Polishing device for inner surface of tubular workpiece

A polishing device and technology of inner surface, applied in surface polishing machine tools, machine tools suitable for grinding workpiece edges, grinding/polishing equipment, etc. , Polishing uniformity, the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

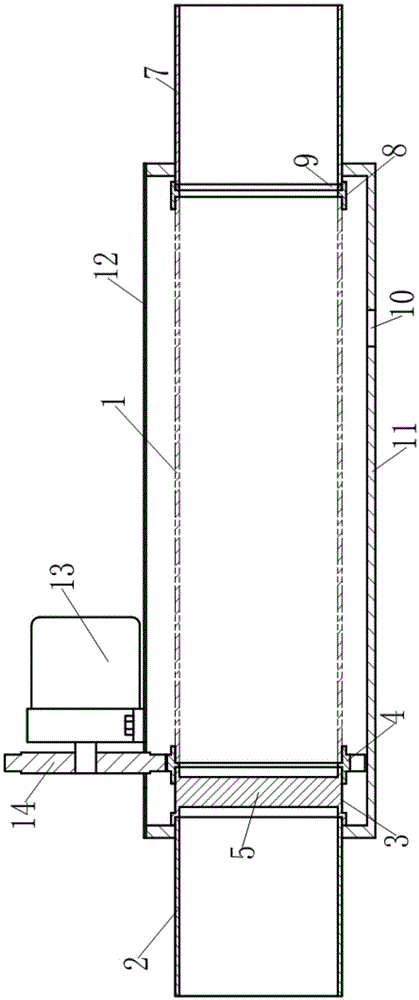

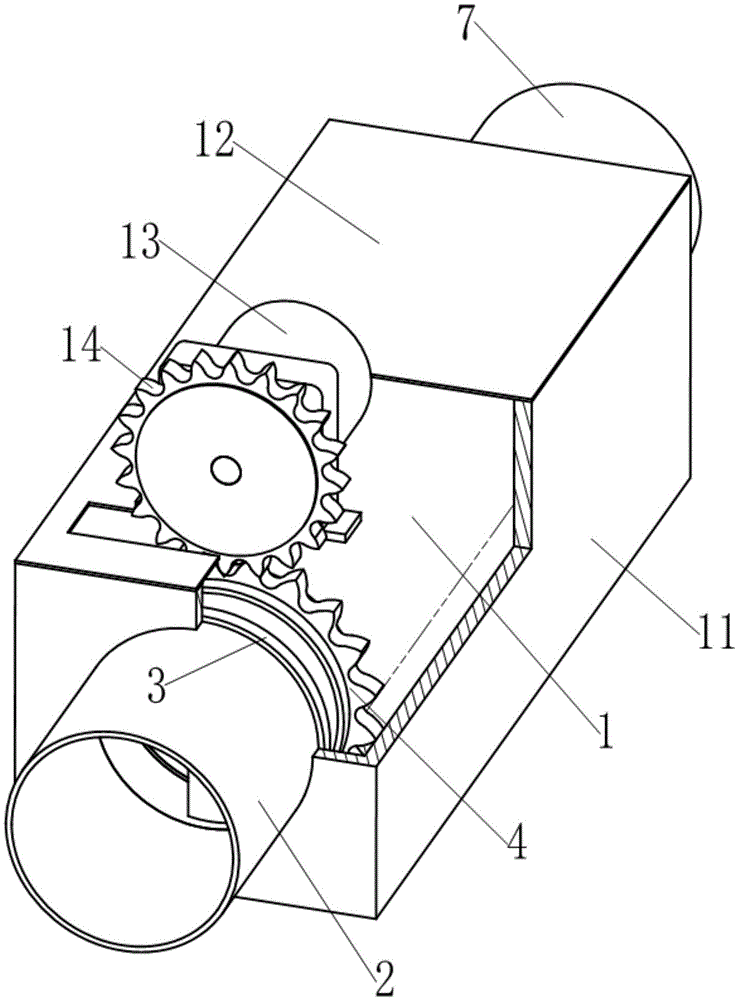

[0034] see figure 1 and 2 , the polishing device in this example has a rectangular parallelepiped frame box, and the frame is made up of a case body 11 and a case cover 12 that cooperate with each other, wherein the bottom of the case body 11 is provided with a return hole 10 for leaking abrasive liquid , used to recover the abrasive liquid leaked during the polishing process; the two ends of the box 11 are respectively provided with a coaxial inlet pipe 2 and an outlet pipe 7 .

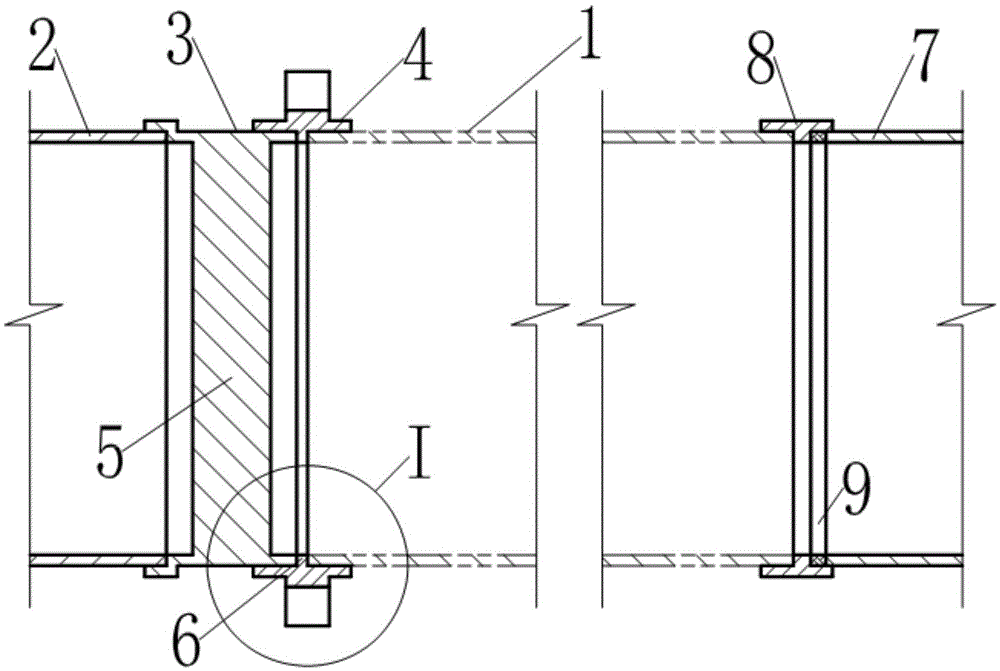

[0035] see Figures 3 to 7 , and combine figure 2 , the end of the inlet pipe 2 located in the box 11 is provided with a static ring 3 tightly fitted therewith, and the end of the outlet pipe 7 located in the box 11 is provided with a moving ring 8 loosely fitted therewith, The inner side of the moving ring 8 is provided with a limiting ring protruding inward, and a wear-resistant sealing gasket 9 is provided between the end of the outlet pipe 7 and the limiting ring. The static ring 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com