Inner diameter processing device simple in structure

A processing device and a technology with a simple structure, applied in metal processing equipment, manufacturing tools, machine tools for surface polishing, etc., can solve the problems of uneven polishing of the inner wall of the long pipe, affecting product quality, uneven inner wall of the long pipe, etc., and achieving a simple structure. , Improve product quality, uniform polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

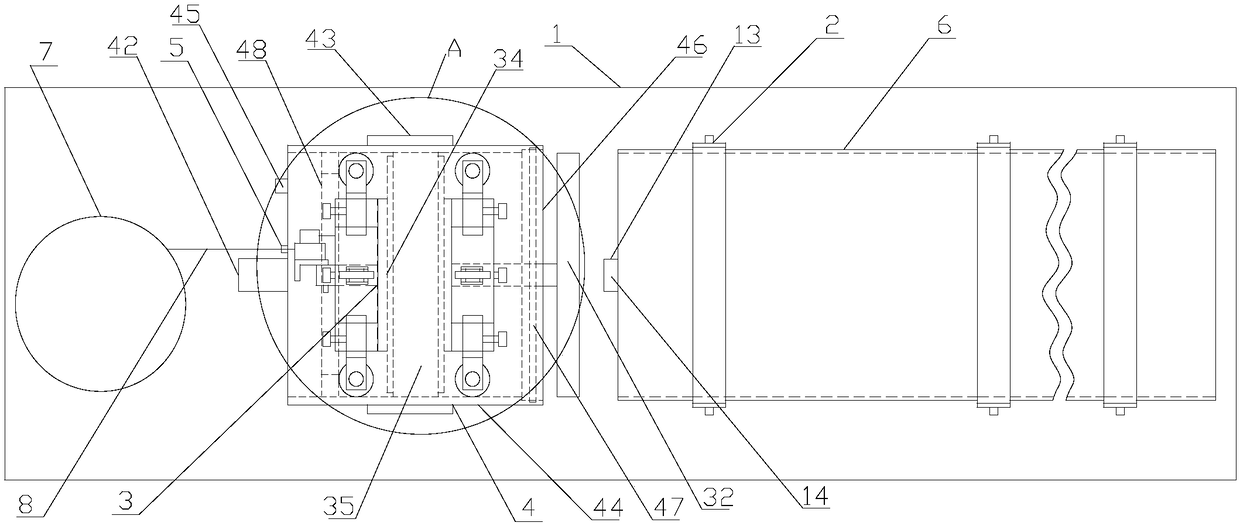

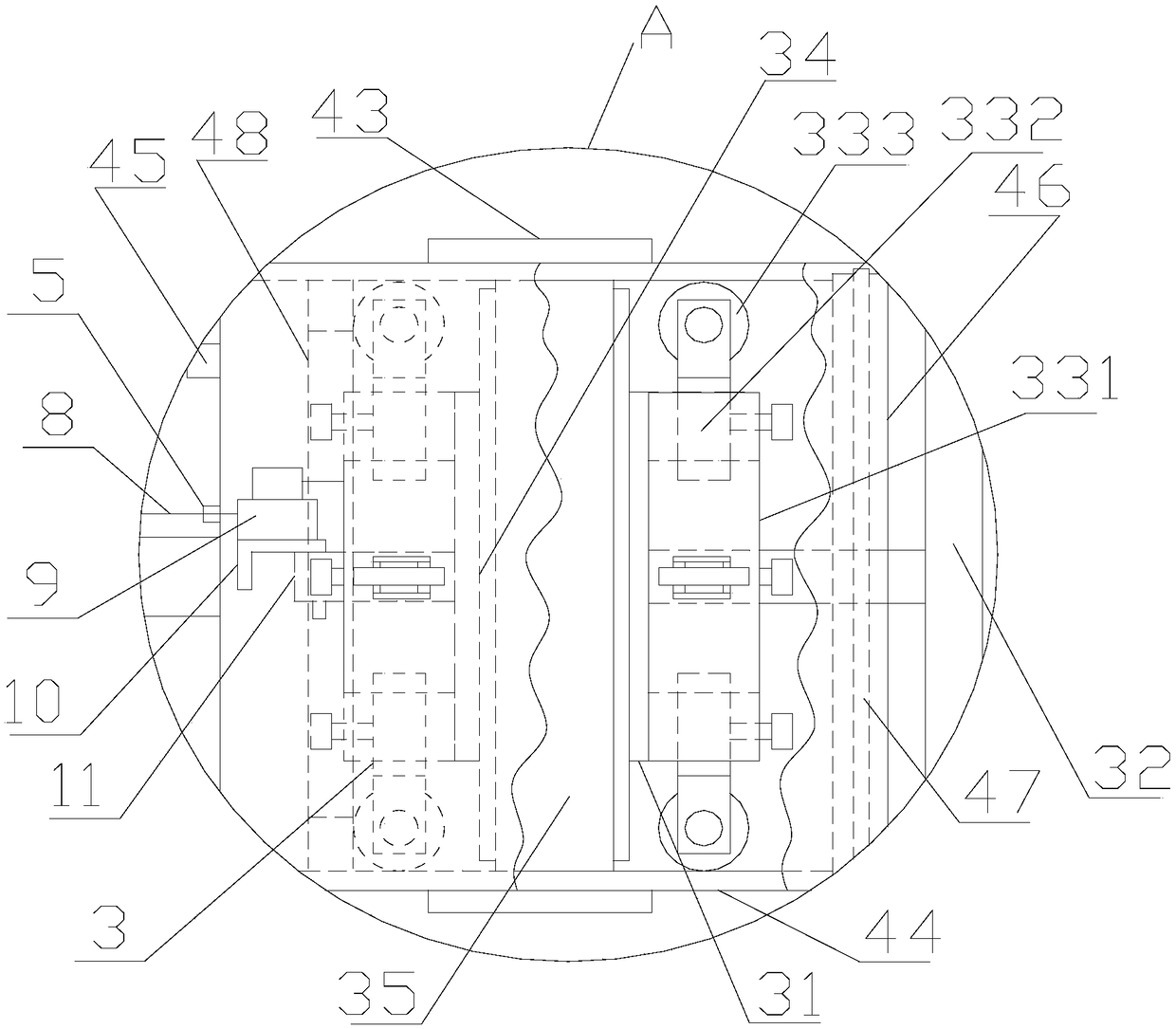

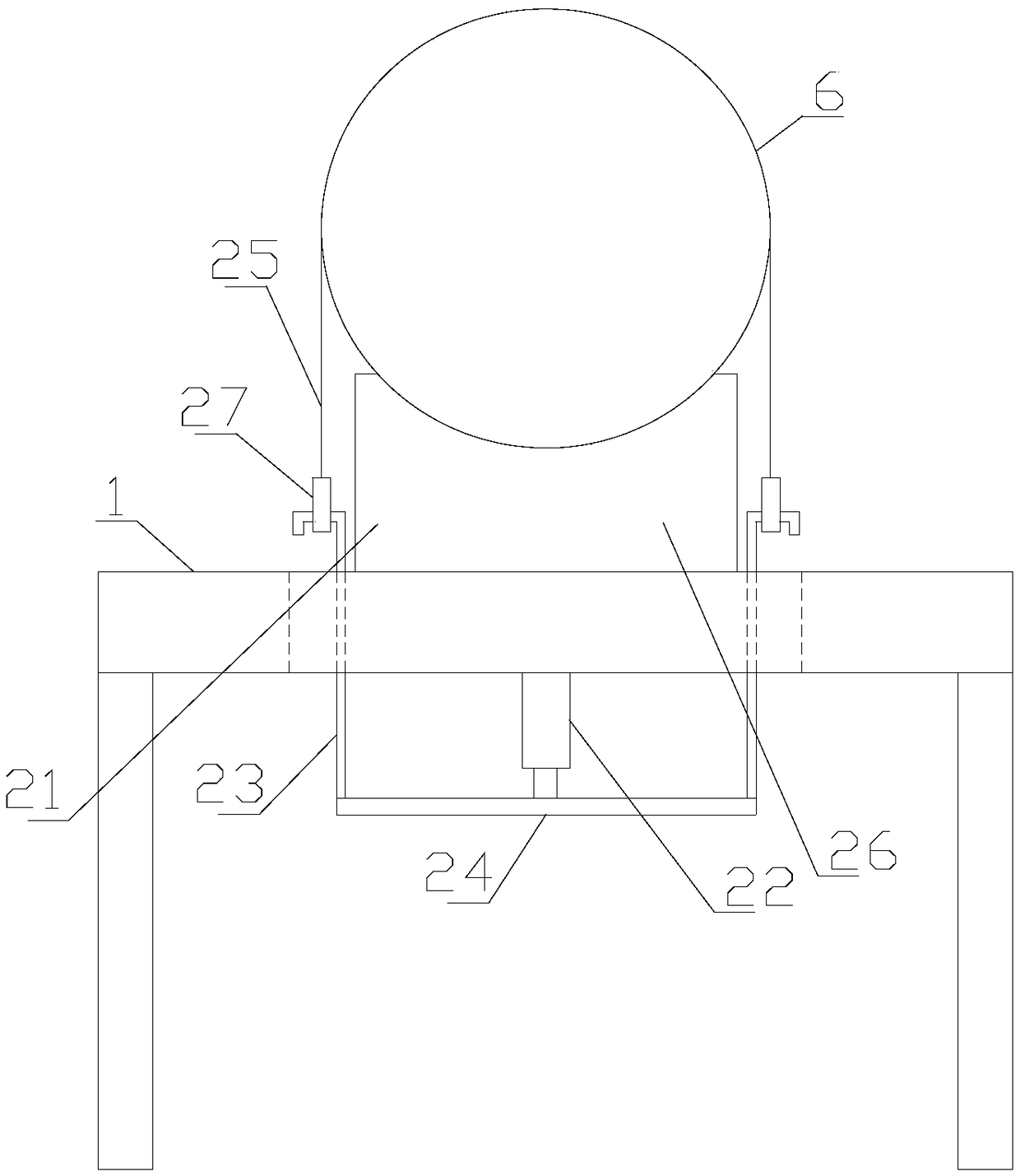

[0018] refer to figure 1 , figure 2 , image 3 and Figure 4 , an inner diameter processing device with a simple structure in the present invention includes a workbench 1, several fixing mechanisms 2, a polishing mechanism 3 and a driving mechanism 4, and all the fixing mechanisms 2 are arranged on the workbench 1 from front to back in sequence for Fix the polished stainless steel tube 6, the workbench 1 is provided with a driving mechanism 4 in front of the frontmost fixing mechanism 2, and the driving mechanism 4 is used to drive the polishing mechanism 3 to pass through the stainless steel tube 6. Polishing mechanism 3 comprises polishing motor 31, polishing wheel 32, two sliding support devices 33, annular body 34 and annular sealing body 35, is provided with polishing wheel 32 on the rotating shaft of described polishing motor 31, and described polishing motor 31 Both ends of the shell of the shell are provided with a sliding support device 33, and the middle of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com