Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Uniform vulcanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cross-linked rubber composition, application thereof, rubber grains prepared by cross-linked rubber composition, preparation method and injection method of rubber grains

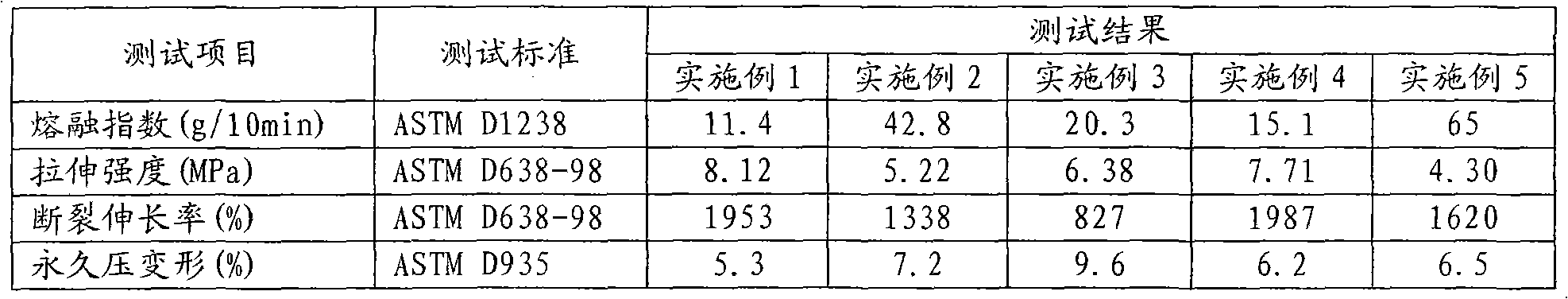

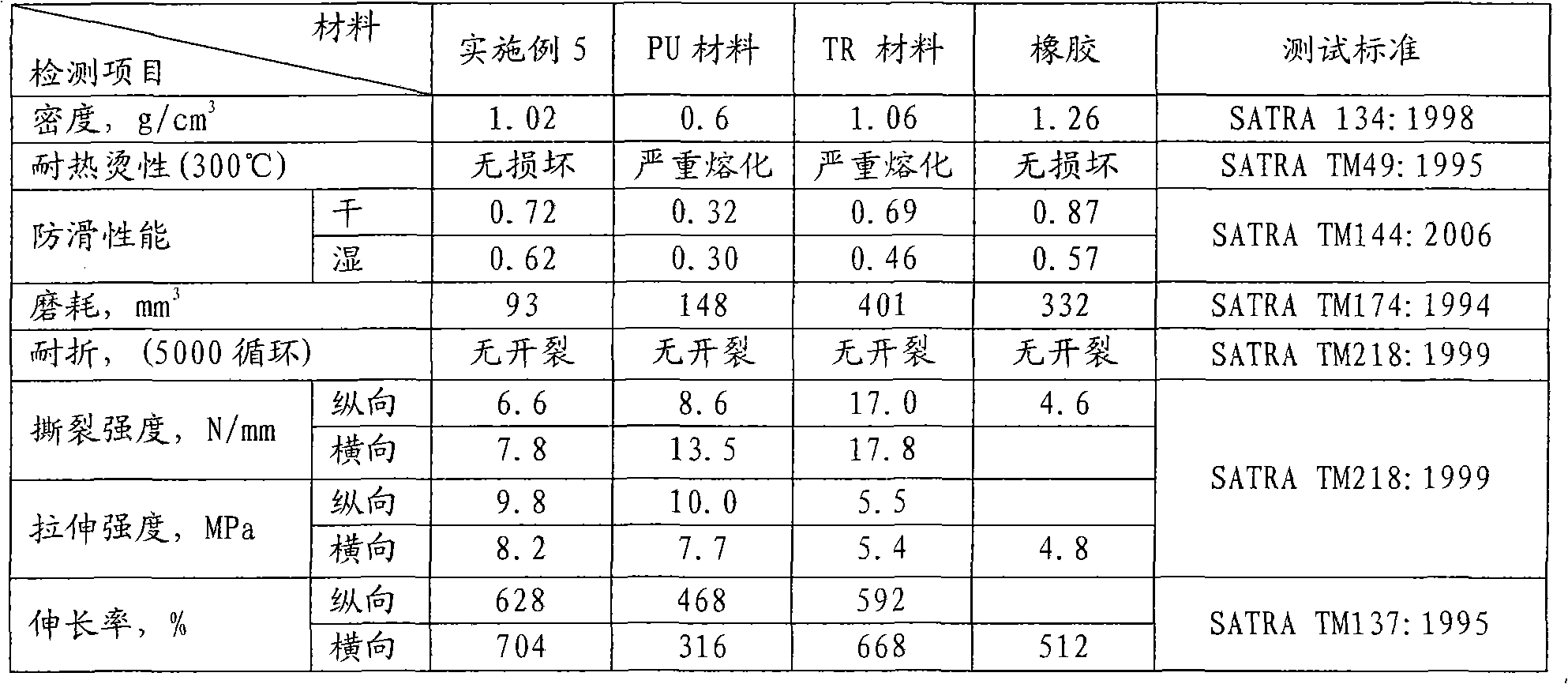

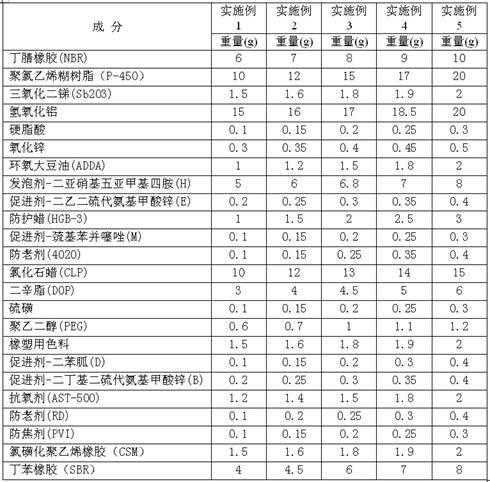

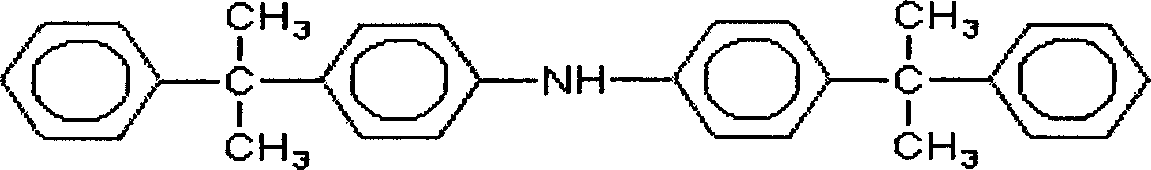

InactiveCN101624461ASmall molecular weightImprove liquiditySolesOvergarmentsCross-linkPolymer science

The invention relates to a cross-linked rubber composition, the application thereof, rubber grains prepared by the cross-linked rubber composition, a preparation method and an injection molding method of the rubber grains. The cross-linked rubber composition at least comprises a styrene-butadiene copolymer, a rubber softening agent, a flow modifying agent and a peroxide vulcanizing agent; the cross-linked rubber composition is suitable for preparing rubber products and can be prepared into non-cross-linked rubber grains below the temperature of 80 DEG C; and the rubber grains are formed by banburying, milling, extruding and granulating. The rubber composition and the rubber grains can be directly molded by injection, have good flow property, can be vulcanized in a later period and can be preserved at room temperature. Compared with the prior art, the rubber grains can be directly molded by injection, rubber particles are not easy to self-vulcanize, the vulcanization speed is easy to control, the rubber grains have no need to be stored at low temperature, and the like.

Owner:陈友明

Color rubber and plastic heat-insulating material and preparation method thereof

The invention relates to a color rubber and plastic heat-insulating material and a preparation method thereof. The rubber and plastic heat-insulating material is prepared from polrvinyl chloride paste resin, dinitrosopentamethylene tetraamine, an antiager, styrene rubber, protective wax, an antioxidant, chlorosulfonated polyethylene rubber, diphenyl guanidine, mercaptobenzothiazole, zinc dibutyl dithiocarbamate, zinc diethydithiocarbamate and the like. The performance and the color difference of the product are stabilized by adding a coloring material to perform banburying on the finished rubber again and combining a new vulcanizing foaming technology and a super-long water-cooling system; the prepared color rubber and plastic heat-insulating material does not have fibers and dust, prevents dew formation, has a smooth surface and high cleanliness, has the same bright color as equipment, is environmentally-friendly and non-toxic, reduces secondary construction, saves cost, greatly improves the using performance of the product, prolongs the service life and takes full advantage of the product performance.

Owner:WINCELL INSULATION CO LTD

Prevulcanizing method for hydrogenating catalyst

InactiveCN1268433CImprove retentionSuitable for hydrogenation reactionCatalyst activation/preparationRefining by aromatic hydrocarbon hydrogenationHigh rateAdditive ingredient

This invention opens one prevulcanization method of hydrogenated catalyst, which contains mixing one component of alkene, organic polysulfide and accessory ingredient, immersing hydrogenated catalyst in oxidation state after being heated; then immersing by hydrocarbon oil, after re-evaporation to dryness, hydrogenated catalyst being vulcanized can be produced. The method is simple and convenient and thus this invention can be easily carried out. By this method, the hydrogenated catalyst after prevulcanization can maintain higher rate of remaining sulphur, and possesses higher catalytical activity at the same time; it is especially applicable in backflow reactor, for it can solve the practical problem that the catalyst decreases its activity because of losing sulphur.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst presulfurizing method

InactiveCN101024204AOvercome lossOvercome CorrosivityCatalyst activation/preparationOil processingVulcanization

This invention discloses a hydrogenation catalyst pre-curing method. The method used the by-products of the oil and gas industry processing acidic gas as medium sulfide, pretreatment the hydrogenation catalyst, the main component of acid gas is hydrogen sulfide and carbon dioxide, the invention can be used inside or outside of pre-vulcanization mode, put the oxidation states catalyst into vulcanization reactor, heated to200-500degree centigrade in an inert atmosphere, and then conducted hydrogen and acid gas to sulphate under 0.1-10MPa pressure, the reaction time is 0.5 to 30 hours, of which an acid gas occupy 1-40%. The invention method not only overcome the presence of sulfide wet curing agent losses, metal tube surface corrosion defects, also have fast curing process, even curing, can greatly improve the activity and stability of catalysts, extended catalyst life and other advantages, and wide sulfide-media sources, easy to get, significantly lower sulfide cost.

Owner:DAQING GASOLINEEUM INST

Process for changing outer temperature of tire when vulcanizing tire

The invention relates to a tire altering outer temperature vulcanization technique. Vulcanization is carried out in a capsule according to conventional technique in optimum cure period; the steam temperature outside a tire is controlled in two or three different temperature periods: the initial outer temperature is higher, namely, 138-150 DEG C, and is kept within 120-500 minutes; or the initial outer temperature is 138-143 DEG C and is kept within 120-300 minutes; the temperature gradually falls in the later period to 125-137 DEG C and is kept within 60-360 minutes; or the temperature falls to 132-137 DEG C and is kept within 120-240 minutes; if the temperature difference in each period is 2-10 DEG C, the altering temperature time is 1-10 minutes; if the temperature difference in each period is 3-5 DEG C, the altering temperature time is 1-3 minutes. The temperature of optimum cure in initial period is higher, so that the temperature outside the tire is increased faster, and the vulcanizing time is shortened. The deep part of the tire is affected slightly after the temperature is decreased, and can be vulcanized continuously. The technique ensures full internal tire vulcanization, avoids or reduces over vulcanization outside the tire, therefore, the technology is applicable to large-tire vulcanization, ensures the quality of the tire, decreases the steam temperature of outer temperature, shortens the use time and reduces energy consumption.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

