Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Uniform impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flavored coffee compositions and methods of making the same

InactiveUS6841185B2Minimize and inhibit segregationMinimize and inhibit and separationRoasted coffee treatmentFood preparationParticle densityFood flavor

The present invention relates to non-segregating flavored coffee compositions. In particular, the present invention relates to novel flavored coffee compositions that minimize or inhibit the segregation and separation of constituent components, and the corresponding processes for making such compositions. The flavored coffee compositions herein are characterized as having a roast and ground, an instant coffee component, or mixtures thereof. The roast and ground coffee component will have a moisture level in the range of from about 1% to about 15%, a particle density in the range of from about 0.1 g / cc to about 0.45 g / cc, and a mean particle size distribution in the range of from about 400 microns to about 1300 microns. The instant coffee components used herein will have a particle density in the range of from about 0.1 g / cc to about 0.8 g / cc, a mean particle size distribution in the range of from about 250 microns to about 2360 microns, and a moisture level in the range of from about 1% to about 4.5%. The flavored coffee composition further contains a flavoring component with a moisture level in the range of from about 1% to about 7%, a particle density in the range of from about 0.1 g / cc to about 0.8 g / cc, and a mean particle size distribution in the range of from about 5 microns to about 150 microns. The ratio of coffee component particle size to flavor component particle size is in the range of from about 100:1 to about 5:1.

Owner:THE PROCTER & GAMBLE COMPANY +3

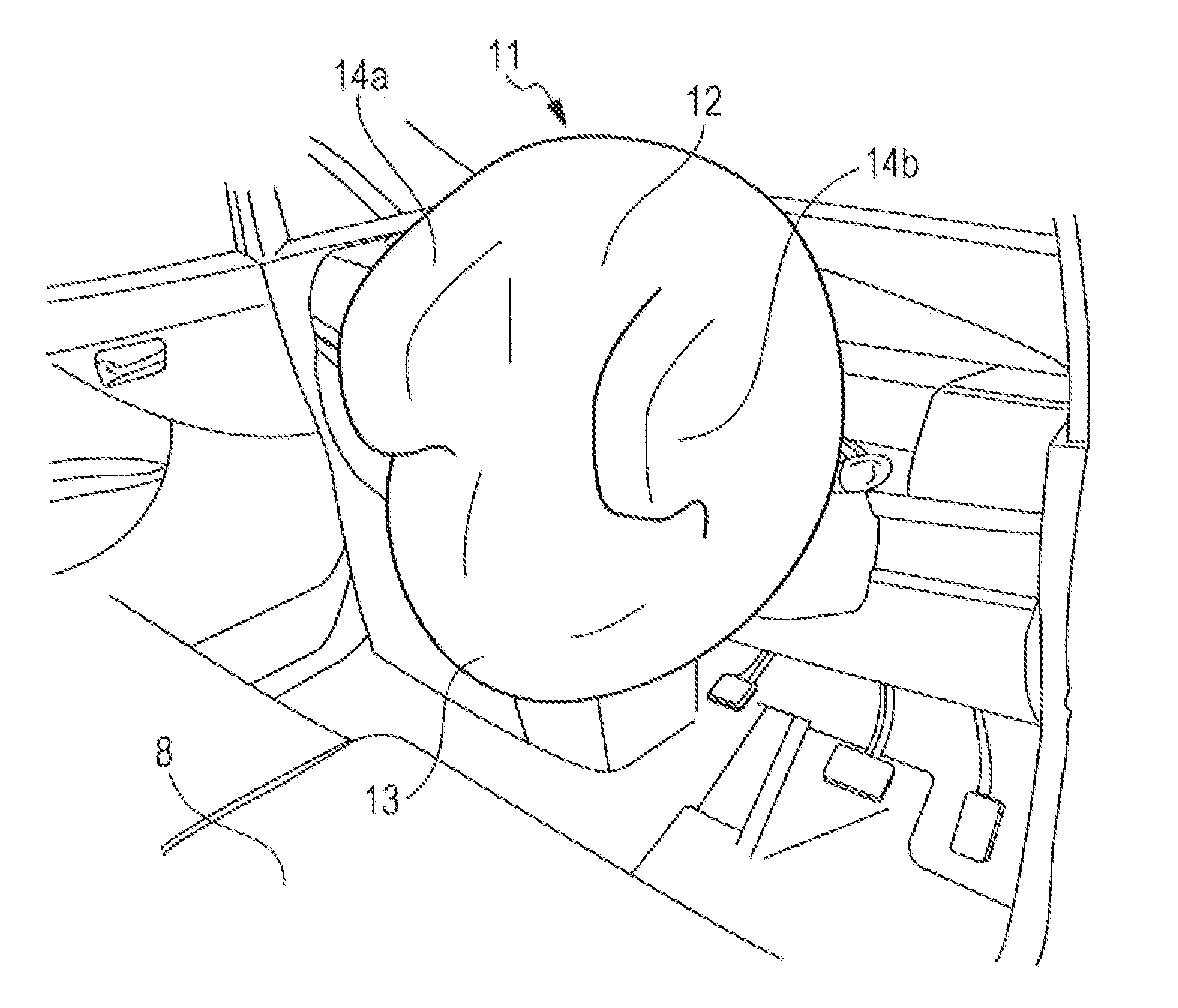

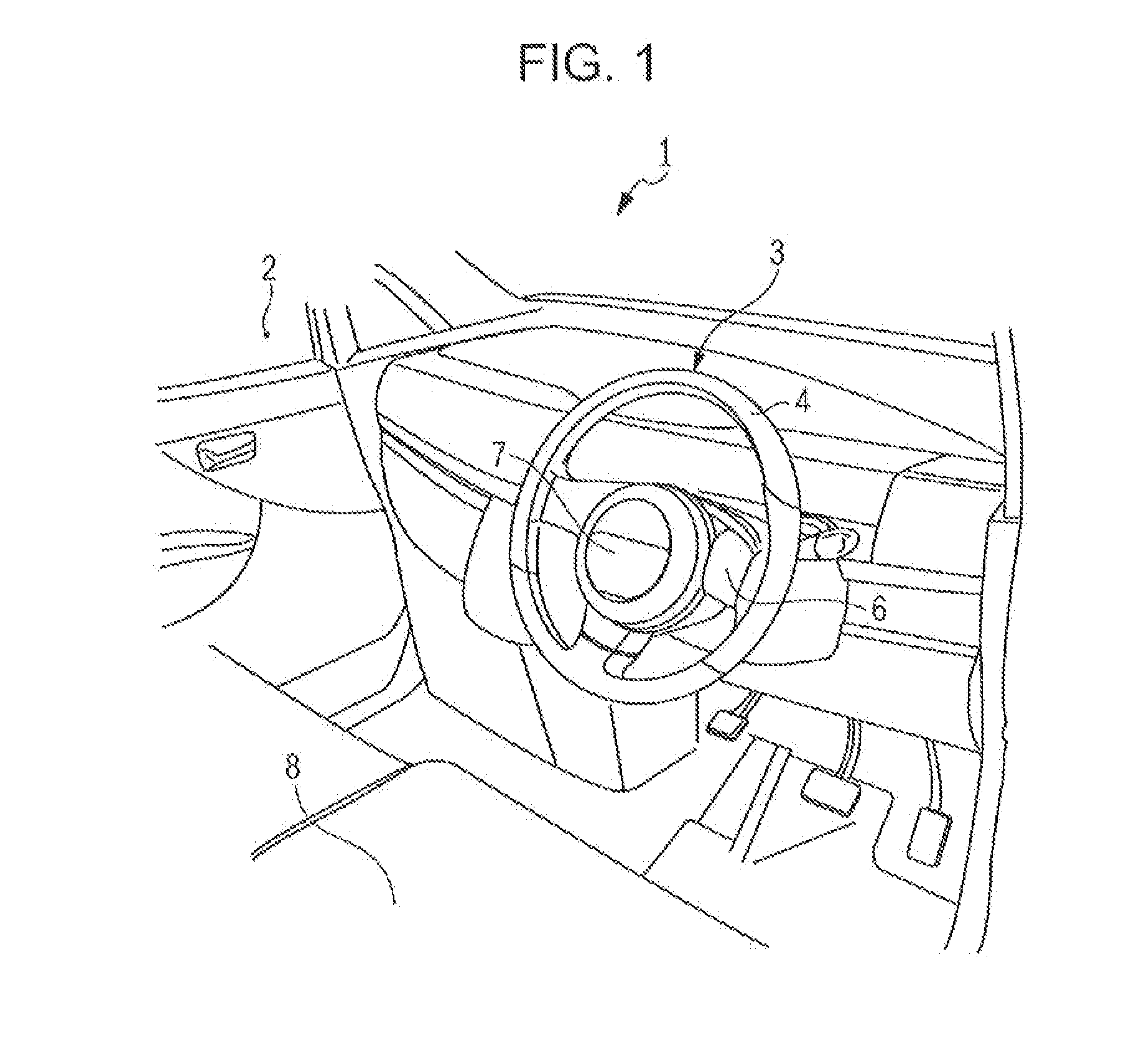

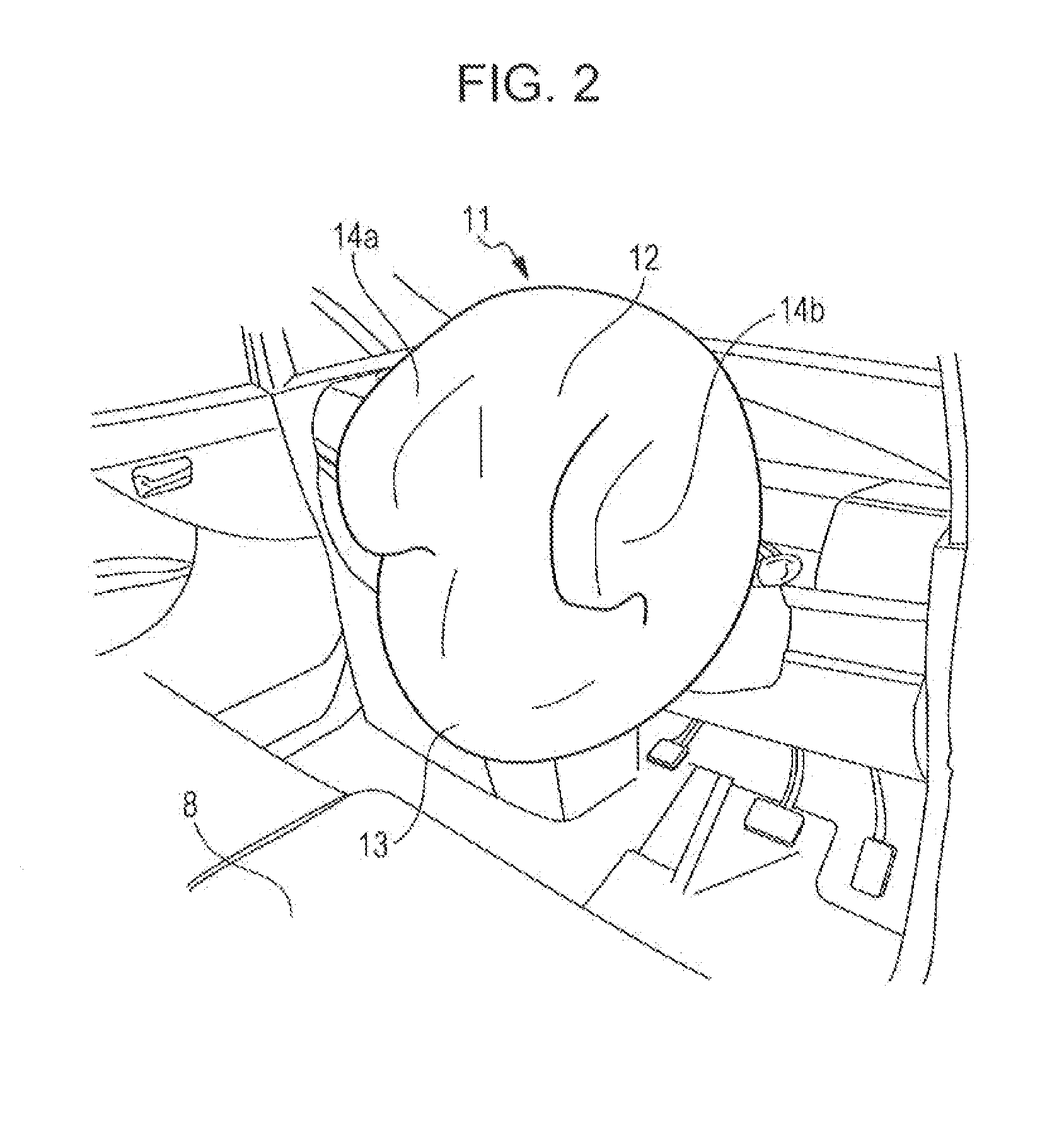

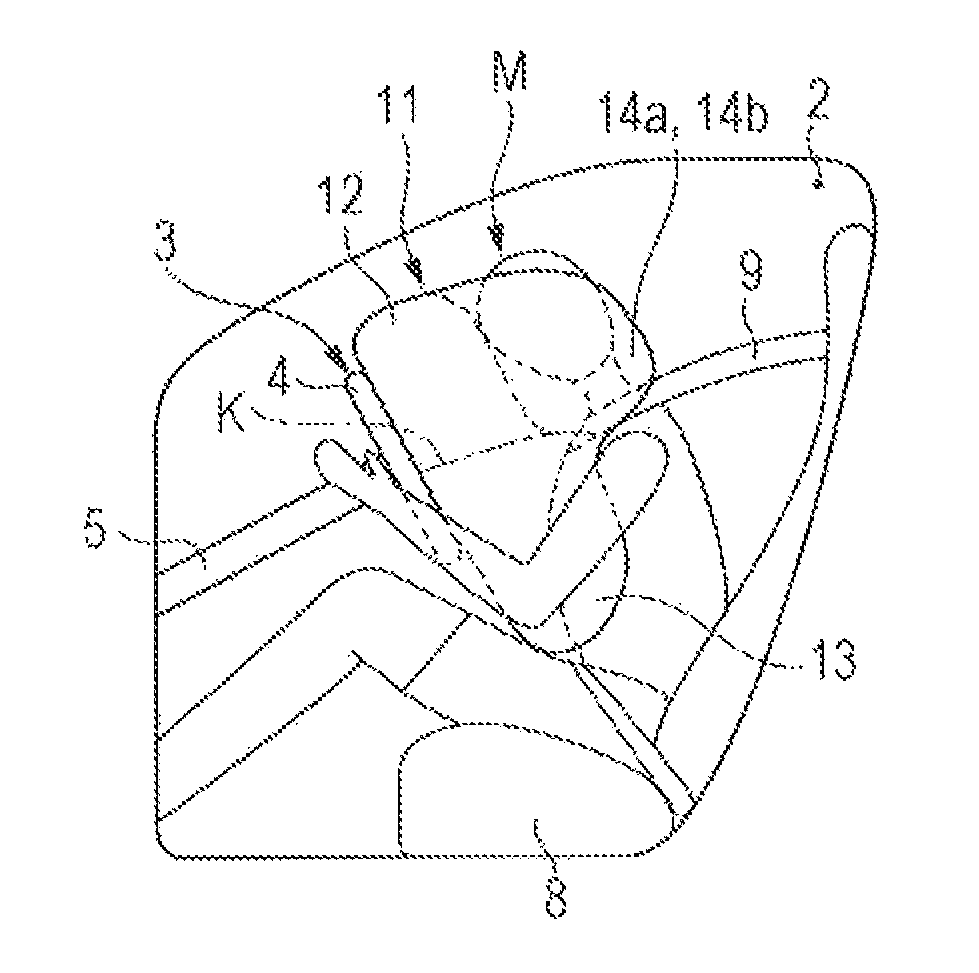

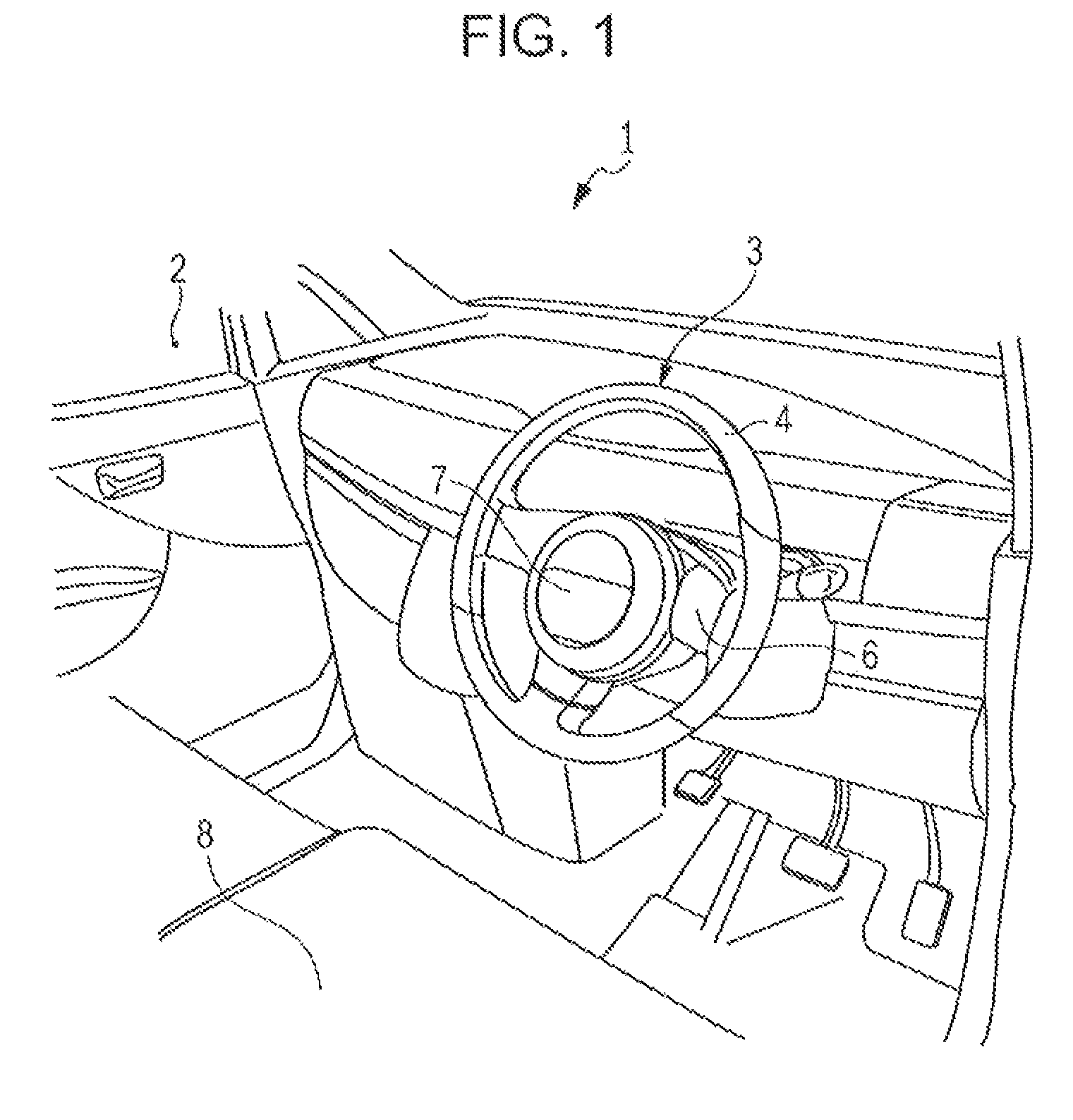

Occupant protection device

ActiveUS20130001934A1Improve securityAvoid shockPedestrian/occupant safety arrangementSteering wheelAirbag

There is provided an occupant protection device. An airbag device includes an airbag that is stored in a center pad of a steering wheel of a vehicle and is expandable toward an occupant side upon a collision of the vehicle. The center pad is disposed to have a non-rotating structure independent from the steering wheel. The airbag includes a first extension portion and a second extension portion which are disposed at opposing edges of the airbag in a width direction of the vehicle and are expandable to extend toward a rear side of the vehicle.

