A kind of slate polishing equipment

A kind of equipment and slate technology, applied in the field of slate polishing equipment, can solve the problems of small polishing range, lack of noise reduction facilities, and inability to adjust the polishing range, etc., to achieve the effect of adjusting the polishing width, increasing the polishing range, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

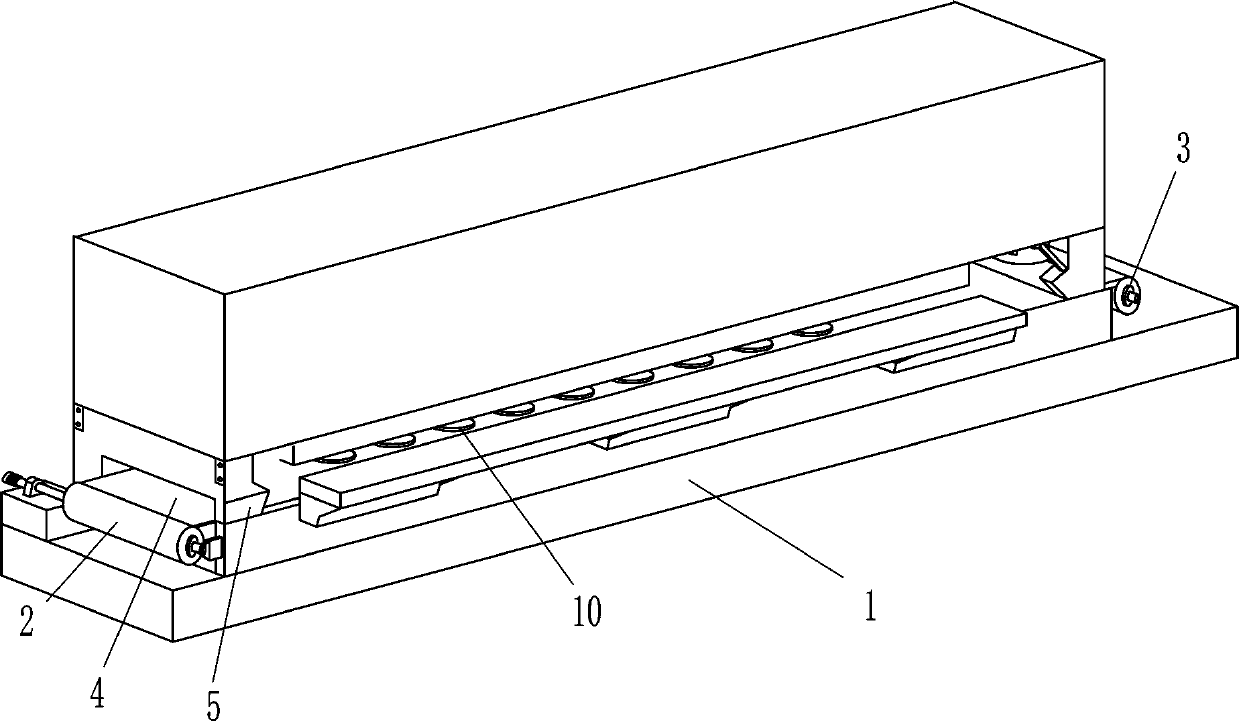

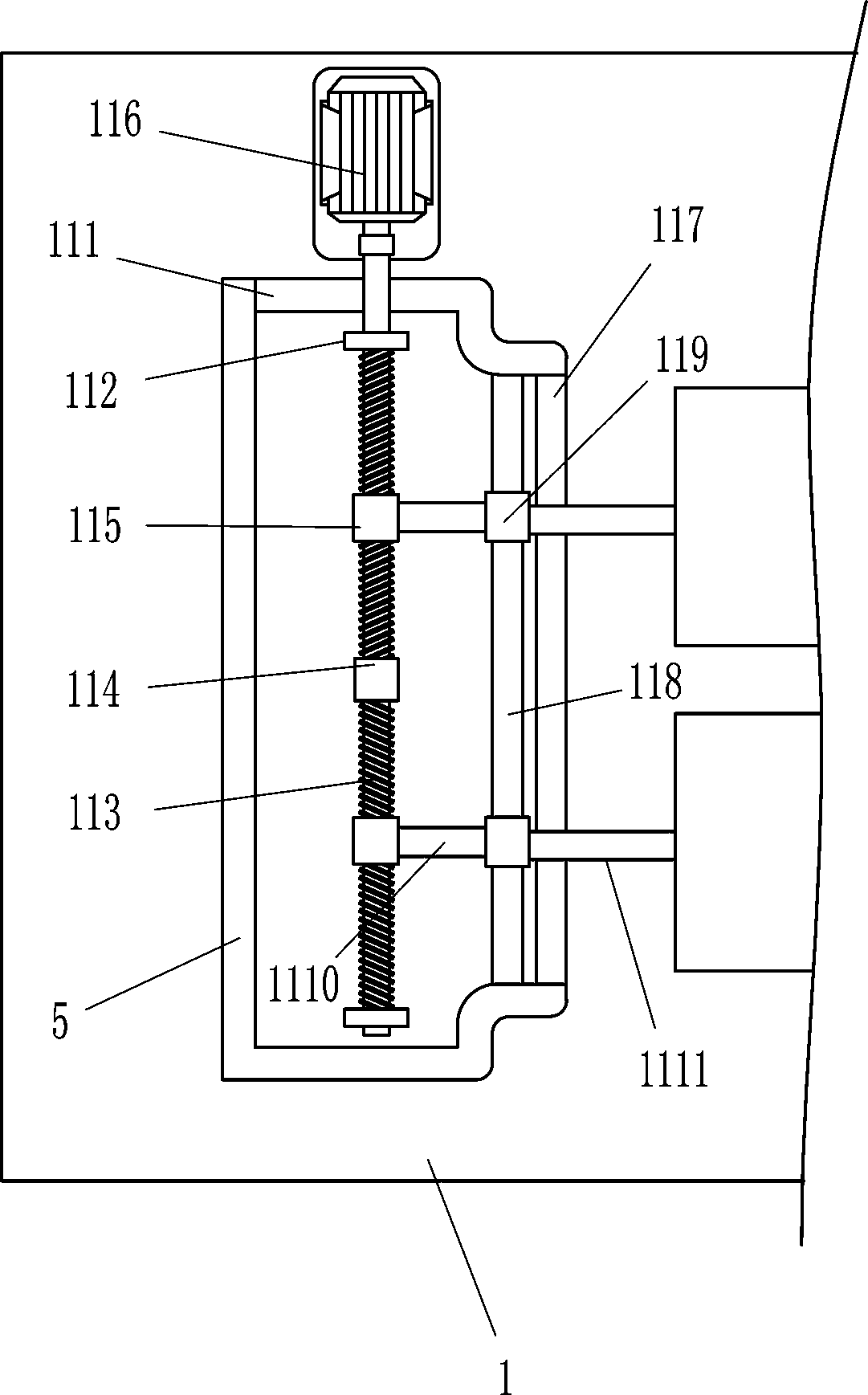

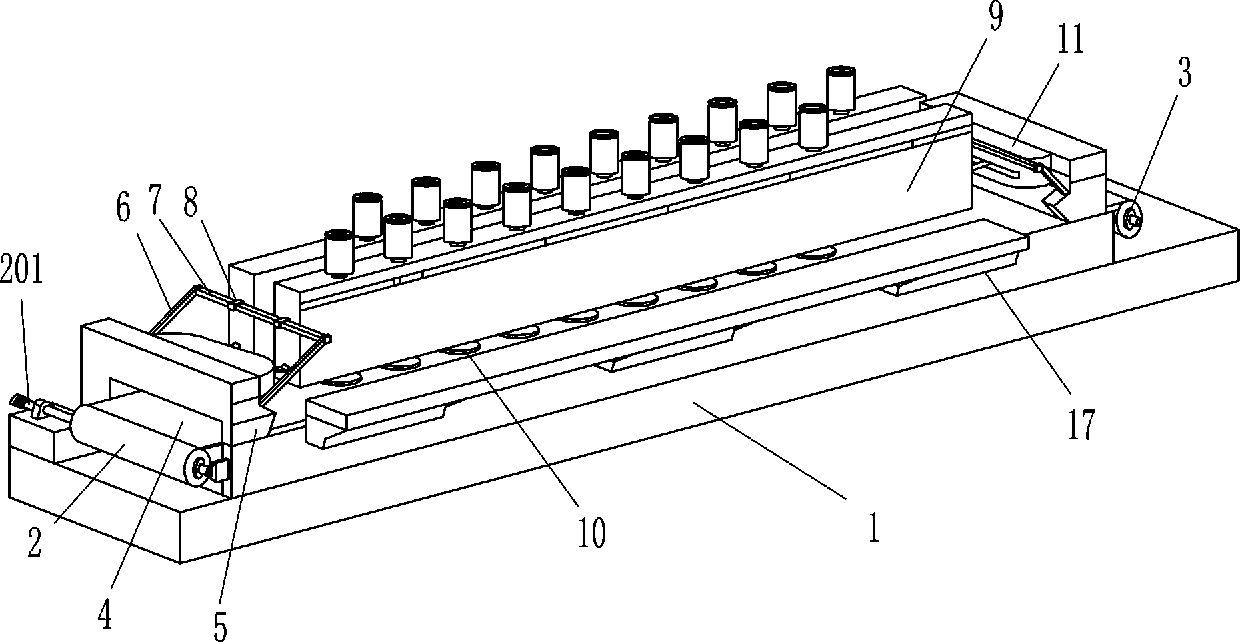

[0020] A slate polishing equipment such as Figure 1-6 As shown, it includes a frame 1, a driving roller 2, a driving device 201, a driven roller 3, a conveying belt 4, a fixed seat 5, a support rod 6, a sliding rod 7, a sliding block 8, a beam 9, a grinding head 10 and an adjustment The device 11, the driving roller 2 and the driven roller 3 are respectively installed at both ends of the frame 1, the driving roller 2 is connected to the driving device 201, and the conveying belt 4 is installed on the driving roller 2 and the driven roller 3, The two fixing bases 5 are installed on both ends of the frame 1 respectively, the fixing bases 5 are connected