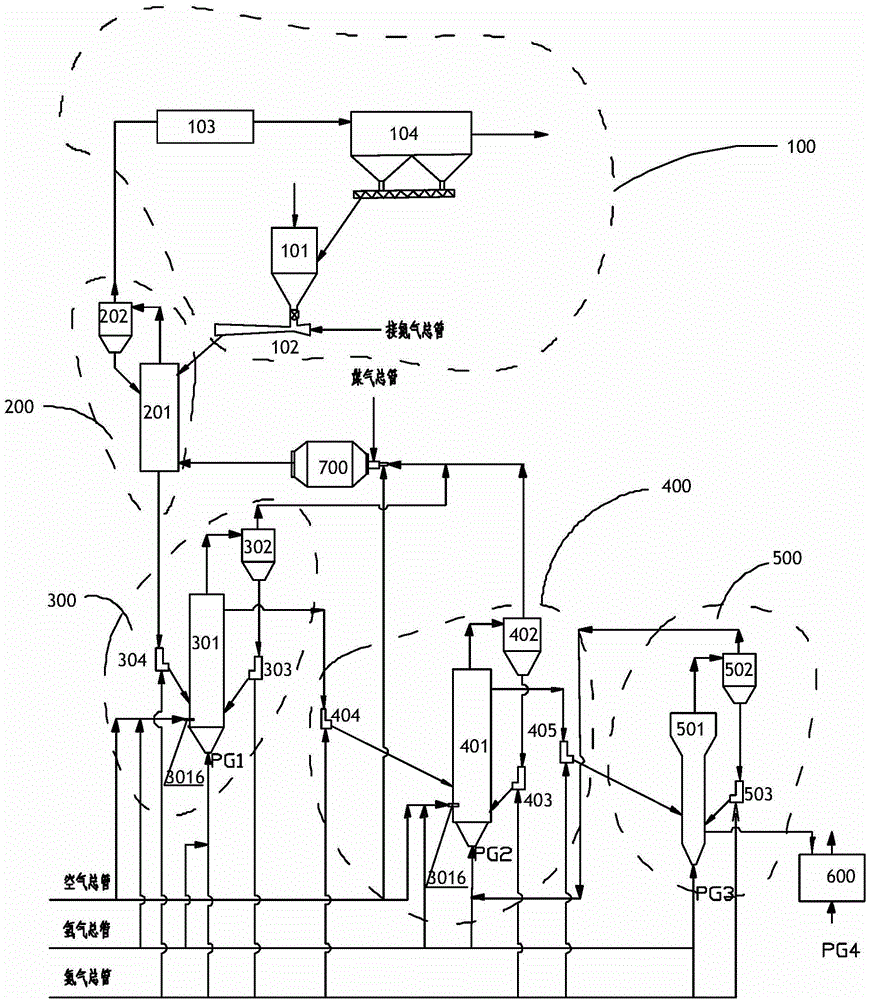

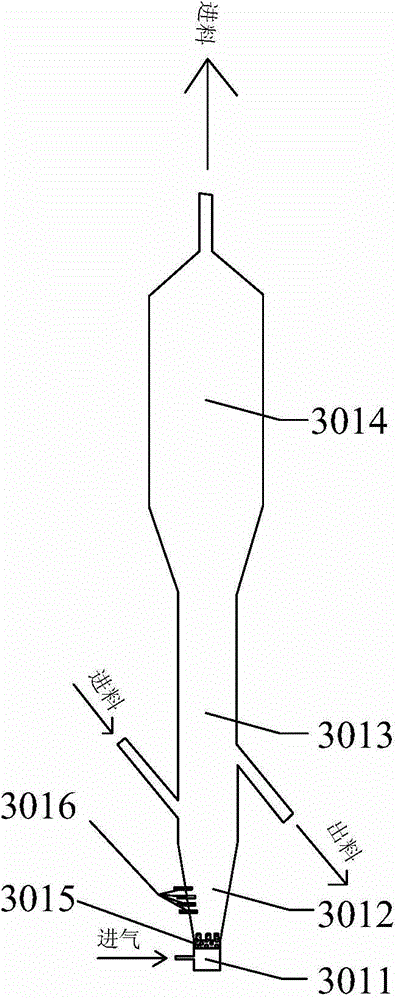

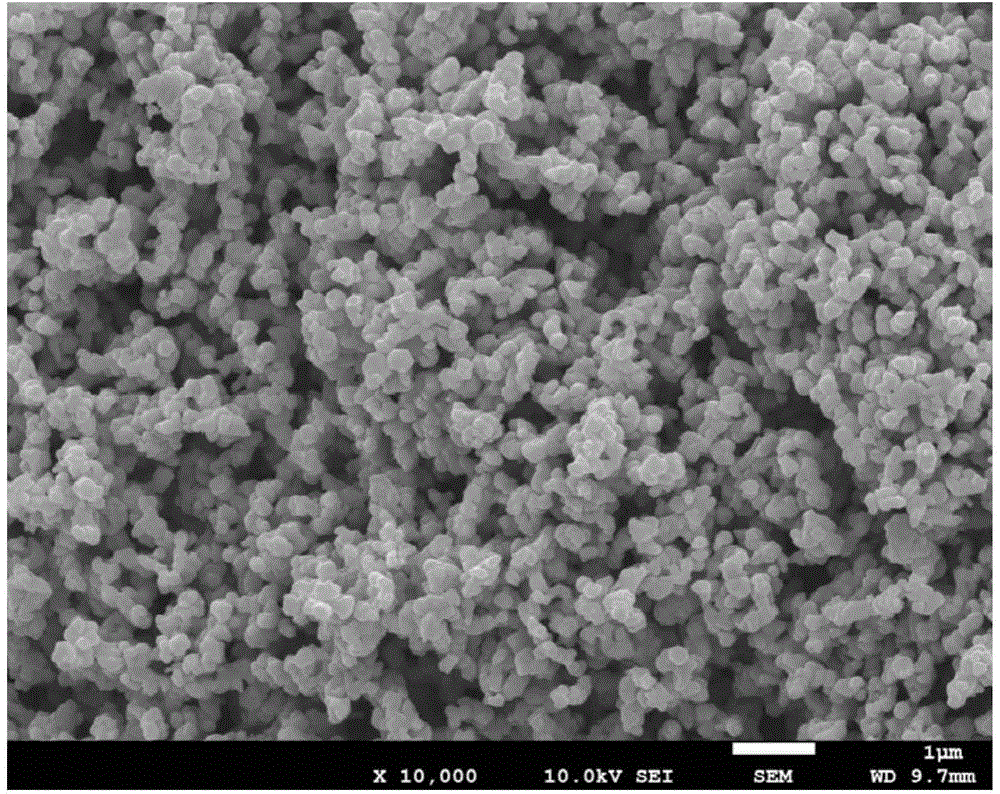

Equipment and method for preparing nanometer metal powder

The invention relates to equipment for preparing nanometer metal powder. The equipment comprises a feeding system, a preheating system, a pre-reduction system, a deep reduction system, a cooing system and a passivating device which are connected in sequence, wherein the preheating system is connected with a combustion chamber providing heat, and the combustion chamber is connected with the pre-reduction system and the deep reduction system; the pre-reduction system comprises a first fluidized bed reduction furnace for carrying out a pre-reduction reaction; the deep reduction system comprises a second fluidized bed reduction furnace for carrying out a deep reduction reaction; an internal cavity of the fluidizing section of the first fluidized bed reduction furnace and the second fluidized bed reduction furnace comprises a constant diameter section and a circular truncated cone-shaped diameter-reducing section, and the inner diameter of the lower part of the circular truncated cone-shaped diameter-reducing section is gradually reduced, and the taper angle of the circular truncated cone-shaped diameter-reducing section is smaller than or equal to 30 degrees. By using the equipment for preparing nanometer metal powder provided by the invention, the purity is 99% or above, and the grain diameter is uniform.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

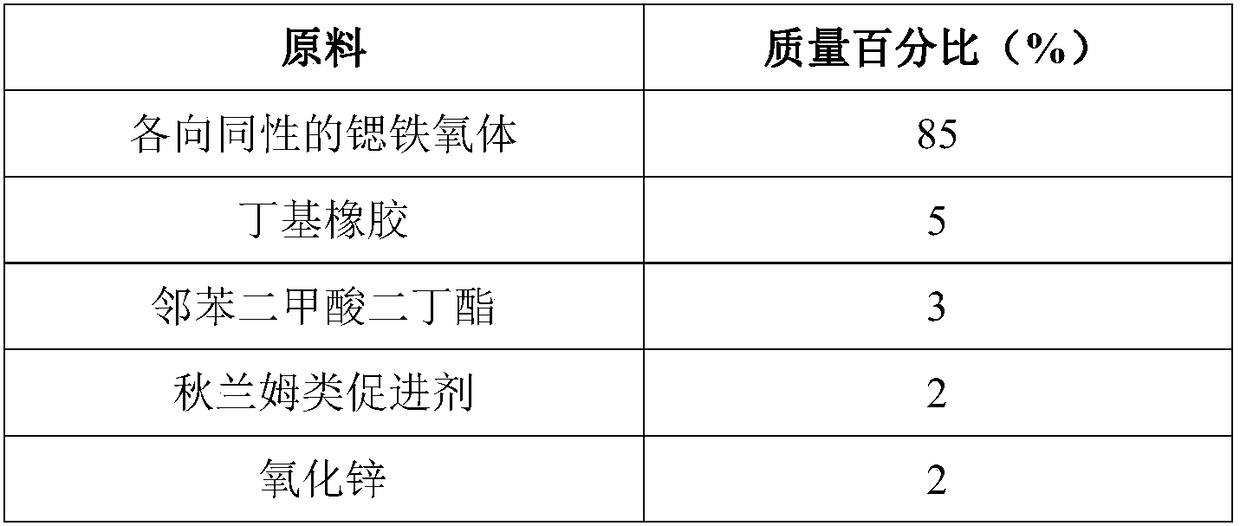

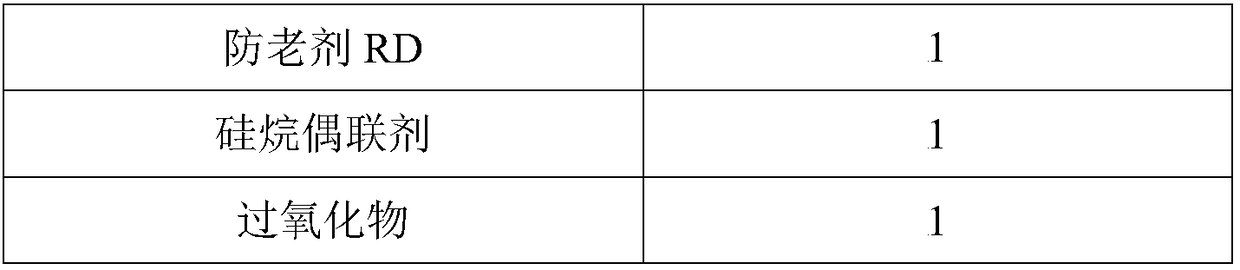

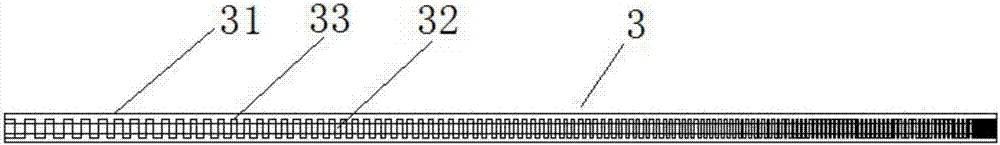

Rubber magnetic stripe and preparation method thereof

The invention discloses a rubber magnetic stripe and a preparation method thereof. The rubber magnetic stripe is prepared from the following ingredients in mass percent content: 75% to 85% of permanent-magnet ferrite magnetic powder, 5% to 15% of rubber, 1% to 5% of plasticizer, 1% to 3% of accelerant, 1% to 3% of activating agent, 0.5% to 2% of anti-ageing agent, 1% to 3% of coupling agent and 0.5% to 3% of vulcanizing agent. The preparation method comprises the following steps: 1) modifying the permanent-magnet ferrite magnetic powder to obtain modified magnetic powder; 2) mixing and smelting the modified magnetic powder, the rubber, the plasticizer, the accelerant, the activating agent, the anti-ageing agent and the vulcanizing agent to obtain a blank; 3) mixing and breaking the blank and rolling the blank into pieces to obtain semi-finished product pieces; 4) cutting and vulcanizing the semi-finished product pieces to obtain vulcanized pieces; 5) performing microwave treatment on the vulcanized pieces and cooling and cutting the vulcanized pieces. The rubber magnetic stripe disclosed by the invention has the advantages of large magnetism, high mechanical strength, good dimensional stability, evenness in internal and external vulcanization, long service life, simple preparation technology and low energy consumption.

Owner:GUANGZHOU GOLDEN SOUTH MAGNETIC MATERIAL

Flame-retardant sealing ring for motors of range hoods

The invention discloses a flame-retardant sealing ring for motors of range hoods. The flame-retardant sealing ring is made from raw materials including nitrile rubber, zinc oxide, stearic acid, carbon black, white carbon black, sulphur powder, an accelerant CZ, an accelerant M, an accelerant TMTD, ETU-80, light magnesium oxide, pottery clay, chloroprene rubber adhesive, aluminum hydroxide, a silane coupling agent, zinc borate, antimonous oxide, modified flame retardant, dioctyl phthalate, carnauba wax, antiager 2246, antiager BZ and a processing agent WB-16. The flame-retardant sealing ring is good in high-temperature resistance and flame retardant performance, and meanwhile has the advantages of oil resistance, no halogen, low toxicity and environment friendliness.