Owner:SUBARU CORP

Method of making flavored coffee compositions

InactiveUS7763300B2Minimize and inhibit segregation and separationLow costRoasted coffee treatmentFood preparationParticle densityFood flavor

The present invention relates to non-segregating, non-agglomerated flavored coffee compositions. In particular, the present invention relates to novel flavored coffee compositions that minimize or inhibit the segregation and separation of constituent components, and the corresponding processes for making such compositions. The flavored coffee compositions herein are characterized as having a roast and ground, an instant coffee component, or mixtures thereof. The roast and ground coffee component will have a moisture level in the range of from about 1% to about 15%, a particle density in the range of from about 0.1 g / cc to about 0.45 g / cc, and a mean particle size distribution in the range of from about 400 microns to about 1300 microns. The instant coffee components used herein will have a particle density in the range of from about 0.1 g / cc to about 0.8 g / cc, a mean particle size distribution in the range of from about 250 microns to about 2360 microns, and a moisture level in the range of from about 1% to about 4.5%. The flavored coffee composition further includes a flavoring component with a moisture level in the range of from about 1% to about 7%, a particle density in the range of from about 0.1 g / cc to about 0.8 g / cc, and a mean particle size distribution in the range of from about 5 microns to about 150 microns. The ratio of coffee component particle size to flavor component particle size is in the range of from about 100:1 to about 5:1.

Owner:THE FOLGERS COFFEE +2

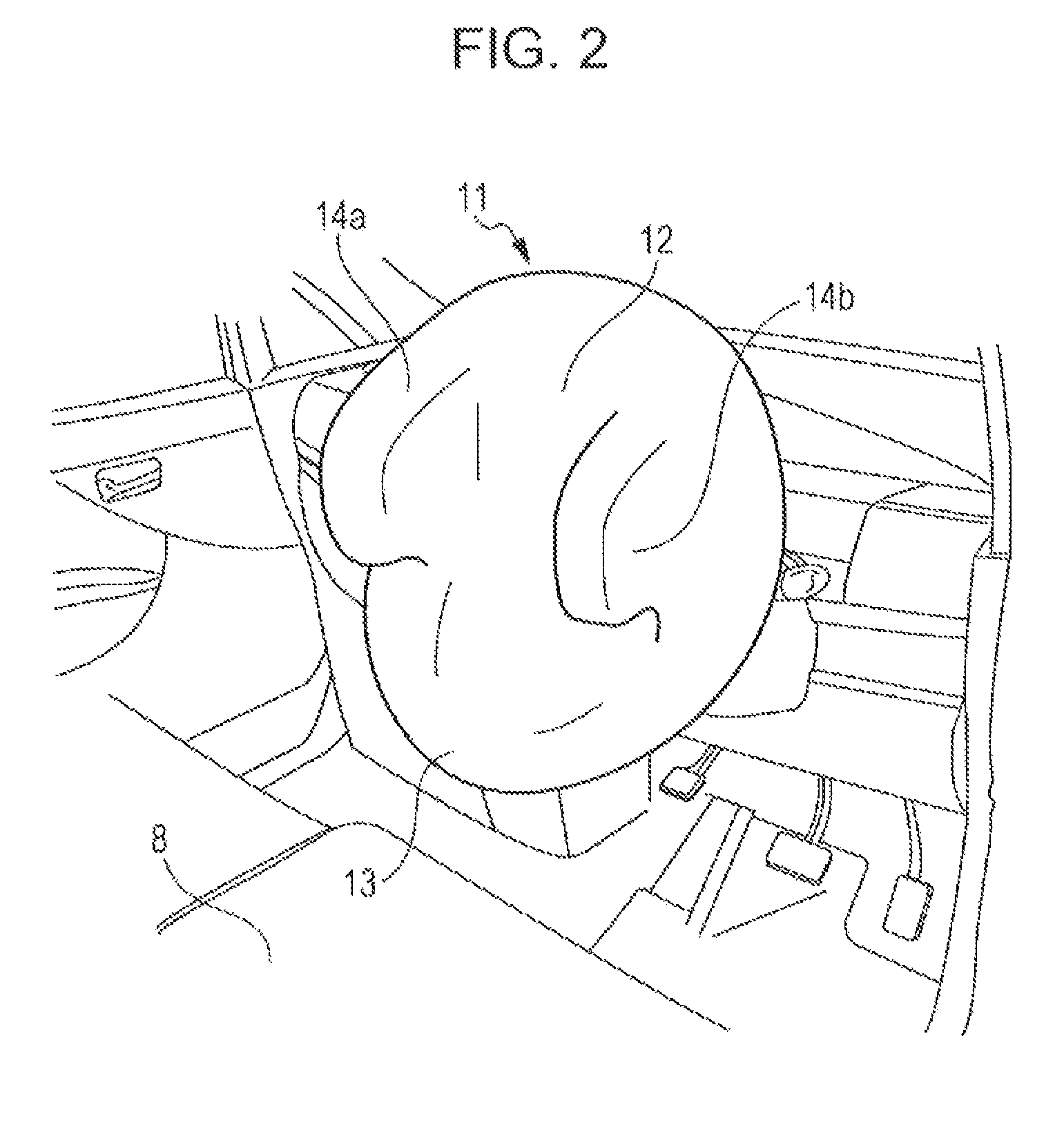

Occupant protection device

ActiveUS8678429B2Improve securityAvoid shockPedestrian/occupant safety arrangementSteering wheelEngineering

There is provided an occupant protection device. An airbag device includes an airbag that is stored in a center pad of a steering wheel of a vehicle and is expandable toward an occupant side upon a collision of the vehicle. The center pad is disposed to have a non-rotating structure independent from the steering wheel. The airbag includes a first extension portion and a second extension portion which are disposed at opposing edges of the airbag in a width direction of the vehicle and are expandable to extend toward a rear side of the vehicle.

Owner:SUBARU CORP

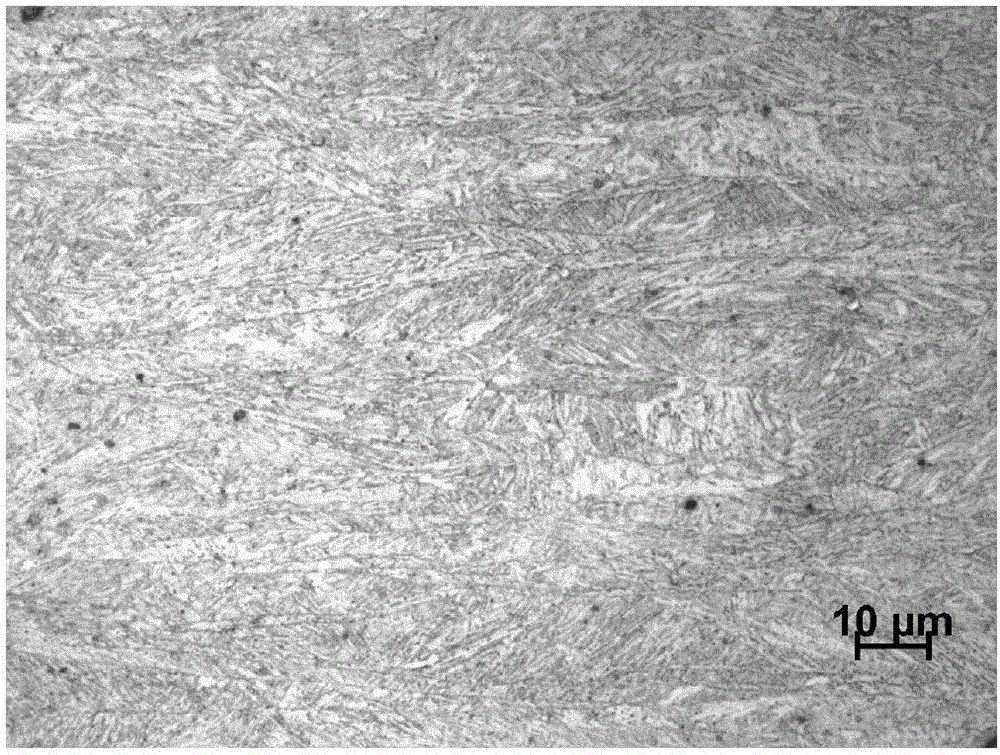

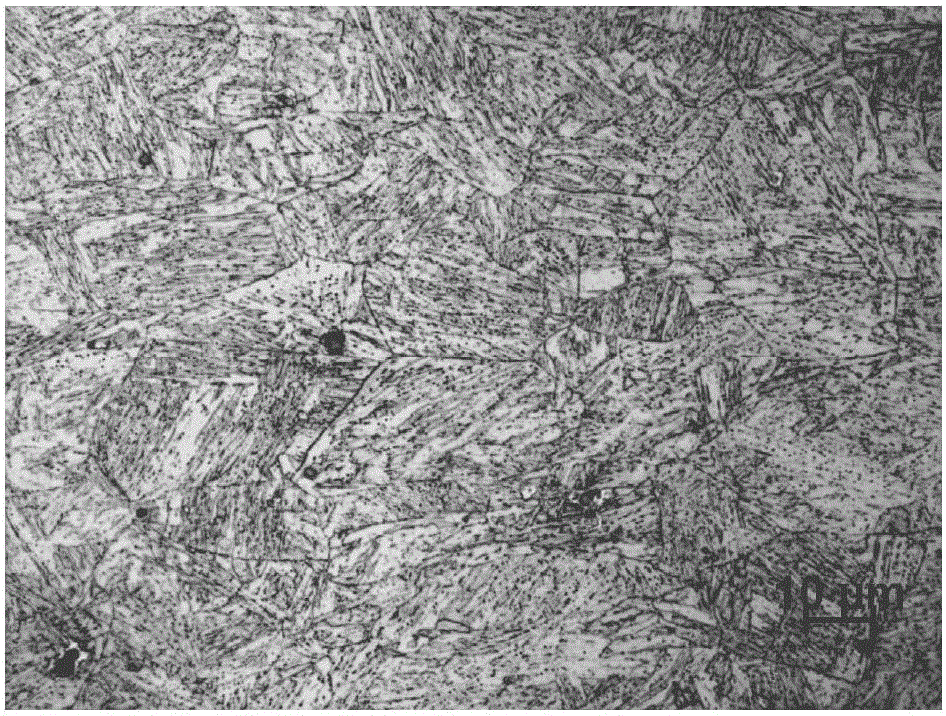

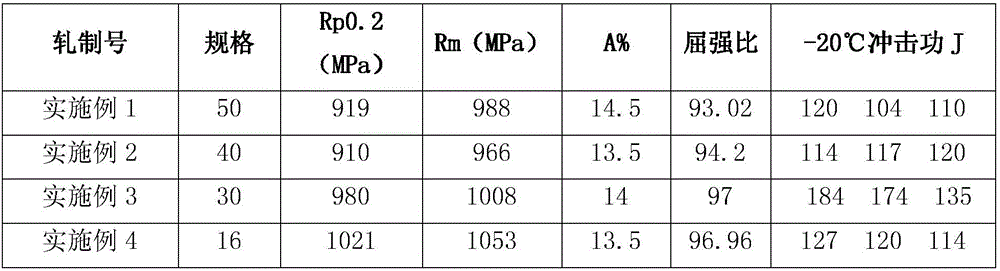

Method for producing Q890 high-strength steel intermediate-thickness plate through online quenching

The invention provides a method for producing a Q890 high-strength steel intermediate-thickness plate through online quenching. The method comprises the steps that rolling is carried out, wherein the heating temperature of a heating furnace is 1180+ / -30 DEG C, the total heating time is 1.0-1.2 hour, two-stage rolling is adopted, rough rolling and scale removing are conducted for two passes, finish rolling and scale removing are conducted for two passes, the temperature at the beginning of the rough rolling is 1050-1150 DEG C, the thickness of an intermediate slab is larger than or equal to 80 mm, the temperature at the beginning of the second-stage rolling is lower than or equal to 860 DEG C, and the finishing rolling temperature is lower than or equal to 830 DEG C; cooling is conducted, wherein water cooling online quenching is adopted, the temperature of the intermediate slab is 780+ / -10 DEG C when entering water, the self-tempering temperature is lower than or equal to 250 DEG C, and the cooling speed is higher than 15 DEG C per second; and heat treatment is conducted, wherein the tempering temperature is 500+ / -10 DEG C, the heating rate is 1.8+ / -0.2 min / mm, the heat preservation time is 20-30 min, the temperature is lowered to the indoor temperature through air cooling, and then a double-phase structure of a lath martensite and a lath bainite is obtained. Online quenching shortens the technological process and reduces cost.

Owner:NANJING IRON & STEEL CO LTD

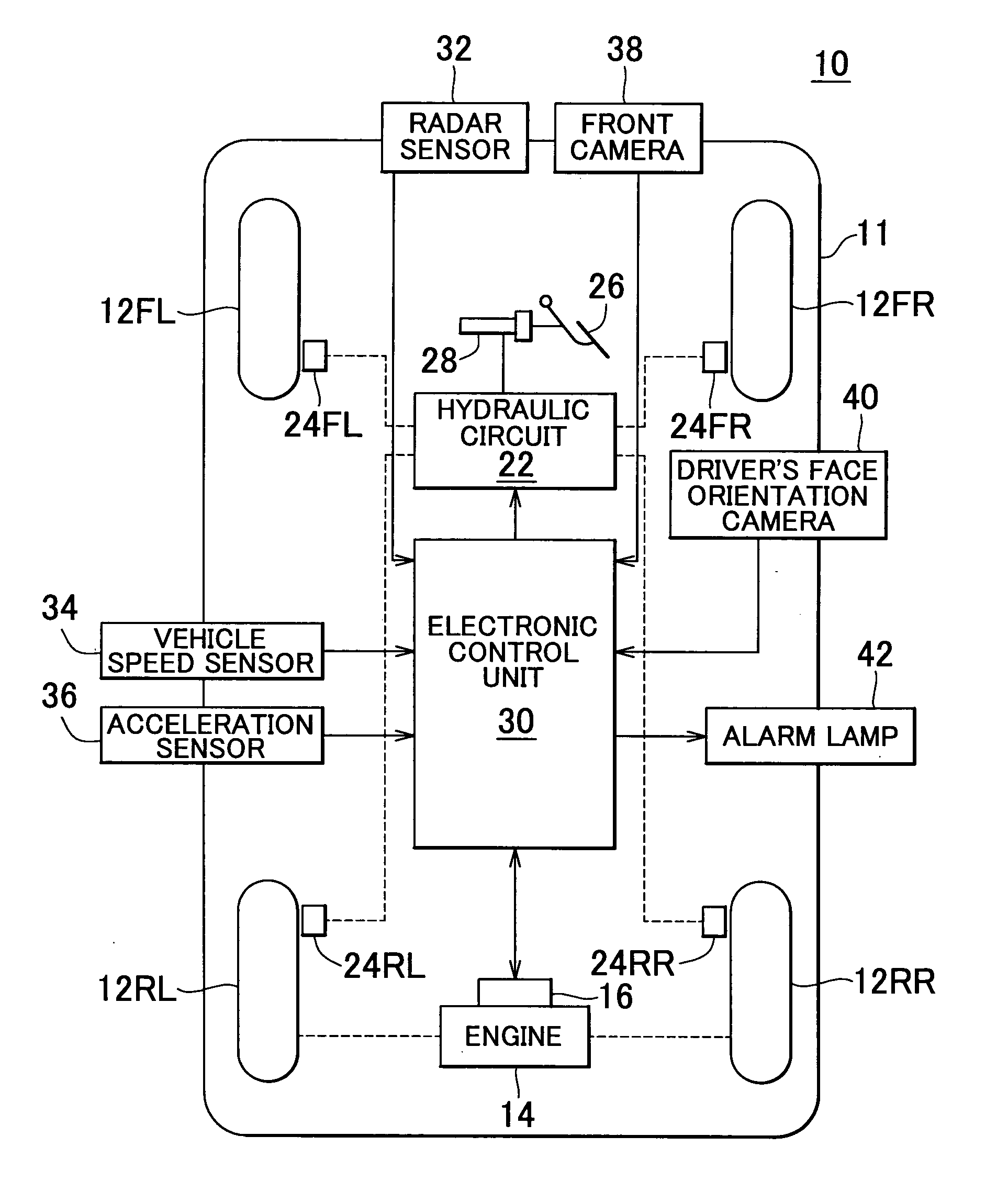

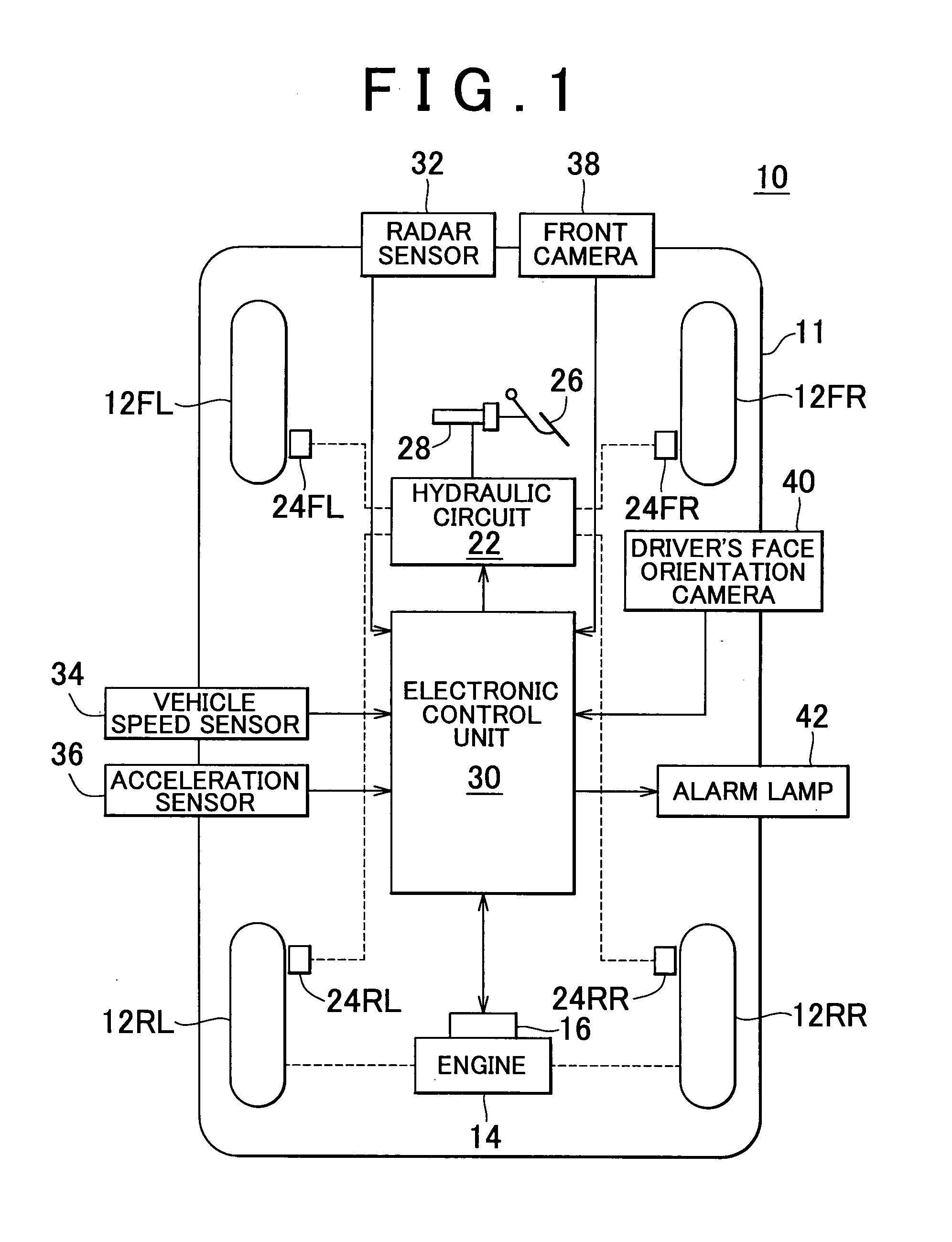

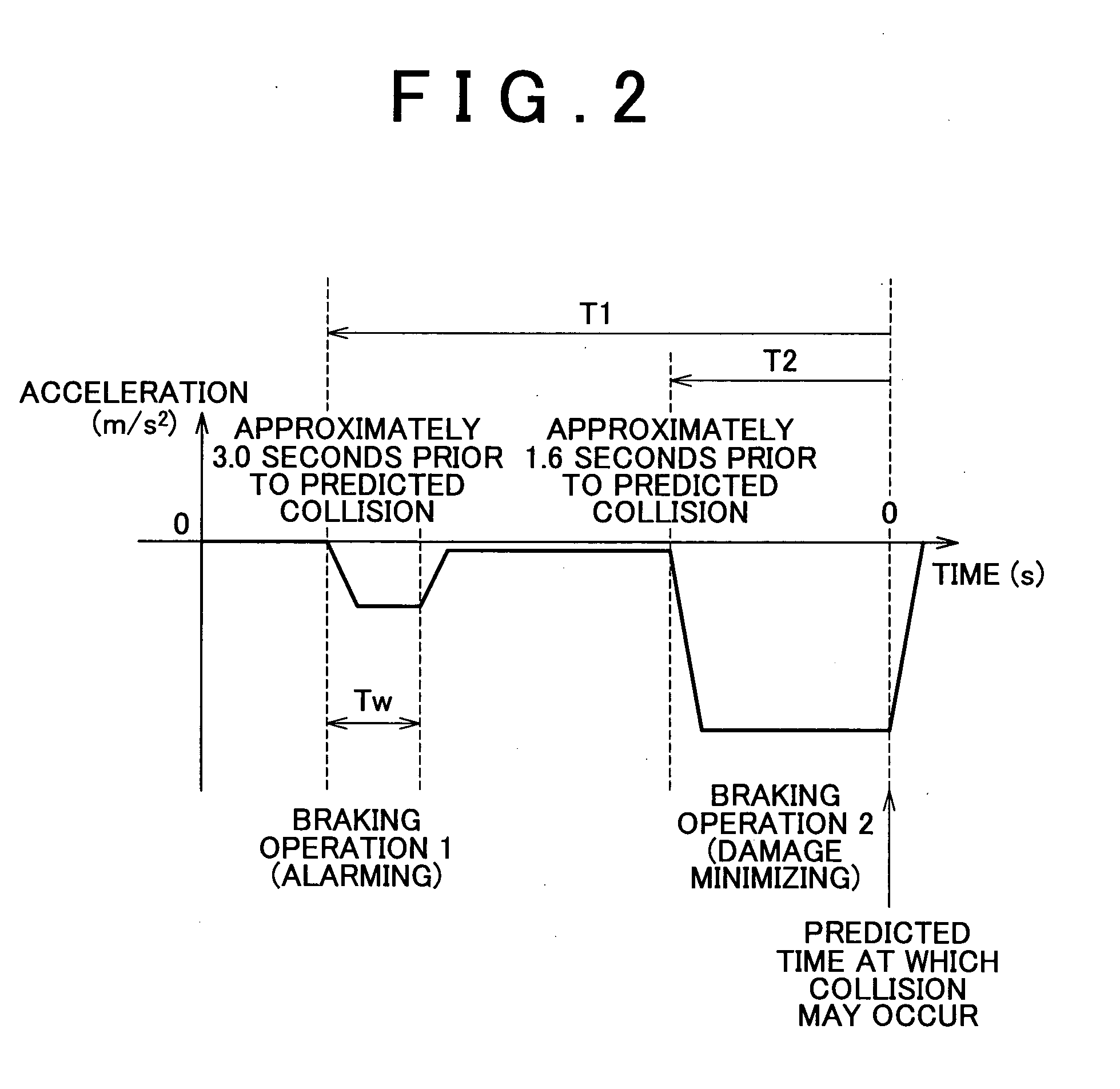

Alarm System and Alarm Method for Vehicle

ActiveUS20090237226A1Large amount of changeUniform impactPedestrian/occupant safety arrangementAnti-collision systemsDriver/operatorCollision probability

