High-efficiency heating solid tire vulcanization device

A solid tire, high-efficiency technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of wasting vulcanizing machine use efficiency, vulcanization degree difference, and large waste of heat energy, so as to improve the overall quality of products and reduce performance differences. , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

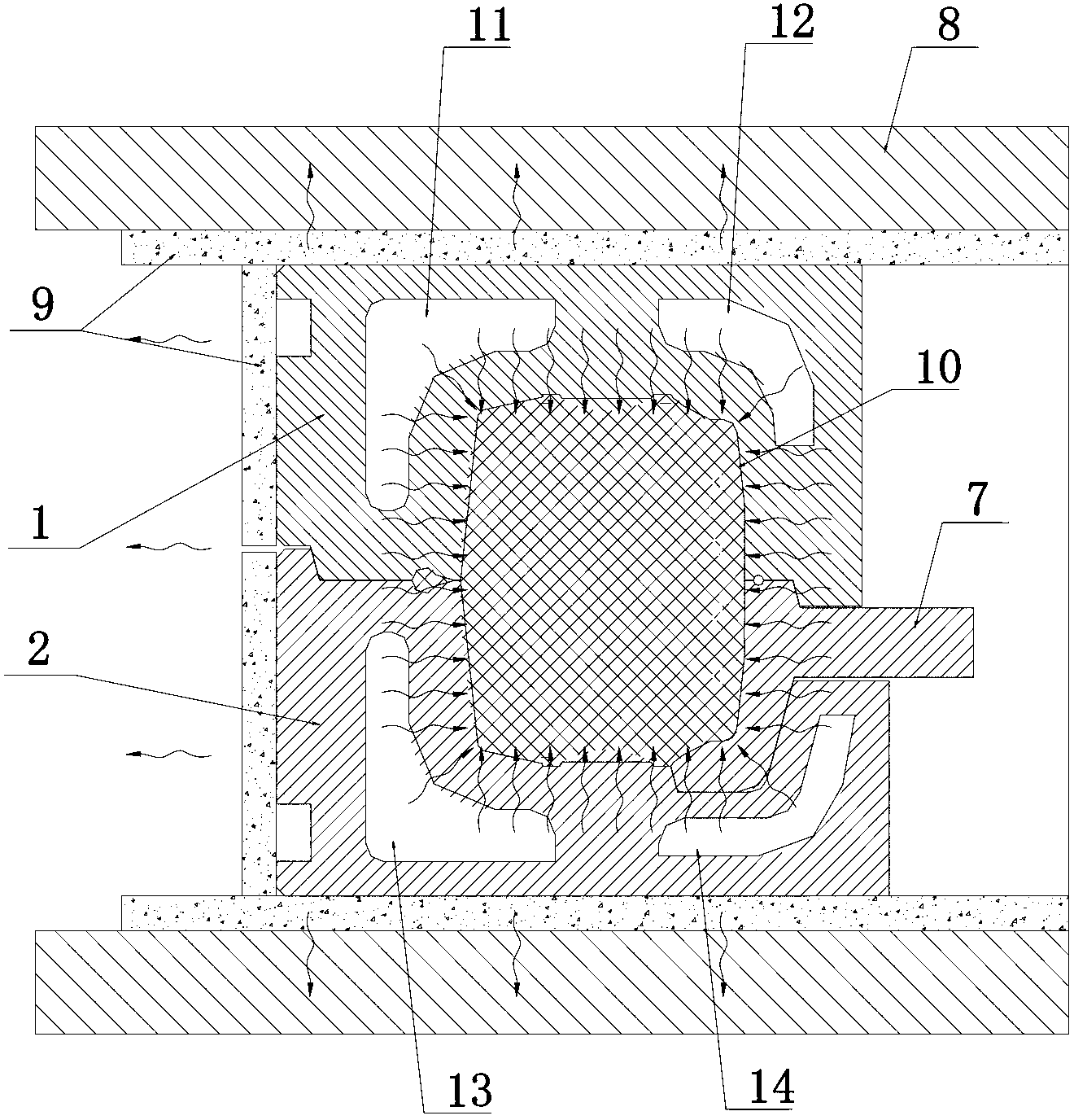

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

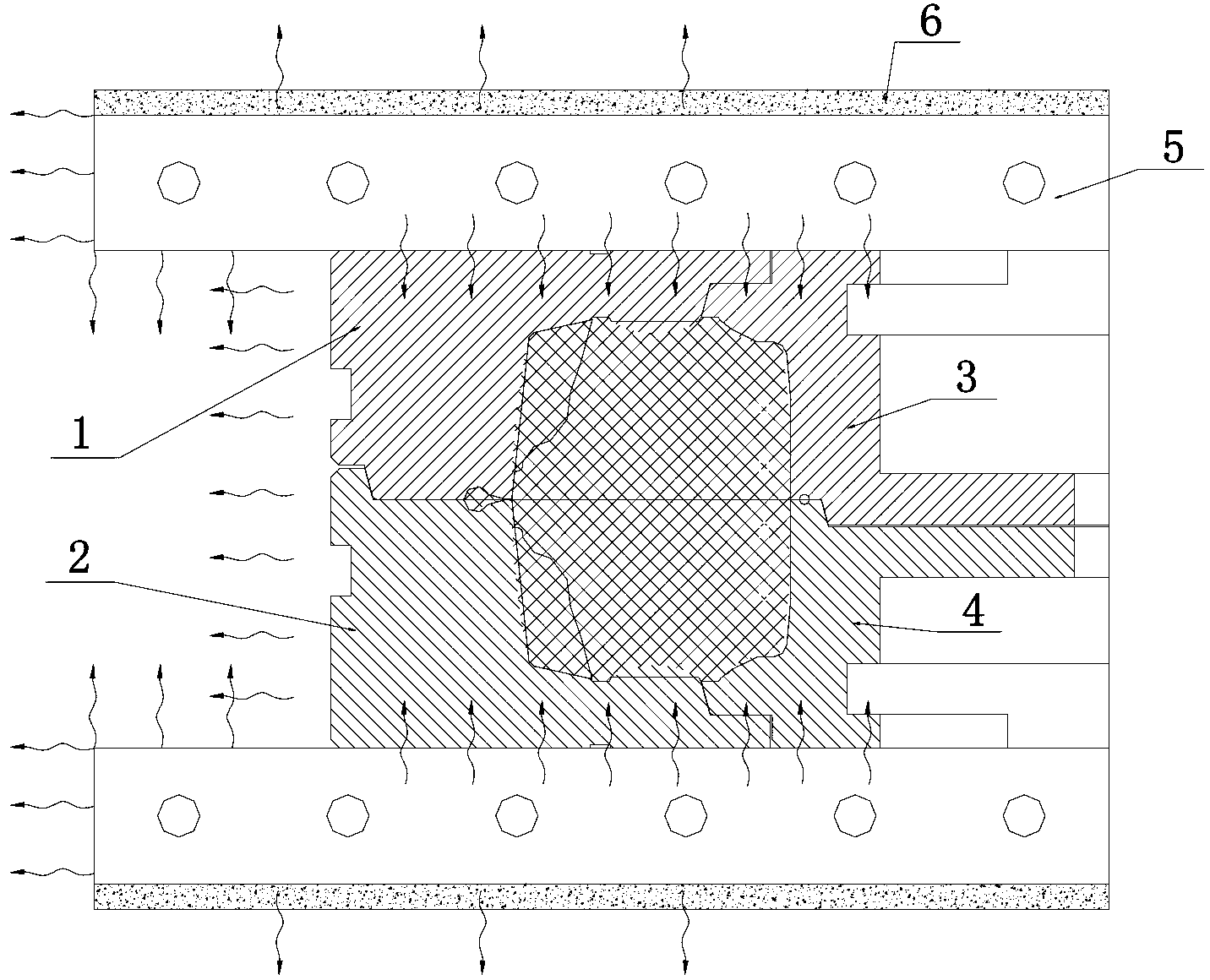

[0012] Such as figure 2 A high-efficiency heating solid tire vulcanization device is shown, the vulcanization device includes an upper mold 1 and a lower mold 2 . The mold cavity of the upper mold 1 constitutes the mold cavity 10 of the half outer surface of the solid tire, and an upper heat medium heating chamber is arranged at least along the tire tread in the upper mold 1; the upper heat medium heating chamber is divided into the left upper heat medium The heating chamber 11 and the upper right heating medium heating chamber 12, the upper left heating medium heating chamber 11 extends to the tread, shoulder and sidewall, and the upper right heating medium heating chamber 12 extends to the tread and shoulder. The right side of the lower die 2 is provided with a lower steel ring 7, the lower steel ring 7 includes an annular po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com