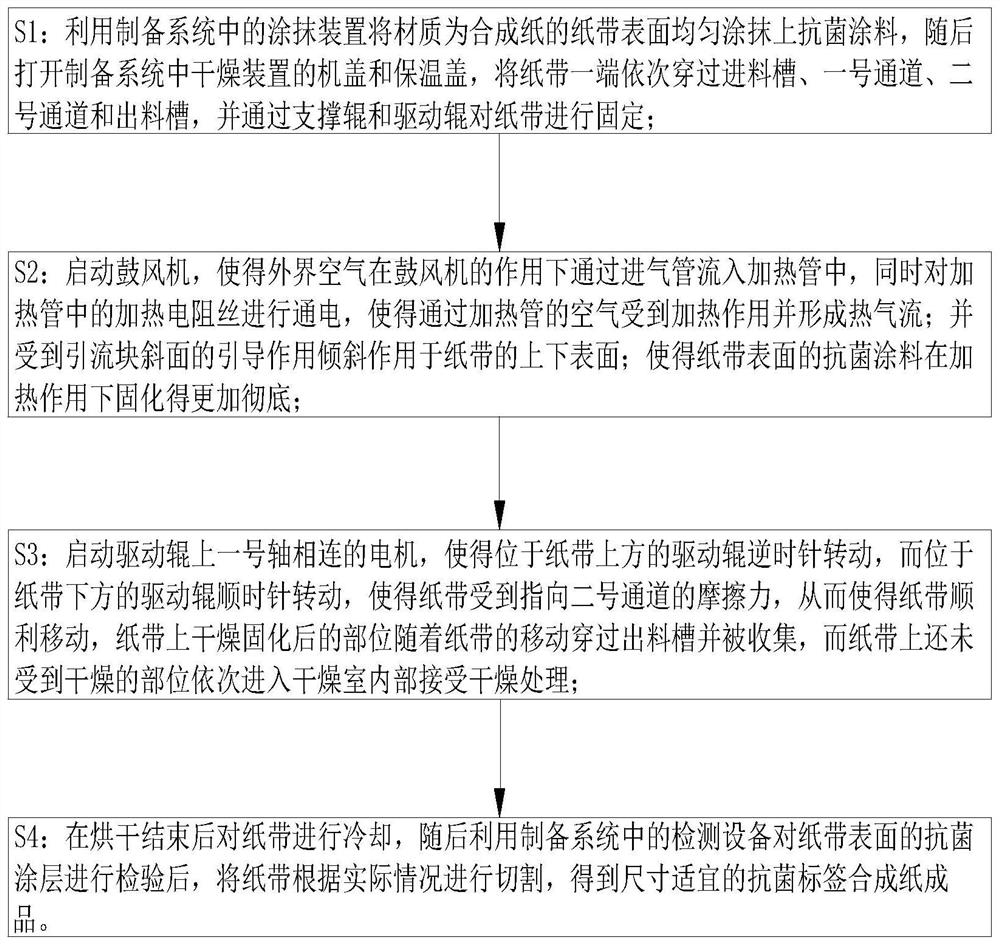

A preparation system and preparation process of antibacterial label synthetic paper

A preparation process and preparation system technology, applied in the field of label synthetic paper preparation, can solve the problems of antibacterial coating peeling off, uneven distribution of antibacterial coating, affecting performance, etc., to achieve increased contact area, avoid uneven thickness, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