A collision probability index value corresponding to a probability of collision between a host vehicle and an obstacle is calculated based on the information indicating the relative relationship between the host vehicle and the obstacle; and the alarming braking operation is performed to cause a driver to recognize that a collision may occur by changing at least one of the drive power and the braking force when the collision probability index value reaches a predetermined threshold value. In the alarming braking operation, a target acceleration that is used as a target value in the alarming braking operation is set based on the acceleration of the host vehicle, which is detected when the collision probability index value reaches the predetermined threshold value; and at least one of the drive power and the braking force is controlled so that the target acceleration is achieved.

Owner:TOYOTA JIDOSHA KK

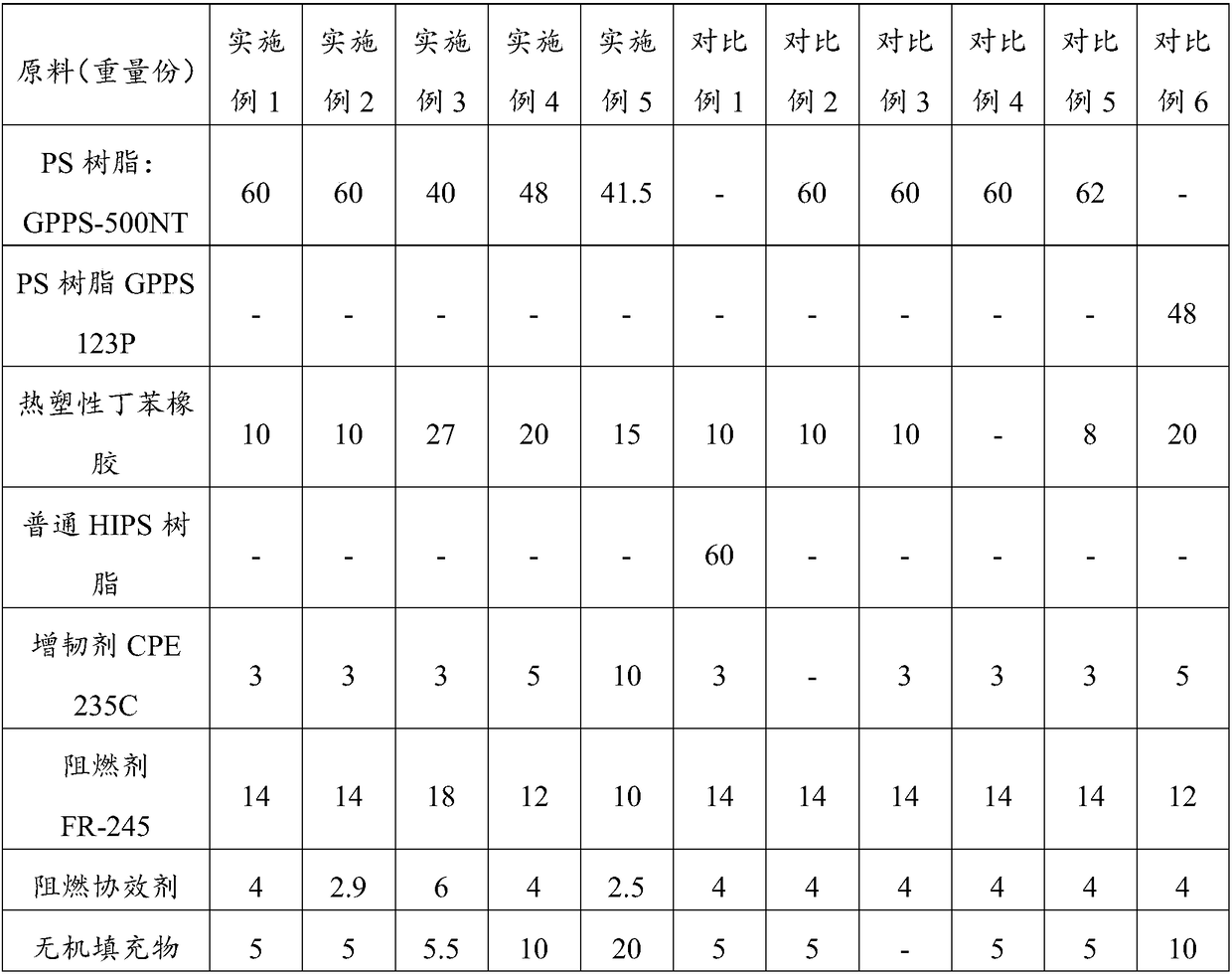

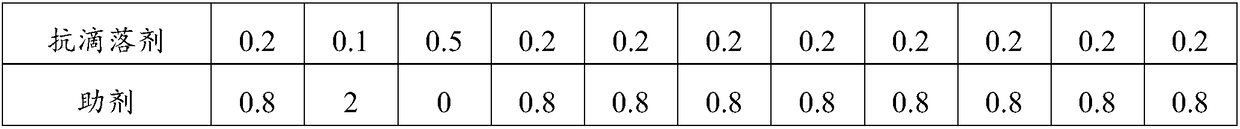

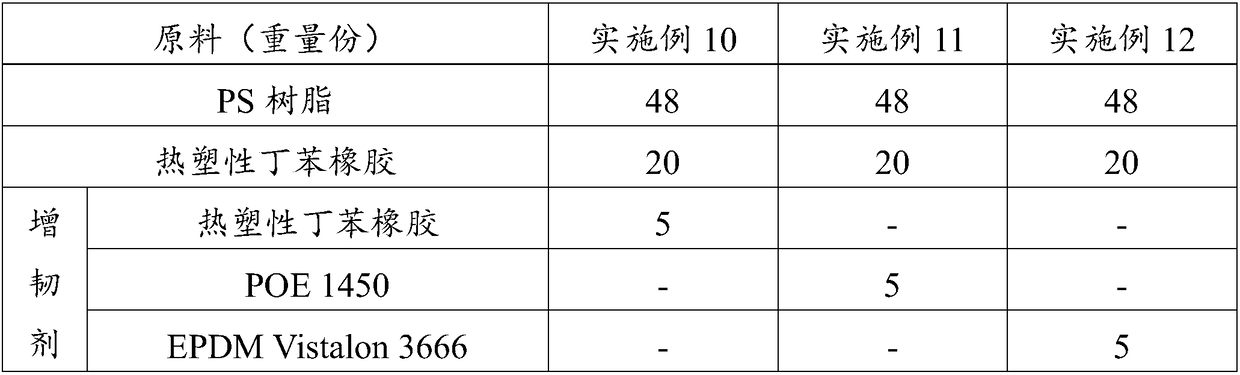

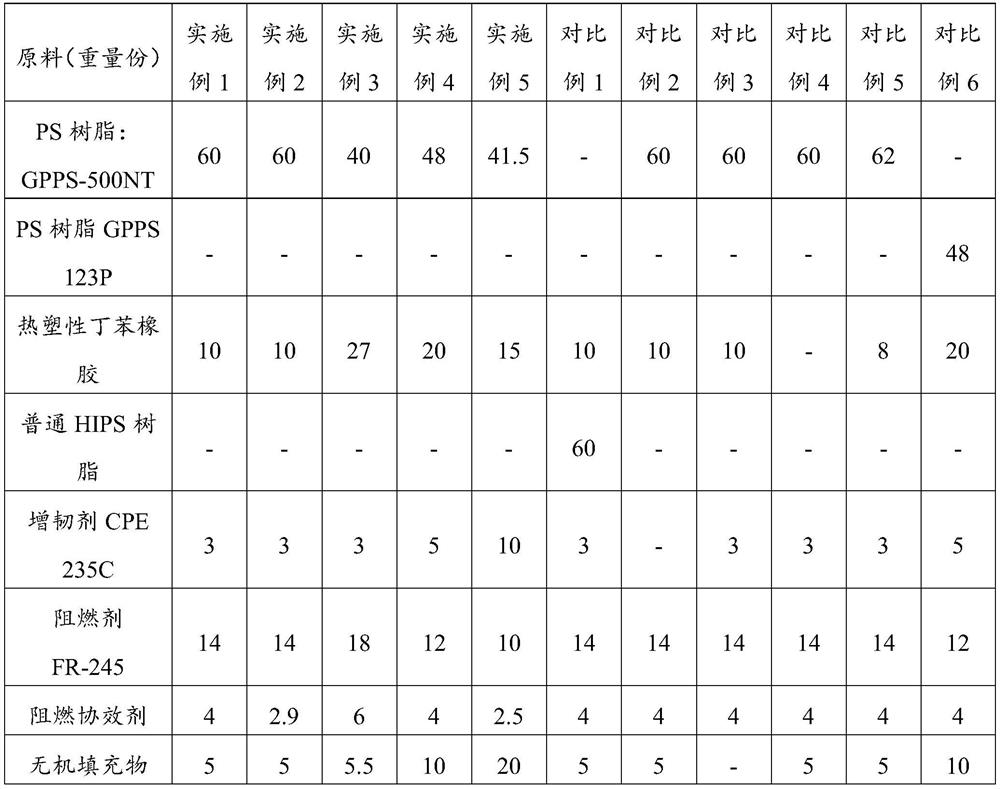

HIPS composite material with high flammability

ActiveCN109503970AHigh flame retardant gradeImprove performanceUltimate tensile strengthFire retardant

The invention discloses a HIPS composite material with high flammability. The HIPS composite material comprises the following components in parts by weight: 40-60 parts of PS resin, 10-27 parts of thermoplastic butadiene styrene rubber, 3-10 parts of flexibilizer, 10-18 parts of fire retardant, 2.5-6 parts of flame retardant synergist, 5-20 parts of inorganic filler, 0.1-0.5 part of anti-drippingagent and 0-2 parts of auxiliaries; weight-average molecular weight of PS resin is more than or equal to 15*104g / mol; melt flow rate MFR is 3-6g / 10min. The HIPS composite material with high flammability disclosed by the invention has the following advantages: 1) high flame retardant level (maximal level can reach up to 2.0mm 5VA level); 2) excellent overall performance and balanced strength and notch impact property; 3) low cost and capability of substituting high-flammability ABS in some situations; 4) good appearance and wide processing window.

Owner:江苏金发再生资源有限公司

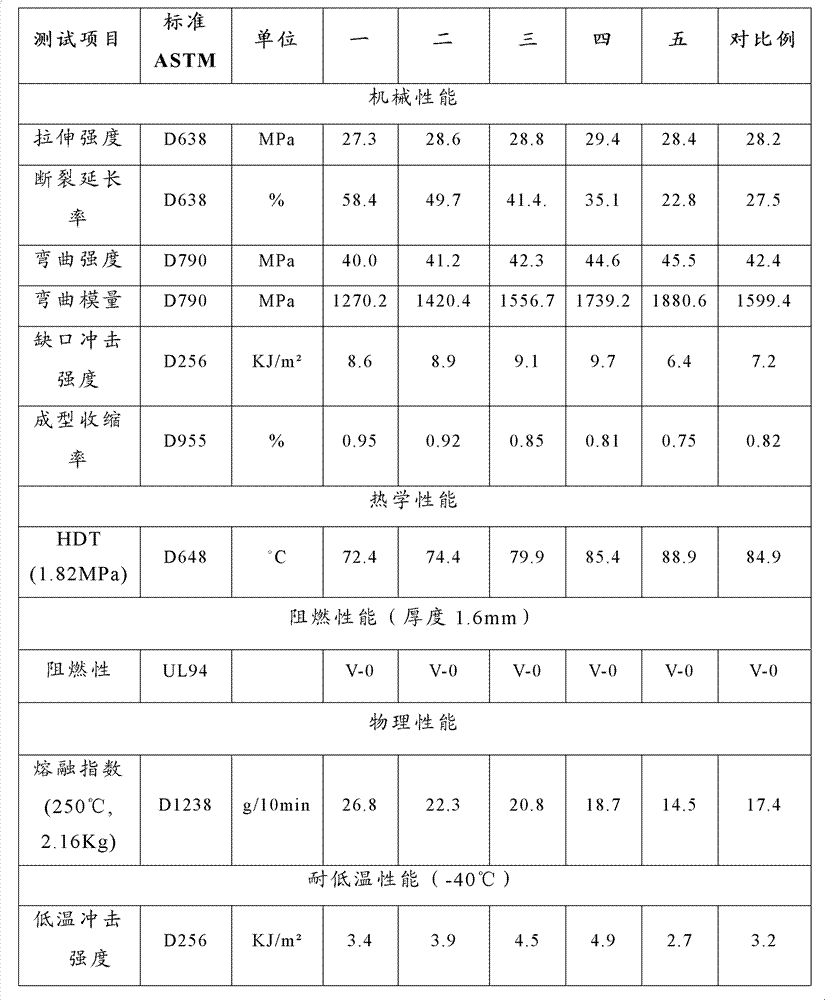

Plastic alloy as well as preparation method and application thereof

The invention provides a plastic alloy as well as a preparation method and application thereof, belonging to the technical field of plastics. The plastic alloy comprises the following components in parts by weight: 10-60 parts of PP (Polypropylene) resin, 10-45 parts of PPO (Polyphenylene Oxide) resin, 10.01-42 parts of active kaolin and 5-25 parts of compatilizer. Because the active kaolin subjected to surface treatment and a right amount of compatilizer are used, the plastic alloy has excellent mechanical properties including tensile strength, fracture extension rate, bending strength, bending modulus, notch impact strength, forming shrinkage rate and the like, and the PP resin and the PPO resin have excellent compatibility.

