Hydrogenation catalyst presulfurizing method

A hydrogenation catalyst and vulcanization medium technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex process and long processing time, and achieve simple operation, fast vulcanization process, Effect of reducing vulcanization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

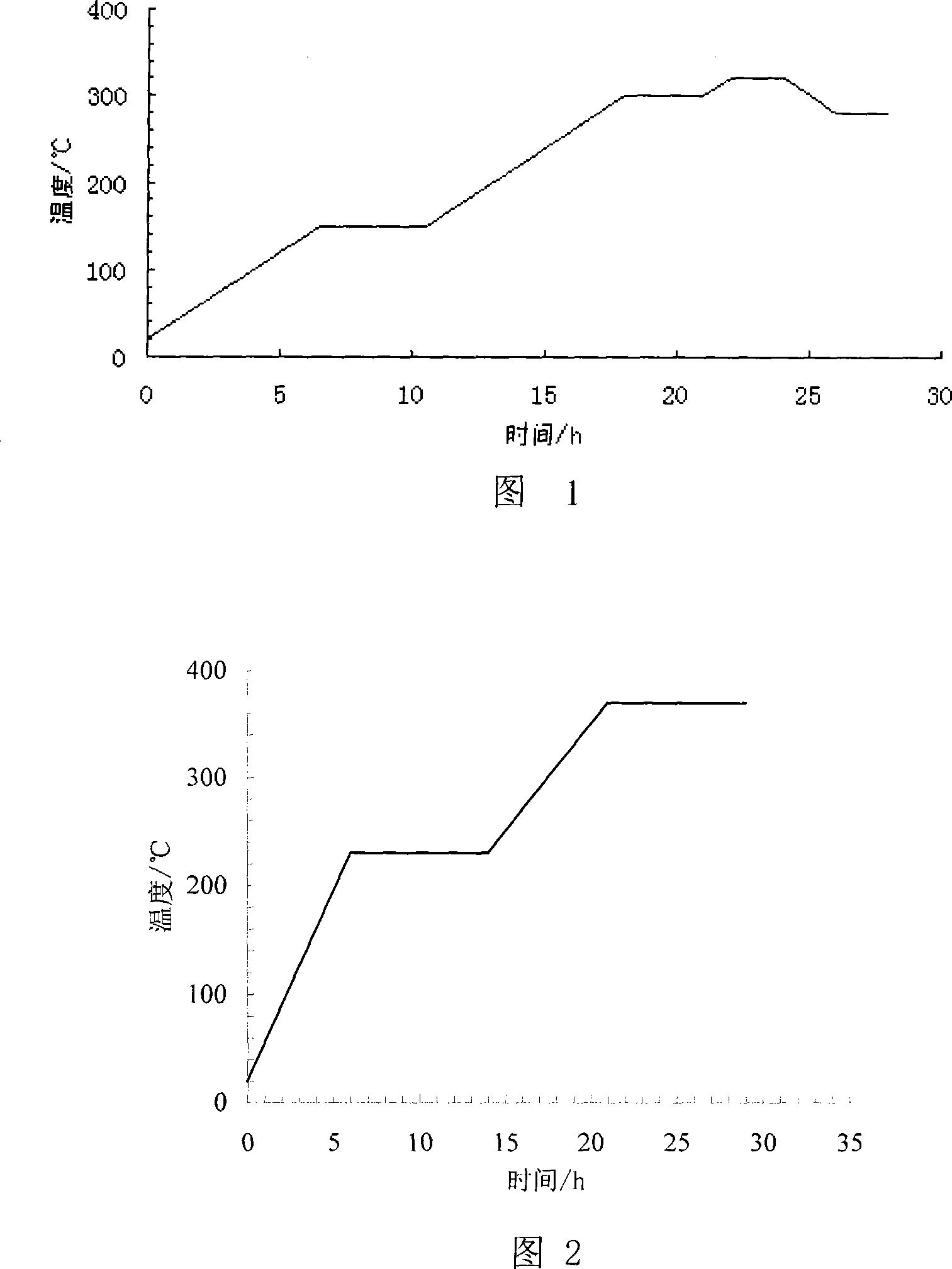

Image

Examples

Embodiment 1

[0022] Embodiment 1, composition MoO of oxidation state catalyst 316.0%, NiO 1.95%, CoO 2.85%, the carrier is alumina, and the particle size of the catalyst is 20-32 mesh. Add 5g of the above-mentioned catalyst into the middle of a fixed-bed vulcanization reactor with an inner diameter of 16mm and a height of 300mm, and fill it with small ceramic balls up and down. Adjust the flow of sulfide gas to 100mL / min, pass it into the fixed bed, and carry out the sulfidation reaction under the conditions of 350 ° C and 0.1 MPa. The reaction time is 0.5 h. 2 Cool to room temperature in atmosphere. The volume percentage of acid gas in sulfide gas is 8%, H 2 10% by volume, N 2 The percentage content is 82%. The acid gas comes from the refinery of Daqing Petrochemical Company, where H 2 S is 38%, CO 2 60%, other impurity gases 2%. The obtained product is measured by combustion-neutralization titration method, the degree of sulfidation of the product is 83.7%, and the bromine value m...

Embodiment 2

[0023] Embodiment 2. Add 5 g of the catalyst in Embodiment 1 into the middle of a fixed-bed reactor with an inner diameter of 16 mm and a height of 300 mm, and fill it up and down with small ceramic balls. Adjust the flow rate of sulfide gas to 100mL / min, pass it into the fixed bed, and carry out the sulfidation reaction under the conditions of 400 ° C and 0.1 MPa. The reaction time is 5 hours. 2 Cool to room temperature in atmosphere. The volume percentage of acid gas in sulfide gas is 22%, H 2 10% by volume, N 2 The percentage content is 68%. The acid gas comes from the refinery of Daqing Petrochemical Company, where H 2 S is 38%, CO 2 60%, other impurity gases 2%. The obtained product is measured by combustion-neutralization titration method, and the degree of sulfidation of the product is 87.4%, and the bromine value measured by SH / T0236-92 petroleum product bromine value determination method is 0.14gBr 2 / 100g.

Embodiment 3

[0024] Embodiment 3. Add 5 g of the catalyst in Embodiment 1 into the middle of a fixed-bed reactor with an inner diameter of 16 mm and a height of 300 mm, and fill it up and down with small ceramic balls. Adjust the flow of sulfide gas to 100mL / min, pass it into the fixed bed, and carry out the sulfidation reaction under the conditions of 500 ° C and 0.1 MPa. The reaction time is 4 hours. 2 Cool to room temperature in atmosphere. The volume percentage of acid gas in sulfide gas is 13%, H 2 10% by volume, N 2 The percentage content is 77%. The acid gas comes from the refinery of Daqing Petrochemical Company, where H 2 S is 38%, CO 2 61%, other impurity gases 1%. The product obtained is measured by combustion-neutralization titration method, and the degree of sulfidation of the product is 79.4%, and the bromine value measured by SH / T0236-92 petroleum product bromine value determination method is 0.73gBr 2 / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com