30-degree soft polishing process applied to rock board surface layer

A slate and surface layer technology, applied in the field of 30-degree soft polishing process, can solve the problems of easy dirt accumulation, polishing effect of slate surface, differences in color levels, inconvenience and hygiene, etc., and achieves uniform polishing and excellent anti-fouling performance. , The effect of soft touch on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] A 30-degree soft polishing process applied to rock slab surfaces, comprising the following steps:

[0020] Step 1: Send the finished bricks into the box-type waste heat drying kiln installed in front of the firing kiln, extract the waste heat from the tail of the firing kiln to heat the drying kiln, and then use the automatic temperature measuring gun to test that the temperature in the drying kiln is 65 -75°C, keep the temperature and continue to dry for 20-30 minutes to complete the drying of the adobe. Finally, after testing, if the moisture content in the adobe is less than 0.6% of the total mass of the adobe, proceed to the next step of processing. If the content is greater than 0.6% of the total mass of the adobe, it will be returned to be dried and dewatered again;

[0021] Step 2: The dry and dewatered bricks in step 1 are replenished with water through the water spray tank, so that the surface of the bricks is moistened, and then the bottom glaze is poured by t...

experiment example

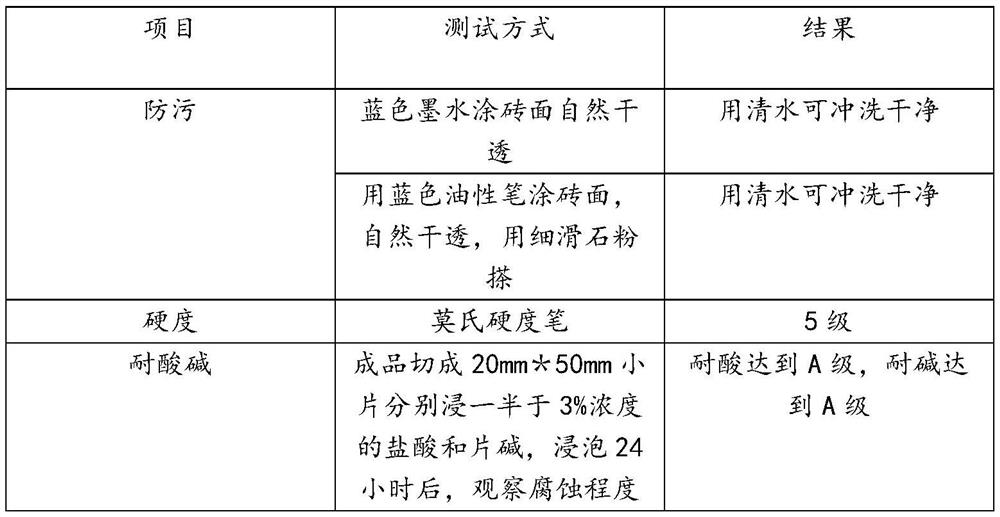

[0030] The weather resistance of the surface of the slate is tested as shown in the following table:

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com