Owner:NINGGUO ZOYE PLASTIC & RUBBER CO LTD

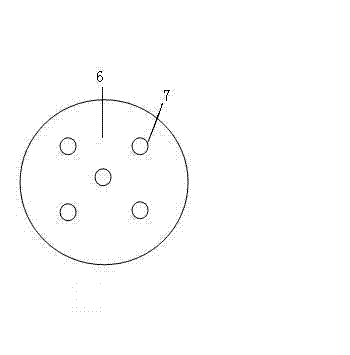

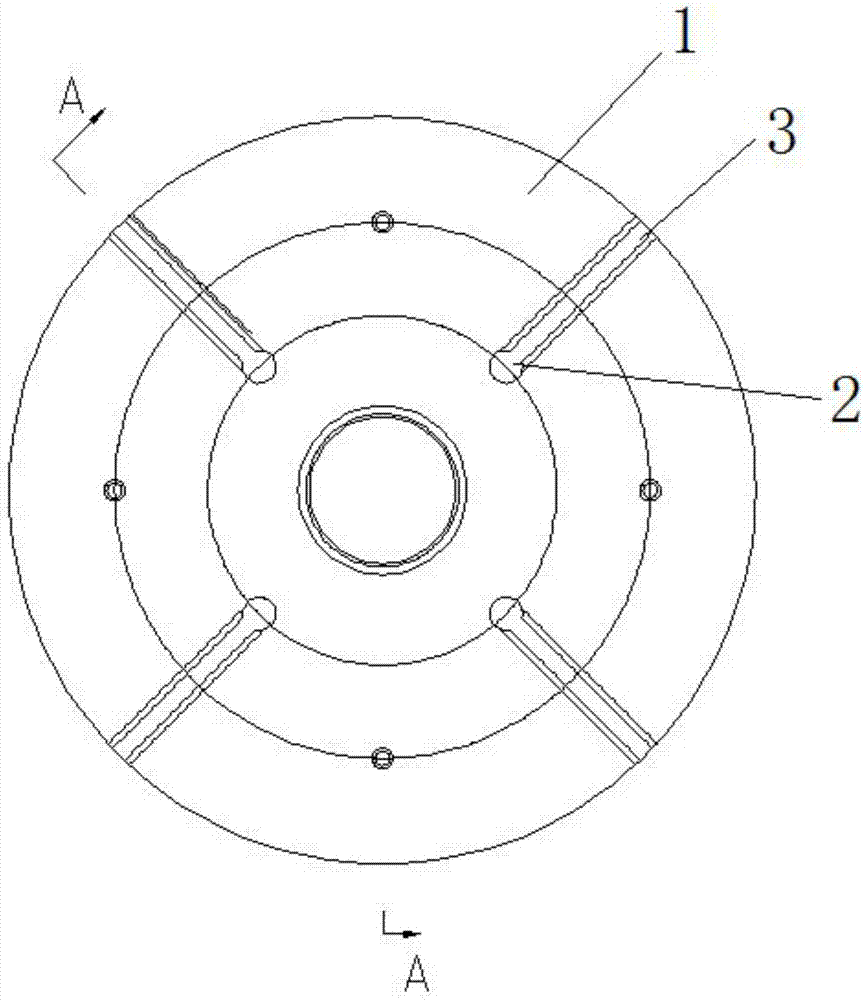

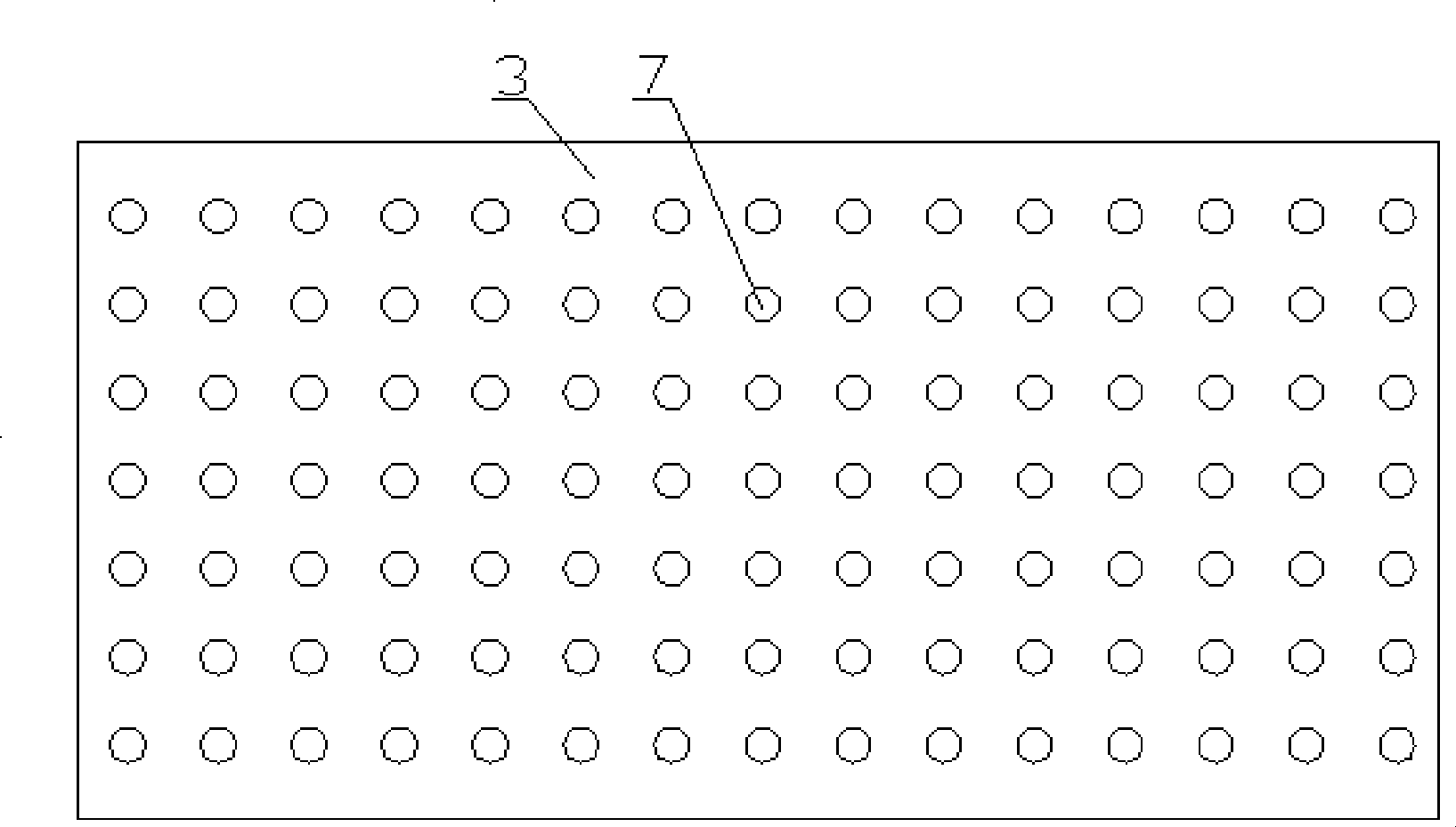

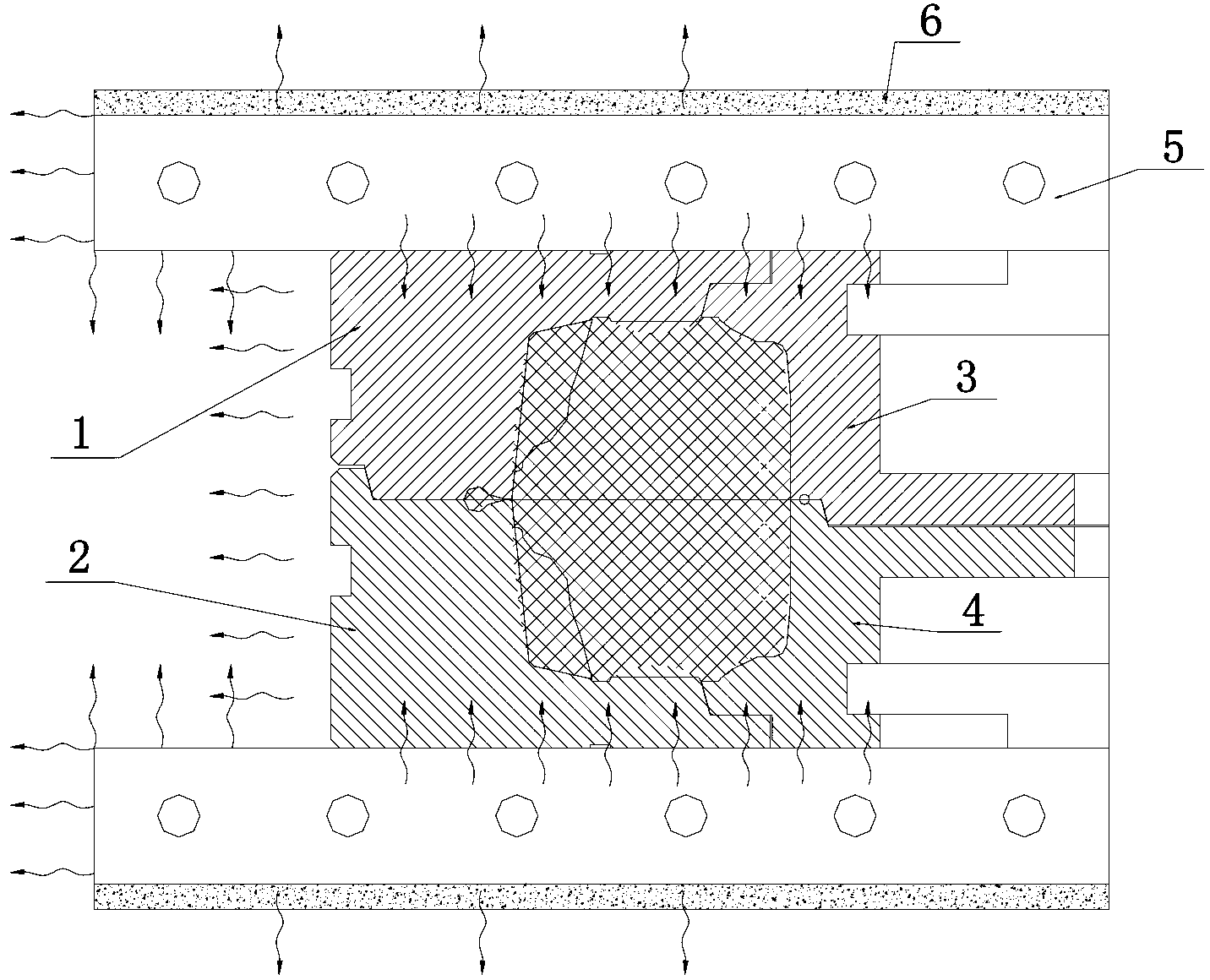

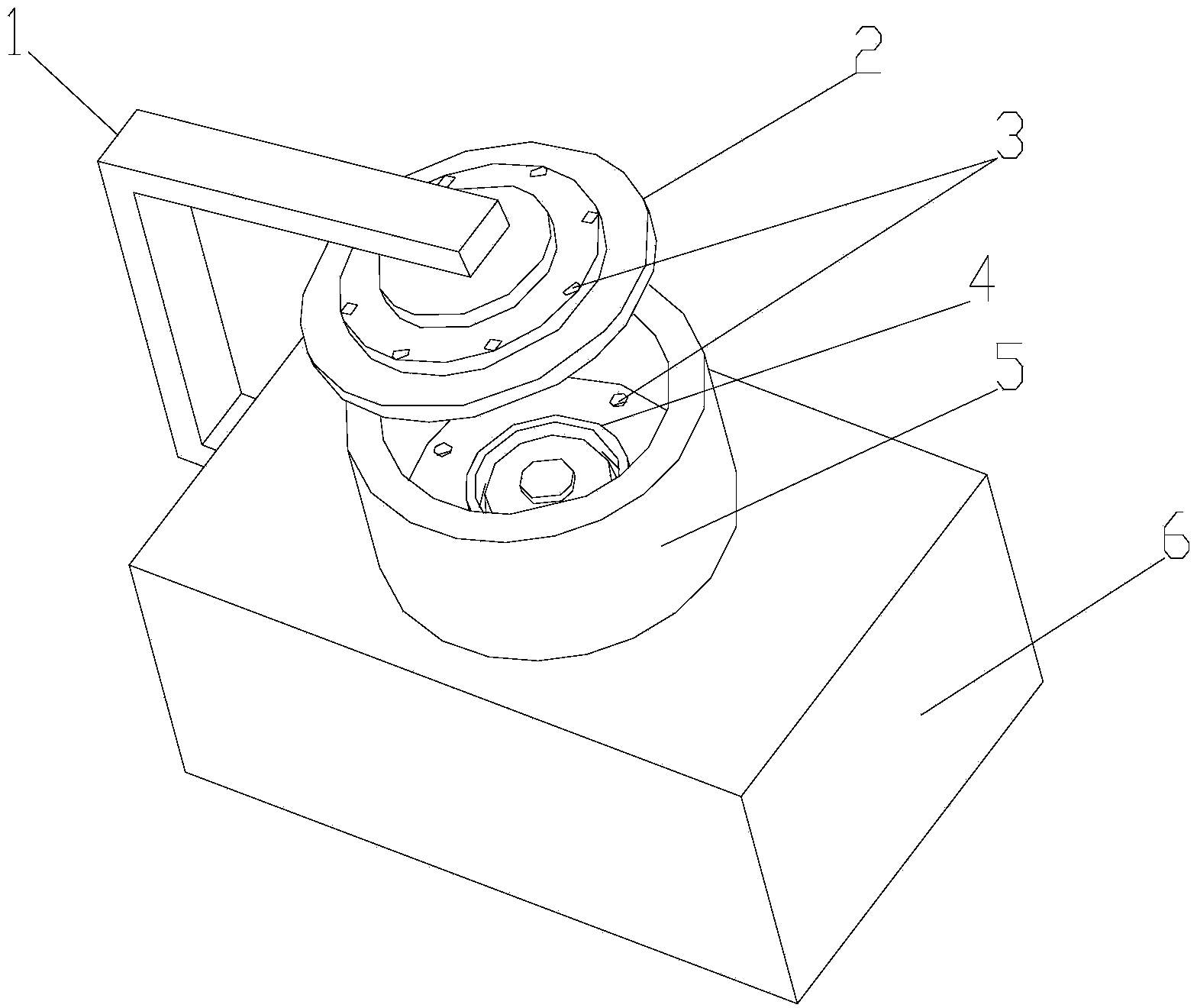

Uniform vulcanization method of seismic isolation rubber support of building

InactiveCN102418389AUniform vulcanizationImprove product qualityShock proofingVulcanizationHeat conducting

The invention relates to a uniform vulcanization method of a seismic isolation rubber support of a building, belonging to the technical field of seismic isolation of rubber supports of buildings. The rubber support to be vulcanized is provided with a plurality of small holes which penetrate through from top to bottom, wherein heat-conducting metal bars are inserted into the small holes of the rubber support which is put into a die, the upper end and the lower end of each heat conducting bar are respectively in contact with the upper wall surface and the lower wall surface of the metal die, and vulcanization is carried out by adopting a vulcanizing press, and the heat conducting metal bars are taken out after the vulcanization is finished. The uniform vulcanization method has the beneficial effects that: the rubber support is vulcanized more evenly, quality and material utilization rate are increased, and vulcanization speed is increased at the same time of ensuring uniform vulcanization.