Owner:江苏沃特特种材料制造有限公司

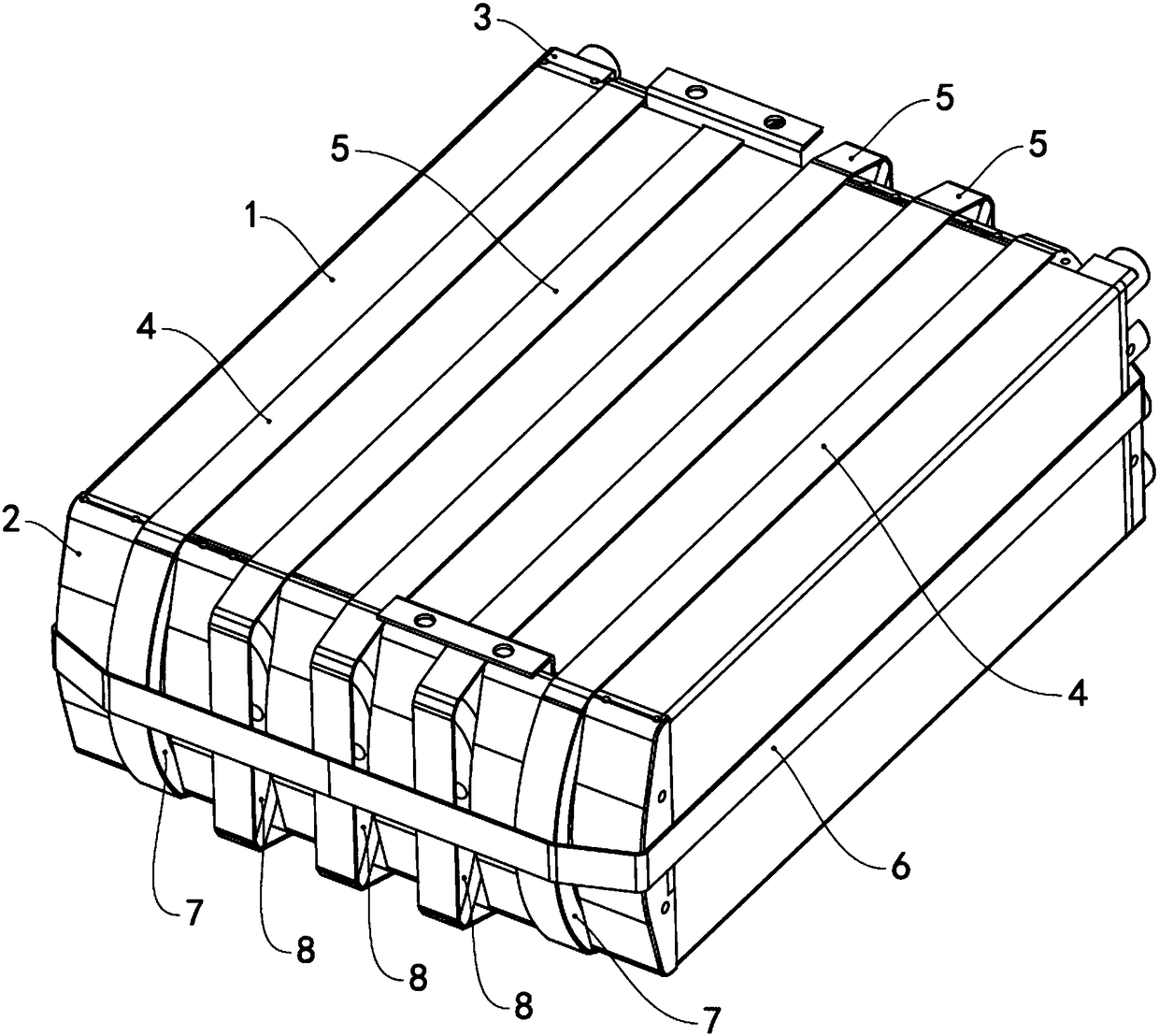

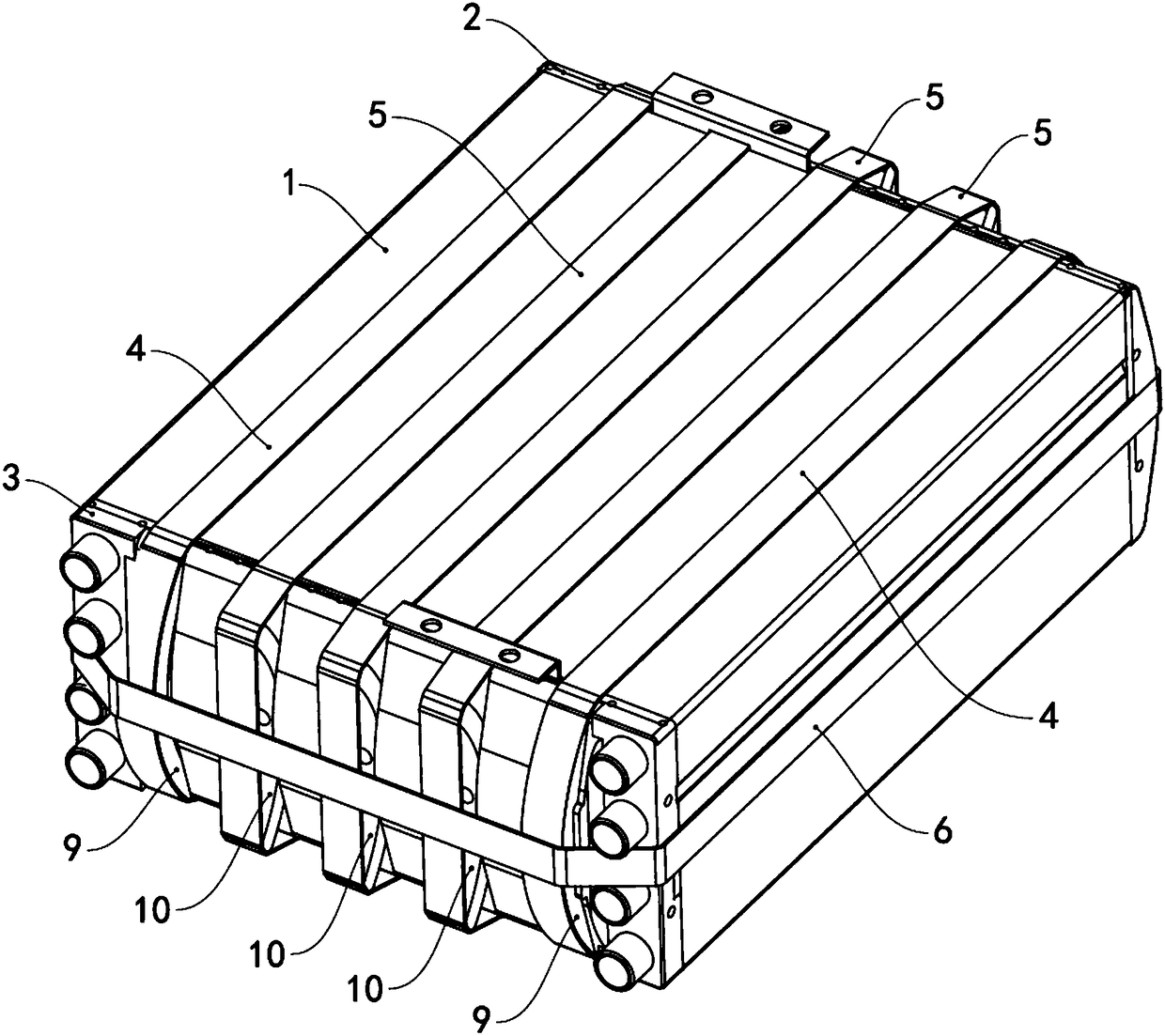

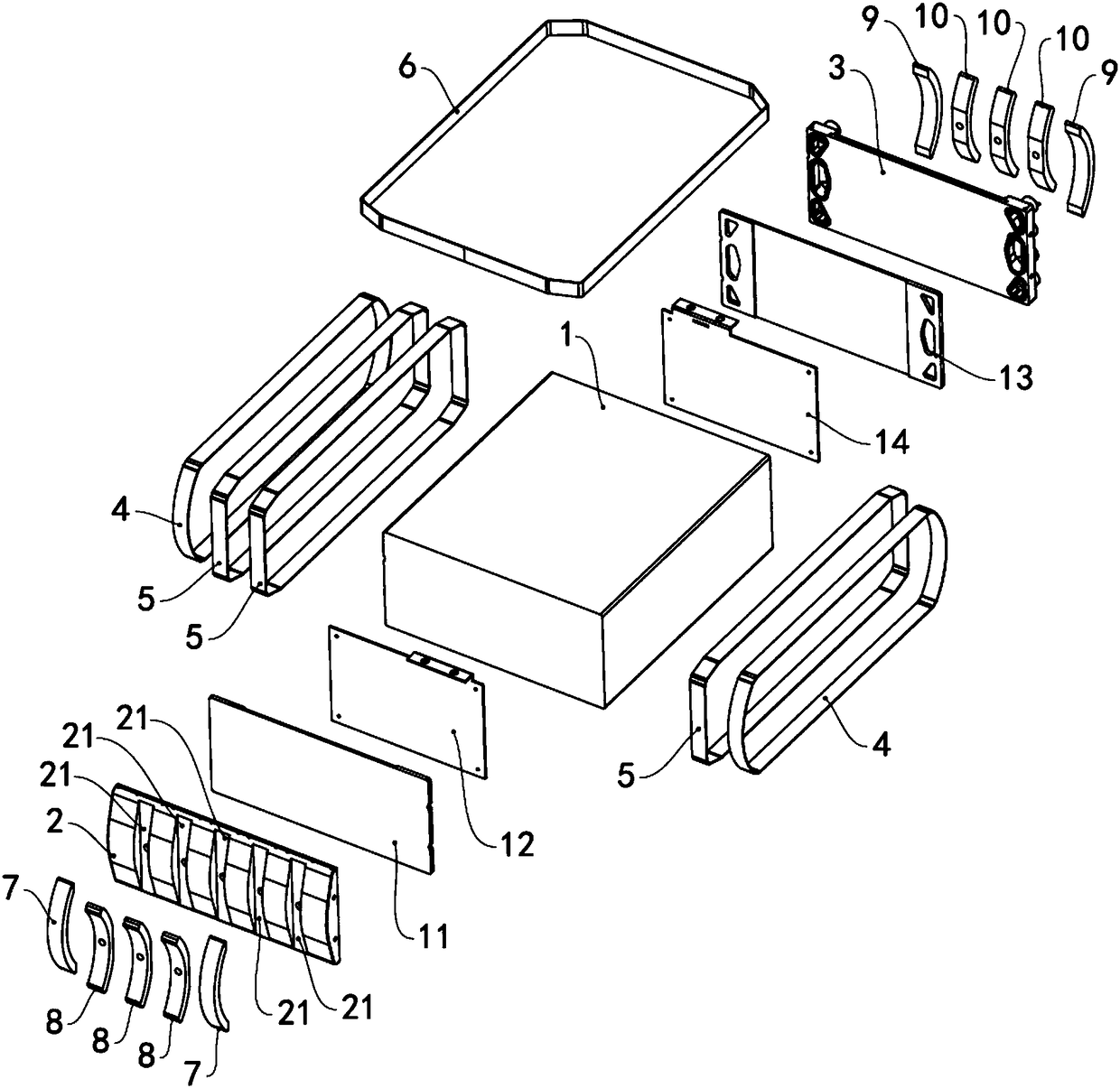

Fastening device for fuel cell stack

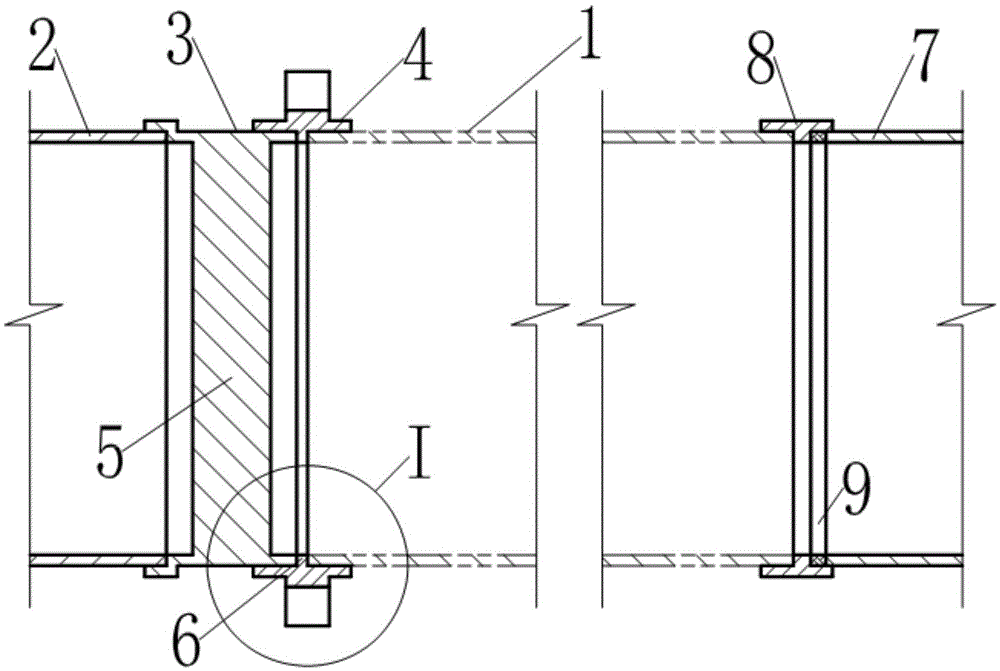

PendingCN108346814AImprove vibration resistanceImprove impact performanceFuel cellsFuel cellsEngineering

The invention provides a fastening device for a fuel cell stack. The fastening device comprises a front tail plate, a rear tail plate, first reverse arc parts, first positive arc parts, second reversearc parts, second positive arc parts, first binding tapes, second binding tapes and a third binding tape, wherein the front tail plate and the rear tail plate are arranged at two ends in a stack direction of the fuel cell stack; the arc surfaces of the first reverse arc parts are arranged on the side surface of the front tail plate facing away from the front tail plate; the arc surfaces of the first positive arc parts are arranged on the side surface of the front tail plate towards the front tail plate; the second reverse arc parts are arranged on the side surface of the rear tail plate; thesecond positive arc parts are arranged on the side surface of the rear tail plate; the first binding tapes sleeve two ends of the first reverse arc parts and two ends of the second reverse arc parts;the second binding tapes sleeve the arc surfaces of the first positive arc parts and the arc surfaces of the second positive arc parts; the third binding tape sleeves the first binding tapes, the second binding tapes and the side surface of the fuel cell stack; and the first reverse arc parts, the first positive arc parts, the second reverse arc parts and the second positive arc parts are preparedfrom an elastic material separately. The fastening device is simple and compact in structure and the stress of the fuel cell stack is uniform.

Owner:江苏氢璞创能科技有限公司

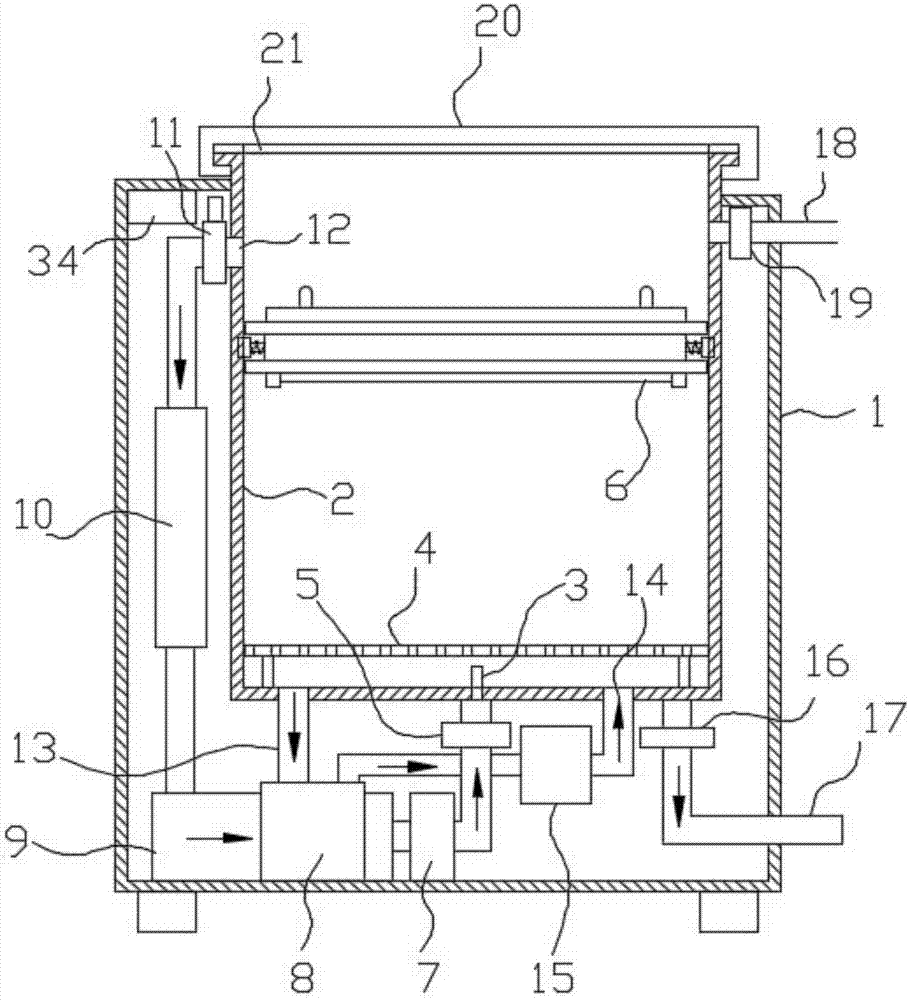

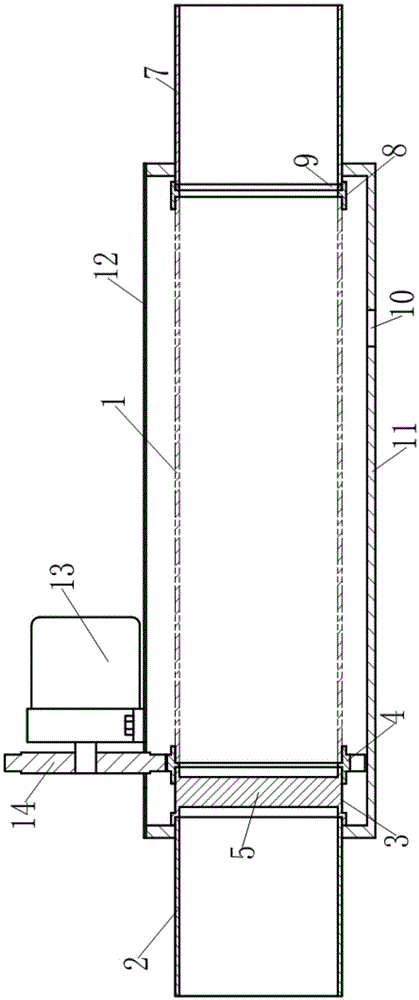

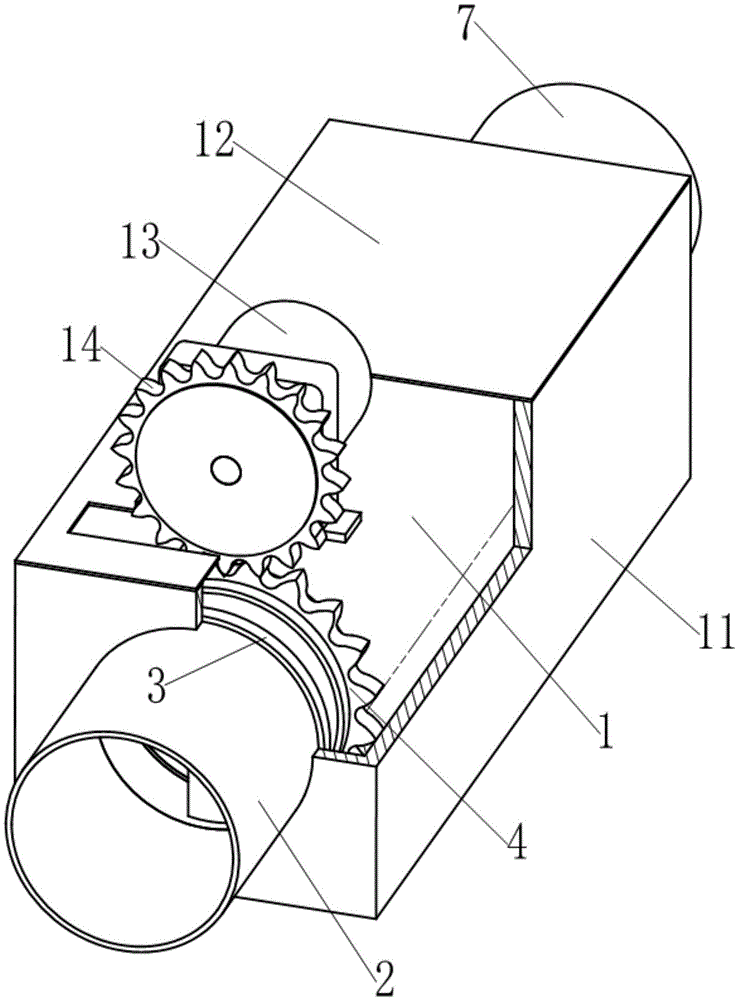

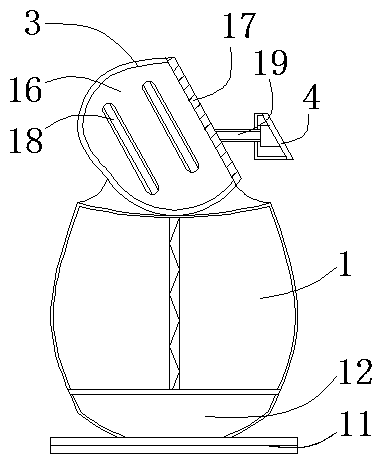

Closed type air washing machine

ActiveCN106894198APromote ruptureImprove ozone utilizationOther washing machinesWashing machine with receptaclesOzone generatorLaundry washing machine

The invention discloses a closed type air washing machine. The washing machine comprises a laundry barrel in an outer box, and the upper end of the laundry barrel is matched with a sealing cover; the laundry barrel is internally provided with a damping net cover of which the position can be adjusted up and down randomly; the damping net cover is provided with a damping net; the center of the bottom of the laundry barrel is provided with a spiral atomizing nozzle; the spiral atomizing nozzle is connected to an air compressor through a check valve and a pipeline, and an air heater is arranged on the pipeline between the spiral atomizing nozzle and the air compressor; the side edge of the bottom of the laundry barrel is communicated with a drainage pipe; the drainage pipe is provided with a normally closed solenoid valve; the upper end of the inner wall of the laundry barrel is communicated with a vent pipe; the vent pipe is connected to an ozonator through a three-way solenoid valve; the ozonator is connected to the air compressor; the air compressor is provided with a circulating water cooling system; a circulating water inlet pipe of the circulating water cooling system is communicated with one side of the bottom of the laundry barrel, and a circulating water outlet pipe is communicated with the other side of the bottom of the laundry barrel. Through the closed type air washing machine, water and clothes can be sterilized and disinfected in the whole course, the washing effect is stronger, and the energy consumption is lower.

