxidant color reducer 0.05

[0050] Xylene 25

[0051] Toluene 5.

[0052] Its preparation steps are:

[0053] 1. Add monoacid, semi-dry vegetable oleic acid and diethylene glycol to the reaction kettle in sequence, and stir evenly;

[0054] 2. Then add maleic anhydride, phthalic anhydride, benzoic acid, pentaerythritol, trimethylolpropane and anti-oxidant color reducer, toluene and xylene in sequence, and then blow nitrogen, heat up, stir, and heat up to 160- React at 170°C for 1-2 hours, then raise the temperature to 210°C for esterification reacti...

Embodiment 2

[0057] The quick-drying alkyd resin for two-component polyurethane primer of the present invention, its raw material and mass proportioning are:

[0058] Raw material ratio%

[0059] Monoacid 8.5

[0060] Semi-dry vegetable oleic acid 11

[0061] Maleic anhydride 0.93

[0062] Phthalic anhydride 22.5

[0063] Benzoic acid 4.5

[0064] Pentaerythritol 15

[0065] Trimethylolpropane 2.5

[0066] Diethylene glycol 6.5

[0067] Antioxidant color reducer 0.07

[0068] Xylene 20.5

[0069] Toluene 8.

[0070] Its preparation steps are identical with above-mentioned embodiment one.

Embodiment 3

[0072] The quick-drying alkyd resin for two-component polyurethane primer of the present invention, its raw material and mass proportioning are:

[0073] Raw material ratio%

[0074] monoacid 10

[0075] Semi-dry vegetable oleic acid 9.92

[0076] Maleic anhydride 1

[0077] Phthalic anhydride 22

[0078] Benzoic acid 6

[0079] Pentaerythritol 11

[0080] Trimethylolpropane 5

[0081] Diethylene glycol 9

[0082] Antioxidant color reducer 0.08

[0083] Xylene 20

[0084] Toluene6.

[0085] Its preparation steps are also the same as the above-mentioned embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com