Owner:YUNNAN QUAKESAFE SEISMIC ISOLATION TECH

Coating rubber roller for high-grade automobile plate production line and manufacturing method thereof

ActiveCN103613861AGood compatibilityGood dispersionLiquid surface applicatorsCoatingsPolyesterEngineering

Owner:南京金三力橡塑有限公司 +1

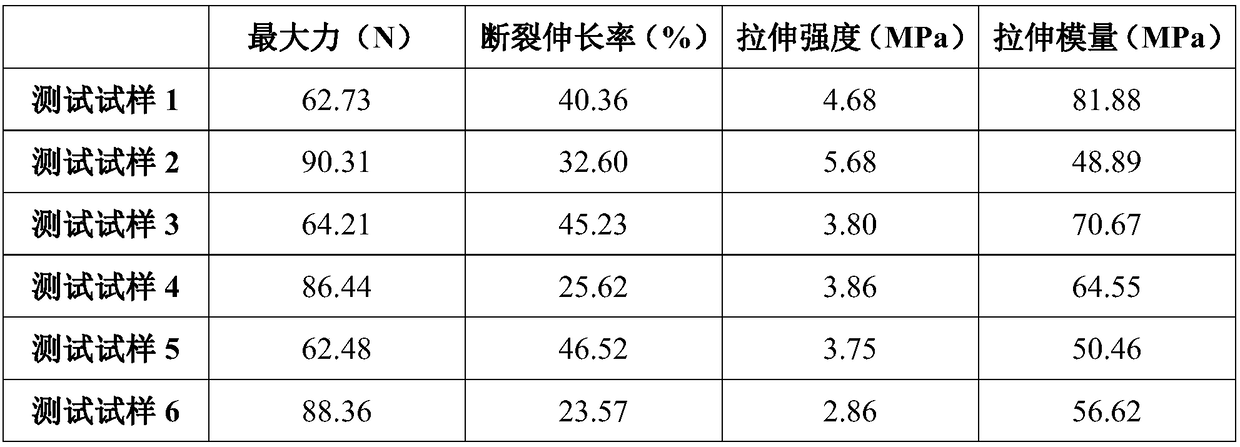

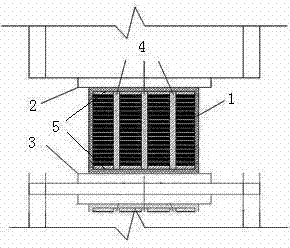

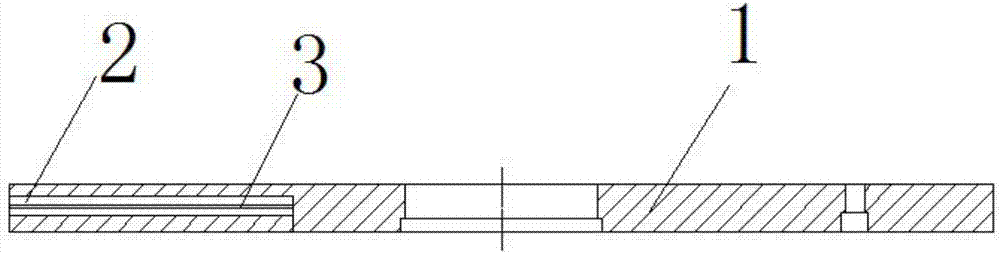

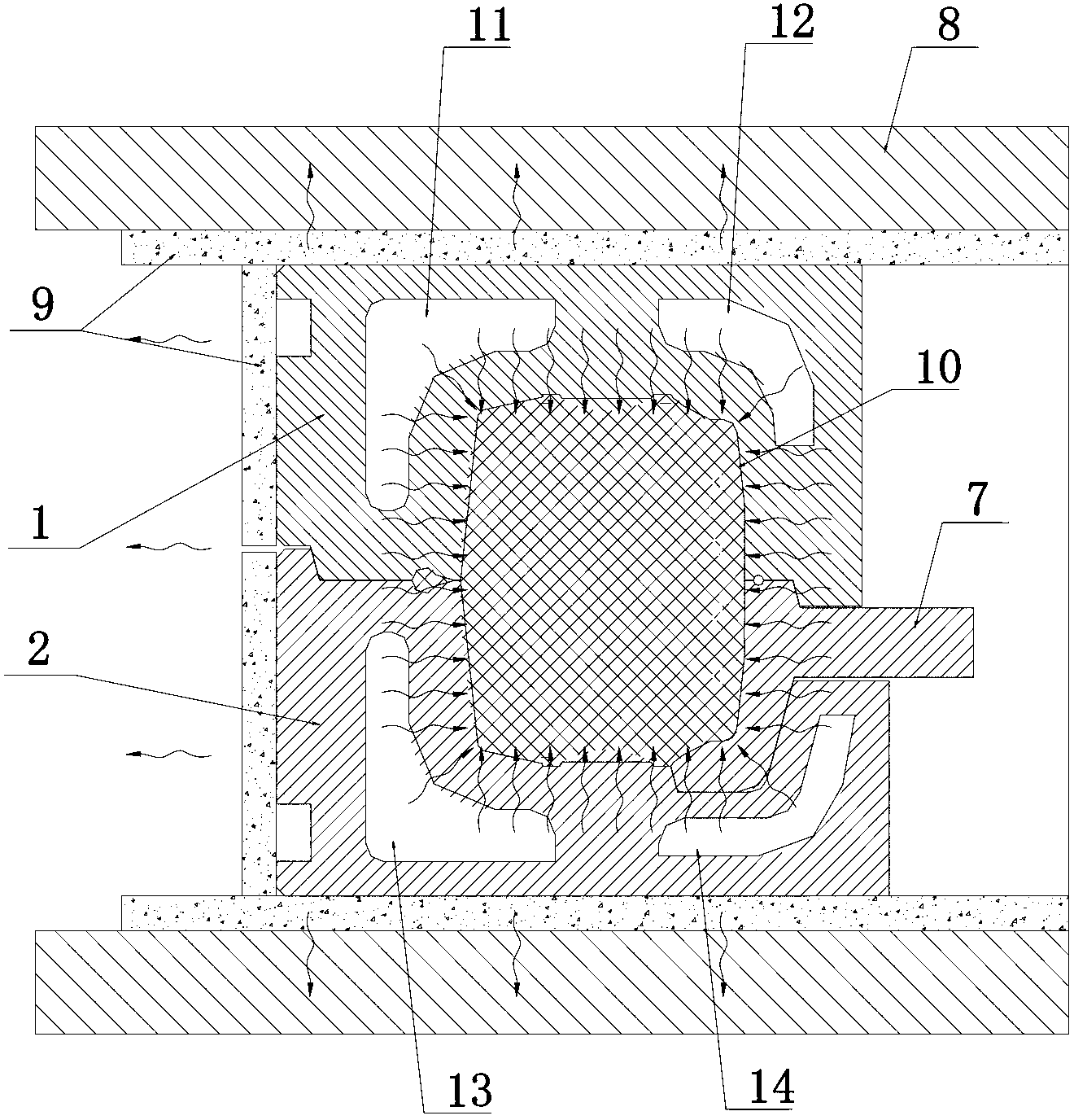

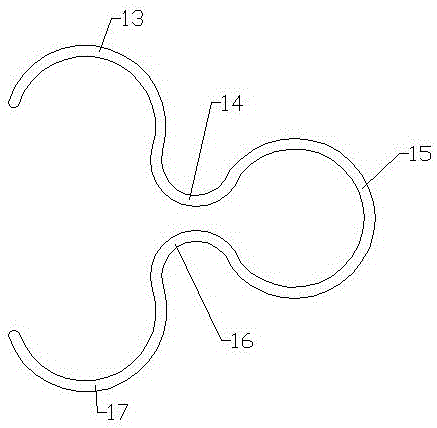

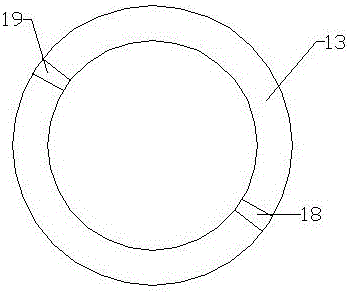

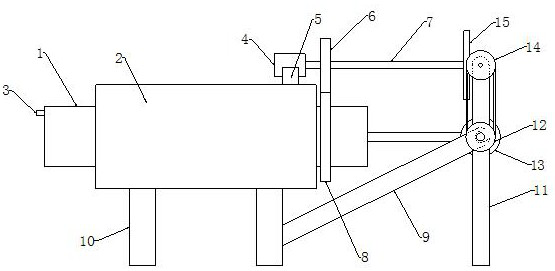

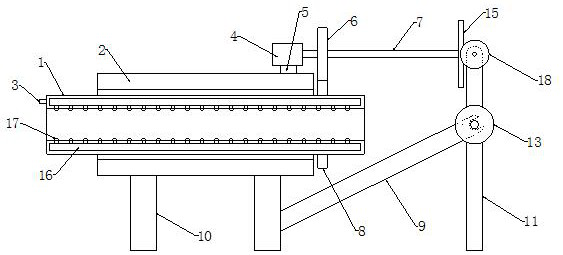

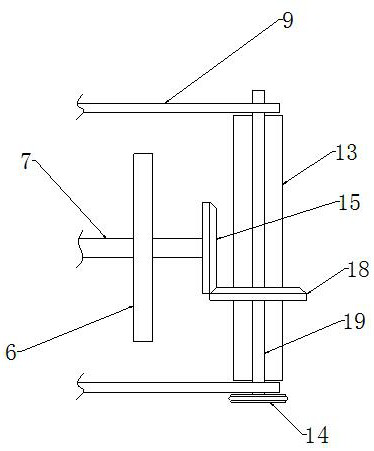

Rapid vulcanization die for building lamination shock insulation rubber bearing

InactiveCN103786282AAvoid heat transfer barriersAchieving direct heat conductionVulcanizationEngineering

The invention discloses a rapid vulcanization die for a building lamination shock insulation rubber bearing. The rapid vulcanization die comprises an inner heating die with a heat conduction strip, an outer heating die with a heat conduction strip, an excessive glue groove, heat conduction strips, an upper heating template, a lower heating template, a positioning shaft, a positioning hole and a positioning shaft mounting groove, wherein the lower heating template is mounted on a support, the outer heating die with the heat conduction strip is arranged on the upper surface of the lower heating template, the inner heating die with the heat conduction strip is arranged in the center of the outer heating die with the heat conduction strip, the height of the outer heating die with the heat conduction strip is equal to that of the inner heating die with the heat conduction strip, and the upper heating template is arranged at the tops of the outer heating die with the heat conduction strip and the inner heating die with the heat conduction strip. The rapid vulcanization die fully utilizes the structural principle of vulcanization equipment and a vulcanization target to realize rapid and uniform vulcanization and efficient mounting, is applicable to vulcanization processing of various rubber bearings, such as a standard rubber bearing, a pencil lead rubber bearing, a high damping rubber bearing and a stacked rubber bearing, and is high in vulcanization efficiency and rapid and convenient to mount and maintain.

Owner:彭勃

Hydrotreating Catalyst External Presulfurization Method

The invention relates to a presulfurization method outside a hydrorefining catalyst. The method is to heat the vegetable oil to a certain temperature and then slowly add powdered sulfur in a certain proportion to generate red-black vulcanized oil; add a hydrofining catalyst to the red-black vulcanized oil in a certain proportion, mix it evenly, and put it into a reaction kettle. Heating and activating at a certain pressure and temperature, and cooling to room temperature completes the external pre-sulfurization of the hydrotreating catalyst. The invention breaks through the traditional method of catalyst vulcanization, and the vulcanization is even, reduces the amount of carbon deposits on the catalyst, increases the sulfur rate, significantly improves the activity and stability of the catalyst, can exist stably in the air, and is convenient for transportation and transportation. Storage greatly reduces the cost of industrial hydrogenation. It is simple to operate and easy to implement. Compared with traditional vulcanization methods, it can significantly reduce the cost of vulcanization.

Owner:一重集团大连工程建设有限公司

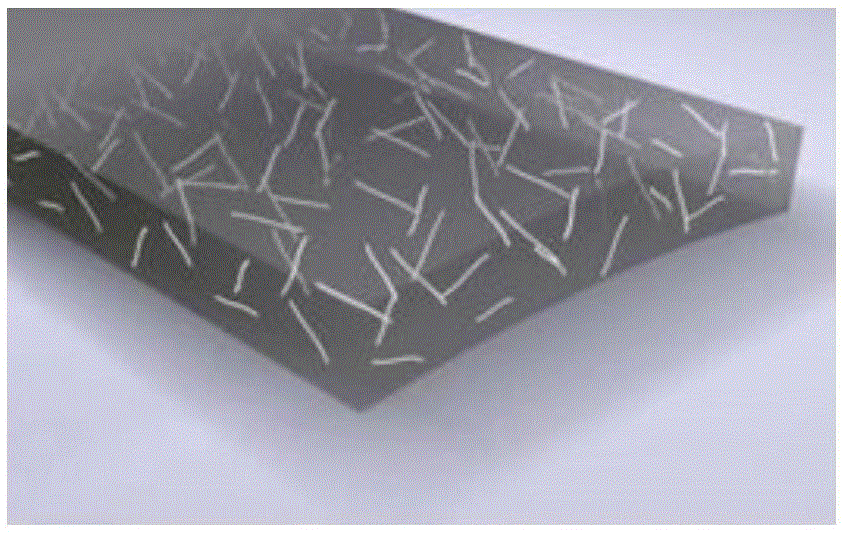

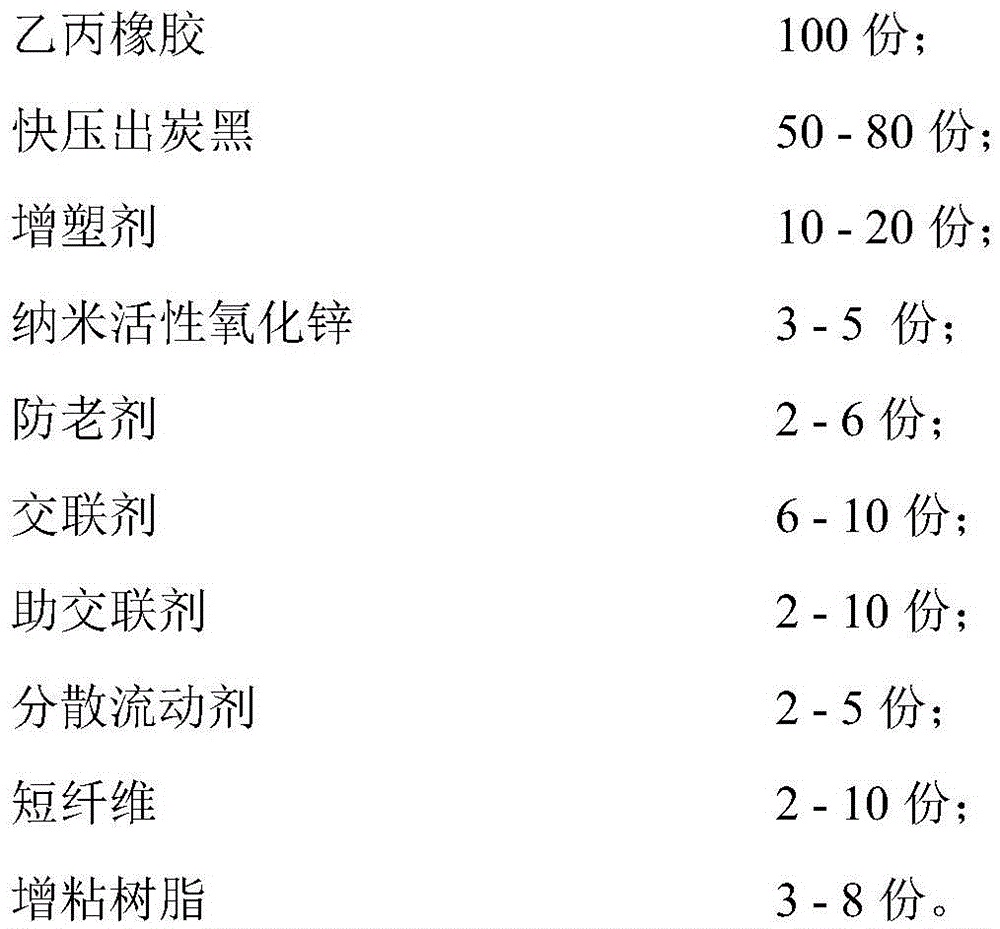

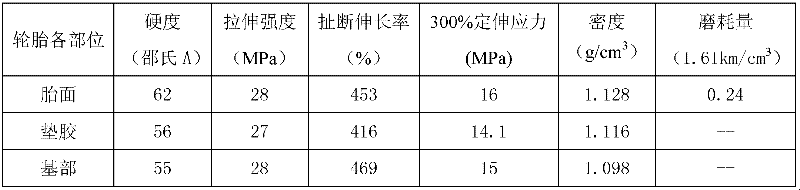

Short fiber-reinforced high temperature-resistant rubber roll, rubber roll rubber material and preparation methods thereof

