Tire retreading method and vulcanizing equipment

A tire retreading and tire vulcanization technology, used in tires, household appliances, other household appliances, etc., can solve problems such as blockage of air holes, tire defects, affecting the quality of retreaded tires, etc., to improve product quality, reduce the defects of retreaded tires, realize The effect of precision injection and uniform vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] After the tire carcass is inspected and polished, it is put into the vulcanization equipment. After inflation and mold closing, the rubber material is injected into the gap between the inner wall of the vulcanization mold and the tread through the injection device. The rubber material is filled in the mold cavity, and the control device senses After reaching the filling level, proceed to vulcanization.

Embodiment 2

[0017] After the tire carcass is inspected and polished, it is put into the vulcanization equipment;

[0018] Mix the rubber compound with the reinforcing short fiber in the injection device;

[0019] After the vulcanization equipment is inflated and the mold is closed, the mixture of rubber and short fibers is injected into the gap between the inner wall of the vulcanization mold and the tread through the injection device, and the mixture is filled in the mold cavity. After the control device senses the filling amount, vulcanization is carried out.

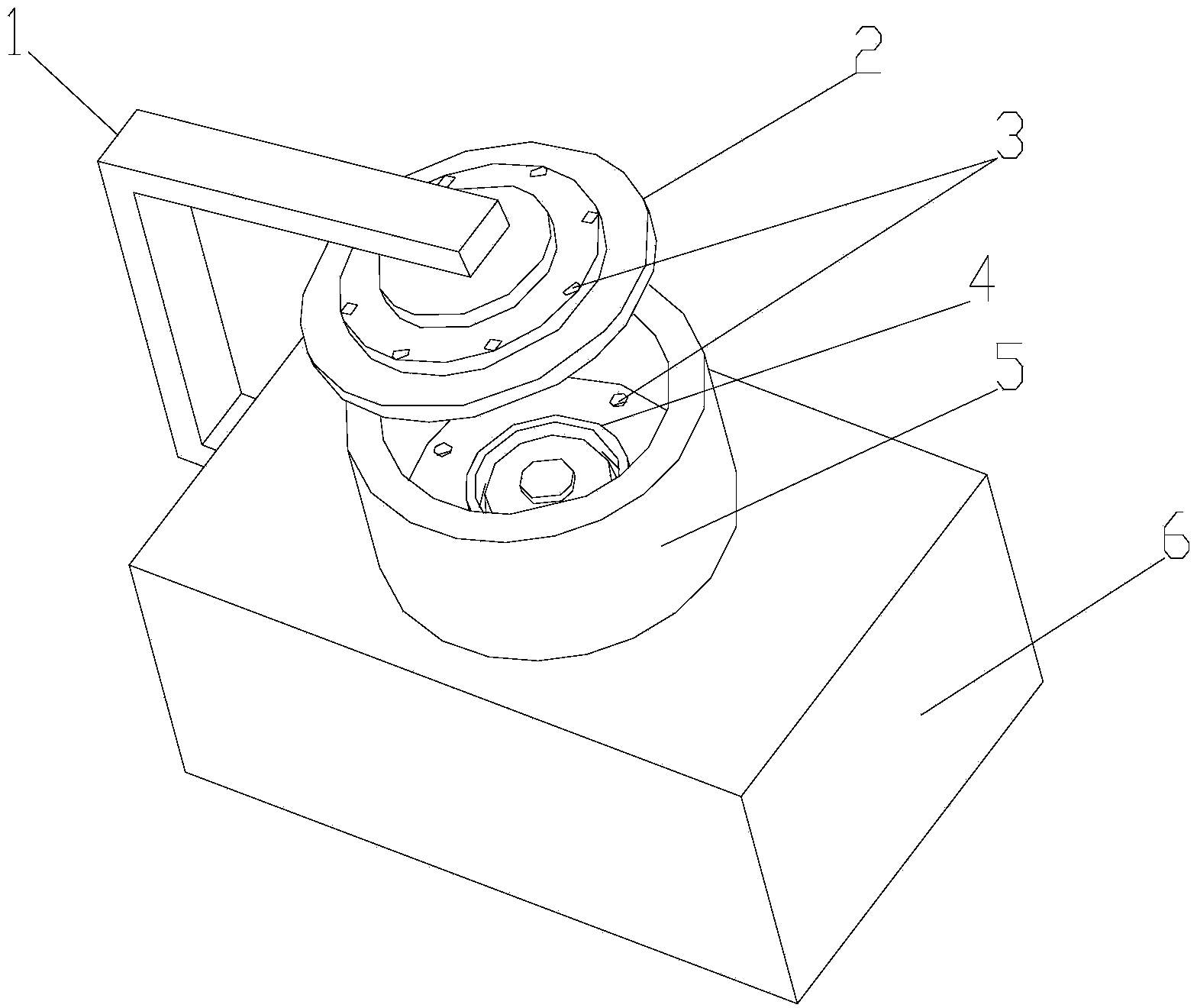

[0020] The tire vulcanization equipment in Embodiment 1 and Embodiment 2 includes a heating device, a vulcanization chamber 5, a control device, an upper mold 2 and a lower mold 4, the lower mold 4 is arranged in the vulcanization chamber 5, and the upper mold 2 passes through the supporting device 1 is connected to the vulcanization equipment 6 and cooperates with the lower mold 4, and the upper mold 2 and the lower mold 4 are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com