Owner:张才友

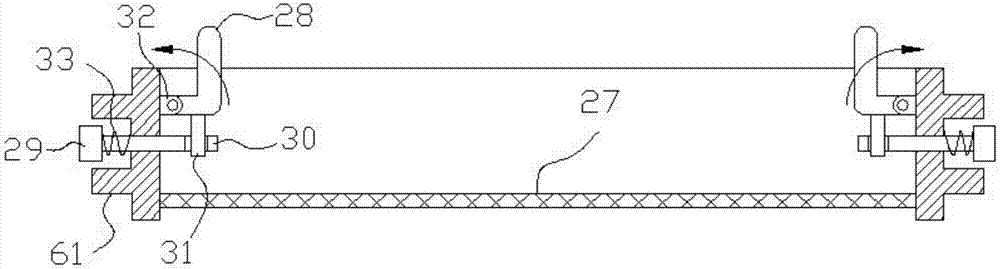

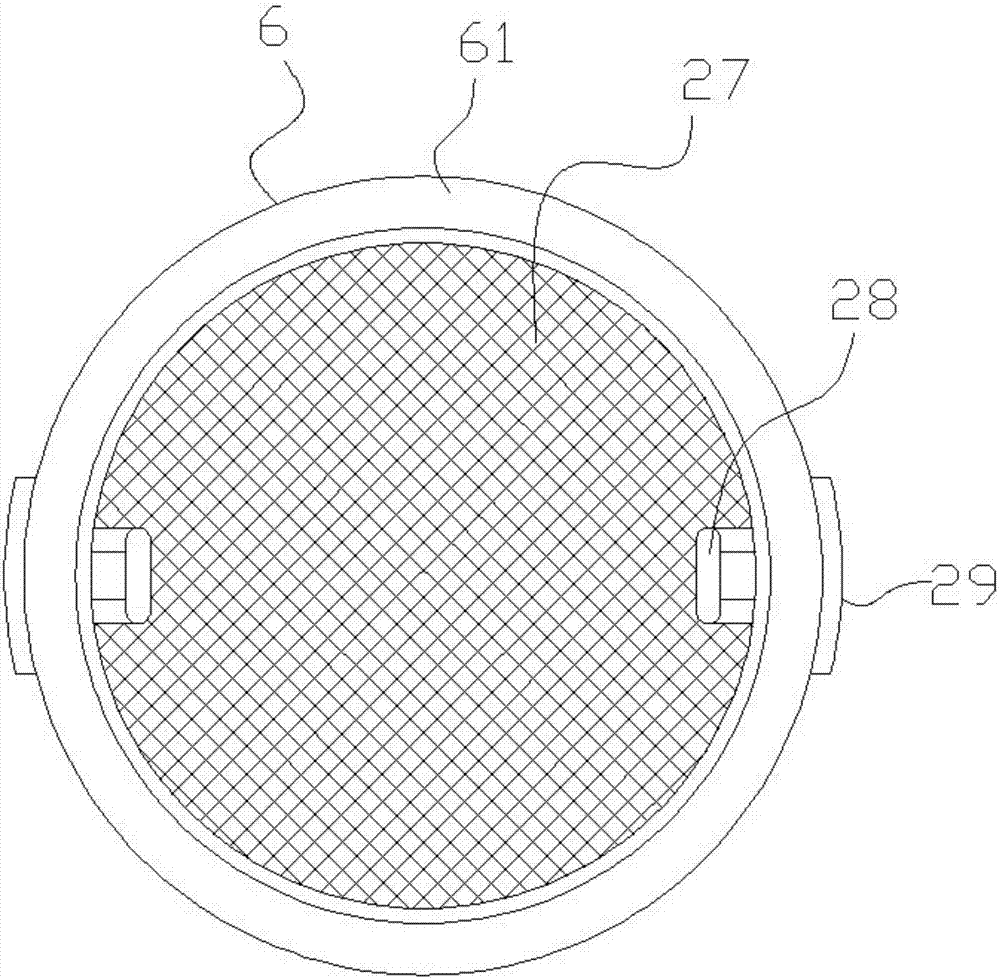

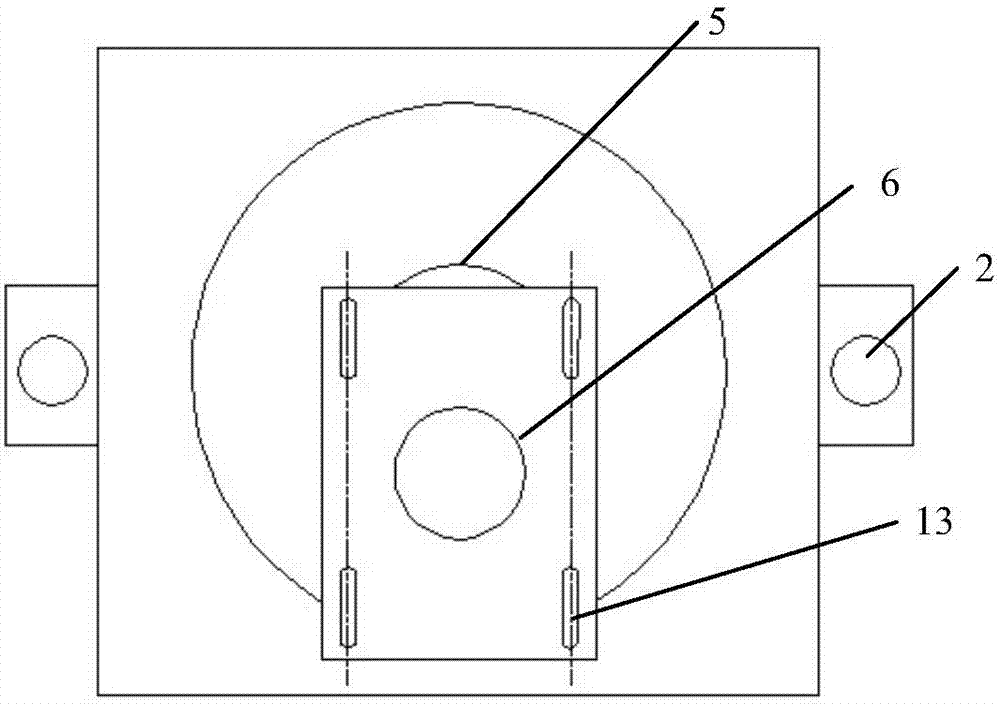

Polishing device for inner surface of tubular workpiece

InactiveCN105458900AEvenly polishedImprove efficiencyEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The invention discloses a polishing device for the inner surface of a tubular workpiece. The polishing device is provided with a cuboid rack box composed of a box body and a box cover. A backflow hole for leaking grinding liquid is formed in the bottom of the box body. An inlet pipe and an outlet pipe which are coaxial are arranged at the two ends of the box body respectively. The tail end, located in the box body, of the inlet pipe is tightly sleeved with a static ring. The tail end, located in the box body, of the outlet pipe is sleeved with a movable ring. A vortex generation column with the two ends extending to the inner wall of the static ring is arranged in the static ring and the static ring is sleeved with a gear ring. A transmission gear engaged with the gear ring is arranged at the portion, corresponding to the gear ring, of the box cover and arranged on an output shaft of a power device supported to the box cover. The gear ring and the inner wall of the movable ring are in close fit with the outer walls of the two ends of the tubular workpiece respectively so that the tubular workpiece, the gear ring and the movable ring can rotate synchronously. The polishing device has the advantages of being even in polishing effect and high in efficiency.

Owner:建湖科技创业园资产经营有限公司

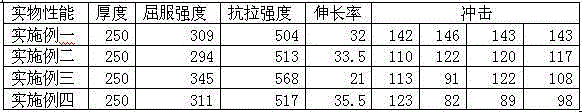

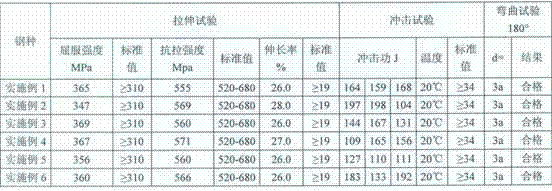

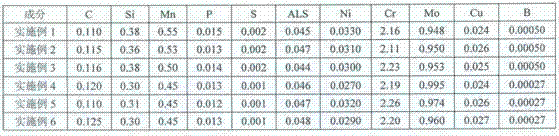

Hardened and tempered steel plate production method

The invention discloses a hardened and tempered steel plate production method. Chemical components of steel include, by mass, 0.08% to 0.24% of C, 0.20% to 0.50% of Si, 0.80% to 1.30% of Mn, smaller than or equal to 0.018% of P, smaller than or equal to 0.005% of S, smaller than or equal to 0.020% or smaller than or equal to 0.050% of Als, smaller than or equal to 0.25% of Cr, smaller than or equal to 0.08% of Mo, smaller than or equal to 0.25% of Cu, smaller than or equal to 0.25% of Ni, and the balance Fe and remaining elements. The method includes the following processing steps of converter smelting, refining, vacuum refining, casting, heating, rolling, slow cooling and thermal treatment. Through continuous casting blank production, the internal quality of blanks is guaranteed, the low-cost chemical components only with Nb, V and Ti alloy added are selected and used for design, the cleanliness of steel is guaranteed through an LF and VD process, and the sum of the levels of various impurities does not exceed 2.0; through rolling control and normalizing treatment, the grain size of the steel reaches more than 8.0; through the effective implementation of the technical measures, steel plates for a carbon-manganese-silicon pressure container and steel plates guaranteeing flaw detection, the mechanical performance and the plate shape for the carbon-manganese-silicon pressure container are successfully produced.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Shot blasting polisher

InactiveCN111843844AAvoid damageNot easy to slipAbrasive machine appurtenancesAbrasive blasting machinesClassical mechanicsStructural engineering

The invention belongs to the technical field of pipeline cleaning, and particularly relates to a shot blasting polisher which comprises a frame body, a box body and an air compressor. The frame body is in cylindrical design; connecting seats which are uniformly distributed are fixedly connected to the side surface of the frame body; the number of the connecting seats is four, and the four connecting seats are all in different horizontal planes according to the design; the sides, far away from the frame body, of the connecting seats are rotatably connected with rotating seats through rotating shafts; the rotating seats are provided with supporting rods; the side, far away from the frame body, of each supporting rods is rotatably connected with rollers through a rotating shaft; the corresponding rollers are symmetrically arranged on the two sides of each supporting rod; the surfaces of the rollers are provided with threads; and the sides, away from the supporting rods, of the rollers arefixedly connected with electric motors. Since the supporting rods and the rollers which obliquely correspond to a pipe wall, the shot blasting polisher spirally ascends and descends in the pipeline,and further is matched with shot blasting pipes at different horizontal planes to perform rotary shot blasting impact, so that the pipeline is more evenly impacted by metal shots, and the shot blasting cleaning effect is enhanced.

Owner:滁州三界外工业设计有限公司

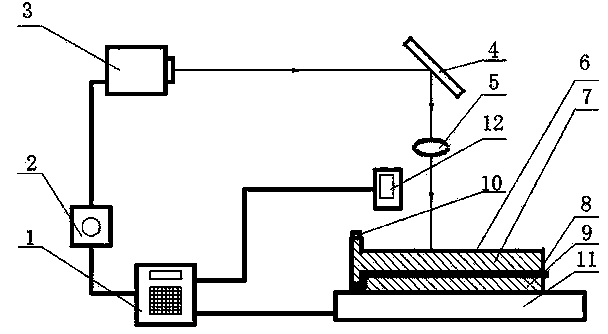

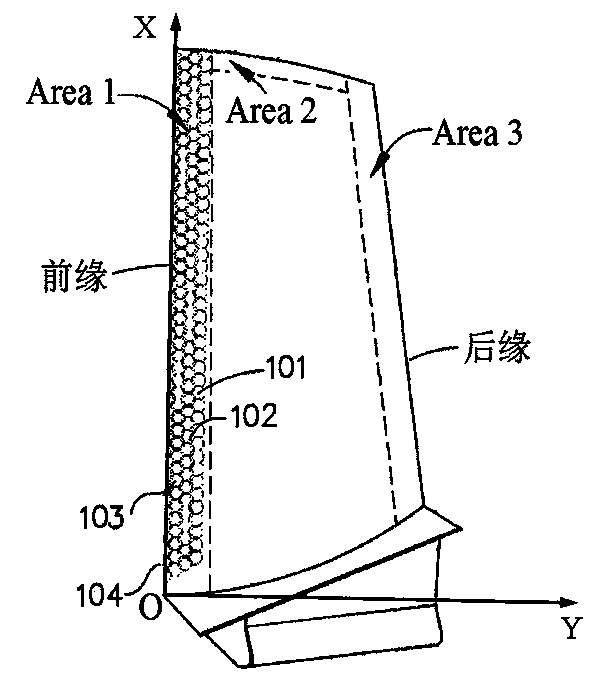

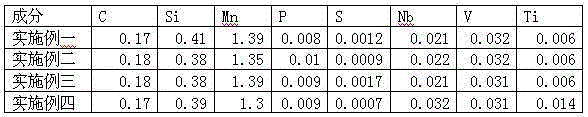

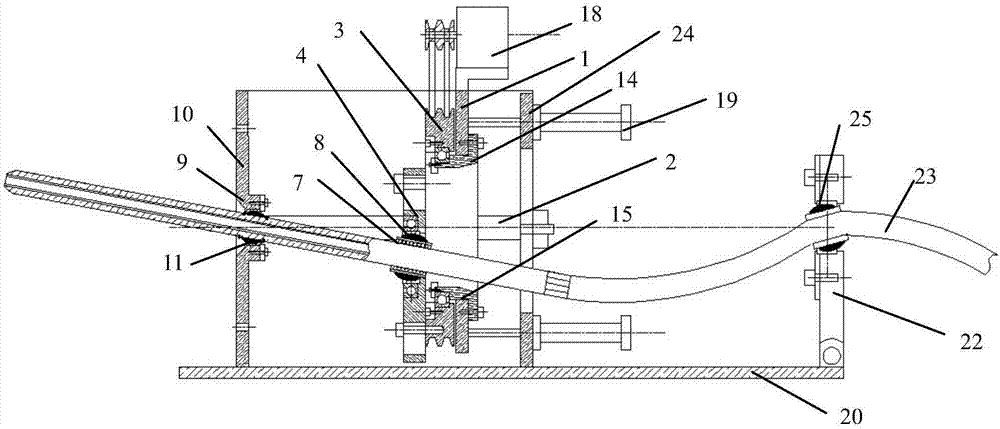

Aircraft turbine blade laser shock method and device

ActiveCN103320579BHigh strengthImprove wear resistanceFurnace typesHeat treatment furnacesNumerical controlComputer control system

The invention discloses a method and a device for laser shocking aircraft turbine blades. Firstly, a die and a flexible pad are used to support the back of the aircraft turbine blade, and secondly, a thickness measuring device is used to measure the thickness corresponding to each point of the aircraft turbine blade. , thickness, and laser shock strengthening parameters, determine the laser process parameters required for each point of the aircraft turbine blade, and finally realize the laser shock strengthening of the entire surface of the aircraft turbine blade according to the above laser process parameters for each point of the aircraft turbine blade. The device for implementing the method includes a high-power pulsed laser, an aircraft turbine blade, a flexible gasket, a die, a three-axis numerical control workbench, a computer control system, and a thickness measuring device. The invention can prevent deformation and cracking of aircraft turbine blades and obtain uniform residual compressive stress distribution, is suitable for strengthening aircraft turbine blades with complex curved surfaces and uneven thicknesses, and can also be extended to laser shock strengthening of steam turbine and water turbine blades.

Owner:JIANGSU UNIV

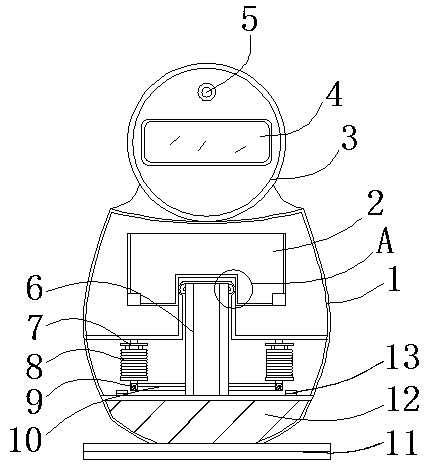

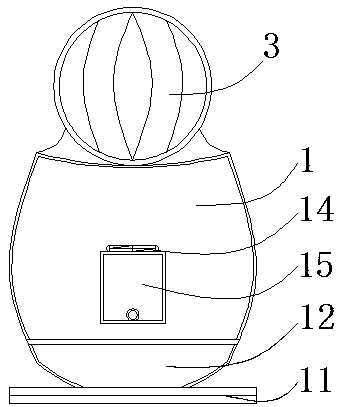

Folding type AI child robot with projection function

InactiveCN109434850AReplace the defect that does not have the projection functionWith projection functionManipulatorRotation functionTransverse groove

The invention discloses a folding type AI child robot with a projection function, and relates to the technical field of AI child robots. A first body and a third body are included. A limiting plate isarranged on the inner side of the first body through bolts. A second body is connected to the top of the first body. The third body is arranged at the bottom end of the first body. An installing plate is fixedly arranged at the bottom of the third body, and a display screen is arranged on the front face of the second body. The folding type AI child robot has the beneficial effects that accordingto the folding type AI child robot with the projection function, through the arrangement of winding discs, rotation shafts, connecting rods, protruding blocks and limiting grooves, rotation structuresare formed by the winding discs through the rotation shafts and the connecting rods, when children need to conduct recycling operation on a string and the winding discs for kite flying, the winding discs are supported, under the rotation function of the rotation shafts, the winding discs rotate around the connecting rods, and when the top ends of the winding discs slide into transverse grooves, the children finish the local folding work for the device.

Owner:DONGGUAN UNIV OF TECH

Production method of ultra-thick low-alloy steel plate

InactiveCN105256218AImprove cleanlinessGreat Physical Quality PerformanceChemical compositionSheet steel

The invention discloses a production method of an ultra-thick low-alloy steel plate. The process route adopted in the production method comprises smelting with a converter, LF refining, vacuum refining, mold casting, heating, rolling, slow cooling, heat treatment and shape correction. The ultra-thick low-alloy steel plate comprises the following chemical components in percentage by weight: 0.12-0.18% of C, 0.20-0.50% of Si, 1.30-1.60% of Mn, P of which the percentage is smaller than or equal to 0.015%, S of which the percentage is smaller than or equal to 0.005%, Als of which the percentage is smaller than or equal to 0.020-0.050%, 0.02-0.04% of Nb, 0.02-0.05% of V, 0.01-0.02% of Ti, and the balance being Fe and residual elements. According to the production method disclosed by the invention, a large-section cast ingot is adopted; in the aspect of component selection, a low-cost chemical component design only employing alloys of Nb, V and Ti is adopted; through an LF technology and a VD technology, the cleanliness of the steel plate is guaranteed; through controlled rolling and normalizing treatment, the grain size of steel can reach above 7.0 grade. The produced ultra-thick low-alloy steel plate has the characteristics that the thickness is 250mm; the crack detection property, the mechanical property and the plate shape can be guaranteed; the yield strength margin is 20-40Mpa; the tensile strength margin is 20-30Mpa; the elongation rate margin is 6%-9%; the impact resistance is uniform; the produced steel plate is particularly suitable for bases of wind driven generators.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

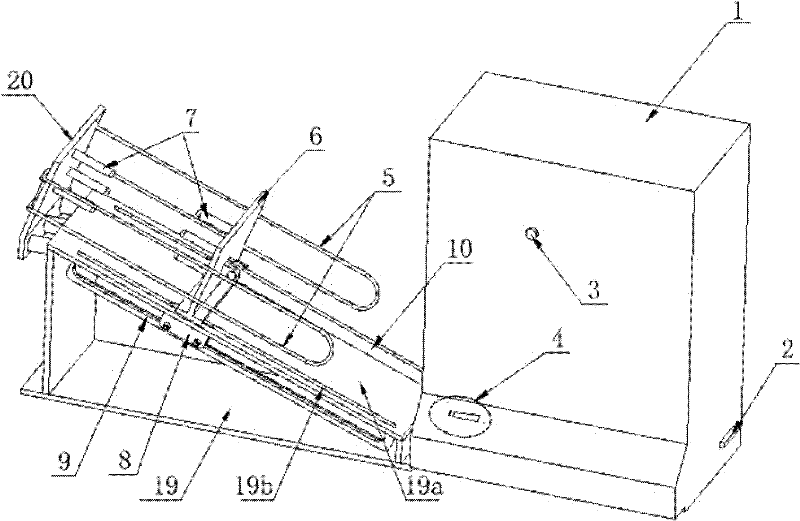

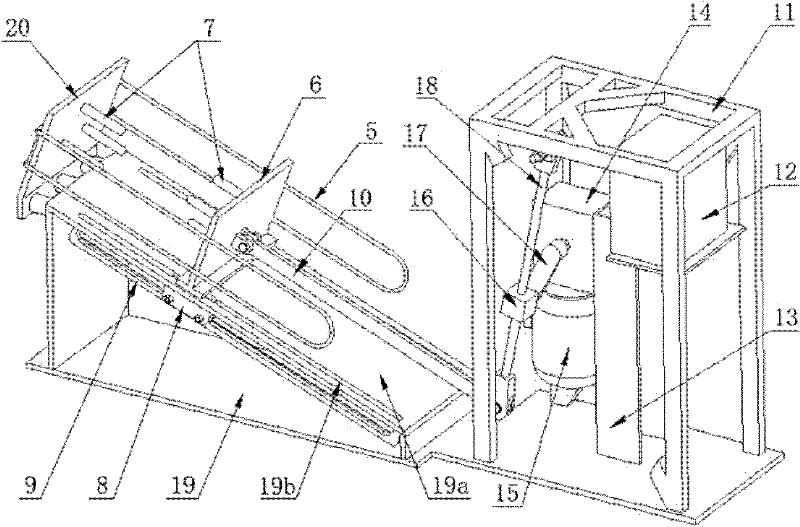

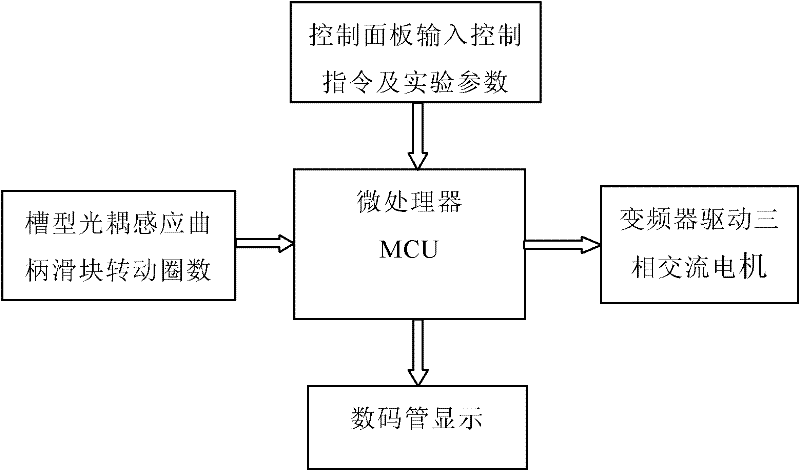

Impact down penetration resistant instrument

InactiveCN102419301AUniform impactUniform areaUsing mechanical meansMaterial analysisImpact areaImpact

The invention relates to an impact down penetration resistant instrument, which is characterized by comprising guardrails, a mobile impact plate, an impact rod, a support, a fixed impact plate and a reciprocating driving mechanism, wherein the support is provided with a support oblique plane which forms a certain included angle with the horizontal plane; the mobile impact plate is placed on the support oblique plane; the plane of the mobile impact plate is vertical to the support oblique plane; the mobile impact plate is driven through the reciprocating driving mechanism and slides up and down on the support oblique plane; the fixed impact plate is arranged at the top of the support; the plane of the fixed impact plate is parallel to the plane of the mobile impact plate; a plurality of impact rods are respectively arranged on the face, which is opposite to the mobile impact plate, of the fixed impact plate; and the guardrails are arranged on the two sides of the mobile impact plate and are fixed on the fixed impact plate. The impact down penetration resistant instrument has a craft and reasonable structure; and by adoption of the impact down penetration resistant instrument, the impact strength and the impact area can be relatively uniform; the external force to a down product in a daily wearing process can be accurately reflected; and the test result is more accurate.