The invention discloses a short fiber-reinforced high temperature-resistant rubber roll, a rubber roll rubber material and preparation methods thereof, and belongs to the technical field of rubber rolls. The rubber roll rubber material comprises the following components in parts by weight: 100 parts of ethylene propylene rubber, 50-80 parts of rapidly-extruded carbon black, 10-20 parts of a plasticizer, 3-5 parts of nanometer active zinc oxide, 2-6 parts of an anti-aging agent, 6-10 parts of a crosslinking agent, 2-10 parts of an assistant crosslinking agent, 3-8 parts of tackifying resin, 2-5 parts of a dispersing flowable agent and 2-10 parts of short fiber. The preparation method of the rubber roll comprises the following steps: preparing the rubber material, wrapping with the rubber material, vulcanizing in a vulcanizing tank, and turning. The rubber material is high in strength, rebound resilience, and resistance to high temperature and low in permanent compression deformation; the rubber roll made of the rubber material is high in resistance to high temperature and acid and alkali corrosion; the rubber roll is highly consistent in inside and outside hardness and material distribution and high in roller surface machining precision; the service life of the rubber roll is twice of or longer than that of the conventional high temperature-resistant rubber roll, so that the service life of the rubber roll is greatly prolonged.

Owner:南京金三力橡塑有限公司

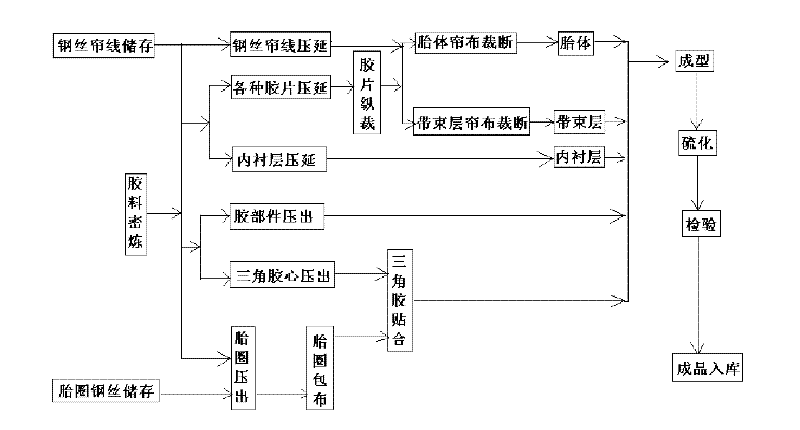

Production process of radial tire

The invention relates to a production process of a radial tire. And an internal mixing operation comprises the steps of: reducing the rotating speed of an internal mixer when a rubber compound is mixed to a temperature of 140-160DEG C, maintaining the rubber compound at a temperature ranging from 140DEG C to 160DEG C for 70-90 seconds, during which a feeding door is opened for 15-25 seconds to discharge water vapor from the internal mixer; during a molding operation, an inside liner and a carcass shape up in the first molding stage; and during a sulfuration operation, the internal pressure iscontrolled in a range of from 2.9MPa to 3.1MPa, the inner temperature is maintained in a range of from 145DEG C to 151 DEG C, and the outer temperature is maintained in a range of from 136DEG C to 140 DEG C. The process of the invention can ensure well mixed rubber compound, uniform steel cord, tight carcass joint and uniform sulfuration, and the product obtained has high physical properties. Therefore, the production process of the invention satisfies the production requirements of giant engineering machinery radial tires.

Owner:山东新豪克轮胎有限公司

Self-lubricating fluorinated silicone rubber seal ring

A self-lubricating fluorinated silicone rubber seal ring relates to the technical field of seal rings, and is characterized by comprising fluorinated silicone rubber, and a PTFE (Polytetrafluoroethylene) thin film arranged on the surface layer of the fluorinated silicone rubber. The invention further provides a production method of the fluorinated silicone rubber seal ring. The production method is characterized by comprising the following steps: injection molding, bonding, hot-forming, cutting and punching. The self-lubricating fluorinated silicone rubber seal ring has the excellent properties of abrasion resistance, pressure resistance and the like, and can be used in complex or bad environments requiring relatively high requirements. The production method has the advantages that the problem of difficulty in bonding polytetrafluoroethylene with fluorinated silicone rubber is solved; the production speed is fast; the machining quality is high.