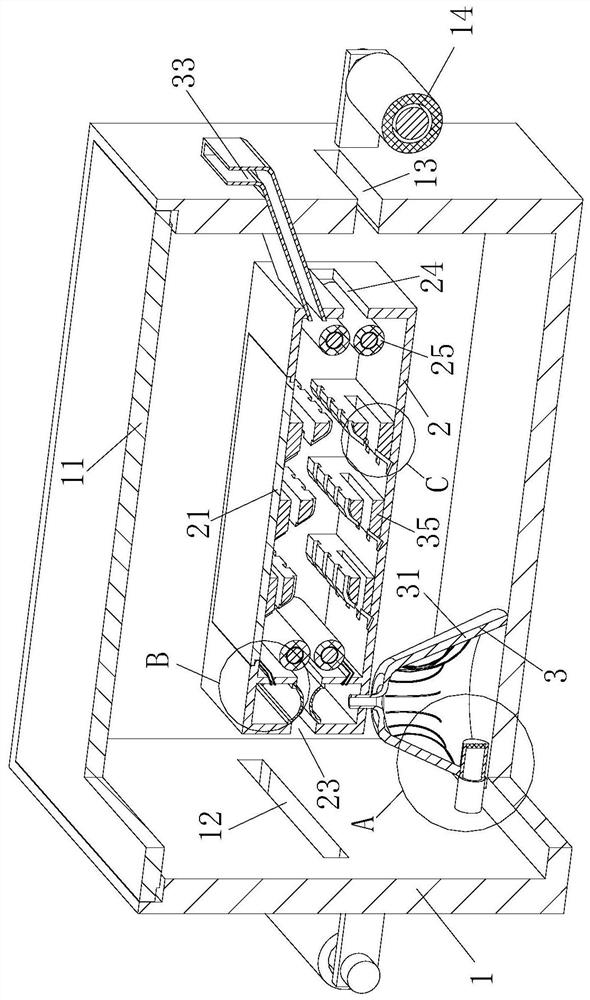

[0039] A preparation system for antibacterial label synthetic paper, the preparation system is suitable for the preparation of the above-mentioned antibacterial label synthetic paper, the preparation system includes a smearing device, a drying device and testing equipment, and the drying device includes a body 1 and a machine cover 11 , drying chamber 2, feed chute 12, discharge chute 13, support roll 14 and drying unit 3; the top of the body 1 is provided with a machine cover 11, the inside of the body 1 is provided with a drying chamber 2, and the top of the drying chamber 2 A heat preservation cover 21 is provided, and a feed trough 12 and a discharge trough 13 are symmetrically provided on the side wall of the body 1, and the outer surface of the side wall of the body 1 corresponds to the feed chute 12 and the discharge chute 13. Supporting roller 14, described supporting roller 14 is rotatably connected with described machine body 1 side wall through supporting shaft; Desc...

Embodiment approach

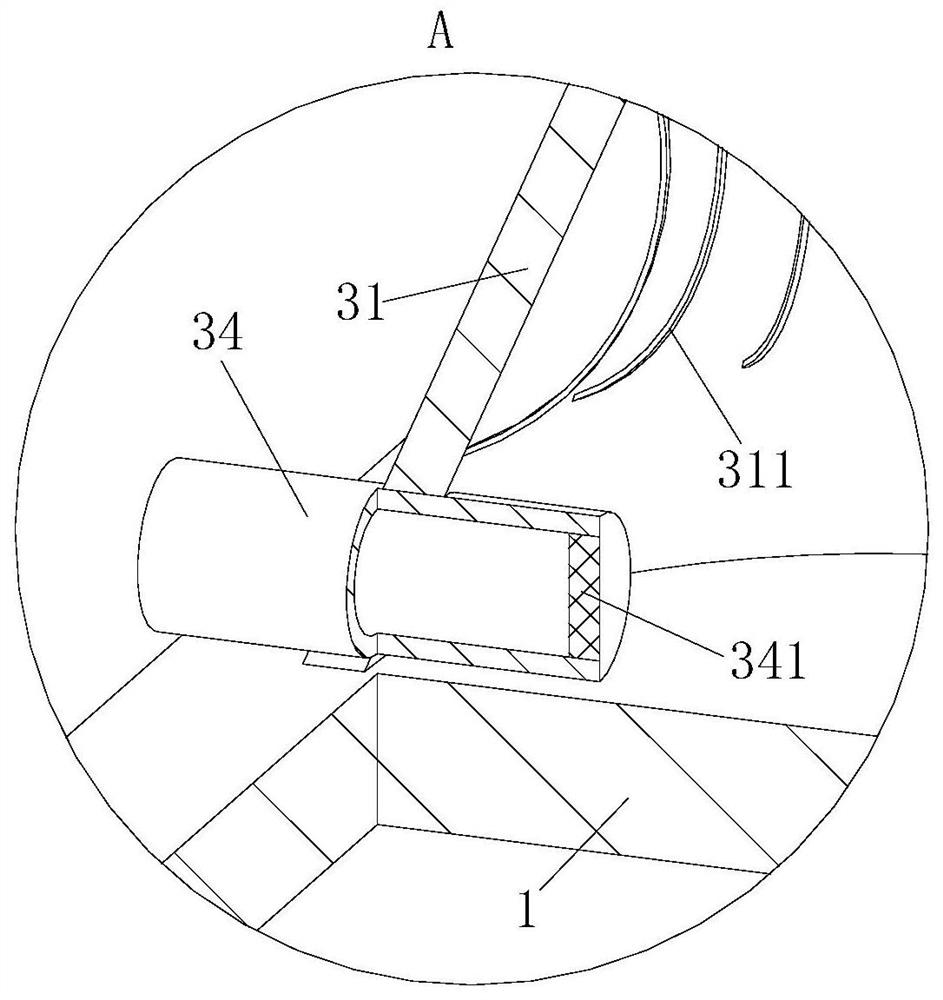

[0049] As a specific embodiment of the present invention, the side wall of the No. 1 chamber 22 located on the upper and lower sides of the No. 1 channel 23 is an arc-shaped preheating part 221, and the surface of the preheating part 221 is curved in a direction close to each other. , and the preheating part 221 is made of aluminum alloy.

[0050] During use, because the side wall of No. 1 chamber 22 is positioned at the preheating part 221 of No. 1 channel 23 upper and lower sides, it is arc-shaped, so when the hot air flow passes in No. 1 chamber 22, the side wall of No. 1 chamber 22 The preheating part 221 is in contact with the hot air flow and is fully heated; then, the arc-shaped preheating part 221 can transfer heat to the paper tape passing through the No. 1 channel 23, so that the paper tape that is about to enter the drying chamber 2 Being preheated, the temperature difference between different parts on the tape is reduced; and the arc-shaped surface has a large cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com