Owner:WUXI ENTRY EXIT INSPECTION & QUARANTINE BUREAU PEOPLES REPUBLIC OF CHINA

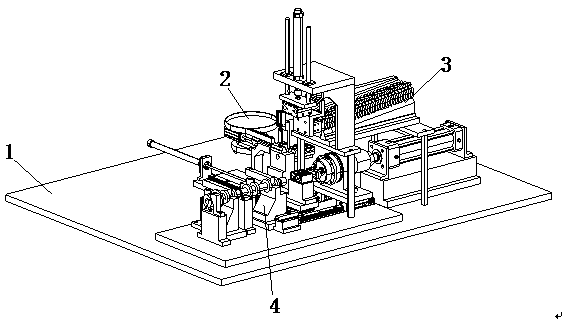

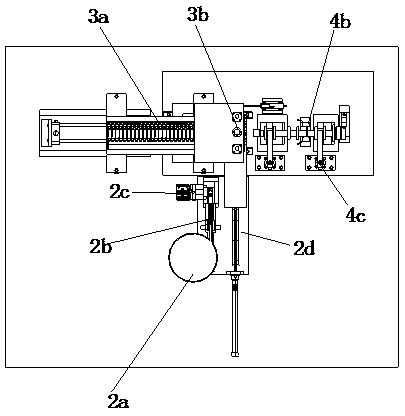

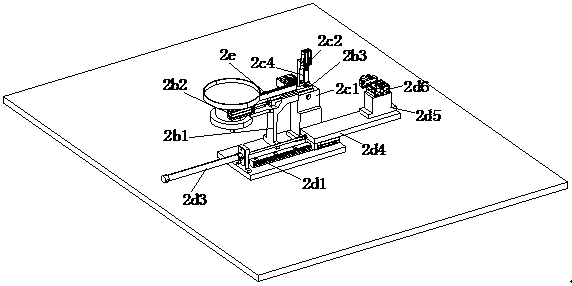

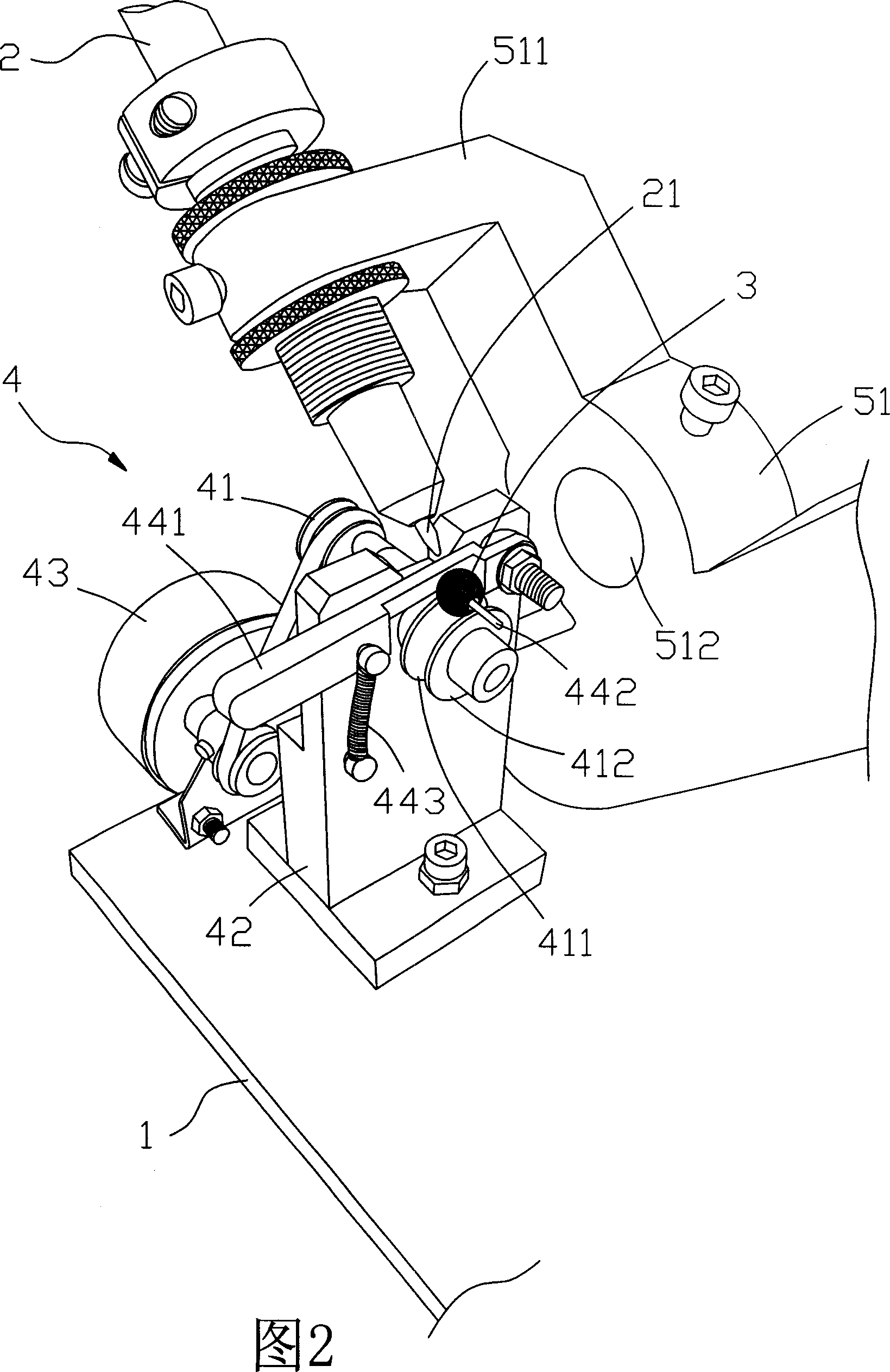

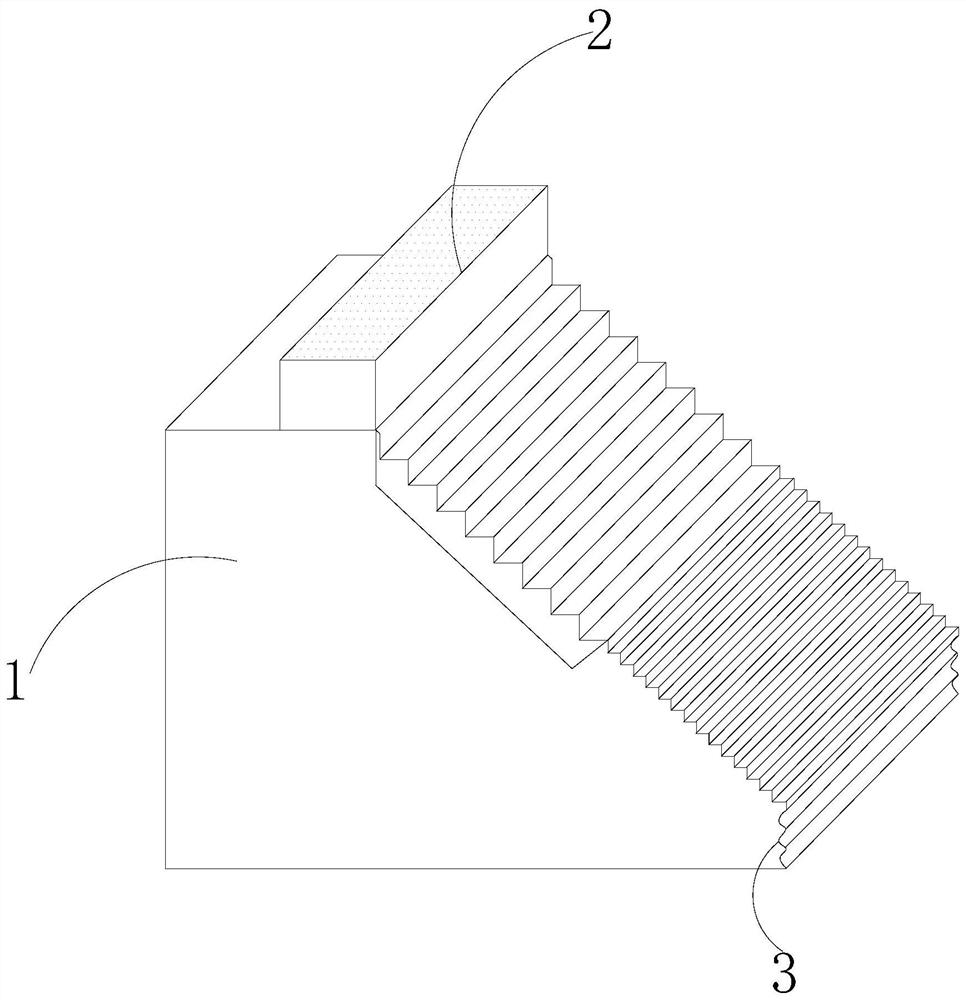

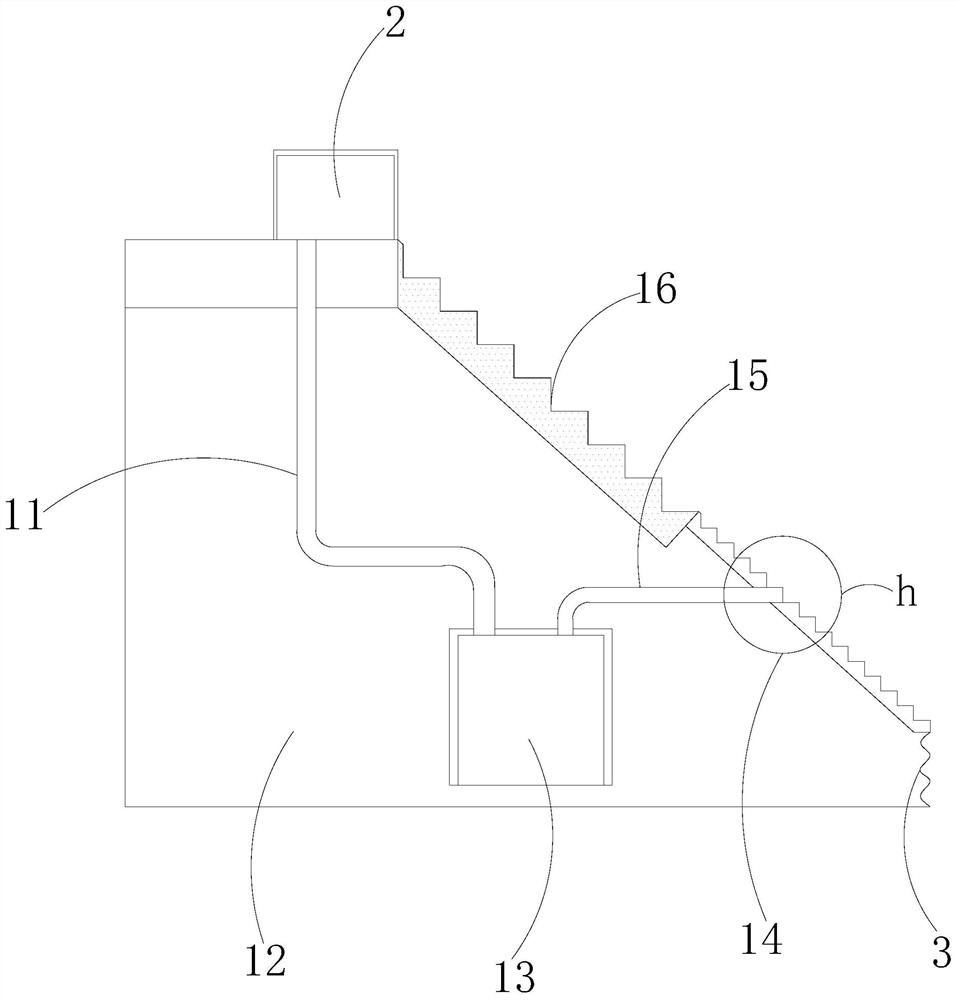

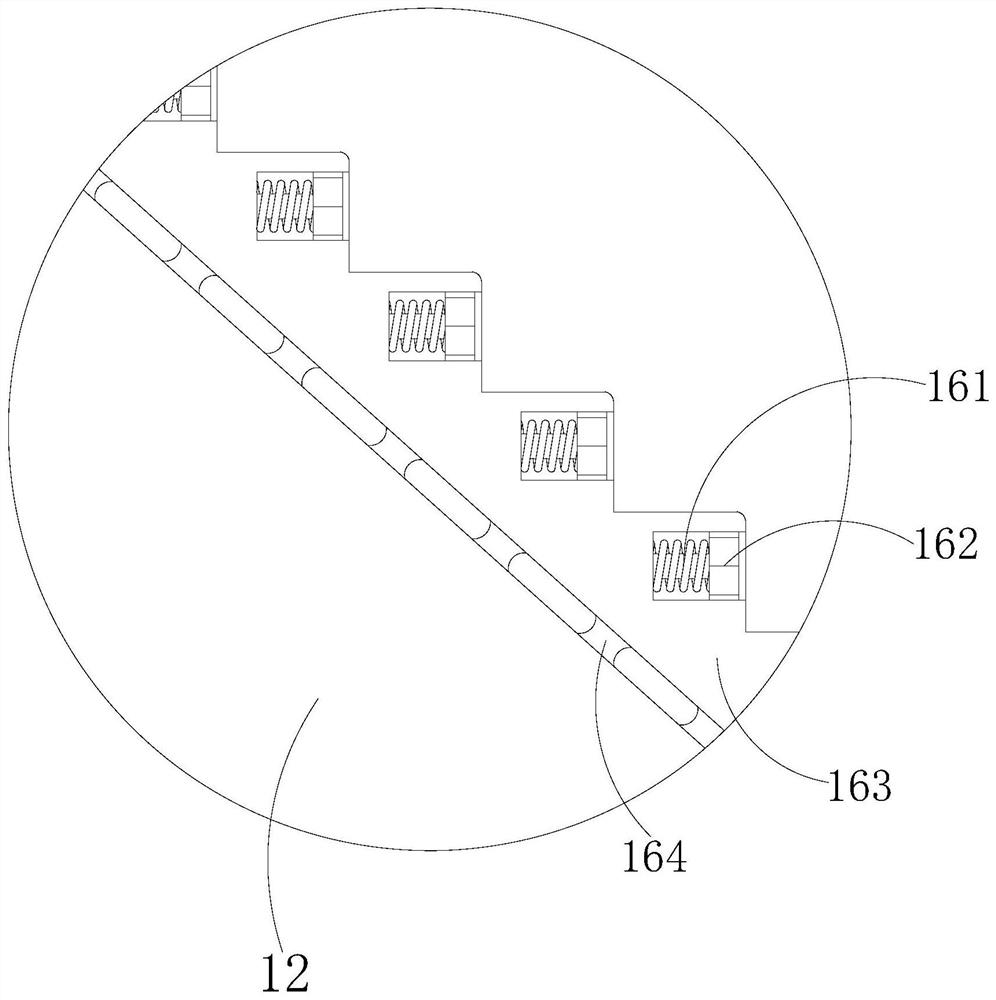

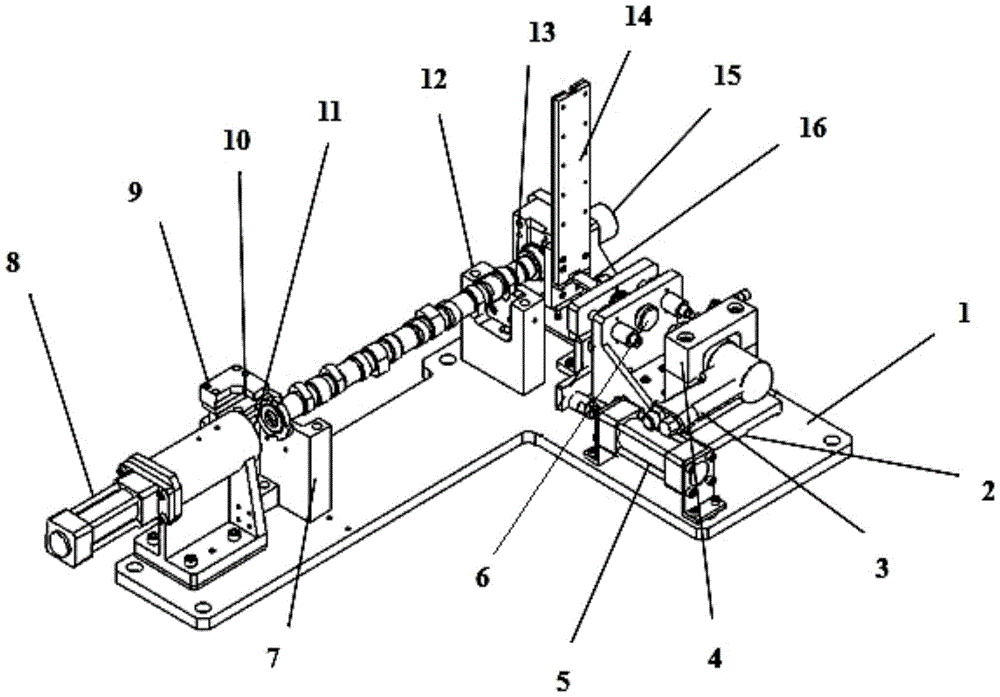

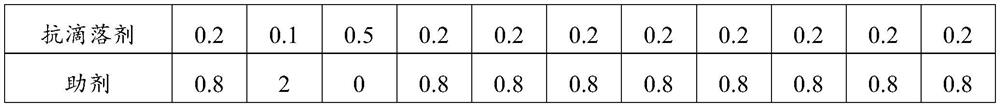

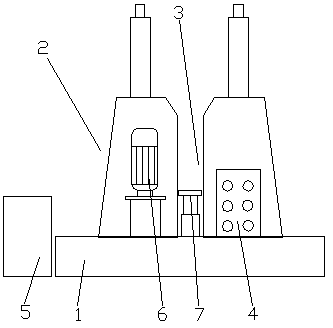

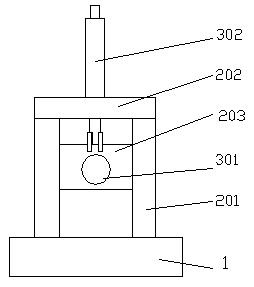

Cam shaft signal wheel bowl plug pressing machine

The invention relates to the technical field of camshaft assembly, in particular to a camshaft signal wheel plug pressing machine. It includes a working seat, a bowl plug feeding device, a signal wheel feeding device and a positioning fixture. The bowl plug feeding device includes a vibrating feeding tray installed on the top of the working seat, a first material transmission part, and a second material transmission part and a third transmission part, the signal wheel feeding device includes a signal wheel feeding part and a positioning assembly part, and the positioning assembly part includes a first drive assembly and a positioning assembly installed on the output end of the first drive assembly, The positioning jig includes a first positioning plate installed on the top of the work seat, a first positioning component installed on the top of the first positioning plate, and two limiting components symmetrically installed on the side of the first positioning component, each of which All the limiting parts can snap fit with the first positioning part. The invention reduces the labor intensity of employees, ensures the quality of products while improving work efficiency, and has strong practicability.