Owner:宁国市格斯特密封件有限公司

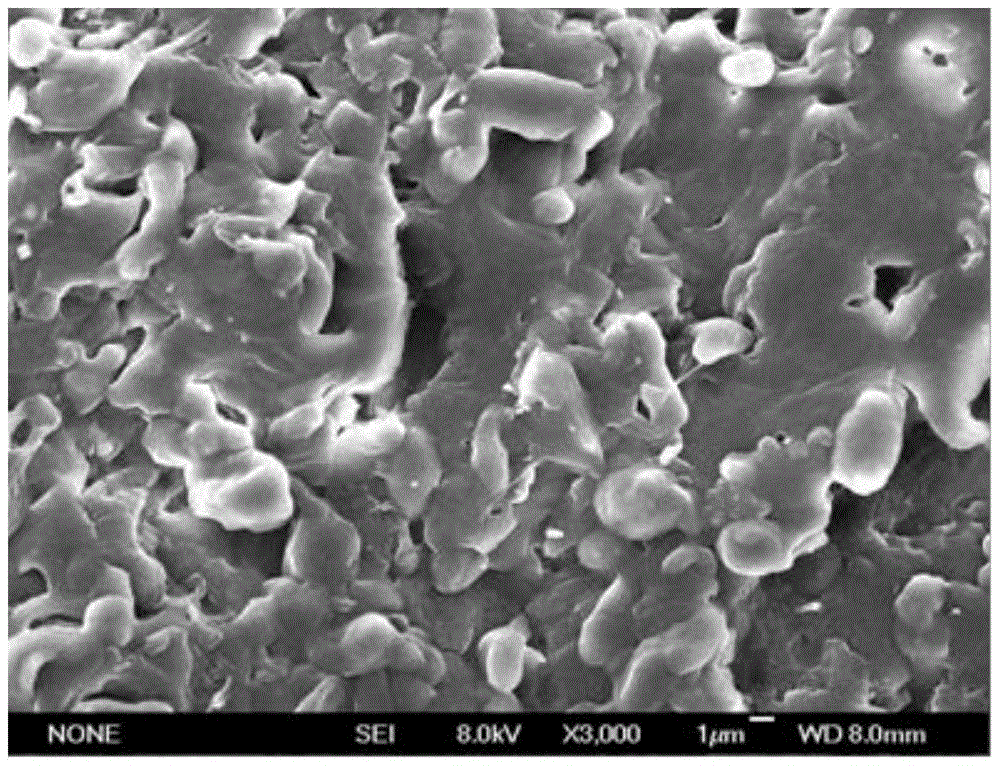

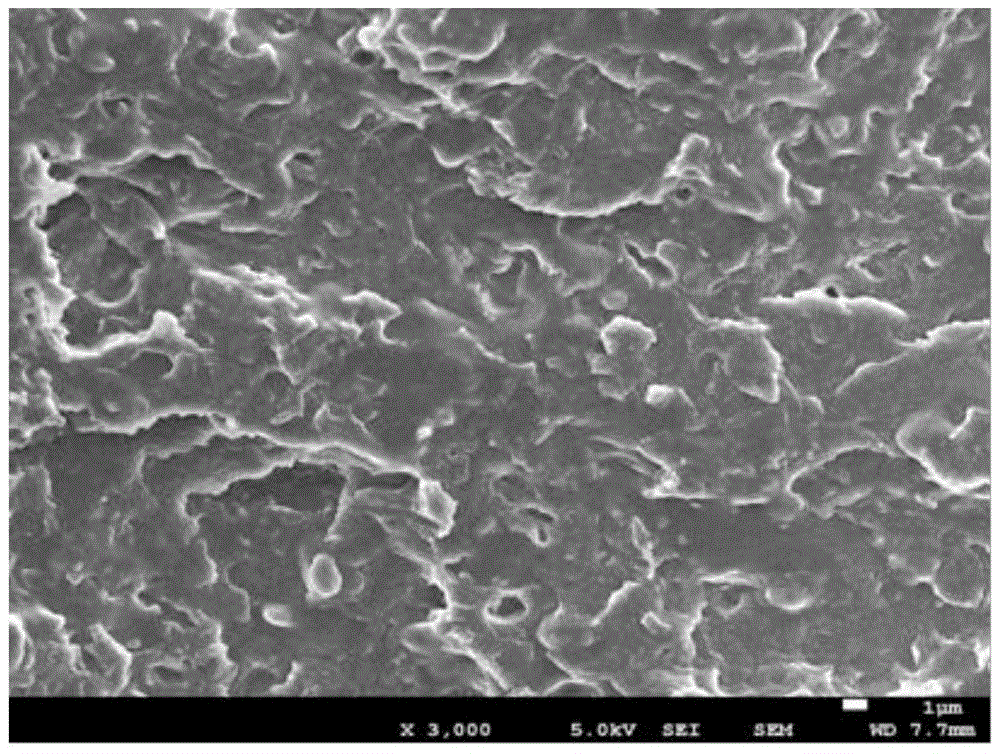

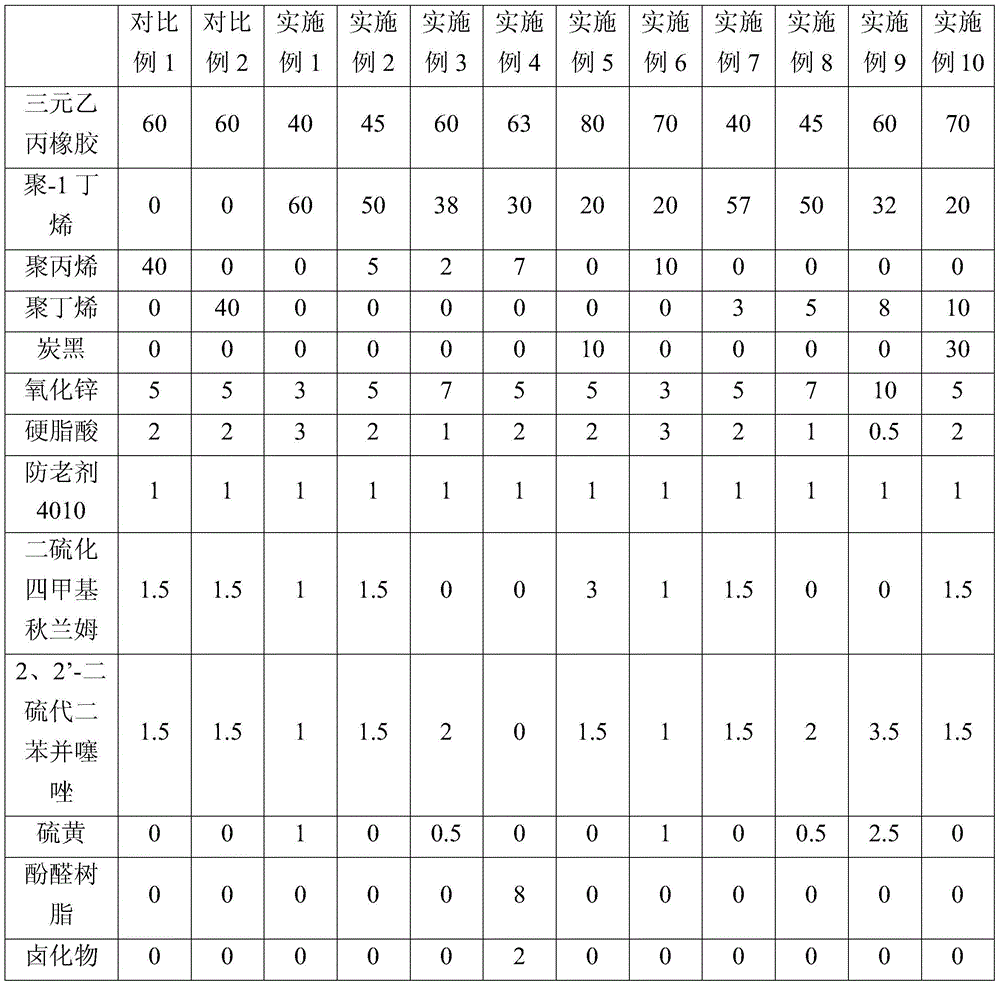

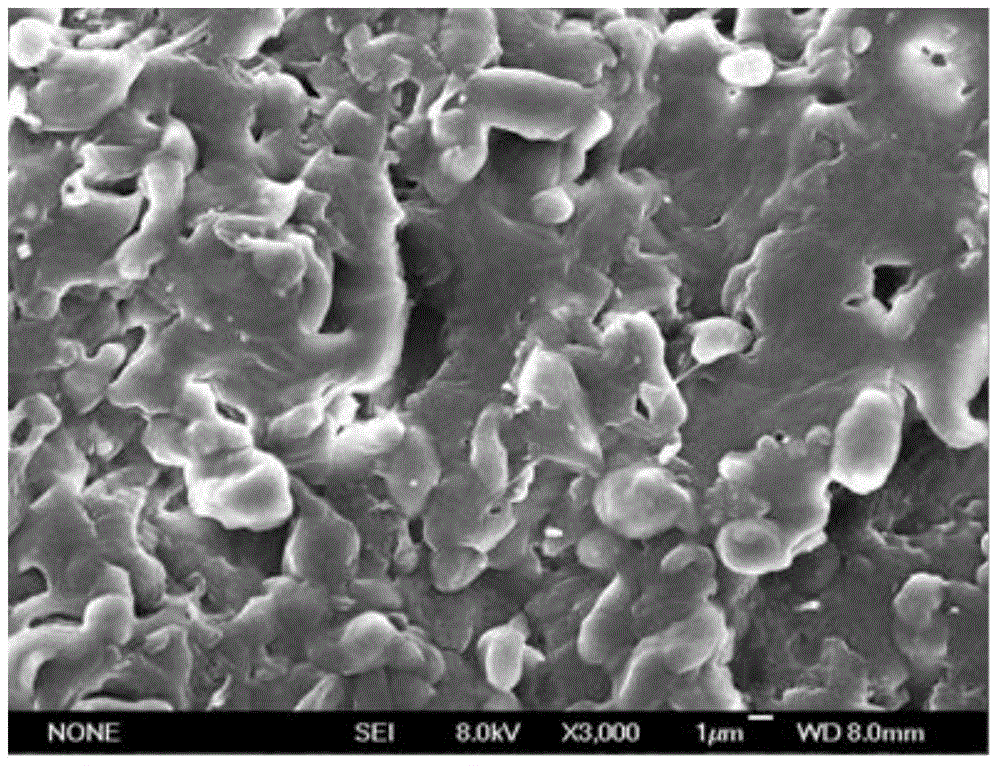

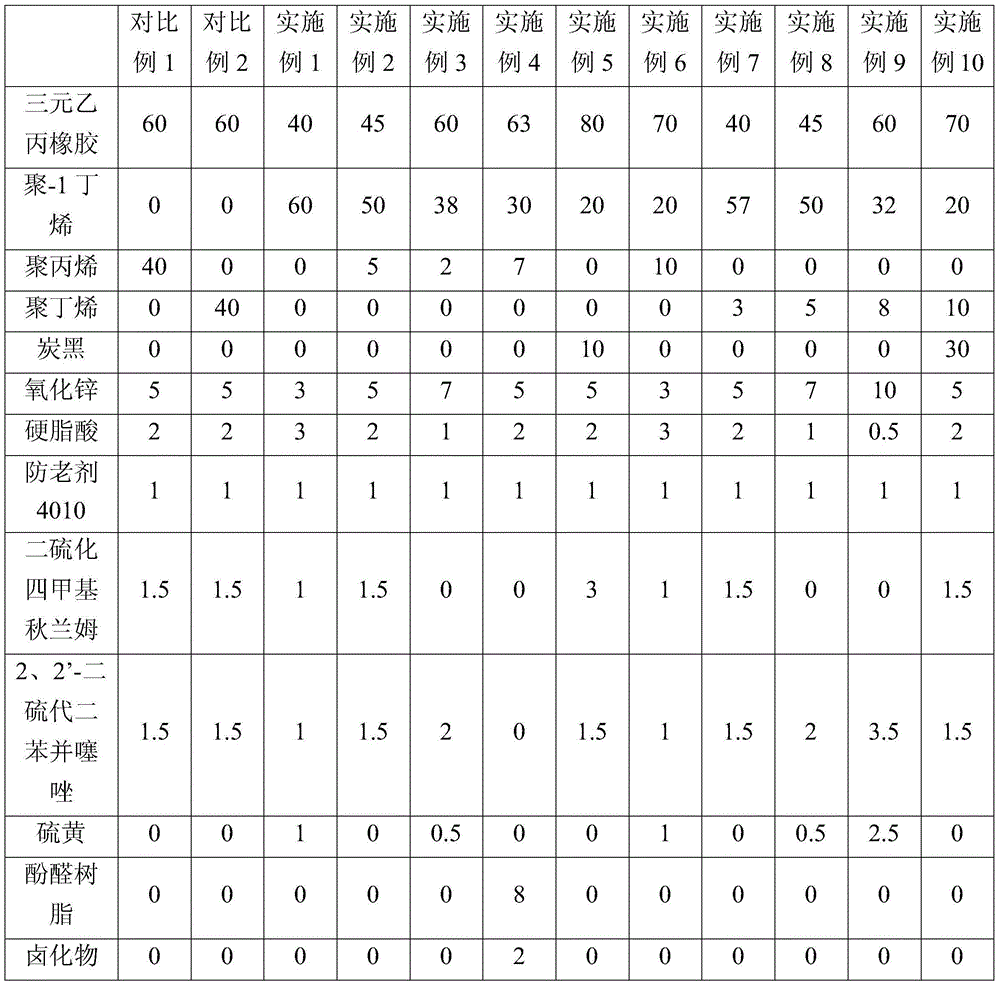

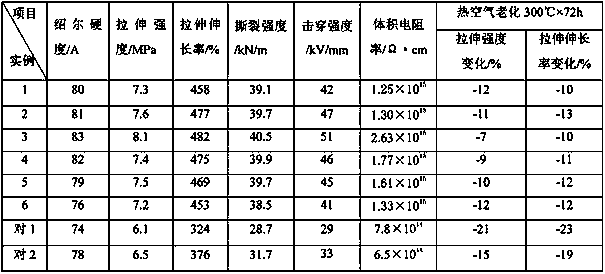

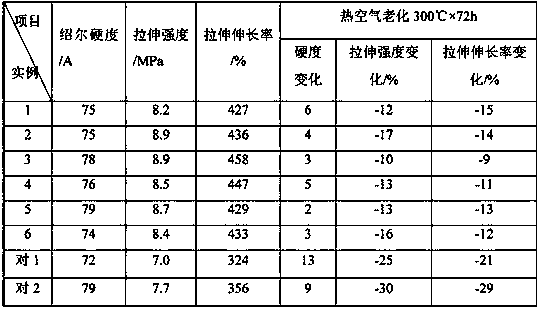

Rubber-plastic blend composition, dynamically vulcanized thermoplastic elastomer and preparation method

The invention provides rubber-plastic mixed composition, a dynamically vulcanized thermoplastic elastomer and a preparation method thereof. The dynamically vulcanized thermoplastic elastomer is prepared by dynamically vulcanizing ethylene-propylene-diene monomer rubber, poly-4-methylpentene-1 and a cross-linking system by adopting an internal mixing process. The thermoplastic elastomer is high in strength, excellent in high-temperature resistance, small in permanent deformation and good in elasticity; the high-temperature resistance of the thermoplastic elastomer prepared by adopting the method cannot be matched by that of a thermoplastic elastomer prepared by other methods.

Owner:QINGDAO UNIV OF SCI & TECH

Energy-saving heating plate of tire vulcanizing machine

InactiveCN107443638AUniform vulcanizationThe energy saving and heat generation of the vulcanizing machine are uniformAgricultural engineeringHeating temperature

The invention discloses an energy-saving heating plate of a tire vulcanizing machine. The energy-saving heating plate of the tire vulcanizing machine comprises a heating plate body, wherein a plurality of linear holes which are recessed towards the center of a circle of the heating plate body are formed in an outer ring wall of the heating plate body; and a heating tube is inserted in each linear hole. Compared with a heating plate of a tire vulcanizing machine in a steam heating mode in the prior art, the electrothermic heating plate of the tire vulcanizing machine has the advantages that the sector heating temperature can be balanced, temperature equilibrium is maintained, the heating plate body of the tire vulcanizing machine can be heated uniformly, tire vulcanizing is uniform, meanwhile, the heat degree of the heating plate body of the tire vulcanizing machine is controlled conveniently, workmanship is simple, sealing is not required, the cost is low, a steamer is not required, and therefore, the energy-saving heating plate of the tire vulcanizing machine is energy-saving and environmentally friendly.

Owner:东莞市富仕节能科技有限公司

Rubber-plastic mixed composition, dynamically vulcanized thermoplastic elastomer and preparation method thereof

The invention provides rubber-plastic mixed composition, a dynamically vulcanized thermoplastic elastomer and a preparation method thereof. The dynamically vulcanized thermoplastic elastomer is prepared by dynamically vulcanizing ethylene-propylene-diene monomer rubber, poly-4-methylpentene-1 and a cross-linking system by adopting an internal mixing process. The thermoplastic elastomer is high in strength, excellent in high-temperature resistance, small in permanent deformation and good in elasticity; the high-temperature resistance of the thermoplastic elastomer prepared by adopting the method cannot be matched by that of a thermoplastic elastomer prepared by other methods.

Owner:QINGDAO UNIV OF SCI & TECH

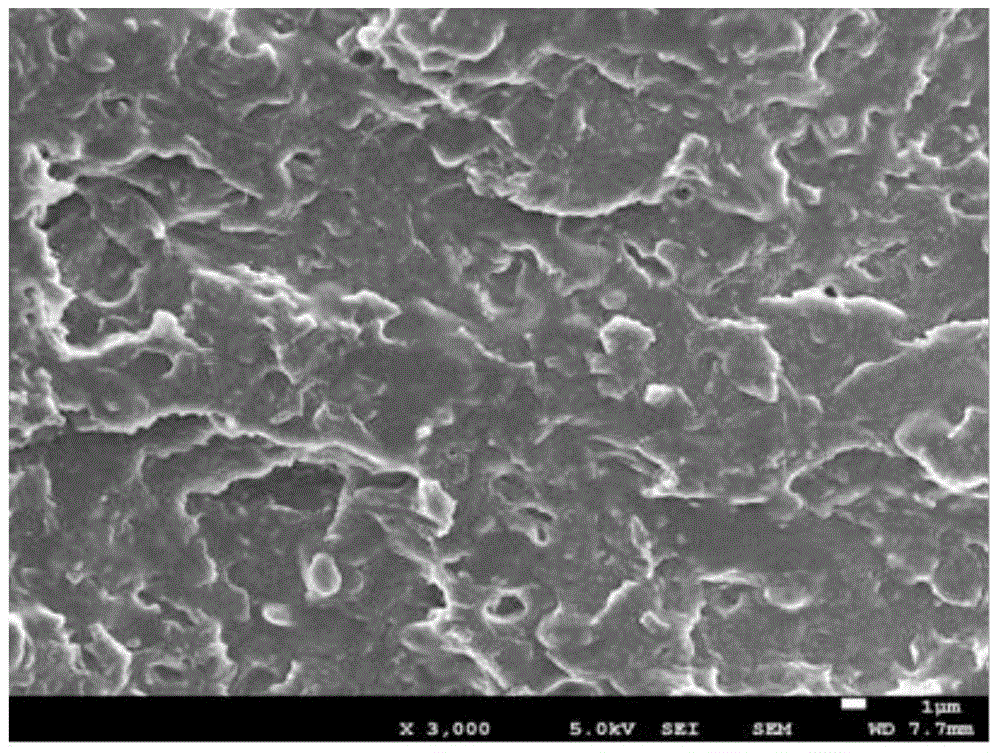

Aging-resistant silicone rubber composite material, and preparation method thereof

The invention discloses an aging-resistant silicone rubber composite material. The aging-resistant silicone rubber composite material is prepared from, by weight, 100 parts of methyl vinyl silicone rubber, 8 to 15 parts of perfluoroether rubber, 20 to 40 parts of fumed silica, 3 to 8 parts of polyimide, 6 to 12 parts of aluminum hydroxide micropowder, 0.5 to 1.0 part of a silane coupling agent, 2to 6 parts of dimethyldiethoxysilane, 1 to 3 parts of hydroxyl silicone oil, 0.5 to 1.5 parts of methyl hydrogen silicone oil, and 1 to 3 parts of a vulcanizing agent. The aging-resistant silicone rubber composite material is high Shore Hardness and mechanical strength, excellent in electrical performance and resistance to hot air aging, and be used for long time working under high temperature conditions.

Owner:国网河南省电力公司新野县供电公司

Ex-situ presulfiding method of hyrorefining catalysts

ActiveCN101665745AReduce carbon depositionHigh activityFatty acid hydrogenationRoom temperatureHeat-only boiler station

The invention relates to an ex-situ presulfiding method of hyrorefining catalysts. The method comprises the following steps: heating plant oil to reach a certain temperature, then slowly adding powdery sulphur according to a certain proportion to generate deep black sulphurized oil; adding the hyrorefining catalysts in the deep black sulphurized oil according to a certain proportion, uniformly mixing and then putting in a reaction kettle, heating and activating under a certain pressure and temperature, cooling to the room temperature to finish the ex-situ presulfuration of hydrogenation refined catalysts. The invention breaks through the traditional sulfuration method of catalysts, has uniform sulfuration, reduces the coke formation, improves the sulfurization degree, enables the activation and the stability of the catalysts to be obviously improved, is stably stored in the air, convenient to transport and store, simple to operate and easy to implement, greatly lowers the industrial hydrogenation cost and can obviously lower the sulfuration cost compared with the traditional sulfuration method.

