Polishing machine

A polishing machine and frame technology, applied in the field of polishing machines, can solve the problems of low manual operation efficiency, many defective products, and many consumables, etc., and achieve the effects of improving the polishing range, improving the gloss and smooth transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

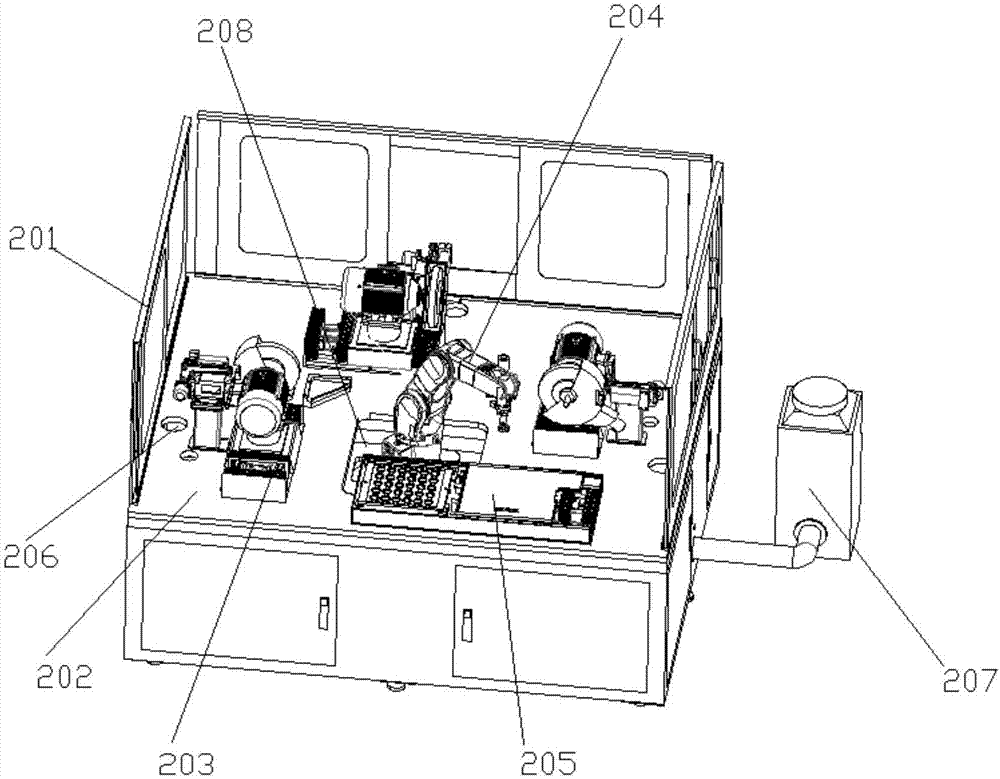

[0027] Such as figure 1 As shown, a polishing machine includes a fully enclosed frame 201, a fully enclosed frame 201 is provided with an installation platform 202, and a plurality of polishing heads 203 with automatic horizontal hard wax functions are arranged at intervals on the installation platform 202 And the robot 204 that is used to grip the product and perform polishing action on the polishing head 203, a plurality of polishing heads 203 form a triangle, the robot 204 is located between the plurality of polishing heads 203, and the front side of the installation platform 202 is provided with The material tray box structure 205 with dust-proof protection and secondary positioning function, the installation platform 202 is located at the rear side of each polishing machine head 203 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com