Owner:尹权邦

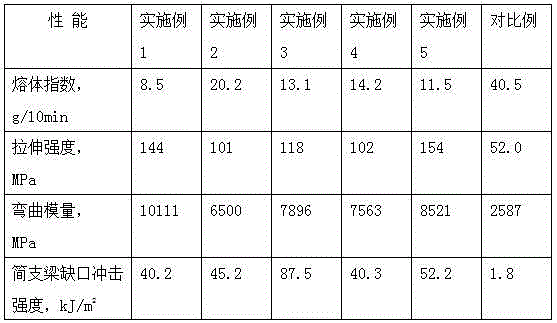

Glass fiber-reinforced AES resin material and preparation method thereof

The invention discloses a glass fiber-reinforced AES resin material. The glass fiber-reinforced AES resin material is prepared from 50-90 parts by weight of acrylonitrile-ethylene propylene diene monomer-styrene (AES), 10-40 parts by weight of glass fibers, 3-10 parts by weight of a compatilizer, 0.5-2 parts by weight of a coupling agent and 0.5-5 parts by weight of tributyl citrate. The glass fiber-reinforced AES resin material has excellent stretching and bending performances and balanced fluidity and impact resistance. The glass fibers reduce an AES material cost so that the AES material has a wide use range. Through synergism of the tributyl citrate, compatilizer SMA and coupling agent, an interface bonding force of AES and glass fibers is maximized so that material mechanical properties are improved and shock resistance is greatly improved. The preparation method has simple processes and can be implemented easily.

Owner:HEFEI GENIUS NEW MATERIALS

Plastic alloy as well as preparation method and application thereof

The invention provides a plastic alloy as well as a preparation method and application thereof, belonging to the technical field of plastics. The plastic alloy comprises the following components in parts by weight: 10-60 parts of PP (Polypropylene) resin, 10-45 parts of PPO (Polyphenylene Oxide) resin, 10.01-42 parts of active kaolin and 5-25 parts of compatilizer. Because the active kaolin subjected to surface treatment and a right amount of compatilizer are used, the plastic alloy has excellent mechanical properties including tensile strength, fracture extension rate, bending strength, bending modulus, notch impact strength, forming shrinkage rate and the like, and the PP resin and the PPO resin have excellent compatibility.

Owner:JIANGSU WATER SPECIAL MATERIAL MFG CO LTD

Pattern marking machine for decoration surface treatment

InactiveCN1857931AHigh glossEnhance layeringDecorative surface effectsEmbossing decorationsEngineeringBrightness perception

The present invention relates to mechanical technology and especially a kind of pattern making machine for decoration surface treatment. The pattern making machine has one churn drill set on the machine frame with drill bit capable of striking axially and revolving around the workpiece. The workpiece is fixed onto the rotating table for rotating in the direction crossing to the revolving direction of the drill bit. Therefore, the drill bit can move in certain locus to form patterns with excellent brightness and layer feelings on the surface of the workpiece.

Owner:吴金水

Glass fiber reinforced AES resin material and preparation method thereof

The invention discloses a glass fiber reinforced AES resin material and a preparation method thereof. The glass fiber reinforced AES resin material is prepared from the following ingredients in parts by weight: 50-90 parts of acrylonitrile-ethylene propylene diene rubber-styrene, 10-40 parts of glass fibers, 3-10 parts of compatibilizer, 0.5-2 parts of coupling agent and 1-5 parts of dimethyl itaconate. The glass fiber reinforced AES resin material prepared by the preparation method has excellent tensile and bending properties and balanced flowability and impact properties. Due to the use of the glass fibers, the cost of the AES material is reduced, and the range of use of the AES material can be wider. The preparation method disclosed by the invention is simple and easy to implement. According to the glass fiber reinforced AES resin material and the preparation method thereof, a synergetic effect is achieved among the added dimethyl itaconate, the compatibilizer SMA (styrene-maleic anhydride copolymer) and the coupling agent, and the interfacial bonding strength between the AES and the glass fibers can be maximized, so that the mechanical properties of the material can be improved, and particularly the impact resistance of the material can be improved greatly.

Owner:HEFEI GENIUS NEW MATERIALS

Ecological revetment for water conservancy project

InactiveCN112144475AReduce inertial sliding forceAvoid passingNon-rotating vibration suppressionCoastlines protectionStructural waterWater flow

The invention discloses an ecological revetment for a water conservancy project. The ecological revetment structurally comprises a pressure-resistant mechanism, a blocking shaft and a bending groove.The pressure-resistant mechanism is provided with a sealing pipe, a pressure-resistant block, a water tank, a pressure-resistant mechanism body, a flowing pipe and a blocking structure. Water flow impacts the blocking structure under inertia force, the impact effect of the water flow on rubber strips is kept uniform, and therefore bending plates are stable; sliding grooves on the outer sides of sliding shafts are driven to slide in force bearing plates, the water flow is prevented from passing through the blocking shaft under blocking of the stepped force bearing plates, impacting on rear crops is avoided, the water flow impacts openings on the right sides of extrusion holes, and therefore rubber plates are bent to drive force bearing holes to achieve extrusion; and when the water tank isfull of water, the water flow entering from the flowing pipe forms water pressure, the water pressure enables the water flow to enter the sealing pipe from the water tank, the impact force of the water flow is converted into the water pressure, and therefore the water pressure is consumed, the impact force of the water flow on the pressure-resistant block is reduced, meanwhile, overlarge impact force borne by the revetment is avoided, and the situation that cracks are formed due to the fact that concrete is corroded is avoided.

Owner:汪昕

12Cr2Mo1R steel plate for ultra-thick hydrogen-contacting equipment and production method thereof

The invention discloses a 12Cr2Mo1R steel plate for ultra-thick hydrogen-contacting equipment and a production method thereof. The 12Cr2Mo1R steel plate comprises the following chemical components, by mass, 0.08-0.15% of C, 0.20-0.50% of Si, 0.30-0.60% of Mn, equal to or less than 0.018% of P, equal to or less than 0.005% of S, equal to or less than 0.020-0.050% of AlS, 2.0-2.5% of Cr, 0.90-1.10% of Mo, and the balance Fe and residual elements. The production method comprises steps of converter smelting, LF refining, vacuum refining, casting, heating, rolling, controlled cooling, slow cooling, and heat processing. A whole production process from molten iron pretreatment to steel plate heat treatment is executed in strict accordance with above technology, so the object quality performance margin of products is large, wherein the yield margin is 40-80Mpa, the tensile margin is 55-70Mpa, and the elongation margin is 6-9%, thereby the impact performance is uniform and the margin is large.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

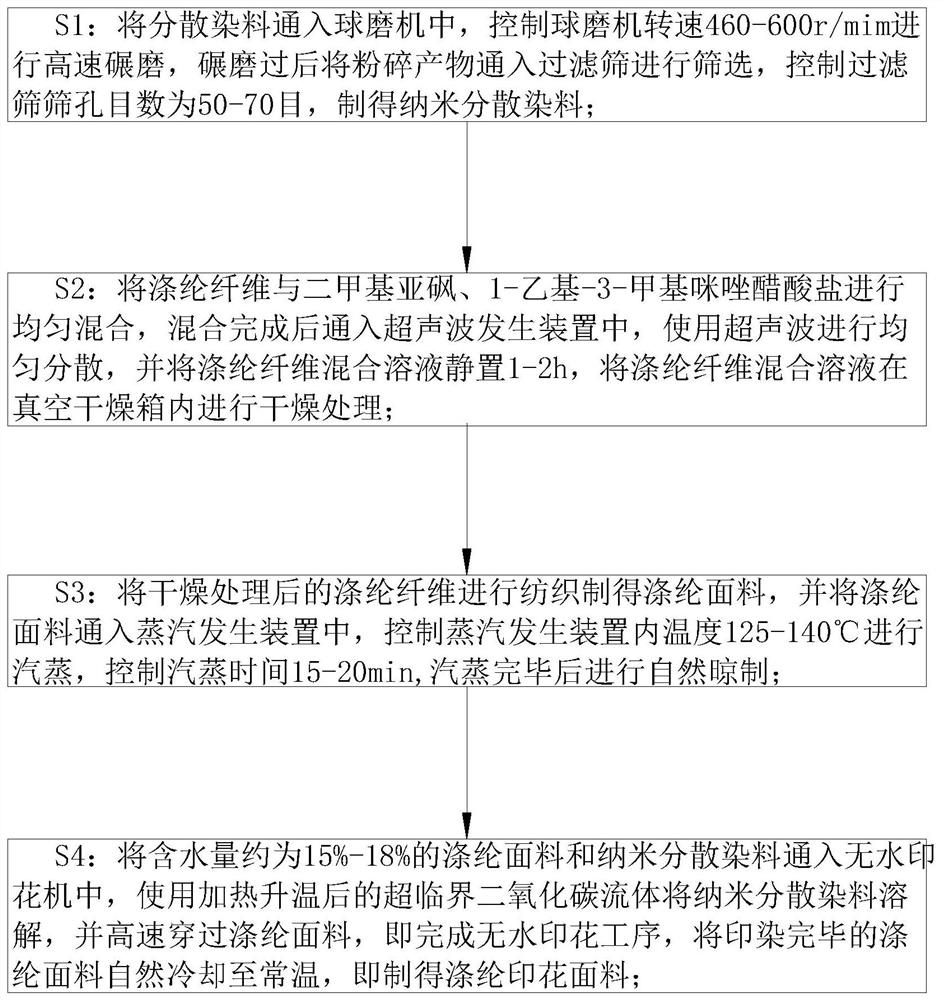

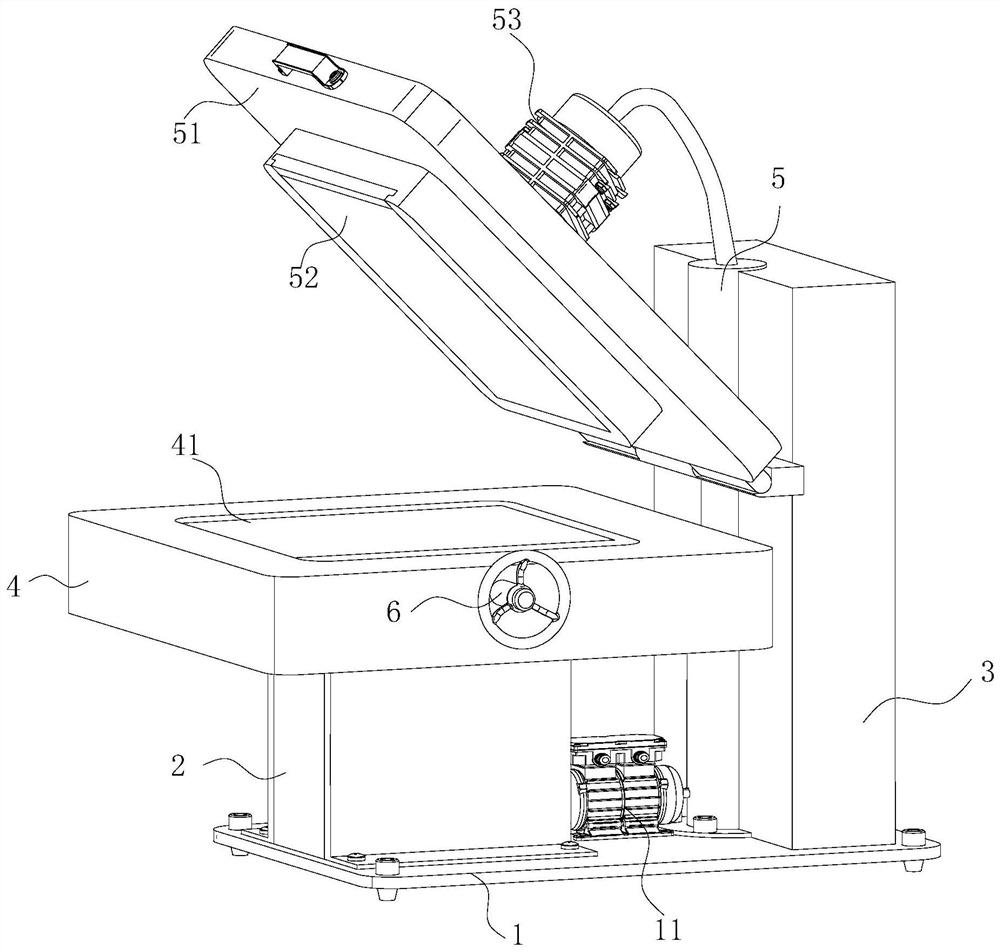

Nano-osmosis washing-free technology for polyester fabric

ActiveCN111793998AReduce diffuseLow costDyeing processBulk chemical productionDisperse dyeTextile printer

The invention belongs to the technical field of printing and dyeing, and particularly discloses a nano-osmosis washing-free technology for polyester fabric. A base, a motor and a controller are included; a pressurizing box and a separating box are mounted on the upper surface of the base; a pressurizing cavity is formed in the pressurizing box; a separating cavity is formed in the separating box;the motor is mounted between the pressurizing box and the separating box; the motor is a bidirectional output motor; a power cavity is formed in the position, located below the pressurizing cavity, ofthe pressurizing box; a power cavity is formed in the position, located below the separating cavity, of the separating box; output shafts of the motor extend into the power cavities; and the parts, located inside the power cavities, of the output shafts of the motor are sleeved with first bevel gears. According to the technology, through gasification and compression of a carbon dioxide fluid andthrough osmosis of dissolved disperse dyes into fibers in the gasification process, on one hand, carbon dioxide is gasified quickly under the normal pressure without residues, meanwhile, the carbon dioxide is recycled continuously, and the cost of the printing procedure is saved effectively.