with the frame 1 by welding, and the two sliding rods 7 are respectively installed on the fixing bases 5 through the supporting rods 6 , the two beams 9 are slidably installed on the sliding bar 7 through the sliding block 8 respectively, the two beams 9 are evenly provided with grinding heads 10, and the grinding heads 10 on th...

Embodiment 2

[0022] A slate polishing equipment such as Figure 1-6 As shown, it includes a frame 1, a driving roller 2, a driving device 201, a driven roller 3, a conveying belt 4, a fixed seat 5, a support rod 6, a sliding rod 7, a sliding block 8, a beam 9, a grinding head 10 and an adjustment The device 11, the driving roller 2 and the driven roller 3 are respectively installed at both ends of the frame 1, the driving roller 2 is connected to the driving device 201, and the conveying belt 4 is installed on the driving roller 2 and the driven roller 3, The two fixing bases 5 are installed on both ends of the frame 1 respectively, the two sliding rods 7 are installed on the fixing bases 5 through the support rods 6 respectively, and the two beams 9 slide through the sliding blocks 8 respectively. The two beams 9 are evenly equipped with grinding heads 10, and the grinding heads 10 on the two beams 9 are distributed in a staggered manner. The two adjustment devices 11 are fixedly installe...

Embodiment 3

[0025] A slate polishing equipment such as Figure 1-6 As shown, it includes a frame 1, a driving roller 2, a driving device 201, a driven roller 3, a conveying belt 4, a fixed seat 5, a support rod 6, a sliding rod 7, a sliding block 8, a beam 9, a grinding head 10 and an adjustment The device 11, the driving roller 2 and the driven roller 3 are respectively installed at both ends of the frame 1, the driving roller 2 is connected to the driving device 201, and the conveying belt 4 is installed on the driving roller 2 and the driven roller 3, The two fixing bases 5 are installed on both ends of the frame 1 respectively, the two sliding rods 7 are installed on the fixing bases 5 through the support rods 6 respectively, and the two beams 9 slide through the sliding blocks 8 respectively. The two beams 9 are evenly equipped with grinding heads 10, and the grinding heads 10 on the two beams 9 are distributed in a staggered manner. The two adjustment devices 11 are fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com