A surface polishing treatment device for manhole cover production

A surface polishing and processing device technology, applied in surface polishing machine tools, grinding/polishing safety devices, signal devices, etc., can solve the problems of inability to uniformly polish manhole covers, inability to know the polishing status of manhole covers, and low polishing efficiency. Improve the polishing range, facilitate polishing progress, and uniform polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

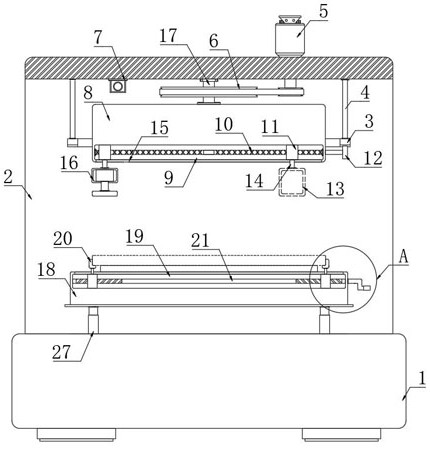

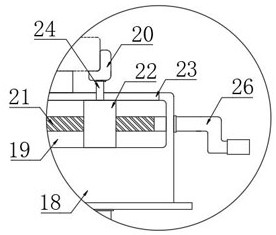

[0029] refer to Figure 1-5 , a surface polishing treatment device for manhole cover production, comprising a base 1, the upper end of the base 1 is fixedly connected with an L-shaped mounting frame 2, the lower end of the L-shaped mounting frame 2 is rotatably connected with a rotating rod 17, and the lower end of the rotating rod 17 is fixedly connected Installing block 8 is arranged, is provided with moving chamber 9 in the installing block 8, and the lower end of moving chamber 9 is provided with the first strip-shaped opening 15, and the two sides inner walls of moving chamber 9 are rotatably connected with rotating rod 10, and rotating rod 10 is provided with Two threaded layers, the two threaded layers of the rotating rod 10 are threadedly connected with a threaded slider 11 (each threaded slider 11 is slidably connected with the corresponding moving cavity 9), and the two threaded layers are connected with the reciprocating screw rod. The thread layer is similar to ens...

Embodiment 2

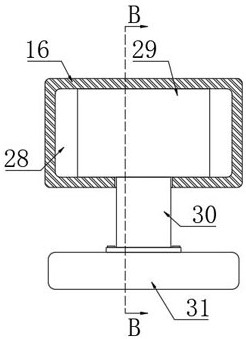

[0040] refer to Figure 6-8 The difference between this embodiment and Embodiment 1 is that a touch switch 25 is installed on the rear inner wall of the sliding cavity 28, and a second warning light body that cooperates with the touch switch 25 is installed on the lower end of the L-shaped mounting frame 2. 34. When the touch switch 25 is touched, the second warning light body 34 will light up, and the lights of the second warning light body 34 and the first warning light body 7 are different.

[0041] In this embodiment, when the polishing is just started, the spring 33 is in a fully compressed state, and the moving block 29 at this time is tightly against the touch switch 25 and the conductive strip 35, and the first warning light body 7 and the second warning light Body 34 is all in the state of constant light, and after polishing for a period of time, moving block 29 moves back slowly, and at this moment the second warning light body 34 can go out first, then first warning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com