High-temperature-resistant silicone rubber material, and preparation method thereof

A high-temperature-resistant silicone rubber and rubber technology, which is applied in the field of high-temperature-resistant silicone rubber materials and its preparation, can solve the problems of high toxicity of benzotriazole, poor mechanical properties, and many inorganic raw materials, and achieve good anti-aging performance in hot air, Good compatibility, the effect of reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

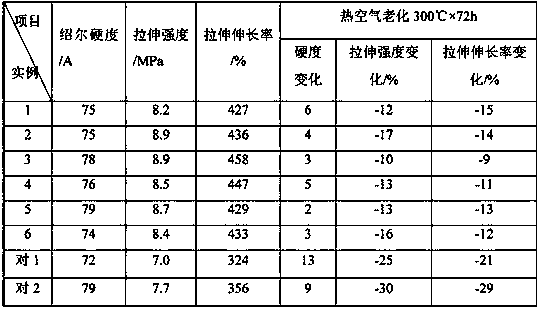

Examples

Embodiment 1

[0026] A high temperature resistant silicone rubber material, made of the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 30 parts of fumed silica, 3 parts of polyimide, 0.5 parts of modified aluminum nitride nanoparticles 0.5 parts of zinc stearate, 2 parts of hexamethyldisilazane, 0.5 parts of methyl hydrogen silicone oil and 1 part of vulcanizing agent.

[0027] The molecular weight of the methyl vinyl silicone rubber is 450000-650000, and the vinyl content is 0.13-0.22%.

[0028] The vulcanizing agent is bis-penta vulcanizing agent.

[0029] The preparation method of the modified aluminum nitride nanoparticles comprises the following steps:

[0030] (1) Mix aluminum nitride nanoparticles, KH570 and absolute ethanol, stir for 5 hours, then add styrene and dibenzoyl peroxide, and react in a water bath at 80°C for 10 hours to obtain a mixed solution;

[0031] The weight ratio of the aluminum nitride nanoparticles, KH570, styrene, and d...

Embodiment 2

[0040] A high temperature resistant silicone rubber material, made of the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 35 parts of fumed silica, 4 parts of polyimide, 0.6 parts of modified aluminum nitride nanoparticles 0.6 parts of zinc stearate, 2.5 parts of hexamethyldisilazane, 0.8 parts of methyl hydrogen silicone oil and 1.5 parts of vulcanizing agent.

[0041] The molecular weight of the methyl vinyl silicone rubber is 450000-650000, and the vinyl content is 0.13-0.22%.

[0042] The vulcanizing agent is bis-penta vulcanizing agent.

[0043] The preparation method of the modified aluminum nitride nanoparticles comprises the following steps:

[0044] (1) Mix aluminum nitride nanoparticles, KH570 and absolute ethanol, stir for 6 hours, then add styrene and dibenzoyl peroxide, and react in a water bath at 65°C for 12 hours to obtain a mixed solution;

[0045] The weight ratio of the aluminum nitride nanoparticles, KH570, styrene, ...

Embodiment 3

[0054] A high temperature resistant silicone rubber material, made of the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 40 parts of fumed silica, 5 parts of polyimide, 0.8 parts of modified aluminum nitride nanoparticles 0.7 parts of zinc stearate, 3 parts of hexamethyldisilazane, 1.0 parts of methyl hydrogen silicone oil and 2 parts of vulcanizing agent.

[0055] The molecular weight of the methyl vinyl silicone rubber is 450000-650000, and the vinyl content is 0.13-0.22%.

[0056] The vulcanizing agent is bis-penta vulcanizing agent.

[0057] The preparation method of the modified aluminum nitride nanoparticles comprises the following steps:

[0058] (1) Mix aluminum nitride nanoparticles, KH570 and absolute ethanol, stir for 6 hours, then add styrene and dibenzoyl peroxide, and react in a water bath at 70°C for 10 hours to obtain a mixed solution;

[0059] The weight ratio of the aluminum nitride nanoparticles, KH570, styrene, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com