Owner:宣城凯欧纺织有限公司

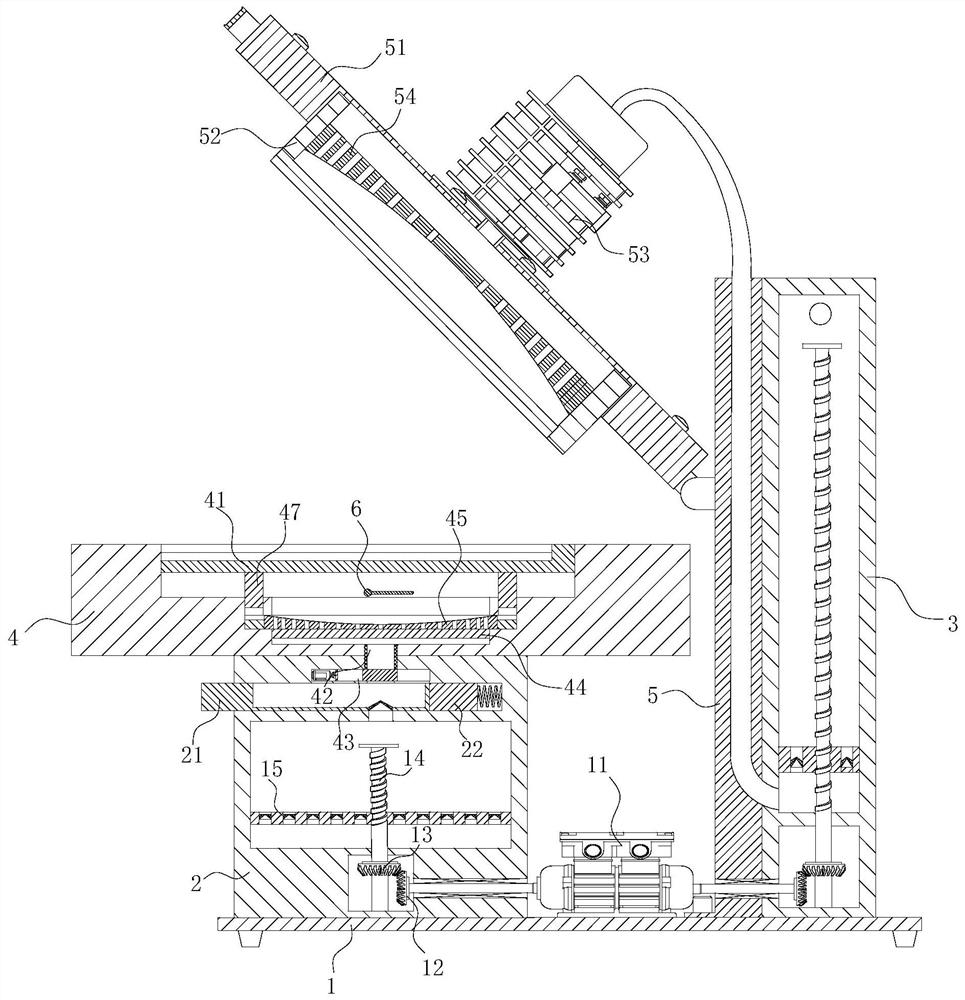

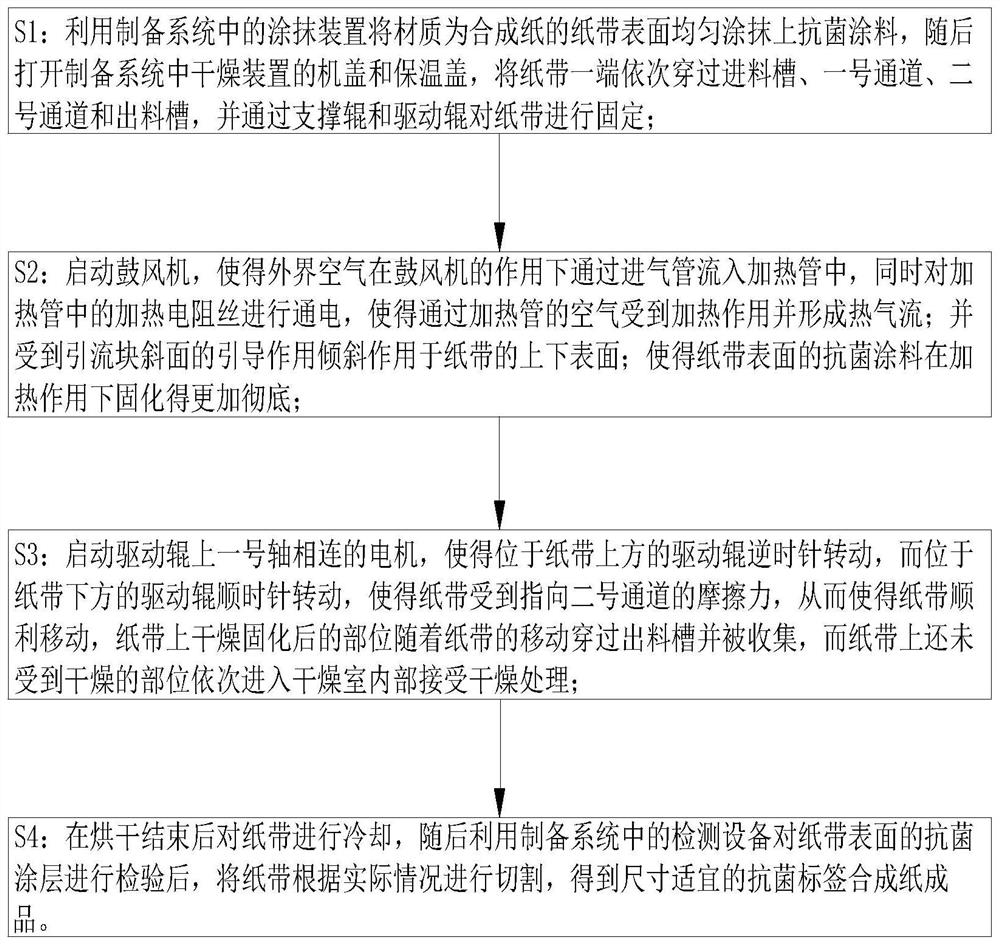

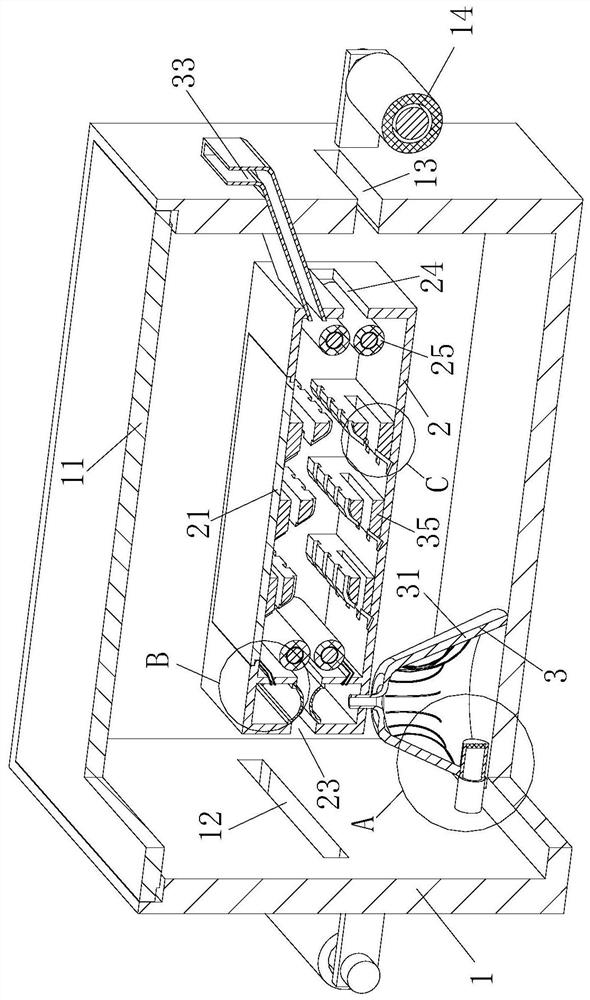

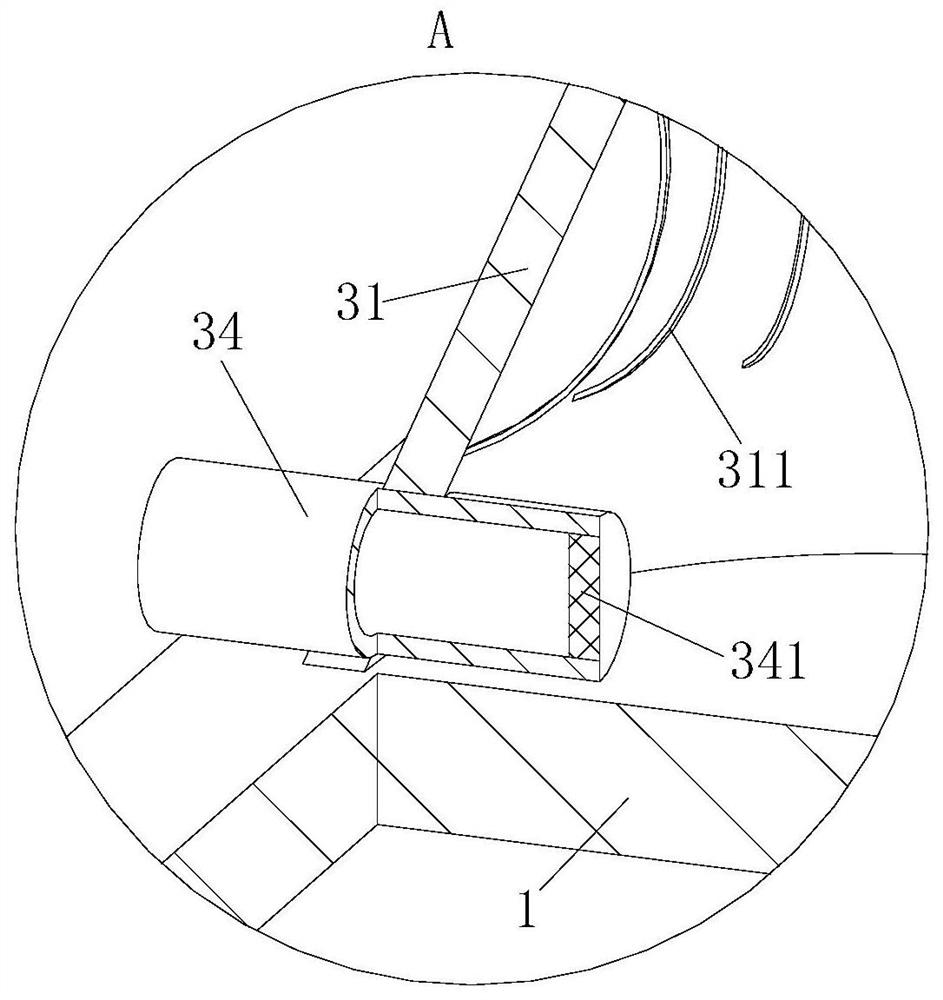

A preparation system and preparation process of antibacterial label synthetic paper

ActiveCN113174782BReduce direct impactPrevent disengagementSpecial paperPaper/cardboardPaper tapeEngineering

The invention belongs to the technical field of label synthetic paper preparation, and specifically relates to a preparation system and a preparation process of antibacterial label synthetic paper. The preparation system includes a smearing device, a drying device and testing equipment, and the drying device includes a machine body and a machine cover. , drying chamber, feeding chute, discharging chute, support roller and drying unit; the top of the body is provided with a machine cover, and the inside of the body is provided with a drying chamber; the present invention makes the end of No. The hot air flow is in contact with the drainage block and is guided by the inclined surface of the drainage block to act obliquely on the upper and lower surfaces of the paper tape; on the one hand, the direct impact of the obliquely flowing hot air flow on the paper tape is small, further avoiding The antibacterial coating is detached under the action of impact; on the other hand, the contact area between the inclined paper tape and the hot air flow increases, and the heating is more uniform, and the antibacterial coating on the surface of the paper tape is cured more thoroughly under the action of heating.

Owner:无锡和烁丰新材料有限公司

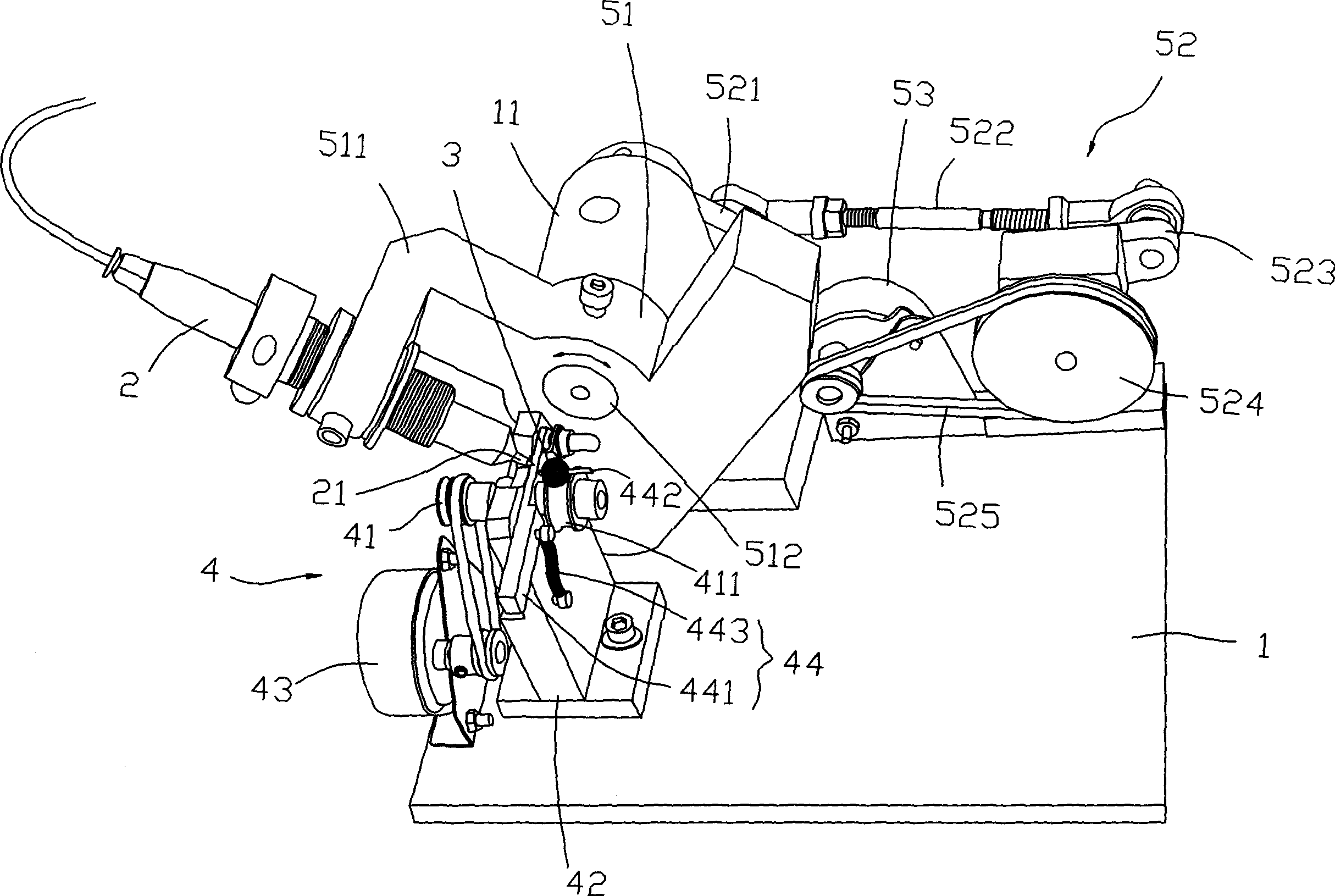

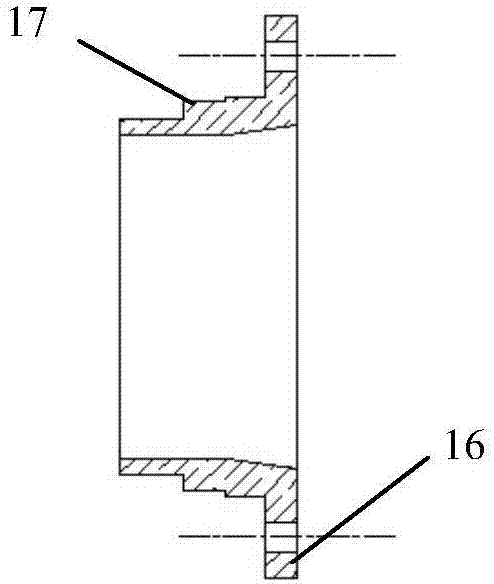

A camshaft half-round key pressing machine

ActiveCN103978358BReduce labor intensityPrecise positioningMetal working apparatusEngineeringImpact hammer

Owner:CHERY AUTOMOBILE CO LTD

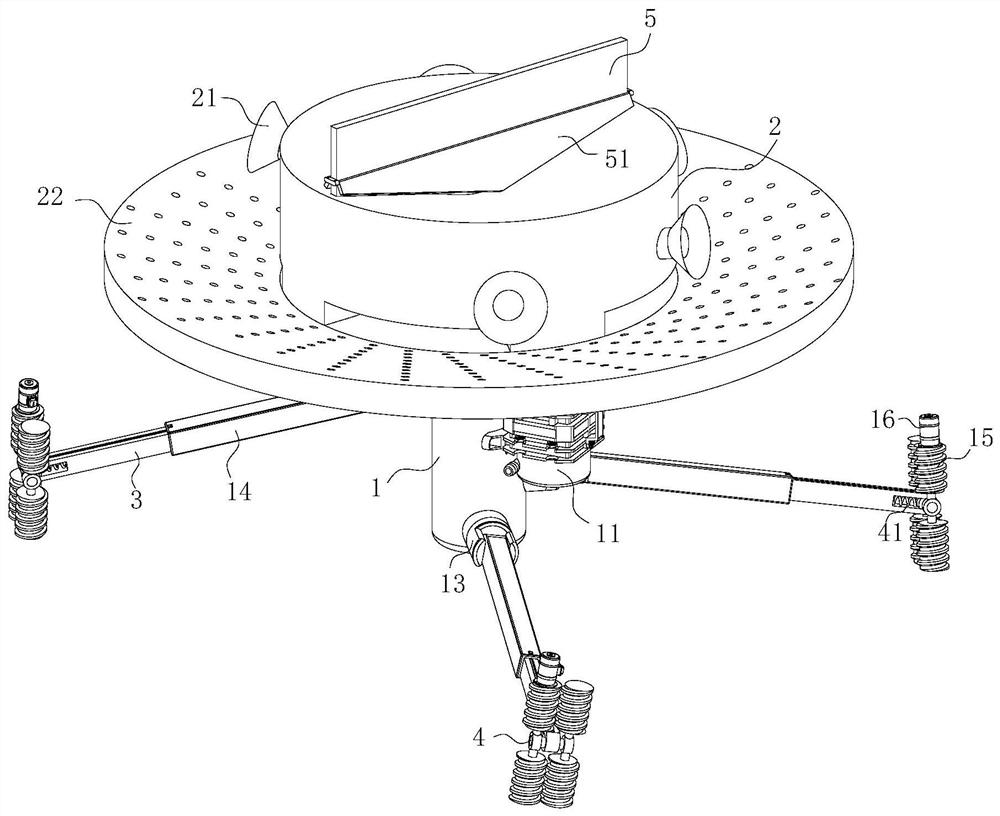

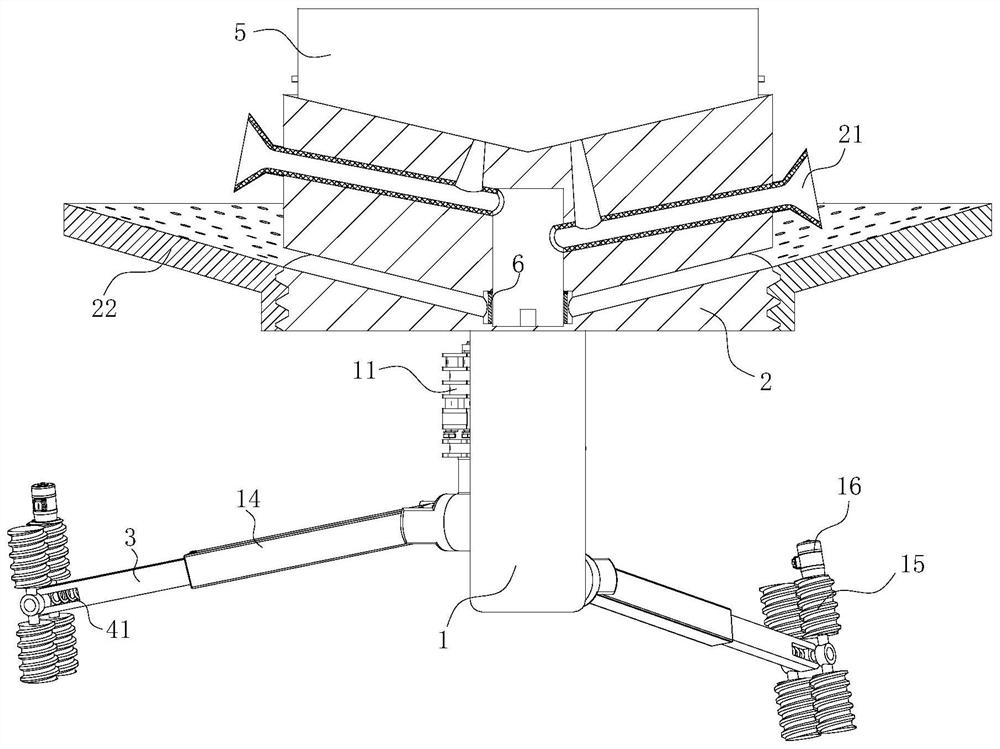

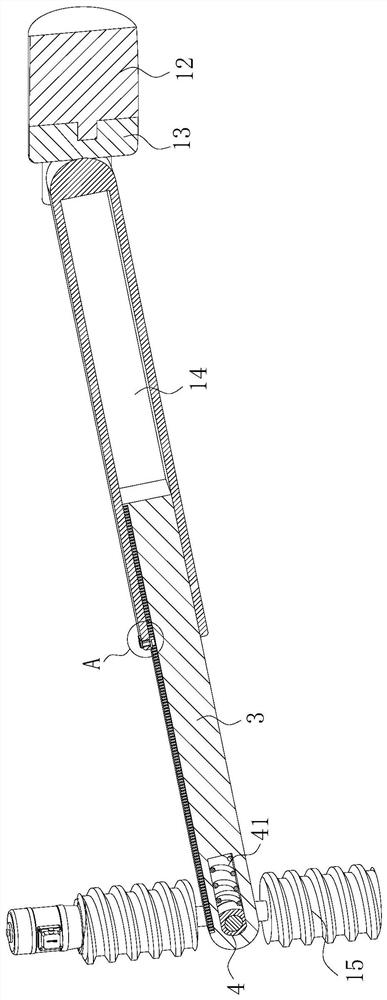

Sandblasting machine

ActiveCN106078526BUniform impactAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention provides a sand blasting machine, and relates to the technical field of treatment equipment of steel tube inner wall dirt and a passivation layer. The sand blasting machine comprises a focusing mechanism and a swing mechanism, and further comprises a spray gun bracket; the swing mechanism is connected with the focusing mechanism; the swing mechanism comprises a driven rotary wheel and an eccentric block; the driven rotary wheel is rotatably connected with the focusing platform, and is positioned at one side, deviating from the focusing platform, of the driven rotary wheel; a rotary wheel central hole is formed in the center of the driven rotary wheel; a spray gun hole is formed in the eccentric block; a spray gun is inserted into the spray gun hole through a joint bearing; a centre line of the rotary wheel central hole and a central line of the spray gun hole are not on the same horizontal line; the tail part of the spray gun is connected with the spray gun hole; and the spray gun bracket and the focusing platform are arranged in parallel. The sand blasting machine provided by the invention solves the technical problem of uneven sand blasting collision in a current sand blasting process.

Owner:SHENZHEN YINXIU TECH CO LTD

A high flame retardant grade hips composite material

ActiveCN109503970BHigh flame retardant gradeImprove performanceFire retardantUltimate tensile strength

The invention discloses a high flame-retardant grade HIPS composite material, which comprises the following components in parts by weight: 40-60 parts of PS resin, 10-27 parts of thermoplastic styrene-butadiene rubber, 3-10 parts of toughening agent, and 10 parts of flame retardant ~18 parts, 2.5~6 parts of flame retardant synergist, 5~20 parts of inorganic filler, 0.1~0.5 parts of anti-dripping agent and 0~2 parts of auxiliary agent; the weight average molecular weight of the PS resin is greater than or equal to 15* 10 4 g / mol, the melt flow rate MFR is 3~6g / 10min. The high flame retardant grade HIPS composite material of the present invention: 1. High flame retardant grade, the highest can reach 2.0mm 5VA grade; 2. Good comprehensive performance, balanced strength and notch impact performance; 3. Low cost, can replace high Flame retardant grade ABS; 4. Good appearance and wide processing window.

Owner:江苏金发再生资源有限公司

Special automotive frame correcting device

The invention relates to a special automotive frame correcting device. The special automotive frame correcting device comprises a pedestal, a rack, a pair of correcting mechanisms, a hydraulic mechanism and an electric box; the electric box is used for correcting the automotive frame by controlling a correction mechanism by virtue of the hydraulic mechanism; the correction mechanism comprises a horizontal oil cylinder and a vertical oil cylinder, wherein the fixed end of the horizontal oil cylinder is vertically installed on a lifting plate; the fixed end of the vertical oil cylinder is horizontally installed at the top of the lifting plate; the end part of a piston of the horizontal oil cylinder is provided with correcting ends; and the two correcting ends are used for uniformly hitting the automotive frame which is clamped between the two correcting ends, thus realizing the aim of correcting the automotive frame. The special automotive frame correcting device provided by the invention can be used for quickly correcting the bending degree of the automotive frame, is convenient to use, lowers the cost of an enterprise, improves the benefits of an enterprise and solves the technicalproblems that the upper and lower alar plates of an existing special automotive frame are bent to different extents, problems can be generated in subsequent welding and installation processes if thealar plates are not corrected in time and the economical benefits of an enterprise can be affected and the like; and compared with the prior art, the special automotive frame correcting device provided by the invention has quite good market prospects and development spaces.

Owner:河南昊搏专用汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com