Owner:一重集团大连工程建设有限公司

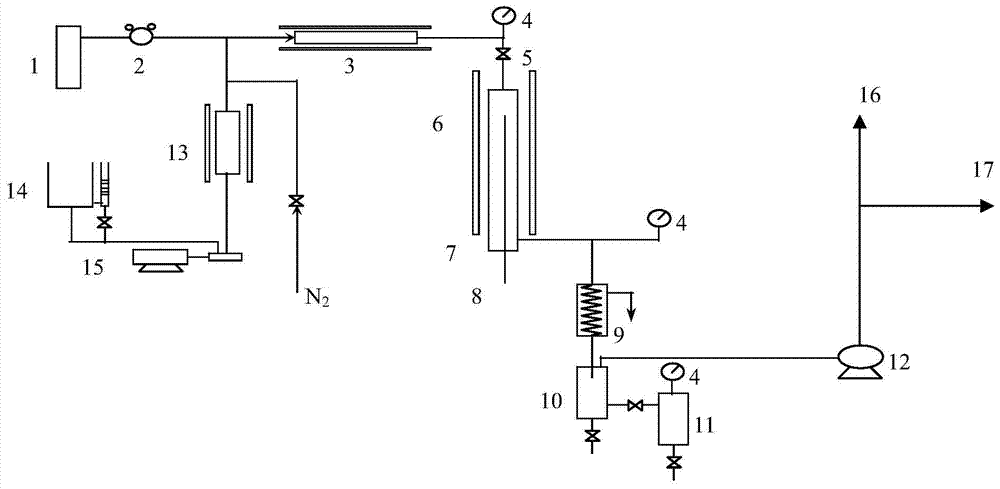

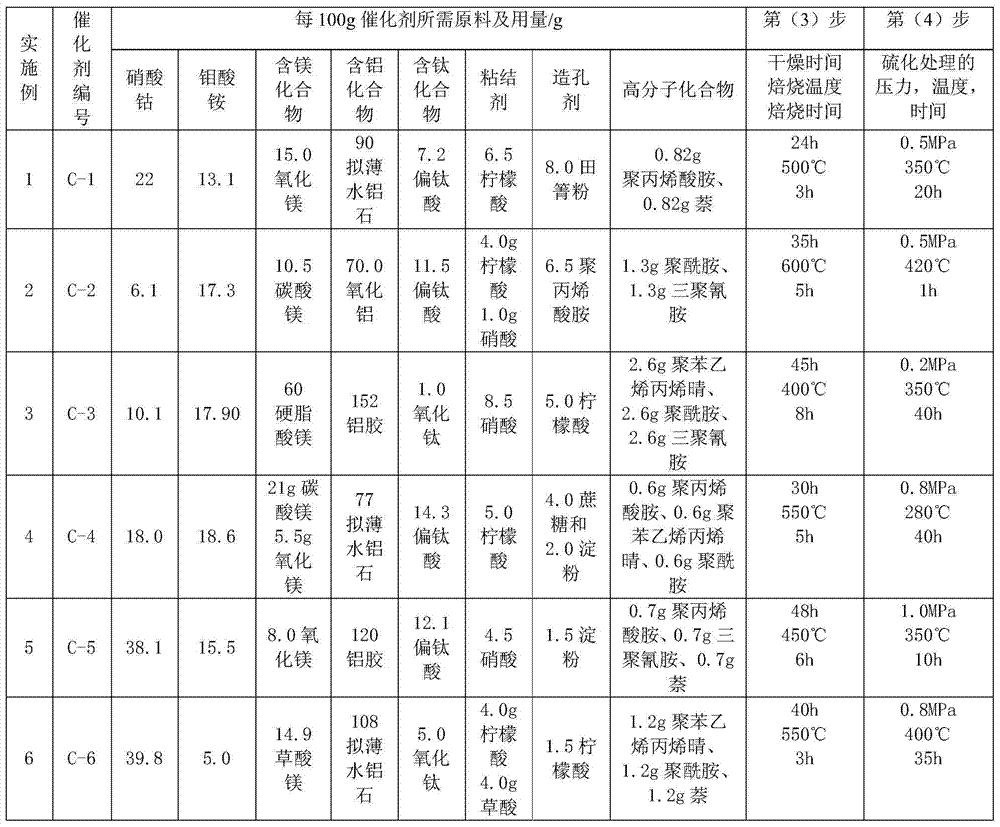

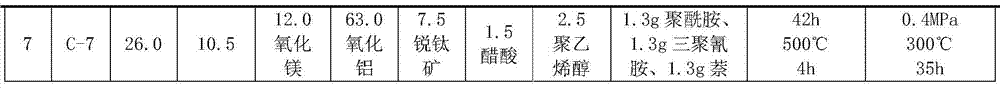

Presulfurized sulfur-tolerant shift catalyst and preparation method

ActiveCN105233867BUniform vulcanizationIncrease the degree of vulcanizationOrganic-compounds/hydrides/coordination-complexes catalystsActive componentSulfidation

The invention relates to a presulfided sulfur-tolerant shift catalyst and a preparation method, belonging to the technical field of presulfurization treatment of sulfur-tolerant shift catalysts. The presulfided sulfur-tolerant shift catalyst prepared by using the method in the invention comprises an active component which is a binary component of a cobalt-contained compound and a molybdenum-contained compound, and carrier raw materials which are a magnesium-contained powdery compound, an aluminum-contained powdery compound, a titanium-contained powdery compound, and an external surface wrappage material composed of a macromolecular compound. The preparation method for the presulfided sulfur-tolerant shift catalyst provided by the invention comprises the following steps: preparation of an active component solution, molding of the catalyst, drying, roasting, presulfurization treatment, and aftertreatment of the catalyst. The presulfided sulfur-tolerant shift catalyst prepared by using the method in the invention is easy to activate when in use, has short activation time and high shift activity, and is convenient for transportation and storage; and the preparation method for the presulfided sulfur-tolerant shift catalyst provided by the invention is simple in process and facilitates realization of industrialization.

Owner:CHINA PETROLEUM & CHEM CORP

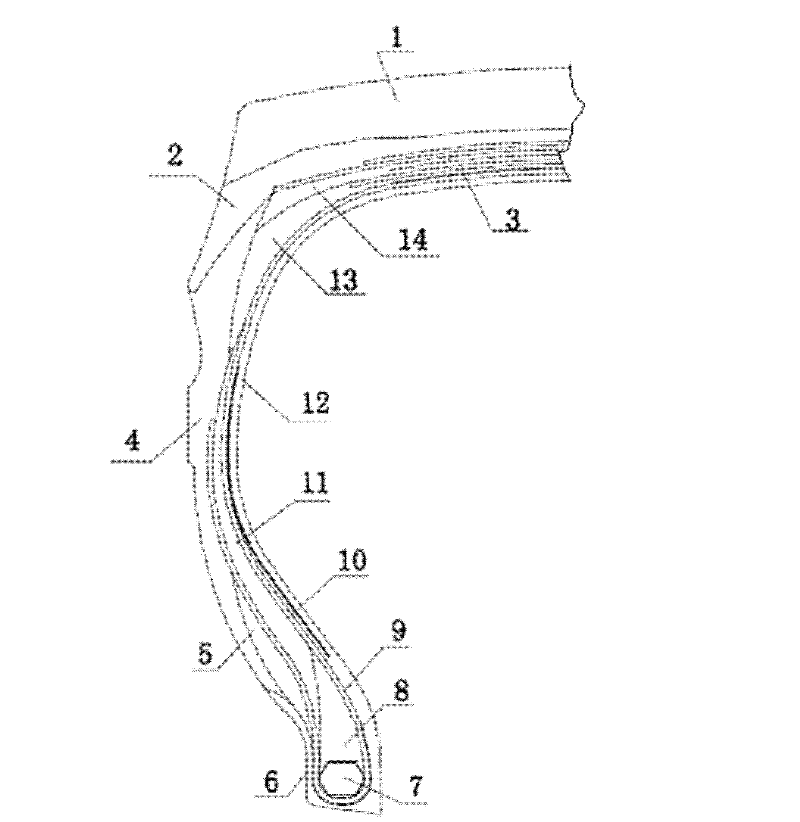

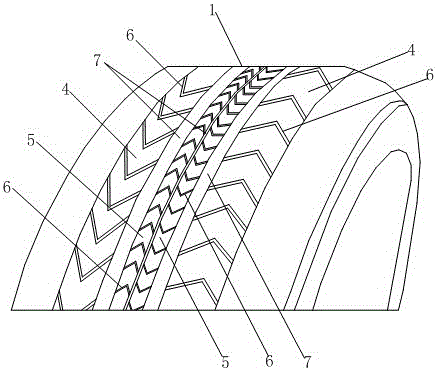

Explosion-proof tire

InactiveCN106317838AImprove explosion-proof performanceReduce forceSpecial tyresCoatingsTire beadVulcanization

The invention discloses an explosion-proof tire which comprises a tire body composed of a tread, a tire body, a buffer layer and a tire bead, wherein the tread is a rubber composition prepared by taking rubber as a matrix and adding with auxiliary materials such as a reinforcing filler, an accelerant, a vulcanizing agent, a vulcanization accelerator and an adhesion promoter; an explosion-proof layer made from high polymer explosion-proof materials is sprayed on the surface of the tread; a plurality of capsule cavities are formed in the tread and filled with leak-repairing glue. With the adoption of a manner of combining the explosion-proof layer, the capsule space and the tread rubber, the explosion-proof layer is sprayed on the surface of the tread, so that the elasticity of the tread surface is increased, and the acting force of a sharp object on the tread rubber is relieved; and moreover, the capsule cavities are formed in the tread rubber, when the sharp object pierces the capsule cavities to reach the tire body, the leak-repairing glue in the capsule cavities reacts with air so as to perform curing, and the condition that running safety is threatened by leakage of high-pressure gas in the inner liner is avoided.

Owner:SICHUAN YUANXING RUBBER

Heat pressing and sulfuration integrated method and device for natural fabric elastic material

The invention discloses a method and a device for hot pressing and vulcanization integration of a natural fiber elastic material. The method is characterized in that natural fiber yarns are prepared to obtain fiber sheets, the fiber sheets are superposed and then are hot-pressed in a closed thermal insulation chamber, and hot air is introduced into the thermal insulation chamber to perform vulcanization treatment on the fiber sheets at the same time. The method combines the prior hot pressing and vulcanization working procedures together, shortens production procedures and time, reduces thermal energy consumption, and reduces production cost. The method realizes the one-step shaping of the fiber elastic material through the synchronous performance of the hot pressing and the vulcanization, thereby greatly reducing the shaping deviation of the fiber elastic material and greatly improving the qualification rate of products; and at the same time, the method realizes the synchronous vulcanization treatment of the inside and the surface, ensures that the fiber elastic material has balanced and complete whole vulcanization, and greatly promotes the service performance of the fiber elastic material.

Owner:GUIZHOU DAZIRAN TECH

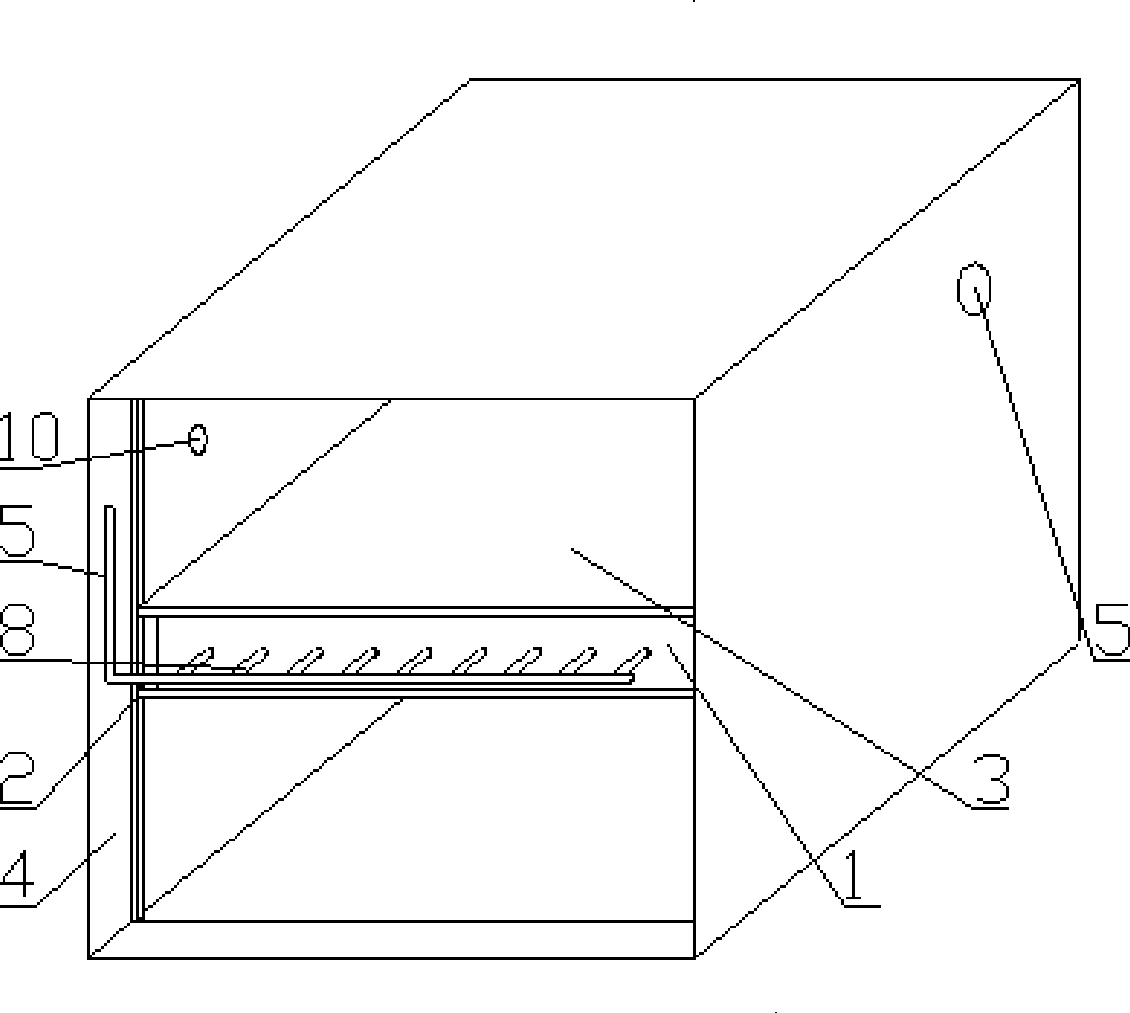

High-efficiency heating solid tire vulcanization device

InactiveCN103240822AVulcanization degree balanceUniform vulcanizationTyresVulcanizationIsolation layer

The invention relates to a high-efficiency heating solid tire vulcanization device which comprises an upper die and a lower die, wherein a die cavity of the upper die forms a die cavity for a half of the outer surface of a solid tire; an upper heating medium heating cavity is at least arranged in the upper die along a tire tread; a lower steel ring is arranged on the right side of the lower die and comprises an annular part; the annular part is arranged on the right side of an inner ring of the lower die; a die cavity is arranged on the left side of the inner ring of the lower die; the die cavity of the lower die and the inner surface of the lower steel ring form a die cavity for the other half of the outer surface of the solid tire; a lower heating medium heating cavity is at least arranged in the lower die along the tire tread; the upper die and the lower die are respectively fixed on a vulcanization device pressing plate; and heat isolation layers are respectively arranged between the upper die and the vulcanization device pressing plate and between the lower die and the vulcanization device pressing plate. By the high-efficiency heating solid tire vulcanization device, the heat energy utilization rate, the production efficiency and the vulcanization uniformity are improved, and thus the overall quality of products is improved.

