Aging-resistant silicone rubber composite material, and preparation method thereof

A composite material and silicone rubber technology, which is applied in the field of aging-resistant silicone rubber composite materials and their preparation, can solve the problems of poor reinforcement effect of raw materials, poor mechanical properties of silicone rubber composite materials, etc., and achieves good electrical performance and air aging resistance. The effect of good, excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

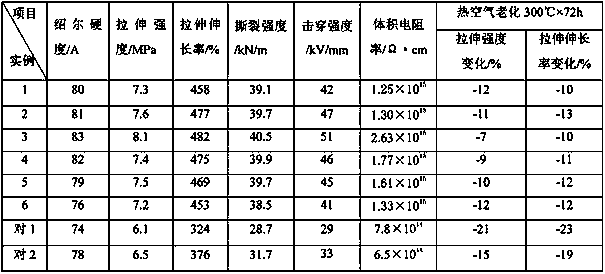

Examples

Embodiment 1

[0022] An aging-resistant silicone rubber composite material, made of the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 8 parts of perfluoroether rubber, 20 parts of fumed white carbon black, 3 parts of polyimide, 6 parts of aluminum hydroxide fine powder, 0.5 part of silane coupling agent, 2 parts of dimethyldiethoxysilane, 1 part of hydroxyl silicone oil, 0.5 part of methyl hydrogen silicone oil and 1 part of vulcanizing agent.

[0023] The molecular weight of the methyl vinyl silicone rubber is 450000-650000, and the vinyl content is 0.13-0.22%.

[0024] The specific surface area of the described fumed white carbon black is 150-250m 3 / g, particle size 20-50nm.

[0025] Described silane coupling agent is KH560.

[0026] The vulcanizing agent is bis-penta vulcanizing agent.

[0027] A preparation method of aging-resistant silicone rubber material, comprising the following steps:

[0028] (1) Put methyl vinyl silicone rubber, per...

Embodiment 2

[0032] An aging-resistant silicone rubber composite material, made of the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 9 parts of perfluoroether rubber, 23 parts of fumed white carbon black, 4 parts of polyimide, 8 parts of aluminum hydroxide fine powder, 0.6 parts of silane coupling agent, 3 parts of dimethyldiethoxysilane, 1.5 parts of hydroxyl silicone oil, 0.8 parts of methyl hydrogen silicone oil and 1.2 parts of vulcanizing agent.

[0033] The molecular weight of the methyl vinyl silicone rubber is 450000-650000, and the vinyl content is 0.13-0.22%.

[0034] The specific surface area of the described fumed white carbon black is 150-250m 3 / g, particle size 20-50nm.

[0035] Described silane coupling agent is KH570.

[0036] The vulcanizing agent is bis(2,4-dichlorobenzoyl) peroxide.

[0037] A preparation method of aging-resistant silicone rubber material, comprising the following steps:

[0038] (1) Put methyl vinyl silico...

Embodiment 3

[0042] An aging-resistant silicone rubber composite material, made of the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 10 parts of perfluoroether rubber, 28 parts of fumed white carbon black, 5 parts of polyimide, 10 parts of aluminum hydroxide fine powder, 0.8 parts of silane coupling agent, 4 parts of dimethyldiethoxysilane, 2 parts of hydroxyl silicone oil, 1.0 part of methyl hydrogen-containing silicone oil and 1.5 parts of vulcanizing agent.

[0043] The molecular weight of the methyl vinyl silicone rubber is 450000-650000, and the vinyl content is 0.13-0.22%.

[0044] The specific surface area of the described fumed white carbon black is 150-250m 3 / g, particle size 20-50nm.

[0045] Described silane coupling agent is KH570.

[0046] The vulcanizing agent is bis-penta vulcanizing agent.

[0047] A preparation method of aging-resistant silicone rubber material, comprising the following steps:

[0048] (1) Put methyl vinyl sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com