Owner:ZHONGCE RUBBER GRP CO LTD

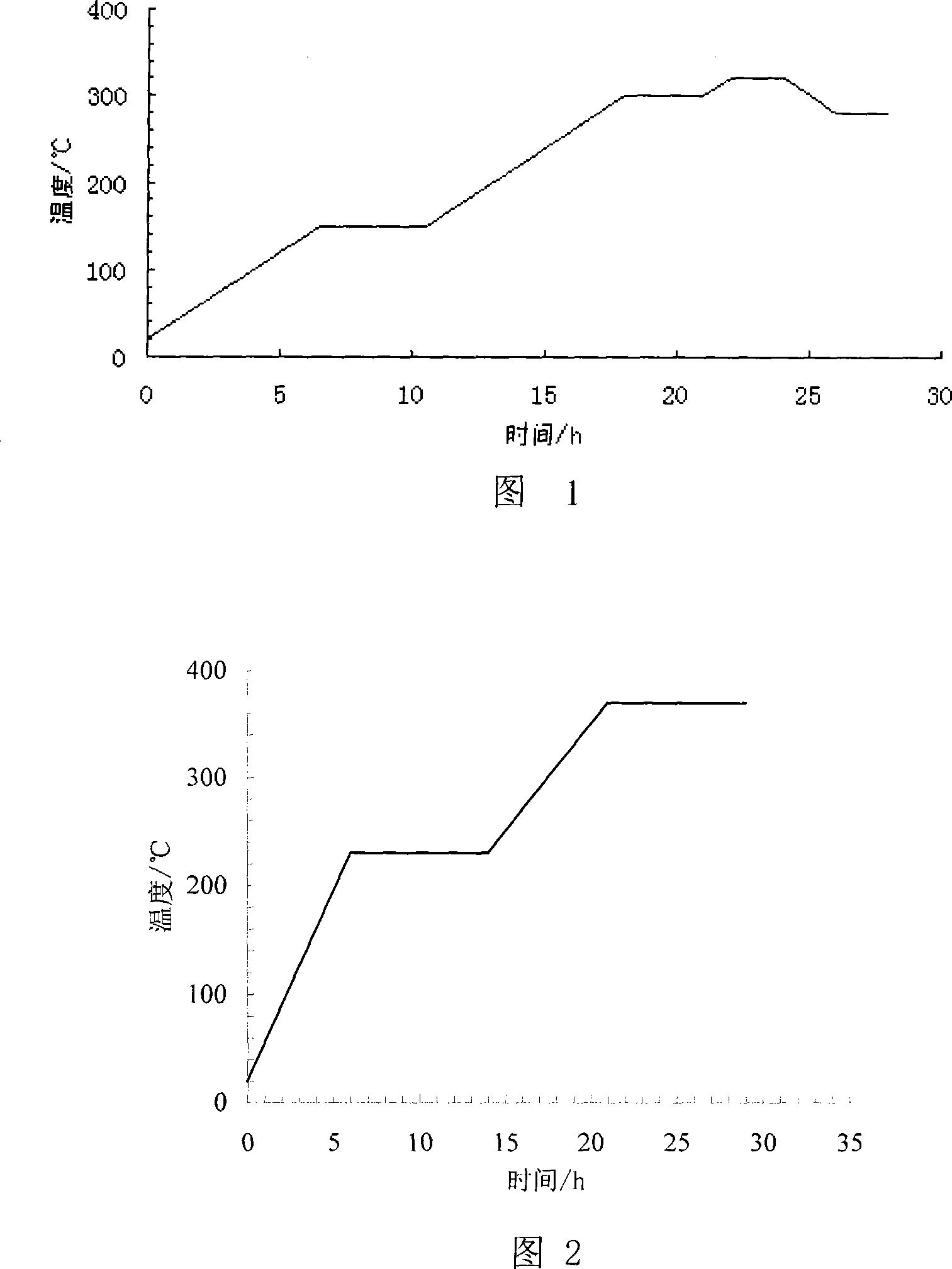

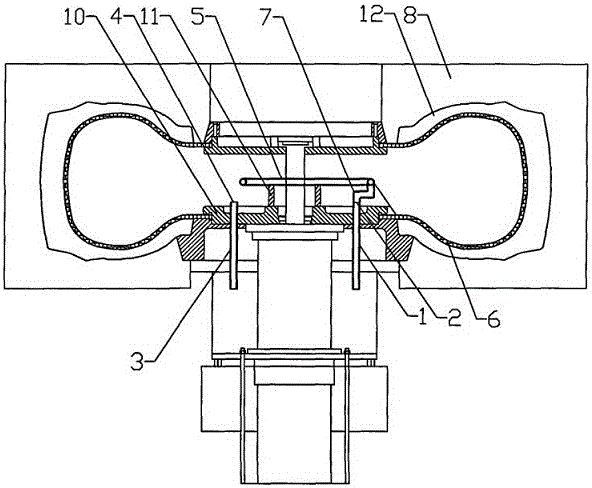

Giant all-steel OTR radial tire nozzle-type hot-water circulation vulcanization equipment and vulcanization technology

The invention relates to giant all-steel OTR radial tire nozzle-type hot-water circulation vulcanization equipment and a vulcanization technology. The equipment comprises a vulcanization die and a water inlet pipe arranged on the vulcanization die. The vulcanization die is provided with a capsule, inside which a nozzle tube communicated with the water inlet pipe is arranged.

Owner:WEIFANG YUELONG RUBBER

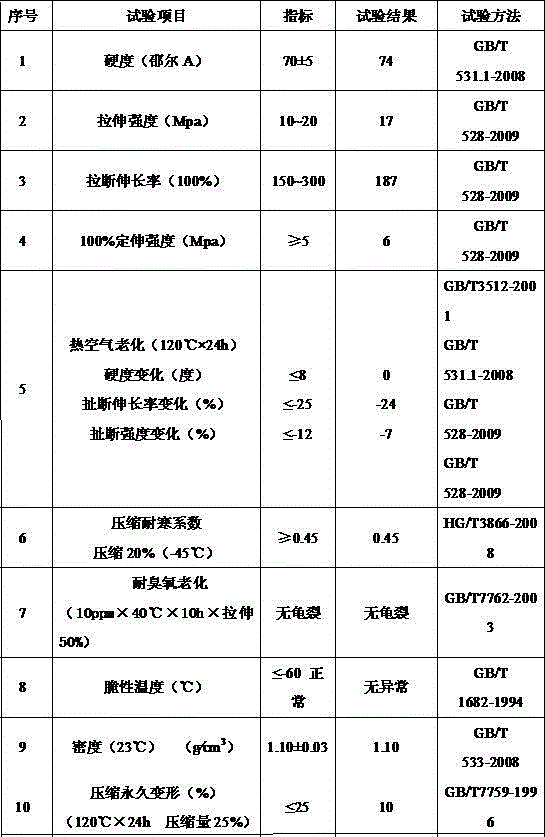

Rubber sealing ring used for GIS composite apparatus and production method thereof

The invention relates to a rubber sealing ring used for a GIS composite apparatus and a preparation method thereof. The rubber sealing ring is produced by steps of plasticating, banburying and mixing on the following raw materials in parts by weight: 100 parts of ethylene-propylene-diene monomer, 3-5 parts of zinc oxide, 1-2 parts of stearic acid, 20-25 parts of high-wear resistant carbon black, 30-35 parts of spray carbon black, 6-8 parts of dioctyl sebacate, 0.5-1 part of an antioxidant MB, and 2-3 parts of a vulcanizing agent BIPB. The product has extremely low permanent compression set value, the actual measurement value is 10%, which is lower than the requirement of less than or equal to 25% in JB / T7052-1993, longer life is guaranteed; the brittleness is abnormal at the temperature of -60 DEG C, so that the usage performance and life of the product at low temperature are guaranteed; the product is tolerable 40% of hydrofluoric acid for 48 hours and the performance has no change; and the aged life assessment of the sealing ring can reach as high as 55.6 years.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP +1

High-temperature-resistant silicone rubber material, and preparation method thereof

InactiveCN109880374AGood weather resistanceImprove insulation performancePolymer scienceFumed silica

The invention discloses a high-temperature-resistant silicone rubber material. The high-temperature-resistant silicone rubber material is prepared from, by weight, 100 parts of methyl vinyl silicone rubber, 30 to 50 parts of fumed silica, 3 to 7 parts of polyimide, 0.5 to 1.5 parts of modified aluminum nitride nanoparticle, 0. 5 to 1.0 part of zinc stearate, 2 to 5 parts of hexamethyldisilazane, 0.5 to 1.5 parts of methyl hydrogen silicone oil, and 1to 3 parts of a vulcanizing agent. The high-temperature-resistant silicone rubber material possesses good raw material mutual compatibility, highhardness, high mechanical strength, good performance after aging by hot air, and is suitable for long time working under high temperature conditions.

Owner:国网河南省电力公司新野县供电公司

Tire retreading method and vulcanizing equipment

The invention relates to a tire retreading method and vulcanizing equipment for implementing the retreading method. The tire retreading method comprises a tire body checking step, a tire body grinding step and a vulcanizing step, and comprises the following specific steps: grinding the checked tire body; after grinding, arranging the ground tire body into the vulcanizing equipment; inflating and performing die assembly; injecting a sizing material into a gap between the inner wall of a vulcanizing mold and a tire tread through an injection device; filling a mold cavity with the sizing material for vulcanizing. Compared with the prior art, the technical scheme has the advantages that rubber cement does not need to be painted, environmental protection is facilitated, rubber cement, petroleum and labor force are saved, the production efficiency is improved, the labor condition is improved, the health of workers is protected, the influence on a tire caused by few or excessive sizing material is eliminated, and the product quality is improved.

Owner:QINGDAO UNIV OF SCI & TECH

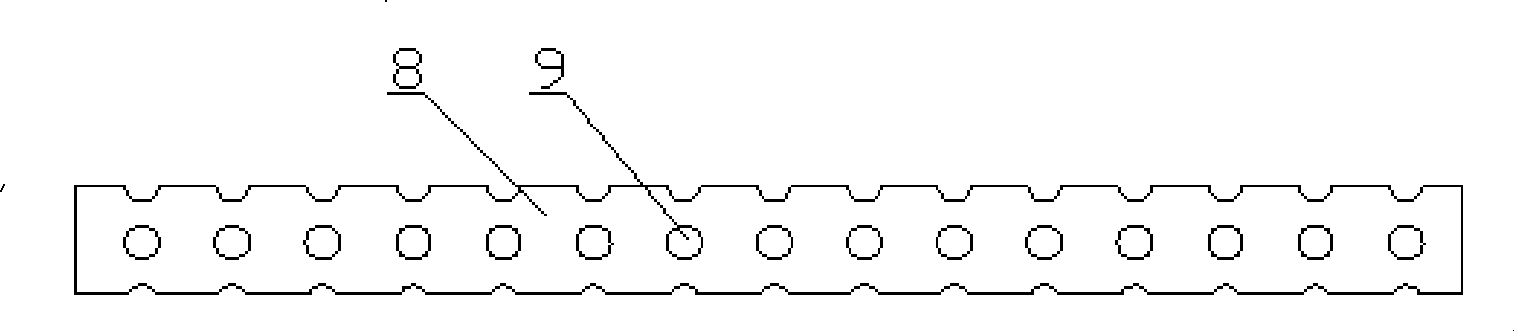

Rubber vulcanizing device for cable production line

InactiveCN112497589ASolve the problem of low vulcanization efficiencyUniform vulcanizationFilament handlingDomestic articlesElectric machineryDrive motor

The invention discloses a rubber vulcanizing device for a cable production line, and relates to the field of cable production. The rubber vulcanizing device aims at solving the existing problem of lowvulcanizing efficiency during cable production. According to the the following scheme, the rubber vulcanizing device comprises an inner cylinder, an outer cylinder and a supporting column, the outercylinder and the inner cylinder are arranged in a through mode, the inner cylinder is arranged in the outer cylinder in a rotating mode, the supporting column is fixedly arranged at the bottom end ofthe outer cylinder, a driving motor is fixedly arranged at the top end of the outer cylinder, an output shaft of the driving motor is fixedly connected with a rotating rod, the circumferential side wall of the rotating rod is fixedly sleeved with a main gear disc, a driving gear is fixedly connected to the end part of the rotating rod, the outer wall of the inner cylinder is fixedly sleeved with an auxiliary gear disc, the main gear disc meshes with the auxiliary gear disc, and air guide pipes are uniformly distributed in the inner cylinder. The cable vulcanizing device has the advantages thatthe structure is novel, uniform vulcanizing operation can be carried out on a cable, meanwhile, the vulcanized cable can be effectively wound up, and the device is suitable for popularization and application.

Owner:安徽宏业仪表电缆有限公司

Tread pattern groove adhesive tape filling vulcanization process for retreading tire

The invention discloses a tread pattern groove adhesive tape filling vulcanization process for retreading a tire, which comprises the following steps of: (1) selecting an unvulcanized standby adhesive tape according to the volume of a tread pattern groove; coating silicon oil on the inner wall of the tread pattern groove; squeezing the standby adhesive tape into the groove; mounting a packaging sleeve, pumping vacuum and vulcanizing in a tank; after the tire is vulcanized, taking out the pattern adhesive tape; (2) suspending the pattern adhesive tape on a rack and sticking a label in the suspending position; (3) selecting the pattern adhesive tape according to the model and specification of a tread pattern; filling the pattern adhesive tape into the tread pattern groove; fixing the pattern adhesive tape in the tread pattern groove; (4) mounting the packaging sleeve, pumping vacuum and vulcanizing in a tank. The invention adopts the pattern adhesive tape which can be recycled in the tread groove, has long service life, vulcanization temperature and pressure resistance, certain elasticity and plasticity, convenient operation, easy acquisition and low cost and can exactly fill the groove, not only can reduce the production cost and improve the bonding quality of the tread, but also can improve the appearance and the abrasion resistant quality of the tire.

Owner:重庆超科实业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com